Process Kit Bolt Torque Specification Market Report Scope & Overview:

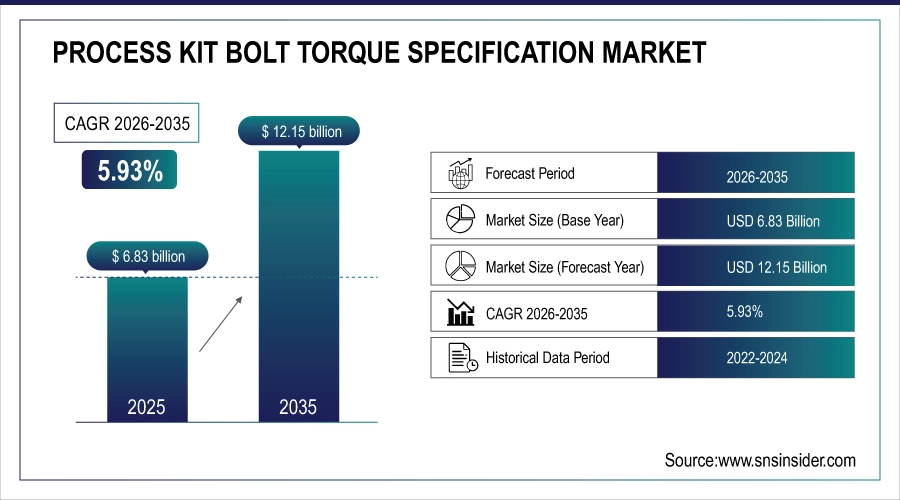

The Process Kit Bolt Torque Specification Market size was valued at USD 6.83 Billion in 2025 and is projected to reach USD 12.15 Billion by 2035, growing at a CAGR of 5.93% during 2026–2035.

The Process Kit Bolt Torque Specification market is evolving rapidly, driven by rising demand for higher fastening accuracy, real-time quality control, and digital traceability in critical industrial assemblies. Advanced torque tools that integrate bolt tension monitoring support stricter torque specifications, reduce rework, and improve compliance across automotive, aerospace, energy, and heavy equipment manufacturing. As production complexity increases and tolerance margins tighten, manufacturers are increasingly adopting intelligent fastening solutions within process kits to ensure consistent clamping performance, operational safety, and lifecycle reliability.

June 2024 – A major innovation in fastening technology emerged with the launch of the TRAXX tightening wrench, combining torque application and real-time bolt tension measurement in a single tool to enhance precision, traceability, and assembly reliability across industrial applications.

Market Size and Growth Projection:

-

Market Size in 2025: USD 6.83 Billion

-

Market Size by 2035: USD 12.15 Billion

-

CAGR: 5.93% from 2026 to 2035

-

Base Year: 2025

-

Forecast Period: 2026–2035

-

Historical Data: 2022–2024

To Get more information on Process Kit Bolt Torque Specification Market - Request Free Sample Report

Process Kit Bolt Torque Specification Market Highlights:

-

Expanding use of torque wrenches across automotive industrial construction and maintenance activities supports consistent demand for torque specification compliance

-

Growing availability of click beam and digital torque tools enables accurate bolt tightening across professional and DIY applications

-

Rising emphasis on fastening accuracy and safety is increasing adoption of precision torque specification practices

-

High performance engine and equipment assemblies rely on strict bolt torque specifications to ensure reliability and durability

-

Increased consumer and technician awareness of correct torque application improves standardization and tool demand

-

Application specific torque requirements in bicycles machinery and specialty equipment are creating niche growth opportunities

