Self-Healing Materials Market Report Scope & Overview:

The Self-Healing Materials Market Size was valued at USD 1.9 billion in 2023, and is expected to reach USD 13.7 Billion by 2032, and grow at a CAGR of 24.6% over the forecast period 2024-2032.

The market for self-healing materials is witnessing tremendous growth since they possess remarkable strength, efficiency, and lifetime material in their mass segments such as cars, electronics, construction, and biomedical applications. Self-healing materials are developed to mend themselves automatically after injury. The recent technological advancements made in self-healing materials are improving the performance of the material thus more products are used in large quantities. One of the driving forces in the market shortly is sustainability and reduced impact on the environment, which has raised the stakes for companies to work on developing materials that would not only avoid the generation of waste but also be more energy efficient. It is especially in the electronics sector that this need is increasing due to a demand for materials that can withstand repetitive usage without degrading. Another driver is biomimicry as material development is based on mimicking nature's processes.

Get more information on Self-Healing Materials Market - Request Free Sample Report

Researchers at Binghamton University now, in May 2024, explored how fire ant's ability to self-assemble can inspire the development of adjustable self-healing materials under changing external pressures. Critical inspections of natural inspirations would therefore push research to new sources for more versatile and efficient mechanisms, especially those materials under extreme temperatures or high mechanical stress. Another sector that fuels the growth of the market is the potential of these materials to be used for wearables, sensors, and other flexible devices. Companies are investing in further research for attempts to replicate these natural processes in synthetic materials.

Additional technological advancements continue pushing forward with the growth of the self-healing materials market. A new device was developed in April 2024 which contained a molecular device that may revolutionize drug delivery systems. This application demonstrated the potential application of self-healing materials at the molecular level. This is particularly attractive for application in the healthcare sector. This type of dynamic material is such that the controlled drug release will have more direct control over a faster response from the patient therefore reducing the harmful effects of treatment. This has been a huge milestone in the biomedical field in terms of self-healing materials being considered part of a solution for improving the delivery of better patient care through advanced medical devices and systems. For example, in April 2024, scientists created a self-healing material that can be used for drug delivery systems, for example. This technology, demonstrated the capability to heal at a molecular scale, opening new and exciting possibilities in medicine in terms of more efficiently managing drugs and medical implants. Such smart materials implanted in the medical field shall have an enormous impression, especially in those areas where traditional materials used here did not satisfy longevity and biocompatibility. Moreover, this innovation presented here regarding self-healing materials propels their diversification for specific applications and therefore increases their market potential across various industries.

Furthermore, hydrogel research is just one of these examples that also demonstrates the potential of such a market. For example, in June 2023, hydrogels for flexible sensors with the dual advantages of flexibility and durability were developed. This innovation finds great interest for industries concerned with robotics, soft electronics, and biomedical devices. Hydrogels with a self-healing ability to fix themselves autonomously are critical in the design of systems that will be more reliable and much longer-lasting. With the growing application of such materials in high-elasticity sectors, like wearable electronics, it further underlines that the importance of self-healing materials would grow even more. Moreover, with increasing value propositions witnessed by self-healing materials companies presenting opportunities to increase product lifetime and lower maintenance costs, investments in this space are expected to grow, propelling market expansion.

Market Dynamics:

Drivers:

Growing demand for sustainable materials that reduce waste and enhance energy efficiency across industries.

The demand for sustainable materials that offer the maximum efficiency of energy while minimizing waste is a huge driver in the self-healing materials market. Automotive, electronic, and construction industries want to work on developing materials that improve the extended lifetime of the products while reducing their environmental footprint as well. By their intrinsic characteristics, self-healing materials thus bring answers to these disadvantages because they can, in an autonomous way, heal themselves by solving problems of wear and tear. This diminishes the tendency of being frequently replaced or maintained with accompanying diminished usage of resources and waste. For example, in the automotive field, self-healing coatings are thus developed to protect vehicles against wear and tear resulting in less frequent repainting or replacement of parts. Another similar material emerging in construction is self-healing concrete, which has enormous potential just for infrastructure. With an ability to automatically heal cracks, this can elongate the lifetime of buildings and bridges and thereby minimize repair needs. This saves raw materials and reduces energy consumption associated with manufacturing and transportation of replacement materials. In electronics, self-healing polymers are integrated into devices that could add more toughness to equipment, especially when parts are subjected to repeated mechanical stress, such as flexible displays and wearable electronics. It increases energy efficiency while following the current sustainable trend in modern manufacturing processes because it could reduce the frequent replacement of broken parts. Pressure from regulation and growing demand from the consumer to have more environmentally friendly products is pushing companies toward driving innovation toward adopting self-healing materials that are aligned with such sustainability objectives.

