Machine Control System Market Report Scope & Overview

Get more information on Machine Control System Market - Request Sample Report

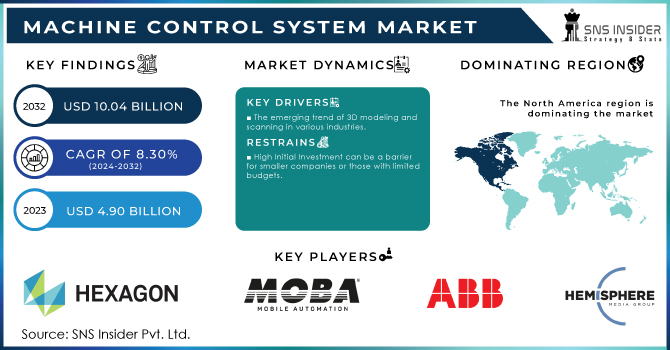

The Machine Control System Market size was valued at USD 4.90 billion in 2023 and is expected to reach USD 10.04 billion by 2032 and grow at a CAGR of 8.30% over the forecast period 2024-2032.

The machine control system market is experiencing a surge driven by the rapid increase of automation in construction and agriculture machinery. U.S. construction spending in June 2024 hit a seasonally adjusted annual rate of USD 2,148.4 billion, showing a small 0.3% drop from May's revised estimate of USD 2,154.8 billion. During the first six months of 2024, the total spent on construction reached USD 1,034.8 billion, showing an increase of 8.6% from the USD 952.5 billion spent in the same period in 2023. Construction projects utilizing automation could experience a 20% reduction in timelines, while machine control systems with GNSS technology, due to their role in achieving precise excavation depths and minimizing material waste.

The increasing need for automation in mining industries has led to significant growth in the machine control system market. In 2022, U.S. coal production increased by 2.9%, which equaled 594.2 million short tons. The total productive capacity of coal mines also grew slightly by 0.1% to 872 MMst. Furthermore, the coal mining workforce expanded to 43,582 employees, which was an increase of 4,064 from 2021. This confluence of factors, improving both project outcomes and working conditions, positions machine control systems as a vital technology for the future of construction and agriculture.

MARKET DYNAMICS:

Drivers

-

The emerging trend of 3D modeling and scanning in various industries.

The growth of the machine control system market is significantly driven by the tendency towards the increasing utilization of 3D modeling and scanning. As various industries become more inclined to implement advanced technologies to achieve higher efficiency, precision, and productivity, such concepts as 3D modeling and scanning have become key elements of various industries, namely construction, agriculture, and mining. This technology allows for the creation of highly detailed digital representations of the physical world, enabling accurately targeted guiding and managing of machines. For example, 3D models are used to plan and implement projects with the highest possible accuracy, which, in turn, minimizes errors and work that has to be redone later. Such models are implemented in machine control systems that operate heavy machinery, which executes said projects.

-

Advancements in Technology like Integration with GNSS and GPS

The growth of the Machine Control System Market is significantly driven by advancements in technology, mainly the integration of Global Navigation Satellite System and Global Positioning System. These systems provide precise and real-time positioning information, which is a vital aspect of the application of machine control systems in construction, agriculture, mining, and other areas. The developed devices and their appliances to machinery, such as excavators, bulldozers, and graders, are highly accurate and efficient, as they allow controlling this equipment with a minimal margin of error. It leads to an increase in productivity and a decrease in operation costs and accidents. For example, in construction, GNSS and GPS can facilitate the machine control systems that guide heavy equipment with sub-centimeter precision to ensure it follows the design as closely as possible and prevents operator mistakes.

Restraints

-

High Initial Investment can be a barrier for smaller companies or those with limited budgets.

The major feature of machine control systems that requires a substantial investment of money is the development and software components. The cost of the development of the machine control system is primarily obtained through the purchase of the machinery and the replacement of other components to grant the machine compatibility with the machine control system. Machine control systems depend on specialized software algorithms to process the input data, provide real-time feedback to the operator to continue controlling the machinery, and the provision of data through a user interface software that communicates the technological system with its user. The implementation of these components is a major software, testing, and customization that generates the cost of money.

-

Data Sharing and Security Concerns

Collecting and using data created by machine control systems leads to an issue that can be classified as data privacy. On the one hand, it can be useful for various stakeholders to benefit from the advantages of such technology. Nevertheless, on the other hand, unauthorized access to data or scams can result in revealing confidential information and decrease security. Moreover, machine control systems work based on algorithms that can be biased based on the analysis of the data. As a result, it means unfair attitudes to the workers or mistakes in response. However, to avoid this, there should be clear regulations and norms.

