Gas Separation Membranes Market Report Scope & Overview:

Gas Separation Membrane Market was valued at USD 1.38 Billion in 2025E and is expected to reach USD 2.4 Billion by 2033, growing at a CAGR of 6.8% from 2026-2033.

The gas separation membranes market is expected to continue its rapid expansion led by government initiatives geared toward reducing greenhouse gas emissions and increasing energy efficiency. To help address these priorities, governments around the world have launched many programs and funding opportunities targeted at developing membrane technology. As an illustration, this year the U.S. Department of Energy initiated a new program called the "Advanced Materials for Energy-Efficient Separations," which provides $25 million in funding toward the development of breakthrough membranes in applications with industrial relevance. Likewise in 2023, the European Union's Horizon Europe program introduced €50 million in funding in support of sustainable membrane technology innovation, aiming to attain carbon neutrality by 2050.

Market Size and Forecast:

-

Market Size in 2025E USD 1.38 Billion

-

Market Size by 2033 USD 2.4 Billion

-

CAGR of 6.8% From 2026 to 2033

-

Base Year 2025

-

Forecast Period 2026-2033

-

Historical Data 2022-2024

Get more information on Gas Separation Membranes Market - Request Sample Report

The gas separation membranes market is expected to continue its rapid expansion led by government initiatives geared toward reducing greenhouse gas emissions and increasing energy efficiency. To help address these priorities, governments around the world have launched many programs and funding opportunities targeted at developing membrane technology. As an illustration, this year the U.S. Department of Energy initiated a new program called the "Advanced Materials for Energy-Efficient Separations," which provides $25 million in funding toward the development of breakthrough membranes in applications with industrial relevance. Likewise in 2023, the European Union's Horizon Europe program introduced €50 million in funding in support of sustainable membrane technology innovation, aiming to attain carbon neutrality by 2050.

The U.S. Gas Separation Membrane market size was valued at an estimated USD 0.52 billion in 2025 and is projected to reach USD 0.90 billion by 2033, growing at a CAGR of 5.4% over the forecast period 2026–2033. Market growth is driven by increasing demand for efficient gas separation technologies across industries such as oil & gas, chemicals, power generation, and environmental applications. Rising focus on carbon capture, hydrogen separation, and natural gas processing, along with the need for energy-efficient and cost-effective separation solutions, is accelerating market adoption. Additionally, technological advancements in polymeric and inorganic membrane materials, expansion of industrial gas applications, and strong investments in clean energy and emission control initiatives further support the steady growth outlook of the U.S. gas separation membrane market during the forecast period.

Gas Separation Membranes Market Trends:

-

Growing adoption of gas separation membranes for carbon capture to meet stringent environmental regulations.

-

Increasing use in natural gas processing for CO₂ removal and methane recovery.

-

Advancements in polymeric and composite membrane technologies improving efficiency and durability.

-

Rising deployment of membrane-based carbon capture in heavy industries like power generation, cement, and steel.

-

Expansion of hydrogen production applications requiring membranes for purification and lower carbon footprints.

Gas Separation Membranes Market Growth Drivers:

The increasing global attention on greenhouse gas emissions reduction and carbon capture technology has made remarkable progress and investment. Gas separation membranes are a key component during this phase, allowing for the effective separation of CO₂ from industrial emissions. Membrane-based carbon capture, for example, is envisaged for mass adoption in power generation and in other major CO₂ emitting industries such as cement and steel. New research shows that emissions from the global cement industry alone represent nearly 8% of annual CO₂ emissions worldwide. This challenge has seen the increasing deployment of membrane-based systems over traditional methods based on chemical absorption, due to the lower energy cost of membranes. Combining technologies including high-efficiency membranes for CO₂ capture, the Norwegian Northern Lights CCS project is a global model, aimed at sequestering more than 1.5 million metric tons of CO₂ annually.

In addition, the transition towards sustainable energy, such as hydrogen, requires gas separation membranes to purify hydrogen. Meanwhile, better technologies such as polymeric and mixed-matrix membranes are developed for more efficient separation for lower carbon footprints in hydrogen production. These trends highlight the reasons why separate gas membranes are critical to meeting all global economy net-zero emission goals by 2050. Gas separation membranes are an integral part of solutions enabling sustainability in valuable climate change mitigation enablers, supported by national trends and technological progress.

Gas Separation Membranes Market Restraints:

The high performance of gas separation membranes under harsh operating conditions is one of the major restraints in the gas separation membranes market. Gas separation membranes are often limited by fouling, the accumulation of molecules on the membrane surface, which decreases the permeability of the membrane and ultimately leads to reduced performance. Chemical degradation is another issue, particularly when membranes are exposed to reactive or corrosive gases like hydrogen sulfide or ammonia. These factors lead to frequent maintenance and reduced operational life, increasing costs for industries relying on these systems.

