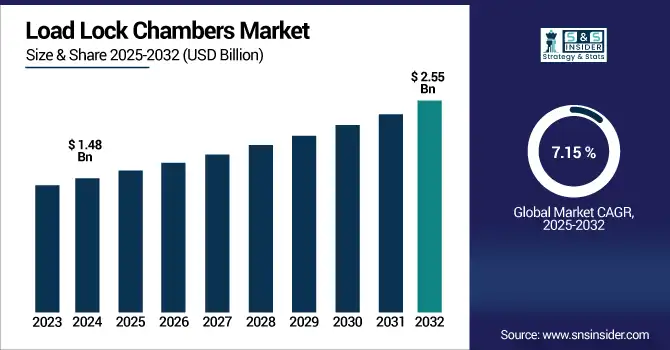

Load Lock Chambers Market Size Analysis:

The Load Lock Chambers Market Size was valued at USD 1.48 billion in 2024 and is expected to reach USD 2.55 billion by 2032 and grow at a CAGR of 7.15 % over the forecast period 2025-2032.

To Get more information on Load Lock Chambers Market - Request Free Sample Report

The global Load Lock Chambers Market is driven by High demand for contamination-free environment combined with automation among the precision industry. Development is uneven from region to region, due to varying industrial growth and technological level. Rising spending in high-tech manufacturing, along with continued innovation, is broadening areas of utilization. You can definitely expect market dynamics to continue to be influenced by competitive innovations and the driving force toward cleaner, more efficient production processes, providing a wealth of opportunities for manufacturers and integrators to capitalize on emerging trends to improve system performance in a wide variety of industries.

The U.S. Load Lock Chambers Market size was USD 0.26 billion in 2024 and is expected to reach USD 0.46 billion by 2032, growing at a CAGR of 7.76 % over the forecast period of 2025–2032.

The US load lock chambers market growth is supported by the surge of deployment of semiconductor fabrication plants, the rising government spending on chip production and the technological progress of the vacuum and deposition processes. Further, the increasing number of tier one market players and growing demand for high purity and contamination free environment are considerably bolstering the demand for technologically upgraded load lock chamber systems in U.S. based establishments.

According to SEMI, 90% of next-gen fabs in the U.S. demand load locks with real-time pressure monitoring, leak detection, and automated transfer systems.

Load Lock Chambers Market Dynamics

Key Drivers:

-

Rising focus on automation and integration of Industry 4.0 practices in manufacturing facilities globally

Increasing requirements for efficiency in operations, precision, and minimization of human intervention in factories has been compelling the integration of automation technologies, thereby contributing toward the growth of the Automatic Load Lock Chambers market. Industry 4.0 combines intelligent process control, real-time monitoring, and predictive maintenance, which is in line with the advanced features of smart load lock systems. Note however, that these automated systems increase the speed of production with a low risk of contamination and human error therefore becoming more and more sought after for the semicon, electronics and vacuum coating industry on a global scale.

According to research, as of 2024, over 65% of global manufacturing companies have adopted some form of Industry 4.0 practices, with automation being the top priority.

Restrain:

-

Limited awareness and technical know-how in emerging economies restrict market expansion

Even though there is rapid industrial expansion, in many underdeveloped countries, the implementation of the Load Lock Chambers is scanty due to lack of knowledge on the benefits and also technical how-about. The lack of strong training infrastructure, and relatively low presence of local suppliers or maintenance services, restricts uptake. In regions such as Southeast Asia, Africa, and some parts of Latin America, end-users continue to depend on traditional systems because of a perceived complexity and lack of operational familiarity, limiting demand growth and decelerating the global market penetration.

Opportunities:

-

Growing adoption of thin-film deposition and vacuum-based coating in emerging industrial applications

High demand for high-performance coatings from solar panels, advanced optics, OLED displays, and aerospace parts is creating demand for precise vacuum processing. Load Lock Chambers are critical to maintaining the integrity of vacuum while doing thin film deposition. Demand for Load Lock Chambers continues to grow as other industries are adapting a vacuum based technology to improve reliability, energy savings and power. This phenomenon will generate new growth opportunities beyond the field of semiconductors expanding the market’s application base.

According to research, Miniaturization and energy efficiency trends are leading over 70% of advanced manufacturing lines to adopt some form of vacuum-based process, including load lock chambers.

Challenges:

-

Maintaining vacuum integrity and leak-proof performance in high-throughput and customized configurations

With the trend towards increased process-step integration, the demand for Inline Load Locks custom designed to a particular process has been growing. However, maintaining the same vacuum condition, eliminating leaks, and keeping reliable in the large-volume or cathode module is not also simple. Rational design of materials compatibility, sealing and integration complexity needs to be taken. Even slight changes in performance can impact yield and contamination, leaving manufacturers facing a dilemma: how to balance customized features with reliable, safe, and cost-effective performance.

