3D Printing Metals Market Report Scope & Overview:

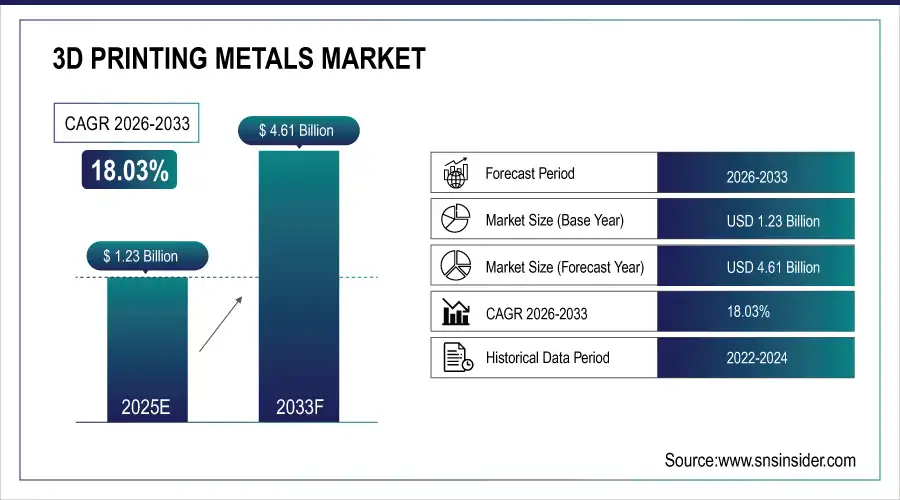

The 3D Printing Metals Market Size was valued at USD 1.23 Billion in 2025E and is projected to reach USD 4.61 Billion by 2033, growing at a CAGR of 18.03% during the forecast period 2026–2033.

The 3D Printing Metals Market analysis report presents detailed information and statistics on the key factors shaping the industry. Growing use across aerospace, automotive, and healthcare industries, along with rising preference for lightweight, high-strength components, supports steady market expansion.

3D printing metal production reached 12.8 thousand tons in 2025, driven by rising adoption in aerospace, automotive, and medical component manufacturing.

Market Size and Forecast:

-

Market Size in 2025: USD 1.23 Billion

-

Market Size by 2033: USD 4.61 Billion

-

CAGR: 18.03% from 2026 to 2033

-

Base Year: 2025

-

Forecast Period: 2026–2033

-

Historical Data: 2022–2024

To Get more information On 3D Printing Metals Market - Request Free Sample Report

3D Printing Metals Market Trends:

-

Increasing demand for lightweight, high-strength metal parts is boosting adoption across aerospace, automotive, and medical sectors.

-

Advancements in metal powder technology and precision printing are enabling complex, customized component production.

-

Growing availability of 3D printing solutions and service providers is expanding access for manufacturers of all sizes.

-

Rising interest in rapid prototyping and on-demand production is shortening product development cycles and reducing costs.

-

Industry focus on durable, sustainable, and high-performance materials is encouraging innovation and diversification of metal 3D printing applications.

U.S. 3D Printing Metals Market Insights:

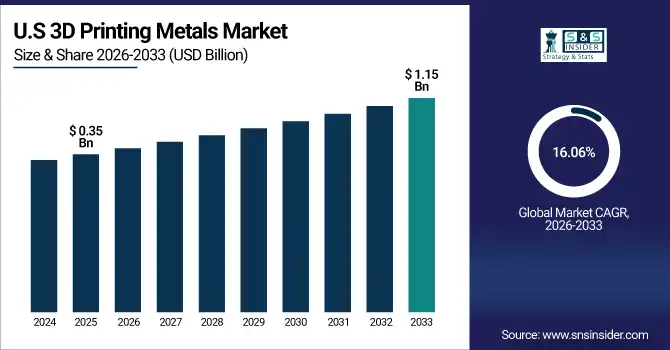

The U.S. 3D Printing Metals Market is projected to grow from USD 0.35 Billion in 2025E to USD 1.15 Billion by 2033, at a CAGR of 16.06%. Growth is driven by strong adoption in aerospace, automotive, and medical sectors, rising demand for lightweight, high-strength components, and increasing use of advanced manufacturing technologies and rapid prototyping solutions.

3D Printing Metals Market Growth Drivers:

-

Rising demand for lightweight, high-strength metal components, fueled by aerospace, automotive, and medical manufacturing applications.

