Demulsifier Market Report Scope & Overview

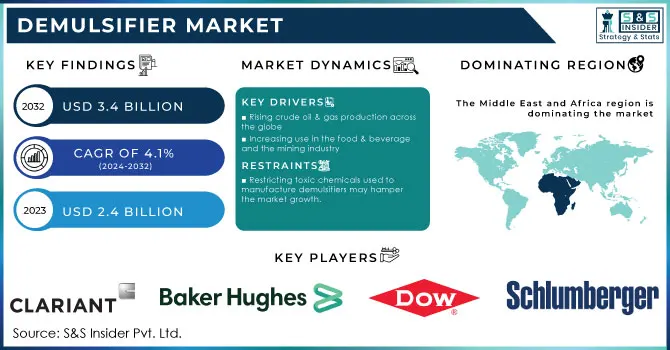

The Demulsifier Market size was valued at USD 2.4 Billion in 2023. It is expected to grow to USD 3.4 Billion by 2032 and grow at a CAGR of 4.1% over the forecast period of 2024-2032. The surge in global demand for oil and gas has prompted a significant rise in exploration and production activities across the industry. As operators seek to maximize output from existing fields and explore new reserves, the necessity for effective separation processes becomes paramount. Demulsifiers play a crucial role in this context, as they facilitate the efficient separation of water from crude oil, thereby enhancing oil recovery rates and processing efficiency.

Get E-PDF Sample Report on Demulsifier Market - Request Sample Report

According to the U.S. Energy Information Administration (EIA), global oil production reached an average of 95 million barrels per day in 2023, a significant increase driven by expanded exploration activities and production in key regions, including the Middle East, the United States, and offshore fields worldwide.

Growing realization regarding environmental sustainability, along with the adverse impact of conventional chemical products is resulting in significant movement toward non-hazardous and bio-degradable demulsifiers. With the increasing urgency of climate and environmental concerns, industries are being more mindful of their ecological footprint and choosing products that have a lower impact but would still get the job done. Due to this trend manufacturers are shifting their focus towards formulation and development of efficient, eco-friendly demulsifiers these influence product development and innovation within the global demulsifier market.

However, recent developments in the formulation of demulsifiers are making new technology a reality and further improving oilfield operations by being economic and ecological while meeting ever-stricter regulatory demands. Newly developed demulsifiers are made to work at a wide range of pressures and temperatures, which is important in offshore and deep-water drilling where extraction can be difficult. This includes biodegradable and environmentally sound formulations that are capable of reducing the oilfield chemical environmental footprint as an aid to solving regulations about eco-centric issues in oil production. Also, the developed demulsifiers focus on enhanced water-oil separation speed for efficient lowering of the processing time and cost. These latest demulsifiers are considered an industry-standard practice that satisfies environmental requirements without compromising operational performance, leading to reduced interface levels making significant contributions to sustainable operational practices, and lowering external environmental risk in oilfield operations.

According to the U.S. Environmental Protection Agency (EPA), regulations on oil and gas operations led to a 30% reduction in chemical discharge limits for offshore drilling by 2023, prompting the industry to adopt environmentally friendly solutions. This shift has accelerated the development and use of advanced, low-impact demulsifiers that meet both efficiency and environmental standards, supporting sustainable practices in oilfield operations

Market Dynamics:

Drivers:

-

Rising crude oil & gas production across the globe

-

Increasing use in the food & beverage and the mining industry

The rising utilization of demulsifiers in food & beverage and mining industries is a major growth driver. Demulsifiers are essential for separating unwanted water from oils and fats in the food & beverage sector, maintaining product purity and quality in key products such as vegetable oils & other food-grade oils. Such an application is necessary because the demand for high-quality, refined food oils increases due to both consumer behavior focusing on healthy foods and stricter safety regulations surrounding these food products. Like the oil industry, where emulsions are formed when water and oil are mixed during mineral processing and extraction, there is a need for demulsifiers in the mining industry. The decomposition of such emulsions reduces extraction efficiency and increases processing costs therefore the demulsifiers fulfill a wide variety of demands in chemical sciences where cheap, effective, eco-friendly solutions for industrial problems are needed.