Load Lock Chambers Market Segment Analysis:

By Product Type

Manual Load Lock Chambers dominated the Load Lock Chambers Market with the highest revenue share of about 32.11% in 2024 owing to its low cost, high reliability, and accommodating to low-to-medium throughput processing. Such systems are traditionally chosen among the R&D labs and small production environments and where complex automation is not needed. For example, products from companies such as Ferrotec Holdings Corporation,su which provide a reliable manual load lock capability allowing accurate vacuum isolation to be achieved without complex programming, are suitable for fundamental/test vacuum processing.

Automatic Load Lock Chambers are expected to grow at the fastest CAGR of about 8.01% from 2025–2032, driven by the continued explosion of fully automated silicon fabs and smart factories. These stations make our process more efficient and make mass production easier. ULVAC Technologies, Inc. has been developing its automated load lock systems and controls for years and is positioned to be extremely appealing to high-volume plants with demanding precision requirements and virtually zero downtime.

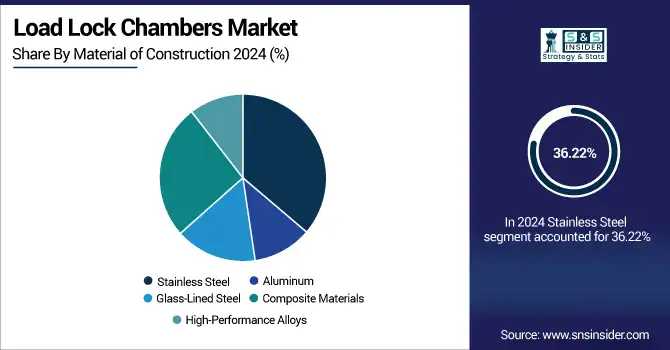

By Material of Construction

Stainless Steel segment dominated the Load Lock Chambers Market with the highest revenue share of about 36.22% in 2024, because of its excellent wear resistance, corrosion resistance, and high compatibility with ultra-clean room. It is ideal for high-temperature and high-vacuum applications in crucial industries. Companies such as Pfeiffer Vacuum Technology AG produce stainless steel chambers that keep its shape and sustain vacuum for semiconductor and pharmaceutical processes needing high-purity process conditions.

Composite Materials segment is expected to grow at the fastest CAGR of about 8.55% from 2025–2032 because of their lightness, low cost, and ease of shaping complex chamber geometries. These materials are being increasingly used in applications with need for mobility or customized structure. The Shinko Seiki Co., Ltd. is one of the innovative companies for working out the composite-made load lock chamber like below for the photonics or life science which has to be light weighted and thermally insulated intensively.

By Application

Semiconductor Manufacturing segment dominated the Load Lock Chambers Market with the highest revenue share of about 31.35% in 2024, due to the necessity for vacuum integrity and cleanliness in processing wafers. As chip manufacturing becomes increasingly complex, load lock chambers companies such as Applied Materials, Inc. are adding load lock systems to the deposition and etch tool (e.g., the mini-environment) to maintain cleanroom cleanliness levels and overall wafer throughput without any adverse impact on yield.

Thin Film Deposition segment is expected to grow at the fastest CAGR of about 8.62% from 2025–2032, driven by the deployment of displays, photovoltaics and optical coatings. Load Lock Chambers for reliable vacuum state during deposition processes. Kurt J. Lesker Company is playing its part in the weight of deposition growth with chambers that support fast loading and unloading of substrates on its thin-film tools, for optimal cycle times and minimal opportunity for contamination between processes.

By Industry

Electronics and Semiconductors segment dominated the Load Lock Chambers Market with the highest revenue share of about 36.27% in 2024 because of the surge in demand worldwide for advanced electronics and high-end chips. Such industries use ultra-high clean and controlled environments to protect yield. Canon Tokki Corporation also provides such integrated systems including advanced load lock chambers for making OLED and microelectronics with perfect vacuum integrity and contamination.

Healthcare and Pharmaceuticals segment is expected to grow at the fastest CAGR of about 8.57% from 2025–2032 as the industry adopts vacuum environments for sterile manufacturing and nano-formulation. Load Locks are used in cleanroom applications for isolated sensitive materials. Edwards Vacuum has designed chamber systems for biotech labs and pharma manufacturing that allow sterile transitions and cut down on particles contaminating the work during research and formulation.

By End-User

Original Equipment Manufacturers (OEMs) segment dominated the Load Lock Chambers Market with the highest revenue share of about 36.70% in 2024 as they incorporate load lock systems with full vacuum process tools. OEMs need a range of solutions which are modular and work for different customer applications. SHI Cryogenics Group services this sector with customized load lock solutions that provide the high performance and flexibility (in both process and performance) required by OEMs in response to increasingly stringent system integration requirements.