Rising demand for lightweight, high-strength metal components is the primary driver of the 3D Printing Metals Market growth. Increased adoption in aerospace, automotive, and medical manufacturing has fueled the need for precise, durable, and customized parts. Advanced metal powders and additive manufacturing techniques enable complex designs and rapid prototyping. Expanding access through specialized service providers and industrial manufacturers supports innovation, efficiency, and high-quality production, strengthening market presence and long-term growth potential.

Sales of 3D Printed Metal components grew 14.2% in 2025, driven by rising adoption in aerospace, automotive, and medical manufacturing.

3D Printing Metals Market Restraints:

-

High costs of metal powders, expensive 3D printing equipment, and skilled labor shortages are limiting market expansion.

High costs of metal powders, expensive 3D printing equipment, and shortages of skilled labor are key restraints for the 3D Printing Metals Market. Manufacturers face significant capital investment and operational expenses, limiting entry for smaller players. High material and machine costs constrain pricing flexibility, slowing adoption in cost-sensitive industries. Additionally, the need for specialized training and expertise restricts large-scale production, keeping market growth moderate and maintaining a competitive balance between established and emerging service providers.

3D Printing Metals Market Opportunities:

-

Expanding use of 3D printed metal parts in aerospace, medical, and automotive sectors presents significant innovation opportunities.

Expanding use of 3D printed metal parts in aerospace, medical, and automotive sectors presents a significant growth opportunity. As industries seek lightweight, durable, and complex components, manufacturers are adopting advanced metal powders and precision printing techniques. Customized, high-performance parts and rapid prototyping solutions enable innovation, reduce production timelines, and improve efficiency. This trend toward technological adoption and component optimization adds value for end-users, strengthens market presence, and drives long-term growth in the 3D Printing Metals Market.

3D Printed Metal accounted for 32% of total aerospace and medical part production in 2025, driven by rising demand for lightweight, high-strength, and customized parts.

3D Printing Metals Market Segmentation Analysis:

-

By Type, Stainless Steel held the largest market share of 42.75% in 2025, while Titanium is expected to grow at the fastest CAGR of 22.14% during 2026–2033.

-

By Printing Technology, Powder Bed Fusion dominated with a 51.28% share in 2025, while Binder Jetting is projected to expand at the fastest CAGR of 21.55%.

-

By Application, Aerospace & Defense accounted for the highest market share of 38.91% in 2025, and Medical & Healthcare is expected to record the fastest CAGR of 23.01%.

-

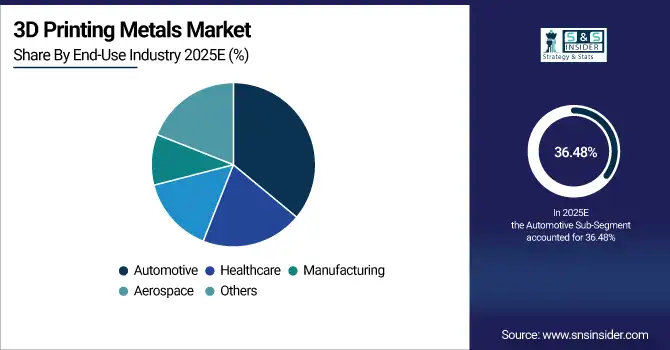

By End-Use Industry, Automotive held the largest share of 36.48% in 2025, while Healthcare is expected to grow at the fastest CAGR of 22.88% during the forecast period.

By Type, Stainless Steel Dominates While Titanium Expands Rapidly

Stainless Steel segment dominated the market due to its versatility, durability, and cost-effectiveness across aerospace, automotive, and industrial applications. Its widespread adoption in 3D printing allows manufacturers to produce strong, reliable, and large-scale components efficiently. Titanium is the fastest growing segment, driven by increasing demand for lightweight, high-performance parts in aerospace, medical implants, and specialized engineering applications. Its superior strength-to-weight ratio and corrosion resistance make it ideal for advanced, precision components.

By Printing Technology, Powder Bed Fusion Dominates While Binder Jetting Grows Fastest

Powder Bed Fusion segment dominated the market due to its high precision, repeatability, and ability to produce complex metal parts suitable for aerospace and automotive sectors. Manufacturers favor this technology for intricate designs and reliable large-scale production. Binder Jetting is the fastest growing segment, supported by lower production costs, faster build times, and increasing adoption for industrial prototyping and small-batch manufacturing. Its flexibility and speed make it attractive for emerging applications.