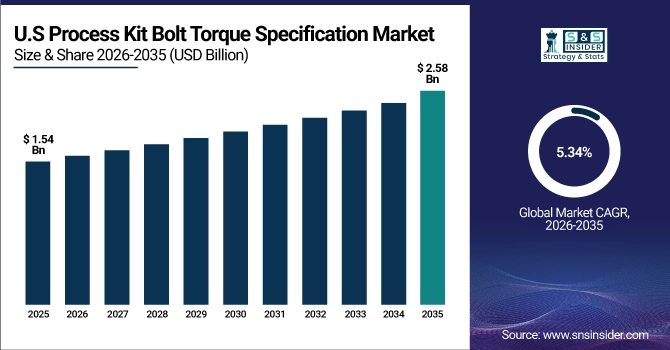

The U.S. Process Kit Bolt Torque Specification Market size was valued at USD 1.54 Billion in 2025 and is projected to reach USD 2.58 Billion by 2035, growing at a CAGR of 5.34% during 2026–2035, driven by strong demand from automotive, aerospace, and energy industries, where precise torque control is critical for safety and compliance. Increasing automation, adoption of smart manufacturing practices, and stringent quality standards are accelerating the need for standardized torque specifications. Additionally, rising investments in infrastructure, electric vehicle production, and advanced maintenance processes are supporting consistent market growth by emphasizing accuracy, traceability, and process reliability across industrial operations.

Process Kit Bolt Torque Specification Market Drivers:

-

Rising Demand for Precision Assembly and Compliance Drives Market Growth

The Process Kit Bolt Torque Specification market is driven by the increasing need for precise, repeatable, and standardized fastening processes across industrial manufacturing. As automotive, aerospace, energy, and heavy machinery sectors adopt complex assemblies and safety-critical components, accurate torque specification becomes essential to prevent failures, ensure regulatory compliance, and improve product reliability. Growing automation, high-mix production lines, and stricter quality assurance norms further elevate the importance of well-defined torque specifications within process kits. Additionally, manufacturers are focusing on reducing rework, downtime, and warranty costs, which reinforces demand for structured torque specification systems integrated with modern assembly and maintenance workflows.

RAD Torque Systems won the 2024 Pro Tool Innovation Award for its B-RAD Xtreme cordless wrench, delivering up to 15,000 Nm torque with 4% accuracy for heavy industrial tasks. Tohnichi released the QL+ and CL+ series adjustable torque wrenches in May 2025 for low-torque (up to 5 Nm) precision work, alongside the AUR-mk2 pneumatic screwdriver

Process Kit Bolt Torque Specification Market Restraints:

-

High Costs and Integration Challenges Limit Adoption of Advanced Torque Tools

The Process Kit Bolt Torque Specification market faces several restraints that may slow adoption. High upfront costs of advanced torque tools, including AR/VR-compatible and digital torque wrenches, limit accessibility for small and medium-sized manufacturers. Integration with existing assembly lines can be complex, requiring workforce training and system upgrades. Dependence on skilled personnel for calibration and maintenance adds operational challenges. Additionally, compatibility issues across different torque systems, inconsistent standards, and concerns over tool reliability in harsh industrial environments may hinder adoption. Regulatory compliance and slow digital transformation in certain regions further constrain market growth despite technological advancements.

Process Kit Bolt Torque Specification Market Opportunities:

-

AR and VR-Enabled Torque Tools Unlock Industrial Efficiency

The integration of AR and VR in production lines presents significant market opportunities for Process Kit Bolt Torque Specification solutions. By overlaying torque values, assembly instructions, and orientation cues directly into workspaces, these technologies enhance precision, reduce assembly errors, and enable faster workforce training. Manufacturers adopting AR/VR-compatible torque tools can optimize high-mix, automated operations, minimize downtime, and improve quality control. Additionally, remote monitoring and virtual simulations allow safer and cost-efficient process planning. Rising demand for connected, intelligent torque solutions in automotive, aerospace, and industrial manufacturing sectors is expected to drive adoption and innovation globally.

November 26, 2025 – AR and VR Boosting Production Planning and Performance Automakers including Ford, BMW, and Bosch use AR/VR to display torque values, assembly steps, and orientation cues, enhancing precision, reducing errors, and improving training on automated high-mix production lines.