Market Segmentation

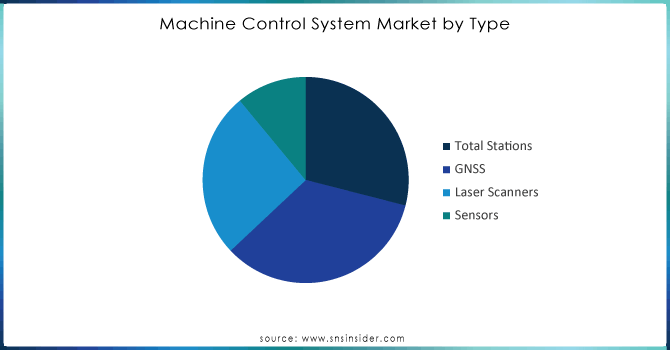

By Type

The Global Navigation Satellite System (GNSS) occupied a market share of over 35% in 2023. The GNSS gives capabilities of tracking with high precision coordinates to the machine control systems and helps them control heavy machinery with high accuracy. To pursue tasks such as grading in construction, or crop managing in agriculture and even mining, precise positioning is needed. Thus, allowing a margin of error and carrying out tasks. As GNSS is used across all industries and has a versatile function, it drives the adoption and market growth.

Laser scanners accounted for a faster CAGR during the forecast period 2024-2032. The laser scanner is used to collect large amounts of data at a single point for example details about a building for mapping or construction. The airborne system is used to acquire information that covers a wider space. The changes in this landscape will help in promoting innovations in these segments as industries aim to achieve high levels of efficiency and accuracy.

Get a Customized Report as per your Business Requirement - Request For Customized Report

By Equipment

Excavators held a significant share of the machine control system market, estimated to be around 35% in 2023, and are to retain its growth during the forecast period, as these are widely used in various sectors such as construction, mining, and infrastructure development. They play an important role in mining, digging, sorting, and material handling tasks. The versatility of by Equipment and the wide field of application in various fields contribute to their dominant position in the market of machine control systems. In addition, machine control systems offer significant advantages when integrated into excavators. These systems provide real-time positioning and guidance, allowing operators to complete excavation tasks accurately and efficiently. Machine control systems improve the accuracy and productivity of excavators by providing automatic control, precise depth control, and intelligent control functions. This integration helps optimize performance, reduce errors, and improve overall operational efficiency.

By Industry Vertical

The industrial segment led the market in 2023 with a market share of over 38%. These are manufacturing, mining, and construction industries. Machine control systems are used widely in these industries as they require precision and automation. Although these demand more complex and advanced systems, other segments also require machines and vehicles to be controlled in one way or another.

The commercial segment is likely growing the fastest during 2024-2032. There has been a growing emphasis on efficiency, safety, and precision in construction projects like office buildings, retail centers commercial logistics centers, and infrastructure projects, including highways, railroads, and airports.

Regional Analysis

North America dominated the market in 2023 with a market share of over 40%. The high growth in the construction industry and the automatic growth of metal processes in all industries drive the market’s growth in the particular region. Additionally, changes in agricultural systems and improved network infrastructure contribute to the size of the market of machine control systems. One major driving force of the growth of the machine control market is the relationship between OEMs and machine control manufacturers. The increase in demand for machine control technology in highway construction projects is also a significant factor.

Asia Pacific is likely to be the fastest-growing region in the market of machine control systems in the forecasted period 2024-2032. Economic growth is rapid, and therefore, many developments are coming up mostly related to infrastructure. Countries in the southeast and East Asia such as China, India, and ASEAN transport networks, construct residential and industrial buildings, and implement smart cities projects. Many farmers currently are using GPS-guided machinery, drones, and sensor-based systems that enable them to use minimal input maximally. The machine control system equipment is pivotal since machines are controlled to do more exact work to support agricultural enterprises massively.

KEY PLAYERS

The major key players are Hexagon, MOBA Mobile Automation, Hemisphere, Eos Positioning Systems, Leica Geosystems, ABB Group, Topcon Corporation, RIB Software AG, Trimble Inc., Andritz, Belden Inc., Mitsui Co., Schneider Electric and other key players.

RECENT DEVELOPMENT

-

In April 2024, Siemens unveiled a new Sinumerik One Control System Including Advanced Cybersecurity Features. This source says that Siemens announced the enhanced cybersecurity features. Security becomes a crucial issue as becomes more connected and the Siemens is moving closer to a safer environment.

-

In January 2024, Industrial automation giant Bosch Rexroth partnered with Nvidia to develop AI-powered machine control systems. This source is telling that the well-known company Bosch has decided to develop an AI machine control tool. Having acquired Nvidia’s GPUs, they claim and highlight the speed of the engine and learning.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 4.90 billion |

| Market Size by 2032 | USD 10.04 billion |

| CAGR | CAGR of 8.30% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Type (Total Stations, Global Navigation Satellite Systems, Laser Scanners, Sensors) • By Equipment (Excavators, Loaders, Graders, Dozers, Scrapers, Paving Systems) • By Industry (Infrastructure, Commercial, Residential, Industrial) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Hexagon, MOBA Mobile Automation, Hemisphere, Eos Positioning Systems, Leica Geosystems, ABB Group, Topcon Corporation, RIB Software AG, Trimble Inc., Andritz, Belden Inc., Mitsui Co., Schneider Electric |

| Key Drivers | • The emerging trend of 3D modeling and scanning in various industries. • Advancements in Technology like Integration with GNSS and GPS |

| RESTRAINTS | • High Initial Investment can be a barrier for smaller companies or those with limited budgets. • Data Sharing and Security Concerns |