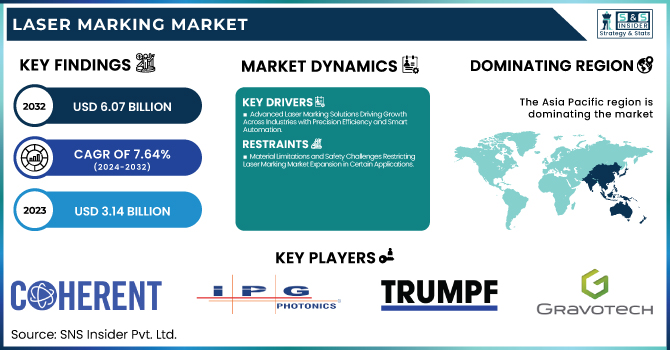

Laser Marking Market Size & Trends:

The Laser Marking Market was valued at USD 3.14 billion in 2023 and is expected to reach USD 6.07 billion by 2032, growing at a CAGR of 7.64% over the forecast period 2024-2032. With fabrication and industrial use rising across automotive, electronics, aerospace, and other sectors, the laser marking market is experiencing substantial growth. With automation, Industrial adoption is gaining momentum and improving accuracy, efficiency, and speed of production. Metals are still the most widely used, but other materials, such as plastics and in some cases ceramics, have also been adopted, albeit to a lesser degree. Smart and automated laser marking systems are becoming important by combining AI and IoT technology which increases real-time monitoring, lowers error, and makes traceability easier in Industrial environments.

To Get more information on Laser Marking Market - Request Free Sample Report

The U.S. laser marking market witnessed significant growth in 2024, attributed to the rising need for traceability and product authentication in various industries, including automotive, aerospace, electronics, and medical devices. Unquestionably, during these years greater use of laser marking found tremendous ground due to the demand for accurate small markings on mini-sized components, especially across the electronics industry. Moreover, the trend of green manufacturing practices also played a vital role in the consumers opting for laser marking instead of traditional forms of marking.

U.S. Laser Marking Market size was valued at USD 0.65 Billion in 2023 and the total Laser Marking revenue is expected to grow at a CAGR of 7.38% from 2024 to 2032. The growth of industrial automation, coupled with the increasing need for eco-friendly manufacturing, along with rising demand for high-quality permanent marking is expected to boost the growth of the U.S. laser marking market in aerospace, automotive, & electronics.

Laser Marking Market Dynamics

Key Drivers:

-

Advanced Laser Marking Solutions Driving Growth Across Industries with Precision Efficiency and Smart Automation

Increased requirement for permanent and high-precision marking solutions across end-use verticals including automotive, electronics, medical devices, aerospace, and others is a major growth enabler for the Laser Marking Market. The growing adoption of laser marking in the electronics segment owing to its significant applications such as marking microchips, printed circuit boards (PCBs), and semiconductor components for traceability and compliance with regulation of stringent standards, is driving the growth of the laser marking market. Moreover, the increasing technological advancement in fiber laser technology which offers high efficiency, low maintenance, and high-speed marking is expected to drive the market growth during the forecast period. The increasing need for product authentication and anti-counterfeiting solutions in industries such as pharmaceuticals and luxury goods is another factor driving the growth of the market for laser marking systems. Also, the transition of Production Units towards Industry 4.0 and automation in production lines has stimulated the demand for smart and laser-based marking solutions for enhanced production processes.

Restrain:

-

Material Limitations and Safety Challenges Restricting Laser Marking Market Expansion in Certain Applications

The technical limitations of some materials act as a primary restraint in the Laser Marking Market. Though efficient at marking metals, fiber lasers may not be appropriate for transparent or highly reflective materials, such as glass and some plastics. This results in a reliance on other laser technologies, like UV or CO₂ lasers, that may not be the ideal solution every time. Moreover, challenges related to laser safety and operational hazards are limiting the growth of the market during the forecast period. Laser marking is an advanced technique that involves the use of high-energy beams, requiring stringent safety protocols, protective measures, and adherence to international laser safety standards, all of which can hamper its adoption in smaller manufacturing units where setting these measures up is often tedious.

Opportunity:

-

Expanding Laser Marking Market Driven by EV Growth Green Solutions and Emerging Technologies in Asia-Pacific

The laser marking market is poised for profitable growth as quickly as electric vehicles (EVs) and battery manufacturing, which rely on laser marking to accurately label components such as cells, module parts, and packs. Moreover, the growing requirement for environmentally friendly and non-contact marking solutions further allows UV and green laser technicians to penetrate the medical and food packaging sector. Asia-Pacific especially China and India will likely be a high-growth region with endless opportunities for industrial growth driven by various government initiatives and programs supporting digital manufacturing. Moreover, with the development of new types of lasers like ultrafast laser and 3D lasers, new methods of processing are emerging, including high-precision micro marking and complex surface engraving.

