Screw Compressor Market Report Scope & Overview:

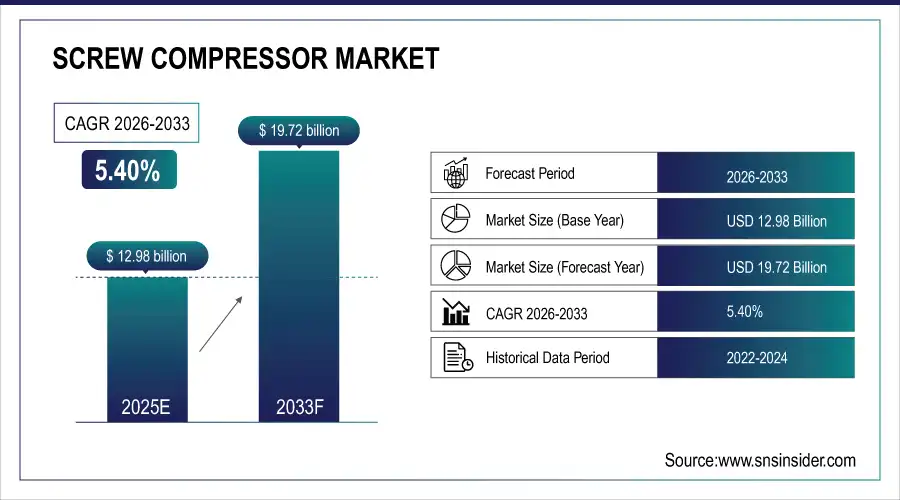

The Screw Compressor Market Size was valued at USD 12.98 Billion in 2025E and is projected to reach USD 19.72 Billion by 2033, growing at a CAGR of 5.40% during the forecast period 2026–2033.

The Screw Compressor Market analysis report provides a basic overview, including definitions, classifications, applications, and industry chain structure. Additionally, growing demand from the manufacturing, construction, and energy sectors for higher-capacity screw compressors is expected to drive market growth and expand scope.

Screw Compressor shipments reached 3.6 million units in 2025, driven by industrial, construction, energy sector demand, and rising adoption of energy-efficient compressors.

Market Size and Forecast:

-

Market Size in 2025: USD 12.98 Billion

-

Market Size by 2033: USD 19.72 Billion

-

CAGR: 5.40% from 2026 to 2033

-

Base Year: 2025

-

Forecast Period: 2026–2033

-

Historical Data: 2022–2024

To Get more information On Screw Compressor Market - Request Free Sample Report

Screw Compressor Market Trends:

-

Rising automation and smart manufacturing in industries is driving the demand for dependable, energy-efficient screw compressors from companies.

-

Increasing emphasis on sustainability and energy efficiency stimulates demand for oil-free or easy maintenance compressor technology.

-

Growing infrastructure, automotive and food & beverages industry is increasing the demand to industrial compressors in larger volume.

-

Current industrial facilities and high precision machinery are driving the need for more advanced rotary and twin-screw compressor systems.

-

Customization and efficiency optimization are the market trends which are making compressors integrated with IoT and predictive maintenance solutions in demand.

U.S. Screw Compressor Market Insights:

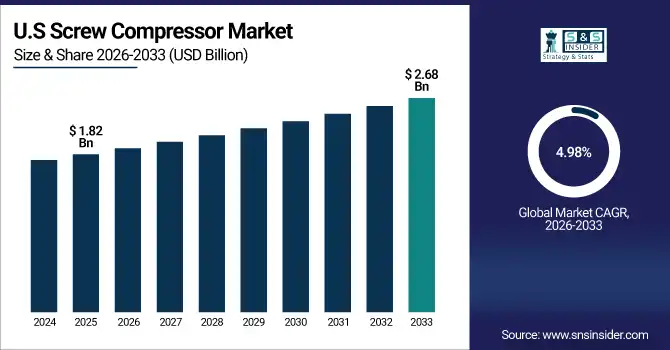

The U.S. Screw Compressor Market is projected to grow from USD 1.82 Billion in 2025E to USD 2.68 Billion by 2033, at a CAGR of 4.98%. Market growth is attributed to the increasing industrial automation, growing demand for energy-efficient and high-capacity compressors, expansion of manufacturing industry & construction sector, and adoption of eco-friendly oil-free technology.

Screw Compressor Market Growth Drivers:

-

Rising industrial automation and energy-efficient operations are boosting demand for high-capacity, low-maintenance screw compressors.