Increasing adoption of self-healing technologies in electronics, automotive, and medical applications for improved product durability and longevity.

The self-healing technologies in electronics, automotive, and medical applications are showing significant growth in the self-healing material market due to their potential to enhance the product's durability and increase its lifespan. In electronics, self-healing polymers are now being included in foldable phones and wearable gadgets wherein the components have to undergo repeated mechanical stress. These materials can self-heal minor damage, such as cracks or fractures, so that lifespan is extended and maintenance or replacement costs minimized. In the automotive area, self-healing materials are already incorporated into the coating and into panels of bodies of cars to be able to recover them against damage or scratches without human intervention, which apart from improving their appearance reduces long-term maintenance needs. This is particularly useful in high-performance or luxury vehicles, where a perfect appearance is crucial. In medicine, self-healing hydrogels and polymers are increasingly applied for use in wound healing care, implants, and drug delivery devices. Such materials can heal themselves within the body, increasing the time between replacements and effective function without requiring invasive procedures for replacement or repair. A self-healing hydrogel can be designed for soft robotics and implants, wherein healing in situ may be conducive to superior patient outcomes and reduce complications. For these applications, the adoption of self-healing materials increases the product lifespan, reduces downtime, and improves overall reliability, thus constituting a really useful concept in current manufacturing and technological development.

Restraint:

High production costs of self-healing materials limit mass adoption.

The significant production cost of self-healing materials is a strong barrier to mass applications in many industries. Advanced manufacturing processes may be required for such materials, say, complex polymers or nanomaterials integration, which are challenging to produce at very large scales. Thus, sophisticated technologies raise the cost of developing self-healing coatings and polymers on their own for automotive and electronics applications, cutting into their potential mass-market reach. This cost barrier places their use primarily in high-end or application-specific situations where durability and long lifetime would be justified investments, such as luxury cars or complex medical devices. In addition, the need for continued research and development to further improve the efficiency and scalability of these materials increases the cost and delays entry into consumer products where price efficiency plays a big role.

Opportunity:

Rising use of biomimicry in material innovation offers new possibilities for advanced self-healing solutions.

Biomimicry in material innovation majorly presents a great opportunity for advancing the self-healing solution because, instead of relying on natural processes found in organisms, such as self-healing plants or animals, researchers have been able to develop more efficient and responsive self-healing materials. This can be quite straightforwardly demonstrated by the work of scientists in making polymers that can autonomously repair themselves after experiencing some form of damage, mimicking a certain type of organism, such as lizards and starfish, in their regenerative capabilities. Bio-inspired materials may find promising applications in industries ranging from the self-repairing coatings of construction to advanced medical implants capable of healing inside the body. It then allows new paths for further creating material systems that are more sustainable and resilient, therefore with better performance in harsh or high-stress environments, in line with the increasing quest for innovation in sustainable long-lasting products.

Challenge:

Integrating self-healing capabilities into complex systems while maintaining material performance remains technologically demanding.

Integrating self-healing capabilities into complex systems without affecting the performance of the material is a major challenge in the self-healing material market. Technologically, it is very difficult to have self-repair with reliable consistency without compromising the mechanical, thermal, or electrical properties of the material. For example, incorporating self-healing capabilities in electronic circuits or batteries requires maintenance of conductivity and stability along with autonomous repair after damage. Matters get worse when one considers that materials applied in aerospace or automotive applications have to endure extreme conditions and that the guaranteeing of the retention of strength and durability while self-repair is performed adds to this complexity. The advanced engineering and material science innovations involved may contribute to a delay in their widespread application across highly demanding sectors.