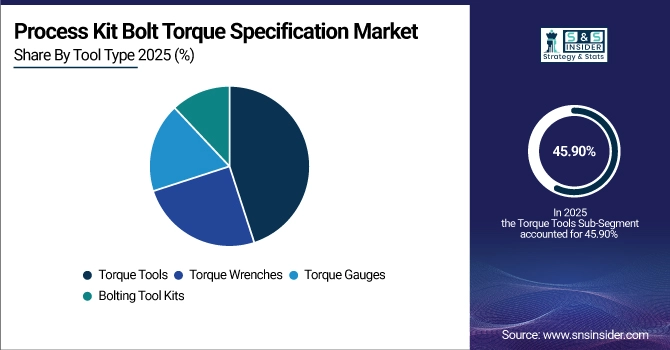

Process Kit Bolt Torque Specification Market Segment Highlights:

-

By Tool Type: Dominant – Torque Tools (45.90% → 40.10%); Fastest-Growing – Torque Gauges (18.90% → 22.70%)

-

By Technology: Dominant – Electric / Powered (32.80% → 37.20%); Fastest-Growing – Hydraulic (8.20% → 10.80%)

-

By Application: Dominant – Automotive (39.30% → 37.00%); Fastest-Growing – Aerospace (15.70% → 17.00%)

-

By End-Use Industry: Dominant – Automotive (41.42% → 37.58%); Fastest-Growing – Energy & Utilities (17.80% → 20.20%)

By Tool Type, Torque Tools and Torque Gauges Dominating and Fastest-Growing

Torque Tools remain the dominant segment in the Process Kit Bolt Torque Specification market, driven by their widespread use in industrial assembly, automotive, and maintenance applications. Torque Gauges are the fastest-growing segment, supported by rising demand for precision measurement, quality control, and smart torque monitoring across manufacturing and aerospace industries.

By Technology, Electric / Powered and Hydraulic Dominating and Fastest-Growing

Electric / Powered tools remain the dominant technology in the Process Kit Bolt Torque Specification market, driven by efficiency, automation compatibility, and high adoption across industrial and automotive sectors. Hydraulic tools are the fastest-growing segment, supported by rising demand for high-torque applications, precision, and heavy-duty assembly solutions.

By Application, Automotive and Aerospace Dominating and Fastest-Growing

Automotive applications remain the dominant segment, fueled by extensive use in assembly lines and vehicle manufacturing. Aerospace applications are the fastest-growing segment, driven by increasing aircraft production, stringent safety standards, and precision torque requirements in aerospace manufacturing.

By End-Use Industry, Automotive and Energy & Utilities Dominating and Fastest-Growing

Automotive remains the dominant end-use industry due to its large-scale assembly and maintenance needs. Energy & Utilities is the fastest-growing industry segment, supported by infrastructure expansion, industrial projects, and the adoption of precision torque tools in power generation, oil, gas, and utility operations.

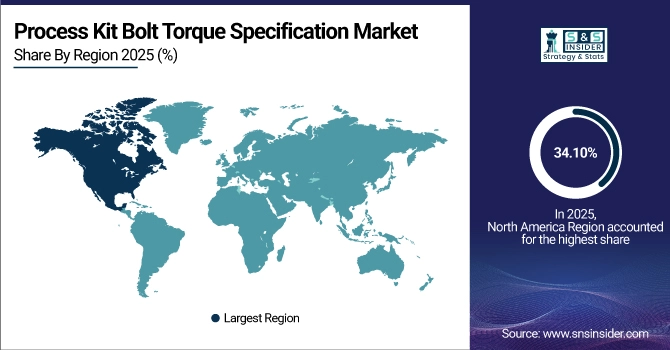

Process Kit Bolt Torque Specification Market Regional Highlights:

