Refractories Market Report Scope & Overview:

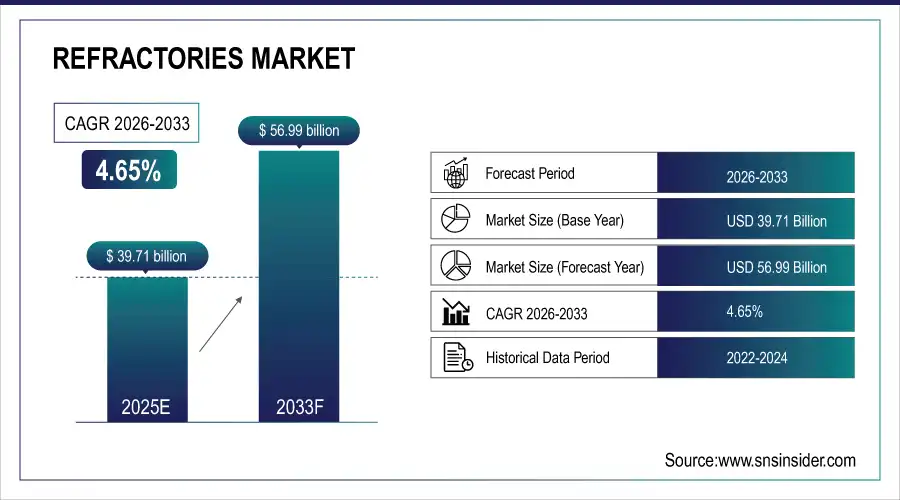

The Refractories Market Size was valued at USD 39.71 Billion in 2025E and is projected to reach USD 56.99 Billion by 2033, growing at a CAGR of 4.65% during the forecast period 2026–2033.

The Refractories Market analysis report provides comprehensive insights into key factors driving growth, including demand from steel, cement, glass, and non-ferrous industries. Increasing focus on high-performance, durable, and energy-efficient refractory solutions is supporting market expansion across regions and end-use applications.

Refractory consumption reached 39.7 million tons in 2025, driven by demand from steel, cement, and glass industries and rising adoption of high-performance solutions.

Market Size and Forecast:

-

Market Size in 2025: USD 39.71 Billion

-

Market Size by 2033: USD 56.99 Billion

-

CAGR: 4.65% from 2026 to 2033

-

Base Year: 2025

-

Forecast Period: 2026–2033

-

Historical Data: 2022–2024

To Get more information On Refractories Market - Request Free Sample Report

Refractories Market Trends:

-

Rising demand from steel, cement, and glass industries is boosting overall refractory consumption, particularly for high-performance and energy-efficient solutions.

-

Adoption of advanced refractory materials and custom shapes is driving innovation and specialized applications across heavy industries.

-

Growth in infrastructure projects and industrial expansion is increasing availability and usage of modern refractory products.

-

Focus on durability, sustainability, and low-maintenance solutions is encouraging investment in premium and eco-friendly refractories.

-

Market dynamics favor product differentiation, customized solutions, and technological innovations that meet evolving industrial performance and safety standards.

U.S. Refractories Market Insights:

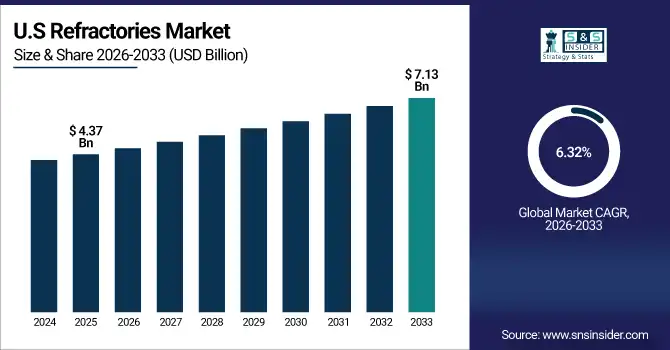

The U.S. Refractories Market is projected to grow from USD 4.37 Billion in 2025E to USD 7.13 Billion by 2033, at a CAGR of 6.32%. Growth is driven by rising steel, cement, and glass production, increasing infrastructure development, and demand for durable, high-performance, and energy-efficient refractory solutions.

Refractories Market Growth Drivers:

-

Rising steel and cement production globally, driving demand for high-performance and durable refractory solutions.

Rising steel, cement, and glass production is the primary driver of Refractories Market Growth. Expanding industrial activity and large-scale infrastructure projects are increasing demand for high-performance, durable, and energy-efficient refractory solutions. Adoption of advanced materials and custom shapes enables specialized applications, while focus on sustainability and low-maintenance products supports long-term industrial efficiency. Innovation and technological advancements create product differentiation, improved performance, and stronger market competitiveness over time.