According to data from the U.S. Department of Agriculture (USDA), the global vegetable oil market reached approximately 213 million metric tons in 2022, with demand projected to grow by 4% annually due to increased food processing activities. This trend highlights the growing need for efficient demulsifiers in the food sector to maintain oil purity and meet quality standards. In mining, the International Council on Mining and Metals (ICMM) reports that over 75% of mining operations globally are implementing chemical solutions like demulsifiers to enhance mineral separation processes, driven by industry standards for cost-efficiency and environmental safety.

Restraints:

Restricting toxic chemicals used to manufacture demulsifiers may hamper the market growth.

The restriction on toxic chemicals commonly used in the manufacturing of demulsifiers is a significant factor that could hamper market growth. Many traditional demulsifiers contain compounds that, while effective, pose environmental and health risks, leading regulatory bodies worldwide to impose strict guidelines and limitations on their usage. For instance, chemicals that are non-biodegradable or have high toxicity levels are now subject to tighter scrutiny and, in some cases, outright bans. As a result, manufacturers face increased pressure to develop alternative, eco-friendly demulsifier formulations, which can be costly and time-intensive. This shift not only raises production costs but may also impact the availability of effective demulsification solutions in the short term, potentially slowing market growth as companies adapt to these evolving regulations.

Opportunities:

-

Rising applications in end-user sectors create the opportunity for the market

-

Raising demand for bio-based demulsifier

A bio-based demulsifier is produced using renewable resources including sugar cane, vegetable oils, and animal fats. Compared to conventional chemical-based demulsifiers, bio-based demulsifiers are more environmentally friendly and biodegradable. As people become more conscious of the need to preserve the environment, there is an increasing demand for bio-based emulsifiers. Demulsifiers made from biological sources are a more environmentally friendly alternative.

Market segmentation

By Type

Oil-soluble demulsifiers held the largest market share around 68% in 2023. As they are extremely effective in the separation of water from crude oil especially heavy oil and complex emulsion systems. These demulsifiers are formulated to dissolve directly in the oil phase and break water-in-oil emulsions effectively immediately. The ability to separate oil from gas after extraction is an essential capability in the oil and gas industry, which internally drives quality–conditioning oil to maintain it at a desired standard. For example, they are highly effective under harsh conditions (high temperature and pressure) which often take place in offshore drilling and unconventional oil extraction. Producers often opt for them due to their reliability coupled with excellent performance across diverse oil kinds and extraction conditions, hence dominating the market.

By Application

Crude oil processing held the largest market share 32% in 2023. This is due to separating water and impurities from crude oil is one of the most vital steps in refining operations. Since the extraction of crude oil usually leads to the formation of stable water-in-oil emulsions, demulsifiers are an important tool for breaking those emulsions enabling the delivery of high-grade crude to refineries. As world energy consumption is projected to keep a rising trend, the need for effective crude oil treatment becomes more pressing since higher loads of crude and unconventional sources tend to yield complex emulsions. With more stringent crude oil quality and environmental regulations, the dependence on efficient demulsification technologies is essential for these producers. The strong demulsifier market for crude oil processing drives their share and more importantly, continues to attract innovations in formulation and application techniques improving separation efficiency.