By Application, Aerospace & Defense Dominates While Medical & Healthcare Expands Rapidly

Aerospace & Defense segment dominated the market due to the industry’s need for lightweight, durable, and high-strength components that enhance performance and efficiency. Complex parts and stringent quality standards drive the use of 3D printed metals in this sector. Medical & Healthcare is the fastest growing segment, fueled by the demand for customized implants, surgical instruments, and patient-specific devices. Precision, biocompatibility, and adaptability are key factors driving adoption in healthcare.

By End-Use Industry, Automotive Dominates While Healthcare Expands Fastest

Automotive segment dominated the market as manufacturers use 3D printing metals for lightweight, high-strength components, rapid prototyping, and streamlined production. Its ability to improve fuel efficiency and reduce weight while maintaining durability strengthens its adoption. Healthcare is the fastest growing segment, driven by patient-specific implants, surgical tools, and medical devices. Rising demand for precision-engineered, high-performance solutions and technological innovations in metal printing fuels rapid expansion in this sector.

3D Printing Metals Market Regional Analysis:

North America 3D Printing Metals Market Insights:

North America dominated the 3D Printing Metals Market with a 38.67% share in 2025, driven by strong adoption across aerospace, automotive, and healthcare industries. Increasing demand for lightweight, high-strength, and customized metal components is fueling growth. Advanced manufacturing infrastructure, skilled workforce, and technological innovation are supporting rapid industrial adoption. Expansion of service providers, rapid prototyping, and precision manufacturing solutions are further enhancing market penetration, positioning the region for sustained long-term growth and industry leadership.

Get Customized Report as per Your Business Requirement - Enquiry Now

U.S. 3D Printing Metals Market Insights:

The U.S. 3D Printing Metals Market is anticipated to be driven by rising demand for lightweight, durable, and customized metal components across aerospace, automotive, and healthcare sectors. Growth is supported by expanding industrial adoption, advanced manufacturing infrastructure, skilled workforce, rapid prototyping needs, technological innovation, and increasing availability of metal 3D printing services, enabling broader market penetration and long-term industry expansion.

Asia-Pacific 3D Printing Metals Market Insights:

The Asia-Pacific 3D Printing Metals Market is the fastest-growing region, projected at a CAGR of 20.51% during 2026–2033. Rapid industrialization, expanding aerospace, automotive, and healthcare sectors, and rising demand for lightweight, high-strength, and customized metal components are driving growth. Key markets include China, Japan, India, and Australia. Increasing adoption of advanced manufacturing technologies, rapid prototyping, and expanding service providers enhance accessibility, supporting long-term regional market expansion.

China 3D Printing Metals Market Insights:

China’s 3D Printing Metals Market is driven by rapid industrialization, rising adoption in aerospace, automotive, and medical sectors, and increasing demand for high-strength, lightweight, and customized components. Expansion of advanced manufacturing technologies, growing service providers, and government support for innovation make China a key contributor to the Asia-Pacific region’s fast-growing 3D printing metals market.

Europe 3D Printing Metals Market Insights:

Europe’s 3D Printing Metals Market is witnessing steady growth, driven by increasing adoption across aerospace, automotive, and industrial manufacturing sectors. Germany, the UK, and France are key markets, supported by advanced manufacturing infrastructure, skilled workforce, and strong industrial R&D. Growth is further aided by rising demand for lightweight, high-strength, and customized metal components, precision manufacturing, and rapid prototyping solutions. Technological innovation, sustainable production practices, and expanding service providers continue to strengthen the regional market presence.

Germany 3D Printing Metals Market Insights:

Germany is a key market for 3D Printing Metals, driven by strong adoption in automotive, aerospace, and industrial manufacturing. Demand is supported by the need for lightweight, high-strength, and customized metal components. Advanced manufacturing infrastructure, precision engineering expertise, and technological innovation are fueling market expansion and strengthening Germany’s leadership in the regional 3D printing metals industry.

Latin America 3D Printing Metals Market Insights:

The Latin America 3D Printing Metals Market is growing due to rising adoption in aerospace, automotive, and industrial sectors. Growth is supported by expanding manufacturing infrastructure, increasing demand for lightweight and customized metal components, and technological advancements. Key markets such as Brazil, Mexico, and Argentina are driving regional expansion and innovation.

Middle East and Africa 3D Printing Metals Market Insights:

The Middle East & Africa 3D Printing Metals Market is expected to grow due to rising adoption in aerospace, automotive, and industrial manufacturing. Growth is driven by increasing investment in advanced manufacturing technologies, expanding industrial infrastructure, and demand for high-strength, lightweight, and customized metal components. Innovation, skilled workforce development, and technological advancement support regional market expansion.