Refractory demand grew 4.2% in 2025, driven by rising steel and cement production and expansion in heavy industrial manufacturing.

Refractories Market Restraints:

-

Fluctuating raw material prices, high energy costs, and complex production processes are restraining large-scale growth of the Refractories Market.

Fluctuating raw material prices, high energy costs, and complex production processes are major restraints for the Refractories Market. Volatility in the prices of key inputs such as bauxite, alumina, magnesite, and graphite impacts profit margins and production stability. Rising fuel and electricity costs further increase manufacturing expenses, particularly in energy-intensive industries. Moreover, strict environmental regulations, sustainability compliance, and the need for advanced processing technologies limit scalability and raise barriers for smaller and regional manufacturers.

Refractories Market Opportunities:

-

Increasing demand for energy-efficient and eco-friendly refractory materials offers opportunities for innovation in design and manufacturing technologies.

Increasing demand for energy-efficient and eco-friendly refractory materials presents a major opportunity for market growth. Industries are shifting toward sustainable production to reduce emissions and energy consumption, driving the adoption of advanced, low-carbon refractories. Manufacturers are innovating with recycled raw materials, nanotechnology, and lightweight designs to enhance performance and durability. This sustainability-driven innovation not only supports environmental goals but also creates premium, high-value solutions that strengthen competitiveness and long-term growth in the Refractories Market.

Energy-efficient and eco-friendly refractory products accounted for 22% of total market innovations in 2025, driven by rising industrial sustainability adoption.

Refractories Market Segmentation Analysis:

-

By Type, High Alumina held the largest market share of 34.76% in 2025, while Silicon Carbide is expected to grow at the fastest CAGR of 5.23% during 2026–2033.

-

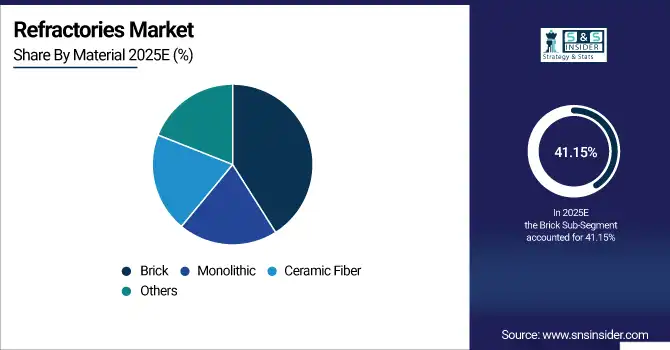

By Material, Brick dominated with a 41.15% share in 2025, while Ceramic Fiber is projected to expand at the fastest CAGR of 6.02%.

-

By Form, Shapes accounted for the highest market share of 37.89% in 2025, and Custom Components are expected to record the fastest CAGR of 5.78%.

-

By End-Use Industry, Steel held the largest share of 45.62% in 2025, while Glass is expected to grow at the fastest CAGR of 6.15% during the forecast period.

By Type, High Alumina Dominates While Silicon Carbide Expands Rapidly:

High Alumina segment dominated the market due to its exceptional thermal stability, durability, and ability to withstand harsh industrial conditions. It is widely used across steel, cement, and glass industries where high-temperature resistance is critical. Silicon Carbide is the fastest growing segment, driven by rising demand for wear-resistant, energy-efficient, and high-performance refractories. Innovations in material engineering and the need for specialized industrial applications are fueling its rapid adoption across emerging and modern industries.

By Material, Brick Dominates While Ceramic Fiber Expands Rapidly:

Brick segment dominated the market due to their proven performance, ease of installation, and cost-effectiveness in high-temperature processes. They remain a standard choice for steel furnaces, cement kilns, and glass production. Ceramic Fiber is the fastest growing segment, supported by increasing industrial focus on lightweight, insulating, and energy-efficient solutions. Technological improvements, combined with the need to reduce energy consumption and enhance operational efficiency, are accelerating its adoption in new and existing industrial facilities.

By Form, Shapes Dominate While Custom Components Expand Rapidly:

Shapes segment dominated the market due to their standardized design, versatility, and ease of integration into multiple industrial processes. Their widespread reliability makes them the preferred option for conventional refractory applications. Custom Components are the fastest growing segment, driven by the need for tailor-made solutions in specialized, high-performance operations. Industries increasingly demand components that maximize efficiency, durability, and energy savings, making custom refractory designs a key growth area for manufacturers.

