Industrial Agitators Market Size & Growth Trends:

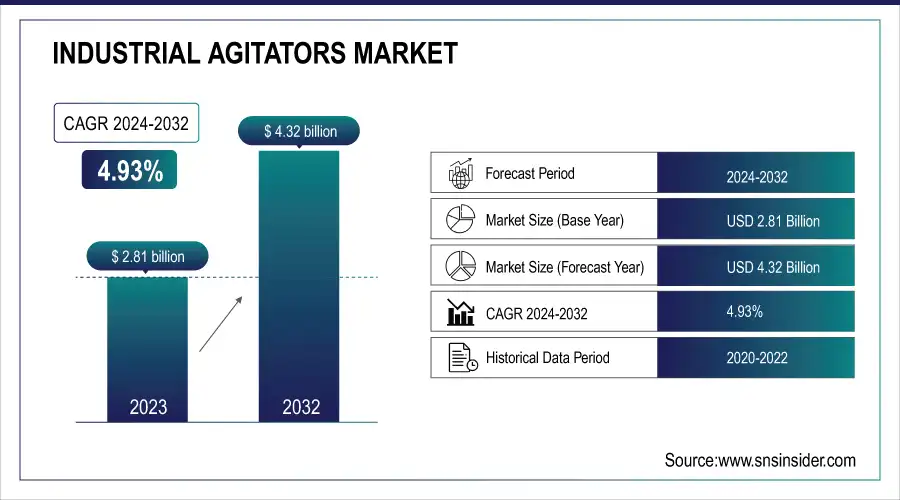

The Industrial Agitators Market was valued at USD 2.81 billion in 2023 and is expected to reach USD 4.32 billion by 2032, growing at a CAGR of 4.93% over the forecast period 2024-2032.

The industrial agitators market is witnessing a change in a trajectory towards the choice of materials towards are durable like stainless steel or quality-specific alloys for use at the center line toughness in case of high-temperature high-pressure exposure zones. Maintenance practices have become more homogenous, with most sectors utilizing preventative insurance within a 6–12 month time frame. A significant emphasis is on energy efficiency, prompting widespread adoption of variable speed drives and smart technologies. Further, dependence is reliant on tank volume propelled by medium-capacity tanks consuming large market stakes across sectors, whereas portable & compact solutions are gaining traction in small-scale markets.

To Get more information on Industrial Agitators Market - Request Free Sample Report

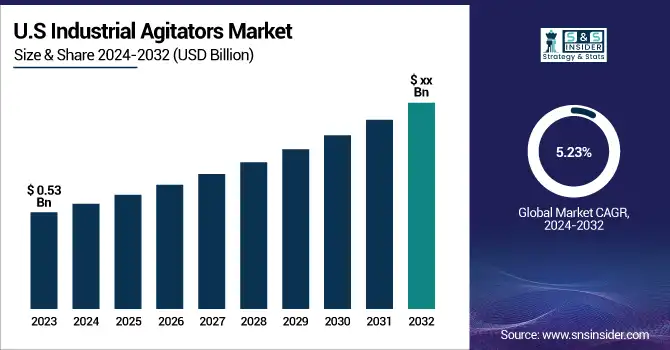

The U.S. industrial agitators market is driven by the increased demand primarily from chemical, pharmaceutical, and food and beverage industries. To boost operational efficiency and meet stringent environmental regulations, manufacturers are increasingly adopting energy-efficient agitators installed with smart technologies such as variable frequency drives and Industrial Internet of Things (IIoT) capabilities. The trend of having customized agitator solutions is also on the rise as players look to get suited equipment for their specific process requirements.

The U.S. Industrial Agitators Market is estimated to be USD 0.53 Billion in 2023 and is projected to grow at a CAGR of 5.23%. Increasing demand for precision mixing in biotechnology and specialty chemicals, along with stricter hygiene regulations in this sector, as well as modernization of aged industrial infrastructure are driving growth of the industrial agitators market in U.S. Agitator adoption in various sectors is being further fuelled by the expansion of modular process plants and increased focus on investments in domestic manufacturing.