Challenges:

-

Innovation Complexity Skilled Workforce Shortage and Industry 4.0 Integration Challenges in Laser Marking Market

Continuous demand for innovation to cater to ever-evolving industry demands is one of the key challenges that will impact the growth of the laser marking market. Manufacturing processes are becoming ever more complicated driving the demand for high-speed, deep engraving, and multi-material marking solutions. The new challenge is to create high-precision, highly focused laser technologies, without losing speed. The second challenge is the unavailability of skilled professionals who are trained to properly operate and maintain laser marking systems. If not dealt with cautiously, it might cause inefficiency, compromise the feature of marking, and expose safety risks. Also, connecting laser marking systems to Industry 4.0 and smart manufacturing processes needs relatively smart software which can be a challenging task for legacy companies.

Laser Marking Market Segment Analysis

By Laser Type

Fiber lasers led the laser marking market with a 42.5% market share in 2023. The use of fiber laser marking systems for metals and other materials is increasing in automotive, electronics, aerospace, and other industrial applications due to their high-speed, high-contrast, and permanent markings. Apart from this, features such as low maintenance, high longevity, and energy efficiency make fiber lasers an ideal option for low-cost, long-lasting marking solutions, and therefore, manufacturers prefer fiber lasers over solid-state lasers.

During the projection period of 2024 to 2032, UV lasers are likely to witness the fastest growth rate, as these are being more widely employed in sectors like medical devices, electronics, and pharmaceuticals that need very fine marking. It's important to note that UV lasers are best for marking softer materials such as plastics, glass, and silicon wafers without thermal damage. This is due to the increasing requirement for environmentally friendly and high-precision non-contact marking solutions, which complements the growing adoption of UV lasers in the upcoming years.

By Application

The laser marking market was led by the machine tool segment in 2023, holding a market share of 22.6% owing to its usage in extensive industrial manufacturing including precision engineering. Marking on machine tools using lasers involves high-quality, hard, and tamper-proof markings on metals and alloys, which fulfills traceability and compliance with industrial standards. The laser marking market is fueled in this segment by increasing automation in manufacturing processes, the need for permanent identification of components or materials, and increased adoption of Industry 4.0 technologies.

Due to strict safety and regulation-based requirements for part identification, the aerospace sector is anticipated to witness the highest CAGR owing to the use of part marking over the period from 2024 to 2032. Marking on critical components of an aircraft, such as engine parts, turbine blades, and structural components ensures high-contrast mark and wear-resistance for both metal and plastic using laser marking. Aerospace manufacturers are increasingly adopting lightweight materials as well as laser technology, driving the demand higher, as these need precise non-contact, and damage-free solutions for marking.

Laser Marking Market Regional Overview

The laser marking market share was led by Asia Pacific in 2023, accounting for 39.8% of the total share, and it is anticipated to witness the fastest car over the next eight years. Factors such as quick industrialization, growth of auto and electronics sectors, and rise in penetration of advanced manufacturing technologies are augmenting the regional growth. China, Japan, South Korea, and India are the leading contributors to this growth, as there is huge demand for laser marking in consumer electronics, semiconductors, and medical devices, among others. Foxconn is one of the biggest electronics manufacturers in China and relies heavily on laser marking to permanently identify smartphone and laptop components. In the automotive sector, Hyundai and Tata Motors use laser marking as a traceability and anti-counterfeit solution in vehicle parts. Moreover, in semiconductor manufacturing, Samsung and TSMC use laser marking to keep chips consistently identified with accuracy. In Asia Pacific, the growing emphasis on automation in the manufacturing industry coupled with strict regulatory specifications and a rise in investments in smart manufacturing are the major market driving factors for laser marking.

Get Customized Report as per Your Business Requirement - Enquiry Now

Key Players Listed in the Laser Marking Market are:

-

Coherent (ExactMark 210)

-

IPG Photonics (LightWELD 1500)

-

TRUMPF (TruMark Series 5000)

-

Mecco Partners (SmartMark Fiber Laser)

-

Gravotech (LS100EX Fiber)

-

Novanta (Synrad CO2 Lasers)

-

Epilog (Fusion Pro Laser Series)

-

Trotec Laser (SpeedMarker Series)

-

Hesai (Pandora LiDAR)

-

Markolaser (Fiber Laser Marking Machine)

-

Artek Laser (Fiber Laser Marking Machine)

-

Starlase Systems (UV Laser Marker)

-

LASIT (MicroMark G3)

-

Han's Laser (EP-20-D)

-

Keyence (MD-X Series)

Recent Trends

-

In October 2024, Coherent Corp. launched the EDGE FL high-power fiber laser series (1.5 kW - 20 kW), designed for precision cutting in machine tools, offering superior performance, energy efficiency, and integrated cutting solutions.

-

In December 2024, IPG Photonics completed the USD 75 million acquisition of CleanLASER, strengthening its position in precision laser cleaning for industries like automotive, aerospace, and manufacturing.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 3.14 Billion |

| Market Size by 2032 | USD 6.07 Million |

| CAGR | CAGR of 7.64% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Laser Type (CO2 laser, Fiber laser, Green laser, UV laser, YAG laser) • By Application (Automotive, Aerospace, Machine tool, Electronics and Microelectronics, Medical, Packaging, Military, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Coherent, IPG Photonics, TRUMPF, Mecco Partners, Gravotech, Novanta, Epilog, Trotec Laser, Hesai, Markolaser, Artek Laser, Starlase Systems, LASIT, Han's Laser, Keyence. |