By End-Use Industry, Steel Dominates While Glass Expands Rapidly:

Steel segment dominated the market due to its heavy reliance on refractories in furnaces, ladles, and continuous casting processes. The segment’s need for durable, high-temperature-resistant materials ensures consistent demand. Glass is the fastest growing segment, fueled by rising production of flat, container, and specialty glass. Advanced refractory solutions that improve energy efficiency, durability, and operational performance are driving its adoption, creating significant opportunities for innovation and growth in the glass manufacturing sector globally.

Refractories Market Regional Analysis:

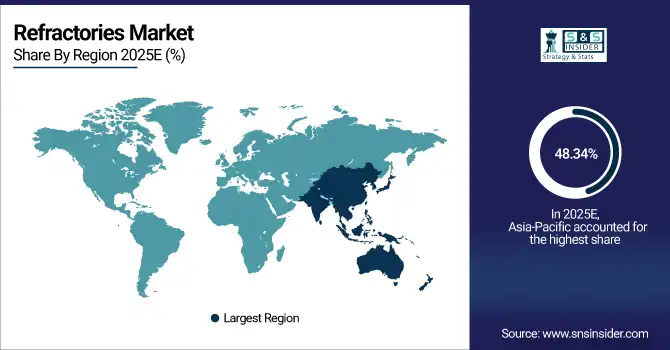

Asia-Pacific Refractories Market Insights:

The Asia-Pacific Refractories Market dominates globally with a 48.34% market share, driven by robust steel, cement, and glass production. Key markets include China, India, Japan, and South Korea. Rapid industrialization, infrastructure development, and urban expansion fuel demand for durable, high-performance, and energy-efficient refractories. Adoption of advanced materials, technological innovations, and sustainable solutions further support growth. Strong manufacturing capabilities and modern industrial processes underpin the region’s leading position in the market.

Get Customized Report as per Your Business Requirement - Enquiry Now

China Refractories Market Insights:

The China Refractories Market is driven by rapid industrialization, expanding steel, cement, and glass production, and large-scale infrastructure projects. Rising demand for high-performance, durable, and energy-efficient refractory materials, combined with technological innovations and sustainable manufacturing practices, makes China one of the largest contributors to the Asia-Pacific Refractories Market.

North America Refractories Market Insights:

North America is the fastest-growing region in the Refractories Market, projected at a CAGR of 6.45%. Growth is driven by increasing steel, cement, and glass production, along with rising infrastructure development and industrial modernization. Demand for high-performance, energy-efficient, and durable refractory materials is accelerating. Technological advancements, sustainable manufacturing practices, and industrial automation further support market penetration, enhancing North America’s regional presence and long-term growth potential in the refractories market.

U.S. Refractories Market Insights:

The U.S. Refractories Market is anticipated to be fueled by growing demand from steel, cement, and glass industries, supported by expanding infrastructure and industrial modernization. Growth is further driven by adoption of high-performance, energy-efficient, and durable refractory solutions, technological advancements, sustainability initiatives, and increasing focus on industrial efficiency and long-term operational reliability.

Europe Refractories Market Insights:

The Europe Refractories Market is experiencing steady growth, driven by demand from steel, cement, and glass industries, alongside infrastructure modernization and industrial upgrades. Key markets include Germany, the UK, and France. Growth is supported by adoption of energy-efficient, durable, and high-performance refractory solutions. Technological advancements, sustainability initiatives, and rising focus on reducing operational costs are further bolstering market presence, while innovations in materials and manufacturing processes enhance competitiveness and long-term expansion across the region.

Germany Refractories Market Insights:

Germany is a key market for Refractories, driven by strong steel, cement, and glass production. Demand is supported by adoption of durable, high-performance, and energy-efficient materials. Technological innovations, sustainable manufacturing practices, and focus on operational efficiency further drive growth, making Germany a significant contributor to Europe’s Refractories Market expansion.

Latin America Refractories Market Insights:

The Latin America Refractories Market is growing due to rising steel, cement, and glass production. Expansion of industrial infrastructure, increasing construction activities, and adoption of durable, high-performance refractory materials are fueling growth. Key markets include Brazil, Mexico, and Argentina, with technological innovations and energy-efficient solutions driving long-term market development.

Middle East and Africa Refractories Market Insights:

The Middle East & Africa Refractories Market is expected to grow due to rising industrialization, infrastructure development, and expanding steel, cement, and glass production. Demand for high-performance, durable, and energy-efficient refractory materials, along with adoption of modern manufacturing technologies and sustainability practices, is driving market expansion across key countries in the region.