Rising industrial automation and the need for energy-efficient operations are the primary drivers of Screw Compressor Market Growth. Increasing application of high-capacity, low-maintenance compressors in manufacturing, construction, energy industries is propelling the market demand. Today’s industrial systems and equipment need to work under demanding conditions, and sustainability projects push oil-free, energy-saving solutions. The integration of smart monitoring and predictive maintenance improves efficiency, resulting in long-term market growth and widespread industrial use.

Screw Compressor shipments grew 6.8% in 2025, driven by rising demand from manufacturing, construction, energy sectors, and adoption of energy-efficient, high-capacity units.

Screw Compressor Market Restraints:

-

High initial investment, maintenance costs, and complex installation requirements are limiting widespread adoption of screw compressors.

High initial investment, maintenance costs, and complex installation requirements are key restraints for the Screw Compressor Market. There is a large capital investment in high capacity and sophisticated compressors which poses an entry barrier for the industry especially small and medium scale ones. Both ongoing maintenance and technical expertise needs contribute to a high operational cost, while also being the time-consuming installations. These components, in combination, limit fast growth of the market and hinder further dissemination of screw compressor technology.

Screw Compressor Market Opportunities:

-

Increasing industrial energy efficiency and sustainability initiatives create opportunities for advanced, oil-free, and smart screw compressors.

Increasing industrial focus on energy efficiency and sustainability presents a significant growth opportunity for the Screw Compressor Market. Manufacturers now include oil-free, low-maintenance, and smart compressors to lower power consumption and to limit environmental impact. The performance and reliability gain by adding IoT connectivity and predictive maintenance. With the cost efficiency and eco-friendliness on top of industry agenda, these trends lay down opportunities across manufacturing, construction and energy sectors for innovation explosion, product differentiation and wide acceptance.

Advanced and oil-free screw compressors accounted for 24% of industrial installations in 2025, driven by energy-efficient and low-maintenance demand.

Screw Compressor Market Segmentation Analysis:

-

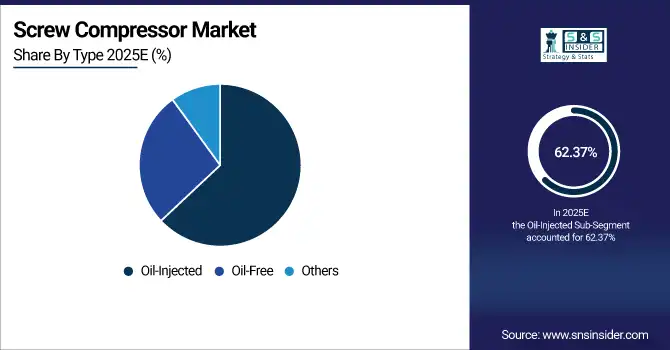

By Type, Oil-Injected held the largest market share of 62.37% in 2025, while Oil-Free is expected to grow at the fastest CAGR of 6.12% during 2026–2033.

-

By Capacity/Power Rating, 101–500 kW dominated with a 54.85% share in 2025, while Above 500 kW is projected to expand at the fastest CAGR of 6.45%.

-

By Technology, Twin-Screw accounted for the highest market share of 57.21% in 2025, and Single-Screw is expected to record the fastest CAGR of 6.30%.

-

By End-Use Industry, Automotive held the largest share of 42.76% in 2025, while Pharmaceuticals is expected to grow at the fastest CAGR of 6.21% during the forecast period.

By Type, Oil-Injected Dominates While Oil-Free Expands Rapidly:

Oil-Injected segment dominated the market on account of its extensive applications, reliable operations and cost efficiency is manufacturing, construction and energy industry. Demand remains strong due to its robust performance under heavy duty applications and lower initial cost. Oil-free is the fastest growing segment driven by increasing demand from energy efficient and sustainable solutions. Increasing popularity of eco-friendly, low-maintenance compressors and strict environment policies propelling demand for oil free technology is stimulating market growth.

By Capacity/Power Rating, 101–500 kW Dominates While Above 500 kW Expands Rapidly:

101–500 kW segment dominated the market due to their versatile nature, wide applicability for almost all industrial applications and cost effectiveness. This section satisfies the mid- to heavy-manufacturing and building procedure. Above 500 kW is the fastest growing segment, influenced by industries who have need for high capacity to run their large-scale operations. Increasing industrial automation and the need for energy efficient high-capacity compressors are promoting the use of bigger devices, driving market growth.

By Technology, Twin-Screw Dominates While Single-Screw Expands Rapidly:

Twin-Screw segment dominated the market on account of its reliability, steady operation and operates at high pressure continuous industries. Strong market share of manufacturing, automotive and energy sectors make it the industry standard. Single-Screw is the fastest-growing segment due to its relatively easier design, lesser maintenance, and increasing industrial automation. Growing interest in energy-saving and compact compressor technology is driving adoption of Single-Screw, offering a potential for market development in new industrial areas.