Industrial Agitators Market Dynamics

Key Drivers:

-

Rising Demand for Advanced Agitators Driven by Process Efficiency Automation and Environmental Compliance

Efficient mixing technologies are being increasingly sought after in industries such as oil & gas, chemicals, pharmaceuticals, and water treatment, which are the key factors driving the growth of the industrial agitators market. Increasing usage of advanced agitator systems owing to the necessity of improved mixing, blending, and heat transfer in complicated chemical reactions has increased the popularity of advanced mixing equipment. Also, enforcing environmental regulations in wastewater treatment is compelling industries to use high-performance agitators for effective processing. In addition, the growing demand for automation and process control and a strong focus on minimizing energy loss will boost the replacement of old and traditional mixing systems with new mixes of efficient and modern types.

Restrain:

-

Design Challenges and Installation Issues Limit Adoption of Complex Industrial Agitators in Diverse Industrial Applications

High design complexities leading to the high cost of industrial agitators are one of the key restraints hampering the growth of the industrial agitators market. However, different process requirements in various industries, such as viscosity, mixing speed, tank geometry, and characteristics of the chemicals, make custom solutions unfeasible. Longer lead times and possible compatibility problems, particularly when retrofitting older systems. More so, the large size and the complexity of moving parts in some of the agitator systems (like top-entry types) can create problems during installation and can lead to space issues too, especially, in small/ portable processing systems.

Opportunity:

-

Emerging Opportunities in Food Pharma and Smart Agitation Technologies Drive Future Industrial Agitator Market Growth

A valuable opportunity that is poised to grow significantly in the future is the food & beverage sector due to consumer preferences shifting, increased health consciousness, along the demand for processed and hygienic food products. In particular, portable agitators are becoming increasingly popular for their versatility and easy installation for small and medium-scale applications. In addition to this, the post-pandemic accelerated growth of pharmaceutical manufacturing, being a valuable market where high precision and contamination-free mixing are required, is again favorable metal mixers and agitators market trends. Also, IoT and smart monitoring, have begun opening a fresh scope of differentiation and process optimization in both product and process, especially in developing economies where industrialization has just started to boom.

Challenges:

-

Harsh Conditions and Skill Shortages Challenge Reliable Performance of Industrial Agitators Across Critical Sectors

Another key challenge is delivering consistent and reliable performance in harsh operating environments. For example, in oil & gas or chemical processing, agitators are continually exposed to corrosive fluids, higher pressures, and elevated temperatures, leading to durability concerns and more frequent maintenance operations. In addition, the adoption of advanced agitation systems can be restricted by the absence of skilled personnel required for operation, calibration, and maintenance, chiefly in developing regions. Especially in the food, beverage, and pharmaceutical industry, manufacturers must cope with the high overhead of continuous innovation and warning compliance with safety, hygiene, and environmental standards.

Industrial Agitators Market Segmentation Outlook

By Product

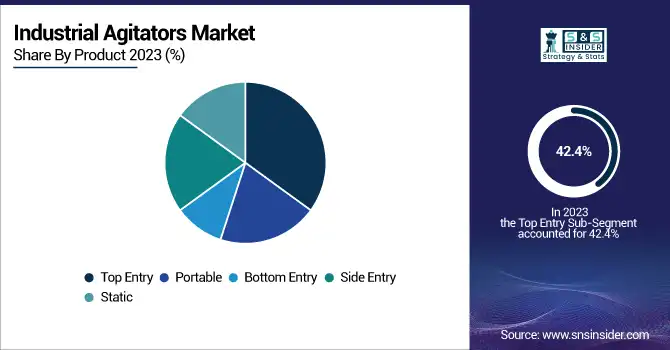

In 2023, the Top Entry agitators segment led the global market and held a share of 42.4% of the total revenue. The performance offered by these agitators such as is widely used in oil & gas, chemicals, and water treatment in large tanks for high-volume mixing. These are good at mixing high-viscosity fluids and establishing homogeneity of complicated operations, which explains why they are the go-to choice for a lot of big-scale industrial operations.

The Portable agitators segment is expected to register the fastest CAGR from 2024 to 2032. These mini plants are lightweight, mobile, and flexible, making them suitable for small to medium-batch processing in the food & beverage, pharmaceutical, and specialty chemicals industries. This segment is likely to grow faster in the next few years as industries move toward modularity and scalability, and portable solutions that offer convenience without sacrificing work performance will be in hot demand.

By End Use

The industrial agitator segment was led by the Oil, Gas, and Petrochemical segment, and accounted for a prominent share of 27.8% in 2023. The reason for this dominance is due to the widespread utilization of these agitators in processes like crude oil blending, chemical reactions, & refining operations where efficient mixing is a must. Apart from that, the agitators have found significant demand owing to the requirement of high-viscosity fluids, maintenance of chemical consistency as well as process safety in volatile environments in the industrial sector.