-

North America: 34.10% → 32.70% in 2035, Leading Share in 2025 with Moderate Decline (CAGR 5.49%)

-

Asia-Pacific: 32.80% → 35.70% in 2035, Dominant Region by 2035 and Fastest-Growing Region (CAGR 6.83%)

-

Europe: 27.50% → 26.80% in 2035, Stable Share with Moderate Growth (CAGR 5.66%)

-

Latin America: 3.00% → 2.70% in 2035, Small Share with Steady Growth (CAGR 4.81%)

-

Middle East & Africa: 2.60% → 2.10% in 2035, Low-Share Region with Gradual Growth (CAGR 3.67%)

North America Process Kit Bolt Torque Specification Market Insights:

The North America Process Kit Bolt Torque Specification market dominates globally, driven by advanced manufacturing technologies, stringent safety and quality standards, and high adoption of precision assembly tools. Strong industrial automation, well-established automotive and aerospace sectors, and growing investment in digital torque solutions contribute to the region’s leading market position.

Get Customized Report as per Your Business Requirement - Enquiry Now

U.S. Process Kit Bolt Torque Specification Market Insights:

The U.S. leads the North America Process Kit Bolt Torque Specification market, driven by advanced industrial automation, rising demand for precision assembly, stringent safety standards, and adoption of smart torque and digital tools.

Asia-Pacific Process Kit Bolt Torque Specification Market Insights:

The Asia-Pacific Process Kit Bolt Torque Specification market is witnessing strong growth, fueled by rapid industrialization, expanding automotive and electronics manufacturing, and increasing adoption of precision assembly and smart torque tools. Rising investments in infrastructure, technology upgrades, and quality-focused manufacturing practices are driving market expansion across the region.

ChinaProcess Kit Bolt Torque Specification Market Insights:

The China Process Kit Bolt Torque Specification market is expanding steadily, driven by industrial modernization, growing automotive and electronics sectors, increasing adoption of smart torque tools, and rising focus on quality and precision assembly.

Europe Process Kit Bolt Torque Specification Market Insights:

The Europe Process Kit Bolt Torque Specification market is growing moderately, supported by advanced manufacturing infrastructure, stringent quality and safety regulations, and the adoption of digital and smart torque tools. Strong automotive, aerospace, and industrial machinery sectors, along with ongoing investments in precision assembly technologies, drive regional market growth.

Germany Process Kit Bolt Torque Specification Market Insights:

Germany’s Process Kit Bolt Torque Specification market is expanding steadily, driven by advanced industrial automation, strong automotive and manufacturing sectors, adoption of precision torque tools, and emphasis on quality, safety, and efficiency.

Latin America Process Kit Bolt Torque Specification Market Insights:

The Latin America Process Kit Bolt Torque Specification market is witnessing steady growth, supported by expanding industrial and automotive sectors, increasing adoption of precision assembly and torque tools, and investments in infrastructure. Growing awareness of safety standards, quality control, and technological upgrades is driving market development across the region.

Brazil Process Kit Bolt Torque Specification Market Insights:

Brazil is the dominant country in the Process Kit Bolt Torque Specification market, driven by strong automotive and industrial manufacturing, growing adoption of precision torque tools, and increasing focus on quality and safety standards.

Middle East & Africa (MEA) Process Kit Bolt Torque Specification Market Insights:

The Middle East & Africa Process Kit Bolt Torque Specification market is growing gradually, fueled by expanding oil, gas, and industrial sectors, rising adoption of precision assembly and torque tools, and increasing investments in manufacturing infrastructure. Focus on safety, quality standards, and technological upgrades supports steady regional growth.

Saudi Arabia Process Kit Bolt Torque Specification Market Insights:

Saudi Arabia is the dominant country in the Process Kit Bolt Torque Specification market, driven by robust oil, gas, and industrial sectors, growing adoption of precision torque tools, and emphasis on safety and quality standards.

