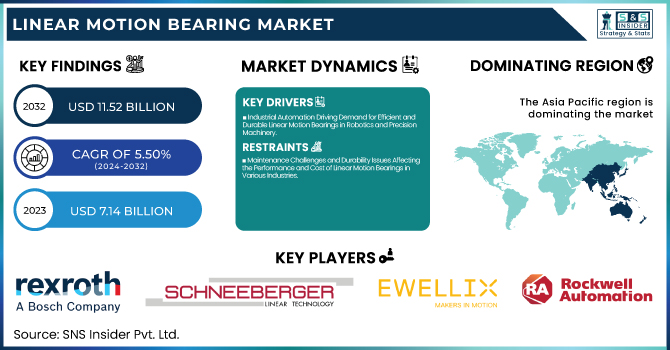

Linear Motion Bearing Market Size & Trends:

The Linear Motion Bearing Market Size was valued at USD 7.14 billion in 2023 and is projected to reach a valuation of USD 11.52 billion by 2032, surging at a CAGR of 5.50% over 2024-2032.

This Linear Motion Bearing Market analysis comprises a wide-ranging analysis of vital market drivers, concentrating on technological adoption, supply chain dynamics, product development trends, consumer behavior, and investment trends. Technological advancements in the bearing systems, which include the integration of smart bearings and automation in industrial applications, are driving the market expansion.

To Get more information on Linear Motion Bearing Market - Request Free Sample Report

The automotive sector remains a significant contributor to demand, with increasing automation and precision engineering. Additionally, the report examines shifts in consumer behavior and evolving preferences, along with the investment patterns that are boosting innovation. A deep supply chain analysis is also showcasing the strategic role of the major players in shaping the future of the market.

Linear Motion Bearing Market Dynamics:

Drivers:

-

Industrial Automation Driving Demand for Efficient and Durable Linear Motion Bearings in Robotics and Precision Machinery

The industrial automation process, which involves robotics and precision equipment, has increased the need for linear motion bearings that are both efficient and long-lasting. Automated manufacturing systems need precise movement and less friction to maintain high performance and reliability. Bearings form part of these systems as they offer the support needed for accurate motion control.

As manufacturing sectors, such as automotive, electronics, and aerospace move toward more advanced and high-speed production lines, high-quality linear motion bearings become indispensable. These types of bearings highly facilitate smoother operation in robotic arms, automatic machinery, and conveyor systems, which further boosts the productivity and raise manufacturing accuracy. This burgeoning automation trend is also driving the demand for linear motion bearing solutions, further boosting the Linear Motion Bearing Market growth globally.

Restraints:

-

Maintenance Challenges and Durability Issues Affecting the Performance and Cost of Linear Motion Bearings in Various Industries

The durability of linear motion bearings can be negatively affected owing to the factors, such as heavy loads, lack of maintenance, and excess dirt in the bearings. As linear motion bearings are manufactured for precision, they can compromise in performance with time, due to poor maintenance and exposure to excess stress. High-load conditions can speed up wear and tear, decreasing the effectiveness of motion control systems.

Furthermore, contact with contaminants including moisture, dirt, or dust, can cause corrosion and also premature failure of the bearings. These issues not only bring high maintenance costs but also make a large impact on operations, further hampering the productivity. Consequently, linear motion bearing-dependent industries have to incur costs on good maintenance practices and regular inspection to sustain their performance, increasing the operational expense.

Opportunities

-

Innovative Materials and Market Expansion Drive Demand for High-Performance Linear Motion Bearings in Automotive, Robotics, and Manufacturing

Advanced materials, such as ceramic and hybrid bearings, are largely enhancing the performance of linear motion bearings. These materials provide higher strength, lighter weight, and greater wear and corrosion resistance, well-suited to demanding uses in a range of industries. Further, the increased use of electric vehicles (EVs) provides new opportunities for the application of linear motion bearings in advanced vehicle systems, such as powertrains and steering. The advent of robotics and automation also provides significant opportunity since companies are relying increasingly on such systems for efficiency. In addition to this, manufacturing capacity growth in emerging economies as well as inclusion of 3D printing technology is stimulating growth in customized and high-performance linear motion bearings.

Challenges

-

Competition from Alternative Technologies and Operational Challenges Limiting Growth Potential in the Linear Motion Bearing Market

The existence of substitute motion control solutions, for example, magnetic or air bearings, is considerable competition for linear motion bearings in niche applications requiring minimal friction or more precision. Such substitutes often come with advantages including lower wear, extended life, and performance under harsh environments. Moreover, the expense of high-performance linear motion bearings, particularly those composed of advanced materials, can be a deterrent for some industries. Moreover, the intricate engineering requirements for the inclusion of linear motion bearings in high-end systems, such as robotics and automation can be problematic. Disruptions in the supply chain and specialized maintenance requirements also make the market scenario more difficult, hindering widespread adoption and expansion.

Linear Motion Bearing Industry Segmentation Analysis:

By Type

The Single-axis Linear Motion System market led the Linear Motion Bearing Market in 2023 with the largest revenue share of about 60%. This is due to its extensive use across manufacturing, automotive, and electronics industries, where precision and reliability are paramount. Single-axis systems are cheaper and easier, suitable for a wide variety of industrial applications that necessitate simple motion control for machinery, conveyors, and robotic arms.