Regional Analysis

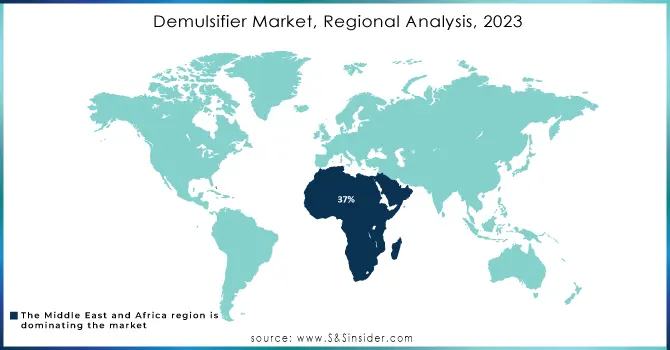

Middle East and Africa held the largest market share around 37% in 2023. It is because of its large oil and gas production capacity. The two biggest oil reserves lie within the Middle East with Saudi Arabia, The United Arab Emirates, and Iraq showing the way in production. In light of the current investments in oil exploration and extraction projects, especially under harsh conditions like off-shore and deep-water fields, there is an increasing requirement for effective demulsification technologies to treat water-in-oil emulsions. Moreover, an increase in emphasis on the betterment of the refining process and strict environmental regulation is driving the growth of demulsifiers. Furthermore, a growing number of newer oil and gas markets in Africa such as Nigeria and Angola have been increasingly explored, which is expected to bolster the potential domestic demand for demulsifiers used in crude oil processing. The MEA region is characterized by a large reserve base as well as production increase and tight regulations, which makes it the favourite market for demulsifiers.

According to the U.S. Energy Information Administration (EIA), the Middle East accounted for approximately 33% of the world's total crude oil production in 2022, with the region producing around 27.4 million barrels per day. Additionally, the African Petroleum Producers Organization (APPO) reported that oil production in Africa is expected to grow by approximately 2.2 million barrels per day by 2025, driven by new exploration and production projects in countries like Nigeria and Angola. This substantial oil output and the anticipated growth in production underscore the increasing demand for demulsifiers in crude oil processing within the Middle East and Africa, reinforcing their dominant market share in the sector.

Get Customized Report as Per Your Business Requirement - Request For Customized Report

Key Players

-

Clariant International Ltd. (Emulsogen, Lutensol)

-

Baker Hughes Company (AquaShift, K-OIL)

-

The Dow Chemical Company (DOWSIL, VERSIFY)

-

Schlumberger Limited (Demi-Sep, Hydroclear)

-

Halliburton Company (Demi-Rem, LCM)

-

Clariant AG (Sustainol, Defoamer)

-

Ecolab Inc. (AquaDri, EcoClear)

-

BASF SE (Ludox, Emulsogen)

-

Nova Star LP (NovaDemul, NovaClear)

-

Croda International (Crodamide, Crodafos)

-

SI Group (DemiCide, SI Demulsifier)

-

Baker Hughes (Separator, Demulsifier)

-

Evonik Industries AG (TEGO, DYNASYLAN)

-

Huntsman Corporation (Amines, TDI)

-

SABIC (SABIC LLDPE, SABIC HDPE)

-

Fuchs Petrolub SE (Fuchs Demulsifiers, Fuchs Emulsifiers)

-

Afton Chemical (Afton 3000, Afton 5000)

-

Lubrizol Corporation (Lubrizol 596, Lubrizol 607)

-

M-I SWACO (M-I Gel, M-I Clear)

-

Kraton Corporation (Kraton D, Kraton G)

Recent Development:

-

In 2023, Clariant launched a new range of eco-friendly demulsifiers designed to enhance oil-water separation processes while reducing environmental impact, specifically tailored for offshore applications.

-

In 2023, Dow expanded its portfolio with the introduction of DOWSIL, a new line of demulsifiers that offer superior performance in high-temperature conditions, catering to the needs of deep-water drilling operations.

-

In 2023, Schlumberger launched Hydroclear, an innovative demulsifier that enhances water removal rates in crude oil processing, particularly for high-viscosity oils.

| Report Attributes | Details |

| Market Size in 2023 | US$ 2.4 Billion |

| Market Size by 2032 | US$ 3.4 Billion |

| CAGR | CAGR of 4.1% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Type (Water Soluble and Oil Soluble) • By Application (Petro Refineries, Sludge Oil Treatment, Crude Oil Processing, Lubricant Manufacturing, Oil-based Power Plants, and Other Applications) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia Rest of Latin America) |

| Company Profiles | Clariant International Ltd., Baker Hughes Company, The Dow Chemical Company., Schlumberger Limited, Halliburton Company, Clariant AG, Ecolab Inc., BASF SE, Nova Star LP, Croda International, SI Group |

| Key Drivers | • Increasing use in the food & beverage and the mining industry • crude oil & gas production across the globe |

| Market Opportunity | • Rising applications in end-user sectors • Raising demand for bio-based demulsifier |