Moreover, membranes are sensitive to pressure and temperature extremes, which can cause physical damage or compromise separation performance. For example, maintaining membrane integrity becomes a critical concern in high-pressure natural gas processing. Improving durability to address these issues is a material science challenge, although existing solutions are either expensive or adopt limited use cases, restricting the scaling necessary for broad industrial commercialization.

Gas Separation Membranes Market Segment Analysis:

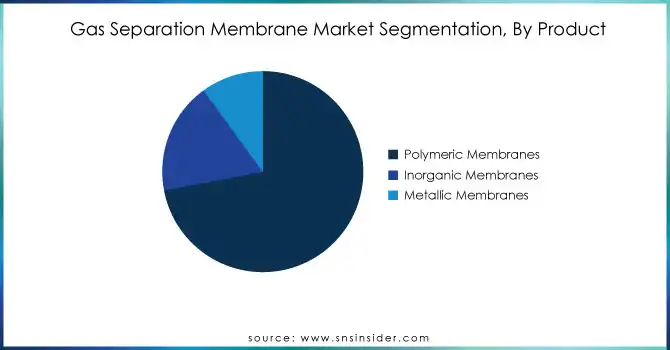

By Product

The polymeric membrane separation segment accounted for the largest share of the global revenue at 72% in 2025. High selectivity, durability, and cost-effectiveness in polymeric membranes for applications such as air separation, CO2 removal, and hydrogen recovery. In 2024, polymeric membranes were in service in more than 70% of the CO2 capture projects throughout Japan, as shown by the Ministry of Economy, Trade, and Industry (METI). Furthermore, recent advancements in polyimide and polysulfone-based membranes have increased their effectiveness, thereby driving their penetration in the market. Polymeric membranes are being pledged to various subsidies and research grants around the world, establishing their market position with the backing of governments.

By application

In 2024, the nitrogen separation segment accounted for more than 22% of the revenue share. This growth can be attributed to the rising adoption of nitrogen for inerting, blanketing, and purging applications across industries. Stiff safety regulations resulted in 2024 numbers from the European Chemicals Agency showing that more than 40% of chemical plants in Europe were using nitrogen-based solutions. Additionally, in the United States, nitrogen separation membranes gained traction in semiconductor manufacturing, where purity standards have become increasingly rigorous. According to a new report released by the International Energy Agency in 2023, the deployment of nitrogen-based technologies experienced a year-over-year growth of 10%, driven by the funding of government-led pilot projects. This is an important factor propelling the offer of nitrogen separation in the gas separation membranes market.

By end-use

Petrochemicals and oil & gas segment dominated the market in 2025, with a revenue share of about 27.0%. It has been the most popular with numerous applications, including hydrogen recovery, carbon dioxide removal, and natural gas dehydration, which drove the membrane dominance. According to the U.S. Energy Information Administration's recent data hydrogen recovery applications accounted for almost 60% of the membrane installations in the oil & gas industry in 2023. Likewise, Saudi Arabia and other Arab countries are also significantly investing in research on membrane techniques for the improvement of petrochemical production. For example, The Saudi Ministry of Energy has announced a $3 billion investment in 2023 for the conversion of facilities utilizing membrane-based CO2 capture technologies under its Vision 2030 initiatives.

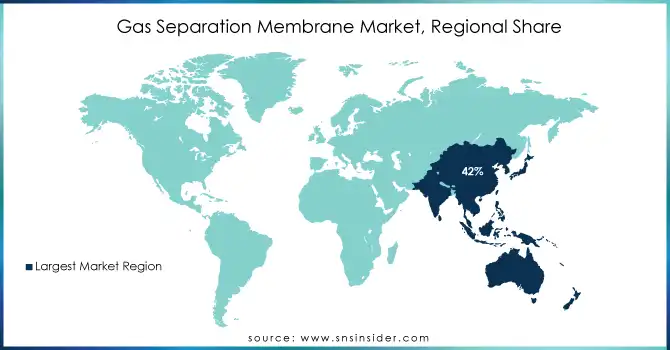

Gas Separation Membranes Market Regional Analysis:

Asia Pacific Gas Separation Membranes Market Insights

The global market was dominated by the Asia Pacific which also captured the highest revenue share of 42% in 2025. This was the case why some countries like China, India, and Japan racing ahead with their rapid industrialization and also making incredible investments in natural gas processing and carbon capture technology. China's Ministry of Ecology and Environment recently announced integrated projects, offering US$2 billion in further funding to support applications for innovative membrane solutions to improve industrial gas separation processes while ensuring peak carbon emissions by 2030.