The Multi-axis Linear Motion System market is anticipated to expand at the fastest CAGR of approximately 6.71% during the period 2024-2032. The reason behind the growth is rising demand for higher complexity and versatile motion solutions across robotics, automation, and aerospace industries. Multi-axis systems offer higher precision and flexibility in motion applications that include simultaneous movement in multiple axes making them suitable for 3D printing, high-end manufacturing, and high-performance robot systems.

By End Use

The Automotive segment led with the largest Linear Motion Bearing market share of about 31%. This is due to the increasing need for high-performance bearings in automotive use, especially in electric vehicles (EVs), autonomous vehicles, and sophisticated automotive systems. Linear motion bearings are integral to components such as steering systems, powertrains, and suspension systems, providing precision, durability, and efficiency that are critical to contemporary automotive engineering.

The Electronics and Semiconductor segment is anticipated to grow at the fastest CAGR of approximately 8.13% during 2024-2032. The growth is mainly due to the rising need for precision motion control in semiconductor and electronic device manufacturing. With electronics shrinking, speeding up, and becoming more complex, the demand for extremely accurate linear motion bearings to provide smooth motion in assembly lines, test equipment, and precision machinery keeps growing.

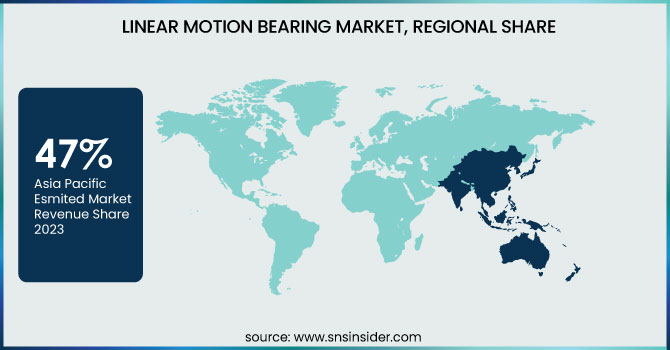

Linear Motion Bearing Market Regional Landscape

Asia Pacific led the Linear Motion Bearing Market in 2023 with the largest revenue share of approximately 47%. This is fueled by the fast industrialization of the region and the high demand for automation in manufacturing industries including automotive, electronics, and robotics. China, Japan, and India are among the leading countries with huge manufacturing hubs and leading Linear Motion Bearing companies, with high investments in precision engineering and automation, leading to a high demand for high-performance and reliable linear motion bearings.

North America will grow at the fastest CAGR of around 7.14% during the forecast period of 2024-2032 owing to the growing advancements in automation, robotics, and the surging electric vehicle (EV) market growth, all of which require high-performance linear motion bearings. The emphasis in the region on innovation and the robust demand from sectors including automotive, aerospace, and electronics, which are promoting motion control technologies' use globally.

Get Customized Report as per Your Business Requirement - Enquiry Now

Key Players Listed in the Linear Motion Bearing Market are:

-

Bosch Rexroth AG (Robert Bosch GmbH) (Linear Motion Guides, Ball Screw Assemblies)

-

SCHNEEBERGER Group (Linear Bearings, Linear Modules)

-

Ewellix (Schaeffler Group) (Ball Screws, Linear Actuators)

-

Hiwin Corporation (Linear Guides, Ball Screws)

-

Thomson Industries Inc. (Lead Screws, Linear Guides)

-

Rockwell Automation (Linear Motion Systems, Actuators)

-

THK Co., Ltd. (Linear Guides, Ball Screws)

-

Nippon Thompson Co., Ltd. (Linear Bushings, Linear Guides)

-

NSK Ltd. (Linear Guides, Ball Screws)

-

PBC Linear (Linear Bearings, Actuators)

-

SKF Group (Linear Bearings, Linear Guides)

-

Parker Hannifin Corporation (Linear Actuators, Ball Screw Assemblies)

-

AutomationDirect (Linear Bearings, Linear Slides)

-

Schaeffler Group (Linear Guides, Ball Screws)

-

Camozzi Automation (Linear Guides, Actuators)

-

Kitanihon Seiki Co., Ltd. (Linear Bushings, Linear Guides)

-

Mitsubishi Electric Corporation (Linear Motors, Linear Guides)

Recent Developments:

-

In 2024, Bosch Rexroth introduced the ctrlX FLOW HS, a high-speed linear motion system designed for fast and precise transport and positioning, seamlessly integrating with the ctrlX AUTOMATION platform for enhanced performance.

-

In 2024, SCHNEEBERGER introduced their MINIRAIL miniature guideways at Formnext 2024, designed for compact, highly precise applications where space is limited and maintenance-free operation is essential.

-

In 2024, Rockwell Automation introduced the Kinetix LDAT Linear Stages, featuring high velocity and acceleration capabilities, designed with direct drive technology and integrated linear bearings to simplify motion control and reduce engineering time.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 7.14 Billion |

| Market Size by 2032 | USD 11.52 Billion |

| CAGR | CAGR of 5.50% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Type (Single-axis Linear Motion System, Multi-axis Linear Motion System) • By End Use (Automotive, Electronics and Semiconductor, Manufacturing, Aerospace, Healthcare, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Bosch Rexroth AG (Robert Bosch GmbH), SCHNEEBERGER Group, Ewellix (Schaeffler Group), Hiwin Corporation, Thomson Industries Inc., Rockwell Automation, THK Co., Ltd., Nippon Thompson Co., Ltd., NSK Ltd., PBC Linear, SKF Group, Parker Hannifin Corporation, AutomationDirect, Schaeffler Group, Camozzi Automation, Kitanihon Seiki Co., Ltd., Mitsubishi Electric Corporation. |