KEY MARKET SEGMENTS

By Product

Concrete dominated the Self-Healing Materials Market in 2023, and it accounted for around 35% of the market. The reason behind such dominance is the huge usage of concrete during construction and infrastructure work, as self-healing properties increase the durability of the said structures and lower maintenance costs. For instance, self-healing concrete can fill cracks without requiring more interventions; because healing agents can be embedded within a matrix, like bacteria or capsules made up of healing compounds that react with moisture and carbon dioxide to form calcium carbonate and thus fill the cracks. The technology is increasingly being used in bigger projects like bridges and highways, showing their practical and economic benefits.

By Form

The Intrinsic segment dominated the Self-Healing Materials Market in 2023, with an estimated market share of nearly 60%. Intrinsic self-healing materials are created with healing mechanisms embedded within their structure. Such intrinsic systems may repair damage automatically without the need for external intervention. Such a method is especially preferred due to its efficiency and reliability. For example, intrinsically self-healing polymers often come integrated with microcapsules or vascular networks that are designed to release healing agents when the material fails, thereby restoring functionality. The area in which the provided technology has a role as a key enabling technology is high-performance coatings and advanced composites, where the preservation of integrity within the material is critical to its safe and effective use.

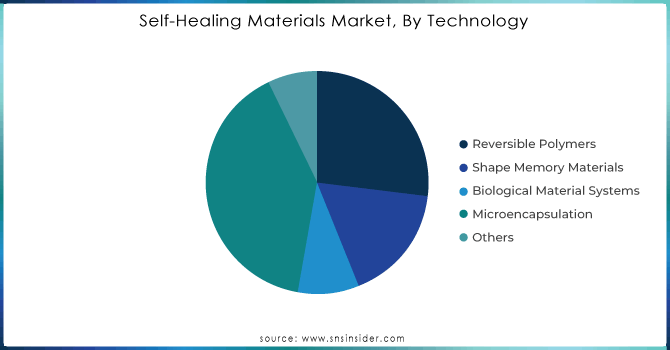

By Technology

In 2023, the Microencapsulation segment had a commanding position in the Self-Healing Materials Market, accounting for an estimated market share of about 40%. Microencapsulation involves the encapsulation of healing agents in minute capsules within the material matrix, which is released into its contents after the material sustains damage. The effectiveness and flexibility offered by this technology make it very applicable. For instance, the healing agents encapsulated in microsized form can be autonomically used for repairing cracks in concretes and coatings by releasing a healing agent that reacts with moisture or air to regenerate the structural integrity of the material. This method has been valued highly in industries where material longevity and maintenance are critical, such as in the construction and automotive sectors.

Need any Customization Research on Self-Healing Materials Market - Enquiry Now

By Application

The Building & Construction segment dominated the self-healing materials market in 2023. It accounted for an estimated market share of around 45%. Such vast usage is sought primarily because the products are made up of self-healing material, and the use of such products is a matter of immense concern in infrastructure projects. That concern is mostly about the durability and the maintenance of the product. As an example, self-healing concrete and coatings are used in ever-growing amounts on roads, bridges, and buildings to autonomously mend cracks and to ensure a longer life cycle compared with traditional ones, while avoiding costly repairs and maintenance. This application is especially beneficial in increasing the lifespan of structures exposed to hostile environmental conditions as well as heavy traffic.

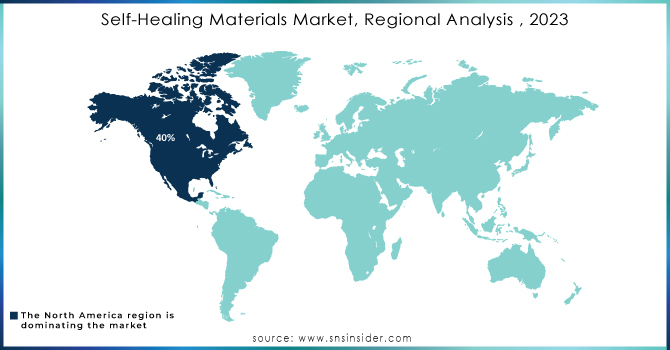

Regional Analysis

In 2023, North America dominated the Self-Healing Materials Market, accounting for about 40%. It houses some of the world's most advanced infrastructures, considerable R&D investments, and early adoption of new technologies. For instance, self-healing concrete and coatings are utilized massively today in the critical infrastructures of the United States, including highways and bridges, to enhance durability and lower the cost of maintenance. Additionally, North America has a high count of leaders within its major corporations and research organizations, which gives an added advantage to the high-scale implementation and research of self-healing materials in this region.