North America Gas Separation Membranes Market Insights

The North American gas separation membrane market is expected to grow at a rapid pace over the forecast period owing to the growing adoption of carbon capture and storage (CCS) technologies and the availability of government incentives. The region is already solidifying its position as a leader in sustainability, as evidenced by a recent announcement in which the U.S. Department of Energy allocated up to $50 million for carbon capture and storage (CCS) demonstrations.

Europe Gas Separation Membranes Market Insights

The Europe gas separation membranes market is expanding due to stringent environmental regulations and growing investments in carbon capture technologies. Demand is driven by applications in power generation, natural gas processing, and hydrogen production. Technological advancements in polymeric and composite membranes are improving efficiency and durability. Supportive policies and sustainability initiatives across the region are accelerating adoption, positioning Europe as a key hub for innovative gas separation membrane solutions.

Latin America (LATAM) and Middle East & Africa (MEA) Gas Separation Membranes Market Insights

The LATAM and MEA gas separation membranes market is growing steadily, supported by rising environmental awareness and industrial expansion. Adoption is driven by demand for carbon capture, natural gas processing, and cleaner energy production. Technological innovation and infrastructure development are enhancing market growth. Regional projects and investments in sustainability are increasing membrane-based solutions adoption, making these regions important emerging markets in the global gas separation membranes industry.

Get Customized Report as per your Business Requirement - Request For Customized Report

Gas Separation Membranes Market Key Players:

Some of the Gas Separation Membranes Market Companies are

-

Air Products and Chemicals, Inc. (PRISM® Membrane Separators, GasGuard® Membranes)

-

Air Liquide Advanced Separations (Medal™ Membranes, OXYTRAP® Membranes)

-

Honeywell UOP (Separex™ Membranes, Polysep™ Membranes)

-

Membrane Technology and Research, Inc. (MTR) (VaporSep® Systems, BioSep® Membranes)

-

Parker Hannifin Corporation (Balston® Nitrogen Generators, Membrane Dryers)

-

Evonik Industries AG (SEPURAN® Green, SEPURAN® Noble Membranes)

-

Schlumberger Limited (Cynara® CO2 Membranes, PoroFlex™ Membranes)

-

Generon IGS (Nitrogen Membranes, CO2 Membrane Systems)

-

DIC Corporation (Neosepta® Membranes, Aqualife™ Membranes)

-

Global CCS Institute (Carbon Capture Membrane Solutions)

Competitive Landscape for Gas Separation Membranes Market:

-

In March 2024, the U.S. Department of Energy announced a collaboration with a leading manufacturer of membranes to develop next-generation polymeric membranes to improve hydrogen separation efficiency. The $10 million project is anticipated to enhance hydrogen production volumes.

UBE Corporation is a leading Japanese chemical and materials company specializing in advanced membrane technologies for gas separation applications. The company develops high-performance polymeric membranes for carbon capture, natural gas processing, and hydrogen purification. With a strong focus on innovation, UBE delivers efficient, durable, and sustainable solutions. Its expertise supports global environmental goals, making it a key player in advancing gas separation membrane technologies for energy transition and climate change mitigation.

-

In January 2023, UBE Corp. announced the expansion of its production capacity for gas separation membrane hollow fibers and membrane modules. The expansion will add a production capacity of approx. 1.8 times the existing production capacity and is being built to cater to the growing demand from environmental and energy sectors with commissioning expected by mid-2025.

| Report Attributes | Details |

|---|---|

| Market Size in 2025E | USD 1.38 Billion |

| Market Size by 2033 | USD 2.4 Billion |

| CAGR | CAGR of 6.8% From 2026 to 2033 |

| Base Year | 2025 |

| Forecast Period | 2026-2032 |

| Historical Data | 2022-2024 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Product (Polymeric Membranes, Metallic Membranes, Inorganic Membranes) • By Application (Nitrogen Separation, Hydrogen Separation, Oxygen Separation, Acid gas Separation, Others) • By End-use (Chemicals, Power Generation, Petrochemicals and Oil & Gas, Pollution Control, Food & Beverage, Pharmaceuticals, Others) |

| Regional Analysis/Coverage | North America (US, Canada), Europe (Germany, UK, France, Italy, Spain, Russia, Poland, Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Australia, ASEAN Countries, Rest of Asia Pacific), Middle East & Africa (UAE, Saudi Arabia, Qatar, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Mexico, Colombia, Rest of Latin America). |

| Company Profiles | Air Products and Chemicals, Inc., Air Liquide Advanced Separations, Honeywell UOP, Membrane Technology and Research, Inc. (MTR), Parker Hannifin Corporation, Evonik Industries AG, Schlumberger Limited, Generon IGS, DIC Corporation, Global CCS Institute. |