Stack Actuator Market Size Analysis:

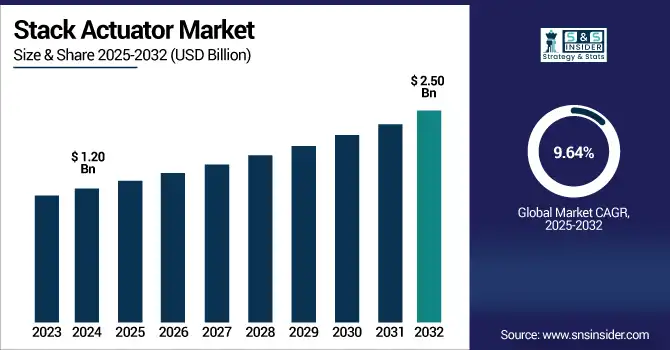

The Stack Actuator Market Size was valued at USD 1.20 billion in 2024 and is expected to reach USD 2.50 billion by 2032 and grow at a CAGR of 9.64% over the forecast period 2025-2032. The global market includes comprehensive insights on segmentation by type, application, material, and end-user, regional performance, and market dynamics. Booming industrial automation industry along with rising demand for compact, high-force actuator in automotive and aerospace sectors are significantly driving the market growth.

To Get more information on Stack Actuator Market - Request Free Sample Report

Stack Actuator Market analysis highlights advancements shaping motion control technologies. Continuous advancements in structural ceramic-based and piezoelectric material technologies play a role in this trend by providing ever wider ranges of efficiencies, precision, and durability in the diverse applications that require high-performance motion control.

For instance, over 60% of global manufacturing facilities are now implementing advanced automation systems, many of which rely on precision actuators for motion control.

The U.S. Stack Actuator Market size was USD 0.27 billion in 2024 and is expected to reach USD 0.55 billion by 2032, growing at a CAGR of 9.33% over the forecast period of 2025–2032.

The U.S. market is growing on account of high investments in aerospace and defense and increasing adoption of precision automation in healthcare and automotive industries. In addition to this, many government initiatives such as the promotion of smart manufacturing and integration with advanced technology and many other factors have provided a boost in the demand for high-accuracy actuation systems. These trends should further underpin stack actuators for both military and commercial applications, securing the U.S. for its fair share of the global market growth.

For instance, over 65% of new surgical robots rely on stack actuators for sub-micron precision in tool positioning and fluid control systems.

Stack Actuator Market Dynamics:

Key Drivers:

-

Advancements in Piezoelectric Material Technologies Enhancing Actuator Capabilities

Developments in piezoelectric ceramics and compositional longevity are improving the performance of actuators including higher force output, higher response performance, and higher temperature. Such enhancements are broadening their application domains in precision sensitive domains such as semiconductor fabrication, optics alignment, and biomedical sensor systems. Improved material lifetime and shrinking size allows for longer use and inclusion into modern small electronic systems. These developments are reducing design restrictions and leading to new applications in the newly challenges of nanotechnology and microrobotics, thereby fostering a strong Stack Actuator Market growth.

For instance, more than 60% of high-precision biomedical sensor platforms integrate stack actuators for fluid metering, diagnostics, and positioning.

Restraints:

-

High Manufacturing Costs of Precision Stack Actuators Limit Mass-Scale Adoption

Stack actuators are made through complicated processes that also require special materials such as piezo ceramics, leading to high initial pricing. More money is added to the cost due to precision design, tight dimensional tolerances, and cleanroom assembly. Particularly in cost-sensitive sectors such as consumer electronics and low-volume industrial applications, these features restrict their affordability. Thus, stack actuators are facing limited adoption in cost-sensitive markets which in turn serves to suppress their more widespread commercialization and slow growth in price-competitive environments.

Opportunities:

-

Expansion of Medical Robotics and Minimally Invasive Devices Boosts Application Scope

The healthcare innovations are moving faster and thus robotic-assisted surgeries and development of microfluidic devices are increasing. This will ultimately drive the demand for stacked actuators as it provides the force precision and miniaturization that is required for several applications including catheter navigation, drug delivery pump, and surgical tools. Moreover, they are silent and biocompatible making them excellent for sensitive medical environments. The combination of an aging global population and increasing demand for minimally invasive treatments traces a robust path of growth for stack actuators into the medical sector, with significant commercialization prospects for actuator manufacturers in areas such as diagnostic and therapeutic prosthetics and smart implants.

For instance, more than 70% of lab-on-chip devices now integrate micro-actuation systems for precise fluid control in diagnostics and therapeutics.