Moreover, the Asia-Pacific emerged as the fastest-growing region in 2023 for Self-Healing Materials, with an estimated CAGR of approximately 12% over the period. This is due to fast growth in the construction industry, increased infrastructure investment, and growing demand for advanced materials in countries like China and India. For instance, self-healing technologies that prolong life and lower maintenance prices are being incorporated into some of the major infrastructure initiatives in smart buildings and transportation networks. Thus, the robust industrial base in this region and the growing concerns about innovation and sustainability will continue to drive dynamic growth in the market for self-healing materials.

Key Players

- Akzo Nobel N.V. (Interpon D Series, Dulux Weathershield)

- Arkema SA (Pebax, Rilsan)

- Autonomic Materials, Inc. (Autonomic Healing Agent, Self-Healing Coatings)

- BASF SE (Microsphere Technology, MasterBond)

- Covestro AG (Baybond, Desmodur)

- Critical Materials S.A. (Critical Polymer Systems, HealTech)

- Dow Chemical Company (Dow Corning, DOWSIL)

- DuPont (Tyvek, Kevlar)

- Evonik Industries Corporation (VESTAMID, TEGOMER)

- High Impact Technology, LLC (HIT Self-Healing Polymers, HIT-Chemicals)

- Huntsman International LLC (Araldite, Vantico)

- MacDermid Autotype Ltd. (Autotype Self-Healing Films, MacDermid Self-Healing Coatings)

- Michelin Group (Michelin Self-Healing Tires, Michelin Self-Healing Rubber)

- NEI Corporation (Self-Healing Coatings, NEI’s Nanotechnology Solutions)

- Sensor Coating Systems Ltd. (Sensor Coatings, Self-Healing Sensors)

- Solvay S.A. (Solef, Ryton)

- The Goodyear Tire & Rubber Company (Goodyear Assurance, Goodyear Eagle)

- Toray Industries, Inc. (Torayca, Toray’s Self-Healing Polymers)

- Toyota Motor Corporation (Toyota Self-Healing Paint, Toyota Nano-Technology Coatings)

- Volkswagen AG (Volkswagen Self-Healing Paint, VW Nano-Coatings)

Recent Developments

- September 2024: Scientists discovered that nanoscale silver is inherently self-healing. A new research study demonstrated that the nanoscale silver particles can heal scratches and other damage automatically. This technology is promising to be applied in paints, coatings, and electronics.

- July 2024: Researchers at UCF have been involved as members of a team whose discovery led to the creation of self-healing glass. Among its latest discoveries, researchers engineered a glass product capable of repairing scratches and minor damage without human intervention for a longer life span of such products in electronics and construction applications.

- December 2023: Drexel University scientists have engineered bacteria-based self-healing concrete. Motivated by this new research, the introduction of this bacteria to the concrete mix can be activated under moist conditions, effectively healing cracks, which would enhance the strength and extended lifespan of the structure.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | US$ 1.9 Billion |

| Market Size by 2032 | US$ 13.7 Billion |

| CAGR | CAGR of 24.6% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | •By Product (Concrete, Polymers, Asphalt, Coatings, Fiber-reinforced Composites, Ceramic, Metals) •By Form (Intrinsic, Extrinsic) •By Technology (Reversible Polymers, Shape Memory Materials, Biological Material Systems, Microencapsulation, Others) •By Application (Energy Generation, Building & Construction, Automotive & Transportation, Electronics & Semiconductors, Medical (Implants & devices), Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Covestro AG, High Impact Technology, LLC., The Dow Chemical Company, Michelin Group, BASF SE, MacDermid Autotype Ltd., DuPont, Akzo Nobel N.V., Evonik Industries Corporation, Huntsman International LLC., Arkema SA and other key players |

| Key Drivers | • Growing demand for sustainable materials that reduce waste and enhance energy efficiency across industries |

| • Increasing adoption of self-healing technologies in electronics, automotive, and medical applications for improved product durability and longevity | |

| RESTRAINTS | • High production costs of self-healing materials limit mass adoption |