By End-Use Industry, Automotive Dominates While Pharmaceuticals Expands Rapidly:

Automotive segment dominated the market, owing to utilization of screw compressors in assembly lines, painting, and pneumatic applications with steady demand. Its market share is propped up by existing production facilities and scale advantages. Pharmaceuticals is the fastest growing segment, spurred by rising investment in biotech, vaccine production and sterile manufacturing where oil-free, high efficiency compressors are required. Increasing regulatory adherence and energy efficient operation driven demand for screw compressors is likely to spur growth in this end-use sector.

Screw Compressor Market Regional Analysis:

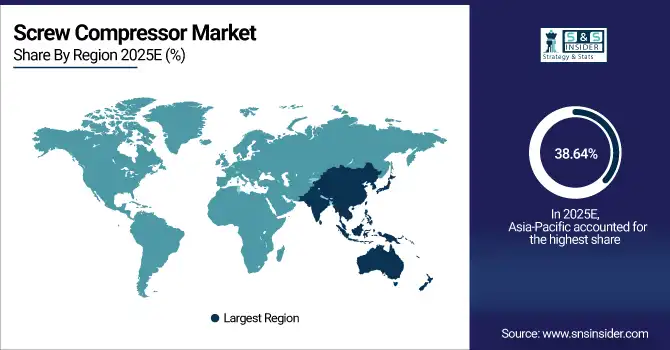

Asia-Pacific Screw Compressor Market Insights:

The Asia-Pacific Screw Compressor Market dominated, holding a 38.64% share in 2025. Strong uptake is fostered by swift industrialization, robust manufacturing, construction and energy industries. The primary markets are China, India, Japan and Australia. Increasing preference for oil-free, energy-efficient and high-capacity compressors is further propelling the market growth. Urbanization and industrial automation further strengthen penetration, while sustainability projects, coupled with modern industrial infrastructure encourage adoption, which supports the easy availability and expansion of screw compressors in the region.

Get Customized Report as per Your Business Requirement - Enquiry Now

China Screw Compressor Market Insights:

The China Screw Compressor Market is driven by rapid industrialization, urbanization, and expansion of manufacturing and energy sectors. Growing need for energy-saving, non-oiled and high-capacity compressors along with advanced industrial infrastructure and automation is likely to foster the market. For these reasons, China is an important driver of growth in the Aisa-Pacific market.

North America Screw Compressor Market Insights:

North America is witnessing steady growth in the Screw Compressor Market, owing to increasing industrial automation, manufacturing and construction activities. With the rising demand for energy-efficient, oil-free and high-performance compressors, adoption has become evident across several sectors. New technology, industrial and infrastructure development is boosting its application. Increasing industrial investment along with the rising business emphasis toward operational efficiency and cost saving will increase the regional market presence & long-term growth of industry.

U.S. Screw Compressor Market Insights:

The U.S. Screw Compressor Market is likely to be driven by rising demand from manufacturing, and energy and construction industries. Market growth is continuing to be fuelled by the increasing adoption of energy efficient, oil free and high-capacity compressors, upgradation of industrial infrastructure, and industrial automation trends and growing emphasis on sustainability and operational efficiency.

Europe Screw Compressor Market Insights:

Europe’s Screw Compressor Market is witnessing steady growth, owing to expanding industrial automation, upgradation manufacturing and construction sectors coupled with growing requirement for energy efficient and oil free compressors. Key markets include Germany, the UK and France. It is propelled by sustainability efforts, demand for high-capacity compressors that are low on maintenance and incorporation of smart monitoring systems. Technological upgrading and emphasis on operational efficiency will likely support market presence and long-term growth.

Germany Screw Compressor Market Insights:

Germany is a key market for Screw Compressors, driven by strong industrial manufacturing, automotive, and construction sectors. Adoption of energy-efficient, oil-free, and high-capacity compressors is driving demand. Both at the regional and international level, a history of sustainable development, innovation integration and operational efficiency is driving additional market expansion and further long-term growth.

Middle East and Africa Screw Compressor Market Insights:

The Middle East & Africa Screw Compressor Market is the fastest-growing region, projected at a CAGR of 6.84% during 2026–2033. Growth is being fueled by increased industrialization, growing manufacturing and construction sectors, and the need for energy-efficient, oil-free compressors. Market expansion is prompted by investments in infrastructure, high-capacity compressor installations, and growing emphasis on operational efficiency and sustainability in the region.