Process Kit Bolt Torque Specification Market Competitive Landscape:

Atlas Copco AB, established in 1873 and headquartered in Nacka, Sweden, is a global leader in industrial tools and equipment. The company specializes in compressors, vacuum solutions, industrial power tools, and assembly systems. Atlas Copco focuses on innovation, sustainability, and efficiency, serving manufacturing, construction, and energy industries worldwide.

-

In July 9, 2025 – Atlas Copco Group won the Red Dot Design Award 2025 for its MTRwrench industrial assembly tool, recognized for efficiency, ergonomics, and precision. The tool features ergonomic design, error-proofing, fast battery replacement, and sustainable materials, supporting continuous workflow in industrial assembly.

DEWALT, founded in 1924 and headquartered in Towson, Maryland, USA, is a premium brand of Stanley Black & Decker. It specializes in power tools, hand tools, and fastening solutions for industrial, construction, and jobsite applications. DEWALT focuses on innovation, durability, ergonomics, and high-performance solutions worldwide.

-

August 29, 2024 – DEWALT, a Stanley Black & Decker brand, launched its highest-rated Max Torque fastening solutions including the 20V MAX XR® High Torque Impact Wrenches and Quiet Hydraulic Impact Driver. The tools deliver enhanced torque, precision, ergonomics, and quieter operation, supporting demanding industrial and jobsite applications.

Process Kit Bolt Torque Specification Companies are:

-

Atlas Copco AB

-

Norbar Torque Tools Ltd

-

Stanley Black & Decker, Inc.

-

Enerpac Tool Group

-

Mountz, Inc.

-

HYTORC (UNEX Corporation)

-

Tohnichi Manufacturing Co., Ltd.

-

Proto Industrial Tools

-

Alkitronic GmbH

-

Plarad (Maschinenfabrik Wagner GmbH & Co. KG)

-

Sturtevant Richmont (Snap‑on division)

-

Ingersoll Rand Inc.

-

Wera Werkzeuge GmbH

-

KUKEN Co., Ltd.

-

Apex Tool Group

-

RAD Torque Systems

-

SCS Concept Group

-

Chicago Pneumatic

| Report Attributes | Details |

|---|---|

| Market Size in 2025 | USD 6.83 Billion |

| Market Size by 2035 | USD 12.15 Billion |

| CAGR | CAGR of 5.93% From 2026 to 2035 |

| Base Year | 2025 |

| Forecast Period | 2026-2035 |

| Historical Data | 2022-2024 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Tool Type(Torque Tools, Torque Wrenches, Torque Gauges and Bolting Tool Kits) • By Technology(Manual, Electric / Powered, Pneumatic and Hydraulic) • By Application(Automotive, Aerospace, Industrial Manufacturing and Maintenance & Service) • By End-Use Industry(Automotive, Aerospace & Defense, Heavy Machinery & Industrial Equipment and Energy & Utilities) |

| Regional Analysis/Coverage | North America (US, Canada), Europe (Germany, UK, France, Italy, Spain, Russia, Poland, Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Australia, ASEAN Countries, Rest of Asia Pacific), Middle East & Africa (UAE, Saudi Arabia, Qatar, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Mexico, Colombia, Rest of Latin America). |

| Company Profiles | Atlas Copco AB, Snap-on Incorporated, Norbar Torque Tools Ltd., Stanley Black & Decker, Inc., Enerpac Tool Group, Desoutter Industrial Tools, Mountz, Inc., HYTORC (UNEX Corporation), Tohnichi Manufacturing Co., Ltd., Proto Industrial Tools, Alkitronic GmbH, Plarad (Maschinenfabrik Wagner GmbH & Co. KG), Sturtevant Richmont (Snap-on division), Ingersoll Rand Inc., Wera Werkzeuge GmbH, KUKEN Co., Ltd., Apex Tool Group, RAD Torque Systems, SCS Concept Group, and Chicago Pneumatic. |