Challenges:

-

Integration Complexity with Existing Systems Slows Down Adoption Rates

In spite of their performance specifications, the integration of stack actuators in conventional systems is frequently highly complex from a technological perspective. These work with specialized drive electronics, precisely tuned controllers, and specific mounting conditions for the best results. This extra need for integration can discourage OEMs from transitioning away from legacy actuators. This makes them very expensive in terms of initial development time and the cost of redesigning systems – not to mention compatibility issues. This presents a barrier to industry scale, especially for smaller businesses, who don't have the resources nor budget to replace all legacy systems.

Stack Actuator Market Segmentation Analysis:

By Type

Electric Actuators accounted for maximum revenue share in Stack Actuator Market due to high flexibility, low energy consumption and higher degree of control with automated systems throughout the forecasted period of 2024–2032, estimated at 32.7%. Stack Actuator Market trends emphasize growing automation and miniaturization demands globally. Electric stack actuators such as those provided by Physik Instrumente (PI) are extremely reliable and ideal for aerospace, robotics and medical applications. Moreover, this segment is also anticipated to record the highest CAGR of 10.48% during the forecast period (2024–2032) as innovators including SMC Corporation are developing compact, intelligent actuators in response to increased demand as a result of electrification and the adoption of Industry 4.0.

By Application

Automotive segment is expected to have the highest share of 26.5% of the Stack Actuator Market in 2024. They are increasingly used in precision systems such as fuel injection, active suspension and emissions control, which explains this dominance. TDK Corporation is a major supplier of stack actuators for automotive motion control applications. Automakers prefer these actuators due to their high force density and responsiveness operate in harsh environments to support a number of performance and safety enhancements.

The Manufacturing segment is expected to grow at the fastest growth rate with a CARG of 11.10% during 2024 to 2032. Smart factories, robotics and precision assembly lines are enabling this growth. Stack actuators do not have any onboard motion control or an embedded feedback sensor to count feedback. Therefore, they provide a highly accurate response, which is critical in most automation applications. For instance, Cedrat Technologies offers small piezo actuators for laser alignment, quality inspection and assembly automation, which allow more efficiency and productivity of modern industrial systems.

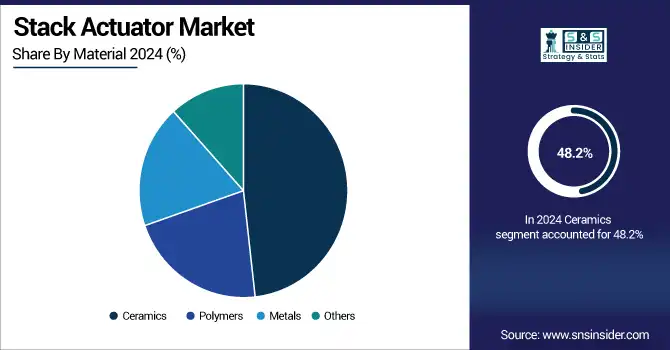

By Material

In 2024, ceramics occupied the highest Stack Actuator Market share at 48.2%, as they possess high stiffness, excellent dielectric properties, and thermal stability for environments requiring precision. Noliac (a CTS company) is the leading manufacturer of high-end multilayer ceramic actuators that can be used for aerospace and metrology purposes. Ceramics will also have the highest CAGR throughout the forecast period of 2024 to 2032, estimated at 10.27% as demand for ceramics in electronics and biomedical is growing, with innovators such as PiezoDrive pushing forward lead-free, high-performance ceramic solutions for future actuators.

By End-User

The Automotive end-user segment accounted for the largest revenue share of the Stack Actuator Market at 27.6% in 2024. Stack actuators are essential for adaptive suspension, emission control, and precise fuel systems in vehicles. Automotive suppliers such as Bosch have built the stack actuator into advanced fuel injection and engine management solutions. The compact design and rapid response enable the industry to deliver on electrification and efficiency promises and is a key differentiator for segment leadership.

The Industrial segment is expected to expand at the highest CAGR of 11.10% during 2024 to 2032. Key is rising automation on production and testing processes. High-force actuators for industrial applications including alignment systems and nanometer-phase positioning are available from companies such as Thorlabs. With an increasing demand for applications such as additive manufacturing, precision tooling, and automated inspection systems, these actuators provide high durability and precision motion.

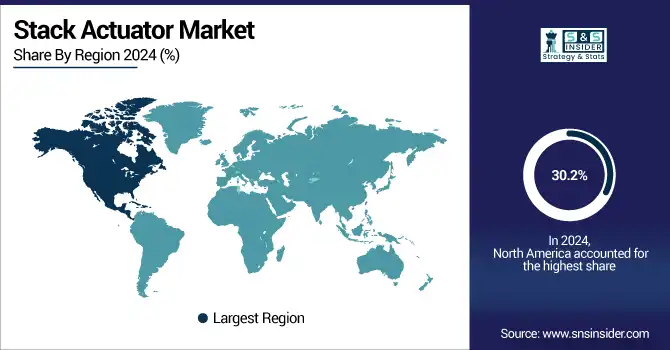

Stack Actuator Market Regional Analysis:

North America accounted for a revenue share of 30.2% in the Stack Actuator Market in 2024, primarily due to the wide base of aerospace, defense, and advanced manufacturing activities. This places the region in a beneficial position due to the presence of established players, early tech adoption, and large investments in automation technologies. In addition, stack actuator applications from North America are further supported by government-backed initiatives and R&D funding across aerospace, medical devices, and energy sectors.