The fastest-growing application segment is food and Beverages in terms of CAGR from 2024 to 2032. There is a rise in mixing technologies due to the increasing demand for processed, packaged, and ready-to-eat food products around the world. Industrial agitators play an important role in hygiene maintenance, uniform distribution of ingredients, and enhancement of overall product quality. Moreover, the need for stringent food safety regulations and the increasing automation of food processing applications are supporting the growth of high-performance agitator sales in this vertical.

Industrial Agitators Market Regional Analysis

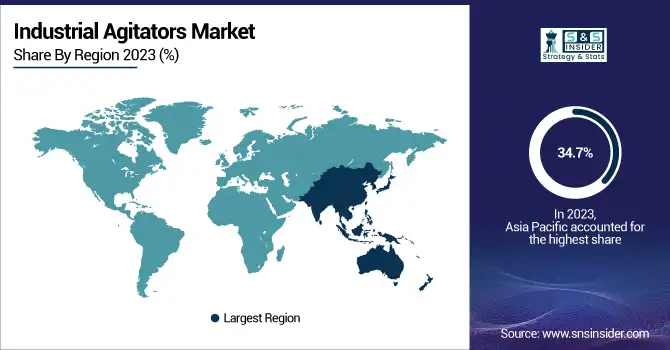

Asia Pacific led the industrial agitators market in 2023, contributing 34.7% of the total share. The reason for this dominance can be attributed to the fast-paced industrial growth and expansion of infrastructure and major industries such as chemicals, oil & gas, food processing, and pharmaceuticals in several regions such as China, India & Southeast Asia. This high demand for industrial agitators in the region is further accelerated by government initiatives to promote wastewater treatment and clean energy top-top with the upsurge in manufacturing output from numerous industries.

Get Customized Report as per Your Business Requirement - Enquiry Now

North America is expected to grow fastest CAGR over the period from 2024 to 2032. Next-gen agitator systems are being adopted, which is propelled by the strong emphasis on advanced manufacturing technologies, automation, and process optimization in the region. Moreover, the rising focus on sustainable operations and modernization of the legacy industrial setups are further high-value mixing investments within the food & beverages, pharmaceutical, and petrochemicals sectors, driving the market expansion.

Key Players in the Industrial Agitators Market are:

-

SPX FLOW (Lightnin Series 10 Agitator)

-

Sulzer Ltd (SALOMIX Agitator)

-

Alfa Laval (ALS Agitator)

-

Philadelphia Mixing Solutions (Philmix Top-Entry Mixer)

-

Xylem Inc. (Flygt 4460 Submersible Agitator)

-

EKATO Group (EKATO EM)

-

National Oilwell Varco (NOV) (Chemineer HT Agitator)

-

Statiflo International (Statiflo Static Mixer)

-

Dynamix Agitators Inc. (DMX Series Agitator)

-

MIXEL Agitators (GSM Agitator)

-

Silverson Machines (Silverson Ultramix)

-

Zucchetti Centro Sistemi (ZCS) (Z-Mix Agitator)

-

Milton Roy (Accudyne Industries) (Milton Roy Mixing Systems)

-

Praxair (Linde Group) (HiGee Agitator)

-

Inoxpa (ME-1100 Vertical Agitator)

Recent Development

-

In February 2025, Sulzer expanded its Vadodara Service Center to enhance support for India's growing energy sector, strengthening its presence alongside the Chennai facility to serve oil & gas and power industries.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 1.40 Billion |

| Market Size by 2032 | USD 2.59 Million |

| CAGR | CAGR of 7.10% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Product (Top Entry, Side Entry, Bottom Entry, Portable, Static) • By End Use (Chemical, Water And Wastewater Treatment, Oil, Gas And Petrochemical, Food And Beverages, Pharmaceutical, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | SPX FLOW, Sulzer Ltd, Alfa Laval, Philadelphia Mixing Solutions, Xylem Inc., EKATO Group, National Oilwell Varco (NOV), Statiflo International, Dynamix Agitators Inc., MIXEL Agitators, Silverson Machines, Zucchetti Centro Sistemi (ZCS), Milton Roy (Accudyne Industries), Praxair (Linde Group), Inoxpa. |