3D Printing Metals Market Competitive Landscape:

EOS GmbH, headquartered in Germany, is a leader in industrial 3D printing and additive manufacturing, specializing in metal and polymer solutions. Its dominance stems from cutting-edge technology, extensive research and development, and high-quality precision systems that serve aerospace, automotive, and medical industries. EOS maintains a strong global presence through comprehensive service networks, training programs, and material development initiatives. The company’s reputation for reliability, scalability, and innovation allows it to lead the 3D printing metals market consistently.

-

In October 2025, EOS launched four new metal materials FeNi36, NickelAlloy C22, Steel 42CrMo4, and StainlessSteel 316L-4404 optimized for Laser Powder Bed Fusion systems. These materials enhance capabilities across aerospace, automotive, energy, and marine industries and address specialized additive manufacturing requirements.

3D Systems Corporation, based in the U.S., is a pioneer in 3D printing technologies, offering metal and polymer additive manufacturing solutions across healthcare, aerospace, automotive, and industrial sectors. The company dominates the market through a broad product portfolio, extensive intellectual property, and decades of experience in rapid prototyping and manufacturing. By integrating advanced software, printing systems, and materials, 3D Systems ensures precision, customization, and scalability, solidifying its leadership and global market influence.

-

In September 2025, 3D Systems introduced the MJP 300W Plus, an advanced 3D wax printer for jewelry manufacturing. The system improves versatility and efficiency, enabling high-quality production of diverse jewelry designs while supporting evolving industry needs and modern manufacturing workflows.

SLM Solutions Group AG, headquartered in Germany, is a leading provider of selective laser melting (SLM) metal 3D printing systems. The company dominates the market with its high-performance, reliable printing technologies that allow for complex, lightweight, and high-strength metal parts production. SLM Solutions serves key industries such as aerospace, automotive, and healthcare. Its competitive edge comes from continuous innovation, strong customer support, and specialized applications, enabling large-scale industrial adoption and long-term market leadership.

-

In June 2025, Nikon SLM Solutions partnered with Rocket Lab, reserving two ultra-large format metal 3D printing platforms. This supports advanced space system production and highlights the potential of large-scale additive manufacturing for aerospace applications and next-generation component fabrication.

3D Printing Metals Market Key Players:

-

EOS GmbH

-

3D Systems Corporation

-

SLM Solutions Group AG

-

Renishaw plc

-

Desktop Metal, Inc.

-

Markforged

-

TRUMPF GmbH

-

Farsoon Technologies

-

Höganäs AB

-

Materialise NV

-

Carpenter Technology Corporation

-

BLT (Bright Laser Technologies)

-

Nikon SLM Solutions

-

Arcam AB

-

Formlabs

-

Optomec

-

3Diligent

-

Xometry

| Report Attributes | Details |

|---|---|

| Market Size in 2025E | USD 1.23 Billion |

| Market Size by 2033 | USD 4.61 Billion |

| CAGR | CAGR of 18.03% From 2026 to 2033 |

| Base Year | 2025E |

| Forecast Period | 2026-2033 |

| Historical Data | 2022-2024 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Type (Stainless Steel, Titanium, Aluminum, Nickel Alloys, Cobalt Chrome, Others) • By Printing Technology (Powder Bed Fusion, Directed Energy Deposition, Binder Jetting, Material Extrusion, Others) • By Application (Aerospace & Defense, Automotive, Healthcare & Medical, Industrial, Others) • By End-Use Industry (Manufacturing, Healthcare, Automotive, Aerospace, Others) |

| Regional Analysis/Coverage | North America (US, Canada), Europe (Germany, UK, France, Italy, Spain, Russia, Poland, Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Australia, ASEAN Countries, Rest of Asia Pacific), Middle East & Africa (UAE, Saudi Arabia, Qatar, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Mexico, Colombia, Rest of Latin America). |

| Company Profiles | EOS GmbH, 3D Systems Corporation, SLM Solutions Group AG, Renishaw plc, Desktop Metal, Inc., Markforged, TRUMPF GmbH, Farsoon Technologies, Velo3D, Höganäs AB, Materialise NV, Carpenter Technology Corporation, BLT (Bright Laser Technologies), Nikon SLM Solutions, Arcam AB, Sandvik AB, Formlabs, Optomec, 3Diligent, Xometry |