-

The U.S. dominates the North American Stack Actuator industry due to its strong aerospace and defense sectors, advanced manufacturing infrastructure, and presence of key players investing in high-precision automation, smart technologies, and innovation-driven industrial applications.

Asia Pacific is expected to witness the fastest CAGR of 10.69% during 2024 - 2032. The main factors that drive this development are fast industrialisation and increasing automotive production and electronics manufacturing in China, Japan, South Korea, and India. The rising government support for smart infrastructure along with the rising domestic high-tech manufacturing is driving demand for precision actuators in the healthcare, semiconductor and electric mobility sectors.

-

China leads the Asia Pacific Stack Actuator Market with its large-scale electronics and automotive manufacturing base, robust government support for industrial automation, and rapidly growing demand for high-performance actuators across healthcare, robotics, and next-generation mobility solutions.

Europe holds an important share for the Stack Actuator Market due to high automotive, aerospace and industrial automation industries. They include a rich engineering ecosystem, a focus on efficiency for energy, and embracing precision motion technologies. With leaders in innovation such as Germany and France and mandatory sustainability directives from the EU pushing for the use of smart and small footprint actuators in many high-tech applications.

-

Germany dominates the European Stack Actuator Market due to its advanced automotive and industrial automation sectors, strong engineering base, and continuous innovation. Companies such as Physik Instrumente and Siemens drive adoption of high-precision actuators across manufacturing, aerospace, and robotics applications.

Middle East & Africa Stack Actuator Market is dominated by UAE due to strong aerospace, defense and automation initiatives. Brazil remains a leader in Latin America, fueled by a growing automotive and industrial base. Boosting investments in smart technologies and precision-centric infrastructure development across key sectors are imperative for both countries.

Get Customized Report as per Your Business Requirement - Enquiry Now

Stack Actuator Companies are:

Major Key Players in Stack Actuator companies are Physik Instrumente, TDK Corporation, CTS Corporation (Noliac), SMC Corporation, Thorlabs, Inc., Cedrat Technologies, PiezoDrive, Aerotech Inc., Johnson Electric, Murata Manufacturing Co., Ltd., APC International, Ltd., Piezosystem Jena, KYOCERA AVX Components Corporation, Piezo Systems, Inc., Triad Technologies, NGK Spark Plug Co., Ltd. (NTK), Tokin Corporation, Dynamic Structures and Materials, LLC (DSM), Micromechatronics, Inc. and EPCOS AG and others.

Recent Developments:

-

In February 2024, Physik Instrumente introduced a new line of piezoelectric stack actuators capable of operating at elevated temperatures, optimizing their use in aerospace and heavy-industrial environments.

-

In April 2025, Murata unveiled advanced Piezo Air Pump Microblowers, utilizing ultrasonic piezoelectric technology for compact, low-noise air discharge, ideal for medical and industrial automation applications.

| Report Attributes | Details |

|---|---|

| Market Size in 2024 | USD 1.20 Billion |

| Market Size by 2032 | USD 2.50 Billion |

| CAGR | CAGR of 9.64% From 2025 to 2032 |

| Base Year | 2024 |

| Forecast Period | 2025-2032 |

| Historical Data | 2021-2023 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Type (Electric Actuators, Pneumatic Actuators, Hydraulic Actuators, Mechanical Actuators and Magnetic Actuators) • By Application (Aerospace, Automotive, Energy & Power, Manufacturing and Healthcare) • By Material (Ceramics, Polymers, Metals and Others) • By End-User (Automotive, Aerospace, Healthcare, Industrial, Consumer Electronics and Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Germany, France, UK, Italy, Spain, Poland, Turkey, Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Singapore, Australia,Taiwan, Rest of Asia Pacific), Middle East & Africa (UAE, Saudi Arabia, Qatar, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Rest of Latin America) |

| Company Profiles | Physik Instrumente, TDK Corporation, CTS Corporation (Noliac), SMC Corporation, Thorlabs, Inc., Cedrat Technologies, PiezoDrive, Aerotech Inc., Johnson Electric, Murata Manufacturing Co., Ltd., APC International, Ltd., Piezosystem Jena, KYOCERA AVX Components Corporation, Piezo Systems, Inc., Triad Technologies, NGK Spark Plug Co., Ltd. (NTK), Tokin Corporation, Dynamic Structures and Materials, LLC (DSM), Micromechatronics, Inc. and EPCOS AG. |