In-House Production Facilities segment is expected to grow at the fastest CAGR of about 8.37% from 2025–2032, fueled by companies bringing important processes in house for more control, IP protection and flexibility. Such throughput plants are in need of handling systems, which are small and convenient in handling. In addition to these laboratory scale users, there is also a demand by compa- nies that produce thin film products for systems that are cost ef- fective, easy to maintain and can be scaled up to accommodate in-house thin film and vacuum coating production.

Load Lock Chambers Market Regional Outlook:

Asia Pacific dominated the highest Load Lock Chambers Market share of about 39.05% in 2024, because of its strong semiconductor manufacturing supply chain, particularly in such countries as China, Japan, South Korea, and Taiwan. Demand has also been greatly supported by major fabrication plants, continual investment in electronics and government-sponsored industrial policies. Moreover, the presence of a large pool of skilled labour and inexpensive manufacturing infrastructure has strengthened the positioning of the region to emerge as a global hub for vacuum based technologies, in turn driving its dominance in the market.

-

China leads the Asia Pacific Market because of its large semiconductor production base, government supported industrial policies and extensive electronics production investment. It is a focal point for the application of vacuum technology with its developed infrastructures and cost privilege.

North America segment is expected to grow at the fastest CAGR of about 8.45% from 2025–2032, driven by increasing investments in advanced chip manufacturing and clean energy. The U.S. government’s emphasis on domestic chip manufacturing and technological autonomy has spurred massive expansion. Moreover, rising R&D activities and adoption of Industry 4.0 in the high-tech industry are rising the demand for automated and accurate vacuum solutions, and the region will be the fastest-growing regional market during the forecast period.

-

The U.S. is the leader in the North American Market on the account of high investments in semiconductor fabrication, advanced R&D facilities, and government funding for chip production in the country. Its technology-led manufacturing environment ensures a ready supply of precision vacuum facilities.

Europe is a prominent region in the Market, with high industrial base, presence of major players in the semiconductor as well as photovoltaic industry, and increasing investments in clean and automation technologies. Germany and the Netherlands are at the forefront of innovative precision engineering, and demand for high-efficient vacuum systems in research institutes and tech-based industries is further underpinning the regional industry statistics.

-

Germany leads the europe Market because of the strong semiconductor industry, modern manufacturing infrastructure, and increasing focus on automation and innovation. All these variables make Austria one of the highest-performing markets for precision vacuum and could lead to it reaching superior levels to those in other European countries.

Middle East & Africa is led by UAE owing to huge investments in advanced manufacturing and government support towards technology growth while Latin America is dominated by Brazil on account of rising electronics and semiconductor industries, growing automation and rising demand across automotive & consumer electronics applications.

Get Customized Report as per Your Business Requirement - Enquiry Now

Load Lock Chambers Companies are:

Major Key Players in Load Lock Chambers Market are Hine Automation, PREVAC, Kurt J. Lesker Company, Nor-Cal Products, Angstrom Engineering Inc., Moorfield Nanotechnology, Ferrovac GmbH, ST Instruments, Thermionics Laboratory, Denton Vacuum and others.

Recent Development:

-

In August 2024, Hine Automation launched the SL-200C and SL-300C automated load locks. These systems offer batch processing capabilities for up to 25 wafers, optimizing space and reducing the need for frequent chamber venting.

-

February 2024, Angstrom Engineering Inc. introduced the Reticle Ion Beam Sputter Deposition System, integrating a load lock chamber to facilitate rapid substrate exchange without compromising vacuum integrity.

| Report Attributes | Details |

|---|---|

| Market Size in 2024 | USD 1.48 Billion |

| Market Size by 2032 | USD 2.55 Billion |

| CAGR | CAGR of 7.15% From 2025 to 2032 |

| Base Year | 2024 |

| Forecast Period | 2025-2032 |

| Historical Data | 2021-2023 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Product Type (Standard Load Lock Chambers, Custom Load Lock Chambers, High-Throughput Load Lock Chambers, Automatic Load Lock Chambers, Manual Load Lock Chambers) • By Material of Construction (Stainless Steel, Aluminum, Glass-Lined Steel, Composite Materials, High-Performance Alloys) • By Application (Semiconductor Manufacturing, Coating Processes, Material Research and Development, Optical Device Fabrication, Thin Film Deposition) • By Industry (Aerospace and Defense, Electronics and Semiconductors, Automotive, Healthcare and Pharmaceuticals, Research Institutions) • By End-User (Original Equipment Manufacturers (OEMs), Contract Manufacturers, Research Laboratories, Academic Institutions, In-House Production Facilities) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Germany, France, UK, Italy, Spain, Poland, Turkey, Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Singapore, Australia,Taiwan, Rest of Asia Pacific), Middle East & Africa (UAE, Saudi Arabia, Qatar, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Rest of Latin America) |

| Company Profiles | Hine Automation, PREVAC, Kurt J. Lesker Company, Nor-Cal Products, Angstrom Engineering Inc., Moorfield Nanotechnology, Ferrovac GmbH, ST Instruments, Thermionics Laboratory, Denton Vacuum. |