Latin America Screw Compressor Market Insights:

The Latin America Screw Compressor Market is growing due to rising industrialization and expansion in manufacturing, construction, and energy sectors. Growth is backed by expanding deployment of energy-efficient and oil-free compressors. Projects focused on infrastructure development, modernization and environmental sustainability are set to boost the market in historical leaders such as Brazil, Mexico and Argentina.

Screw Compressor Market Competitive Landscape:

Atlas Copco, headquartered in Sweden, is a leader in compressed air and gas equipment, including screw compressors. It is the market leader due to its innovations in technology for energy efficient and oil free compressors along with the proven service network and distribution structure. Atlas Copco is a world-leading provider of sustainable productivity solutions. The group serves customers with innovative compressors, vacuum solutions and air treatment systems, construction and mining equipment, power tools and assembly systems.

-

In July 2025, Atlas Copco introduced its next-generation GA and GA+ rotary screw compressors. These models feature an innovative hybrid bearing that extends the drivetrain's lifetime by 33%, along with IE4-efficiency motors and oversized coolers, delivering more air at a lower energy cost than previous generations.

Ingersoll Rand, a leading U.S.-based industrial equipment manufacturer, excels in screw compressors and related solutions. It is the industry leader due to the decades of experience, a vast array of products and attention toward energy efficient long-lasting compressors. The market position is reinforced by distribution, blue chip aftermarket businesses and focusing on innovation that enables operational improvements and efficiency gains and ecosystem support. With their combination of technology, proven processes, and robust products Ingersoll Rand excels in a variety of industries including manufacturing, automotive, construction and energy.

-

In August 2025, Ingersoll Rand unveiled the UP6S 20–30 HP oil-flooded rotary screw compressor. This compact, user-friendly unit offers powerful performance in a space-saving design, catering to industries requiring reliable and efficient compressed air solutions.

Kaeser Compressors, headquartered in Germany, is a prominent manufacturer of screw compressors and compressed air systems. It does so with its focus on precision automation, energy efficient design and long-term reliability in engineering environments. Kaeser stresses sustainable solutions, significant R&D and service. With rugged compressors designed for demanding applications in such areas as manufacturing, automotive and construction, Kaeser earns its reputation for unsurpassed reliability while continuing to grow market share throughout the world through innovative products and exceptional service.

-

In June 2025, Kaeser Compressors introduced the SX 7.5 HP rotary air compressor. This model is designed for industrial use, offering high-quality performance with a belt-driven rotary screw mechanism, suitable for various applications requiring reliable compressed air solutions.

Screw Compressor Market Key Players:

Some of the Screw Compressor Market Companies are:

-

Atlas Copco

-

Ingersoll Rand

-

Kaeser Compressors

-

Sullair

-

Gardner Denver

-

Fusheng

-

Hitachi

-

BOGE Compressors

-

Quincy Compressor

-

Mitsubishi Heavy Industries

-

Siemens Energy

-

Bauer Group

-

Hanwha Power Systems

-

MINNUO Group

-

FS-Curtis

-

Airotech Compressors

-

Comptech

-

Dukas Compressors

-

Shanghai Screw Compressor Co., Ltd.

-

Howden

| Report Attributes | Details |

|---|---|

| Market Size in 2025E | USD 12.98 Billion |

| Market Size by 2033 | USD 19.72 Billion |

| CAGR | CAGR of 5.40% From 2026 to 2033 |

| Base Year | 2025E |

| Forecast Period | 2026-2033 |

| Historical Data | 2022-2024 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Type (Oil-Injected, Oil-Free, Others) • By Capacity/Power Rating (Up to 100 kW, 101–500 kW, Above 500 kW) • By Technology (Rotary, Twin-Screw, Single-Screw, Others) • By End-Use Industry (Automotive, Food & Beverage, Pharmaceuticals, Construction, Others) |

| Regional Analysis/Coverage | North America (US, Canada), Europe (Germany, UK, France, Italy, Spain, Russia, Poland, Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Australia, ASEAN Countries, Rest of Asia Pacific), Middle East & Africa (UAE, Saudi Arabia, Qatar, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Mexico, Colombia, Rest of Latin America). |

| Company Profiles | Atlas Copco, Ingersoll Rand, Kaeser Compressors, Sullair, Gardner Denver, Fusheng, Hitachi, BOGE Compressors, Quincy Compressor, Mitsubishi Heavy Industries, Siemens Energy, Bauer Group, Hanwha Power Systems, MINNUO Group, FS-Curtis, Airotech Compressors, Comptech, Dukas Compressors, Shanghai Screw Compressor Co., Ltd., Howden |