Refractories Market Competitive Landscape:

RHI Magnesita, headquartered in Austria, is a leader in the refractories industry, serving steel, cement, and glass sectors with a comprehensive product portfolio. The company operates over 100 production sites and 14 R&D centers, offering end-to-end solutions from raw material extraction to customized refractory systems. Its vertical integration ensures supply chain reliability, consistent quality, and cost efficiency. Strategic mergers, including the Magnesita acquisition, have expanded its reach, technological capabilities, and market dominance, making it a preferred partner for high-temperature industrial processes.

-

In May 2025, RHI Magnesita launched K-GenesisX™, a sustainable, circular refractory solution. This focuses on eco-friendly high-temperature applications, supporting energy efficiency, reducing environmental impact, and strengthening the company’s leadership in sustainable industrial refractory technologies.

Vesuvius PLC, based in the U.K., specializes in molten metal flow engineering, advanced refractories, and industrial solutions for steel and foundry industries. The company provides consumable ceramic products, systems, and digital monitoring solutions, enabling process optimization and efficiency. Its presence, including strategic growth in Asia and EEMEA, strong R&D, and focus on innovation, has allowed Vesuvius to capture significant market share. The combination of technological expertise, specialized solutions, and extensive client networks helps it maintain dominance in critical refractory applications.

-

In August 2025, Vesuvius PLC introduced 16 new products in molten metal flow engineering. These innovations enhance efficiency, durability, and sustainability in steel and foundry operations, reinforcing Vesuvius’s market position and expanding its portfolio in critical industrial applications globally.

Krosaki Harima Corporation, headquartered in Japan, is renowned for manufacturing high-quality refractory materials and industrial furnaces for steel, cement, and non-ferrous metal industries. The company operates through Refractory, Furnace, and Ceramics segments, providing products, furnace construction, and maintenance services. Its market dominance is driven by technological innovation, sustainable product offerings such as the K-GenesisX™ line, and a strong presence in key industrial sectors. Strategic focus on performance, durability, and energy efficiency has established Krosaki Harima as a leading refractory supplier.

-

In May 2025, Krosaki Harima unveiled the K-GenesisX sustainable refractory range. Focused on high-performance, eco-friendly solutions, the launch addresses industrial energy efficiency and environmental regulations, bolstering Krosaki Harima’s reputation as a leading innovator in the refractories market.

Refractories Market Key Players:

-

Vesuvius PLC

-

Krosaki Harima Corporation

-

Shinagawa Refractories Co., Ltd.

-

Saint-Gobain S.A.

-

Imerys S.A.

-

HarbisonWalker International

-

Refratechnik Holding GmbH

-

Chosun Refractories Co., Ltd.

-

Puyang Refractories Group Co., Ltd.

-

IFGL Refractories Ltd.

-

Resco Products

-

Almatis

-

Calderys

-

Minerals Technologies Inc.

-

RHI Normag

-

Zhengzhou Huaxiang Refractories Co., Ltd.

-

Keller HCW GmbH

-

FRC Global

| Report Attributes | Details |

|---|---|

| Market Size in 2025E | USD 39.71 Billion |

| Market Size by 2033 | USD 56.99 Billion |

| CAGR | CAGR of 4.65% From 2026 to 2033 |

| Base Year | 2025E |

| Forecast Period | 2026-2033 |

| Historical Data | 2022-2024 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Type (Fireclay, High Alumina, Silicon Carbide, Insulating, Others) • By Material (Monolithic, Brick, Ceramic Fiber, Others) • By Form (Shapes, Tiles, Custom Components, Others) • By End-Use Industry (Steel, Cement, Glass, Non-Ferrous Metals, Petrochemical, Power, Others) |

| Regional Analysis/Coverage | North America (US, Canada), Europe (Germany, UK, France, Italy, Spain, Russia, Poland, Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Australia, ASEAN Countries, Rest of Asia Pacific), Middle East & Africa (UAE, Saudi Arabia, Qatar, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Mexico, Colombia, Rest of Latin America). |

| Company Profiles | RHI Magnesita, Vesuvius PLC, Krosaki Harima Corporation, Shinagawa Refractories Co., Ltd., Saint-Gobain S.A., Imerys S.A., HarbisonWalker International, Morgan Advanced Materials, Refratechnik Holding GmbH, Chosun Refractories Co., Ltd., Puyang Refractories Group Co., Ltd., IFGL Refractories Ltd., Resco Products, Almatis, Calderys, Minerals Technologies Inc., RHI Normag, Zhengzhou Huaxiang Refractories Co., Ltd., Keller HCW GmbH, FRC Global |