Tow Prepreg Market Report scope & Overview:

Get More Information on Tow Prepreg Market - Request Sample Report

The Tow Prepreg Market Size was valued at USD 534.6 million in 2023 and is expected to reach USD 1526.0 million by 2032 and grow at a CAGR of 12.4% over the forecast period 2024-2032.

The Tow Prepreg market is experiencing significant growth driven by various market dynamics, including increasing demand for lightweight materials across industries such as aerospace, automotive, and construction. The adoption of advanced composite materials, particularly carbon fiber-based prepregs, is becoming more prevalent due to their superior strength-to-weight ratio, corrosion resistance, and ability to improve fuel efficiency. For example, the automotive sector is increasingly focusing on electric, CNG, and hydrogen-powered vehicles, which require advanced materials like narrow tow prepregs to meet performance and environmental standards. Axiom Materials, in July 2022, introduced new narrow tow prepregs targeted at electric, CNG, and hydrogen-powered vehicles, helping to reduce vehicle weight and enhance performance while supporting the transition to cleaner energy sources. Additionally, companies are focused on expanding their production capacity to meet the growing demand for such materials, as seen with the launch of new prepreg production lines and innovations in processing technologies.

Additionally, recent developments focus on the efforts of companies to innovate within the Tow Prepreg market. For instance, in March 2024, Hexcel Corporation launched its HexTow IM9 24K intermediate modulus carbon fiber, which enhances performance characteristics for industries requiring high-modulus materials, particularly in aerospace and defense applications. Meanwhile, in March 2021, a new prepreg slitting and rewinding unit was introduced for the National Institute for Aviation Research (NIAR) by a leading manufacturer, marking advancements in processing technologies that enable the development of higher-quality prepregs for various applications. Another significant development occurred in March 2020, when Roth Composite Machinery previewed new machinery for composite materials, including prepregs, at the JEC World event, showcasing innovations aimed at improving the efficiency and scalability of prepreg manufacturing. Furthermore, in March 2021, Jilin Chemical started its first 35K prepreg special large tow carbonization line, marking a significant step in expanding production capabilities for high-performance carbon fiber materials used in renewable energy applications. These advancements not only reinforce the increasing focus on enhancing product performance but also underscore the growing emphasis on optimizing production processes to meet the evolving needs of end-use industries.

Tow Prepreg Market Dynamics:

Drivers:

-

Growing Demand for Lightweight Materials in Aerospace and Automotive Sectors Fuels Tow Prepreg Market Growth

The aerospace and automotive industries are increasingly focusing on lightweight materials to enhance fuel efficiency and reduce emissions. Tow prepregs, known for their high strength-to-weight ratio, play a pivotal role in meeting these demands. Manufacturers are adopting advanced composite materials to achieve lighter designs without compromising structural integrity. In aerospace, the use of tow prepregs in aircraft components helps in reducing overall weight, leading to significant fuel savings and lower operational costs. Similarly, the automotive industry is integrating these materials into vehicle structures to improve performance and efficiency. The global push for sustainable practices and the growing regulatory pressure to reduce carbon footprints further accelerate the adoption of lightweight composites. As manufacturers in these sectors strive to innovate and stay competitive, the demand for tow prepregs is expected to continue rising, driving market growth.

-

Rising Applications of Tow Prepregs in Wind Energy Sector Boosts Market Growth

-

Increasing Investment in Research and Development of Composite Materials Encourages Tow Prepreg Market Growth

Investment into R&D focused on composite materials has led to an increase, hence stimulating tow prepreg market growth. Composite solution development from companies and institutions has been mainly based on ideas for innovative composite applications suited for the varied demand patterns in aerospace, automobile industries, and construction sectors, respectively. This R&D focus is helping develop the next generation of tow prepregs with properties such as enhanced thermal stability, improved impact resistance, and better environmental performance. Besides this, joint initiatives by manufacturers, universities, and research organizations are making possible technological breakthroughs in composites. As new and better formulations of tow prepreg become available, this will provide manufacturers with a choice and, thus propel the market further.

Restraint:

-

High Production Costs and Complexity in Manufacturing Tow Prepregs Limit Market Growth

The production of tow prepregs involves intricate manufacturing processes and specialized equipment, leading to high production costs. This complexity can deter smaller manufacturers from entering the market and limit the widespread adoption of tow prepregs in various applications. Additionally, the need for skilled labor and stringent quality control measures adds to the overall expense of production. While the benefits of tow prepregs are substantial, the initial investment required for equipment and technology can be a significant barrier for many companies. Furthermore, fluctuations in raw material prices can impact the cost structure of tow prepreg production, making it challenging for manufacturers to maintain competitive pricing. As a result, the high production costs associated with tow prepregs can restrict their market growth and adoption across different sectors.

Opportunity:

-

Advancements in Recycling Technologies for Composite Materials Create Opportunities for Tow Prepreg Market

-

Growing Trend of Customization in Manufacturing Processes Increases Demand for Tailored Tow Prepreg Solutions

The growing trend of customization in manufacturing processes is creating opportunities for tailored tow prepreg solutions. As industries seek to optimize their products for specific applications, the demand for customized tow prepregs that meet unique requirements is on the rise. Manufacturers are responding by developing specialized formulations and configurations of tow prepregs that cater to particular performance characteristics, such as enhanced thermal stability, flexibility, or strength. This customization not only allows companies to differentiate themselves in competitive markets but also meets the evolving needs of end-users. As more sectors recognize the benefits of utilizing tailored materials, the demand for customized tow prepregs is expected to grow, providing manufacturers with new avenues for expansion and innovation.

Impact of Digitalization on Tow Prepreg Production

|

Impact of Digitalization |

Description |

|---|---|

|

Enhanced Production Efficiency |

Automation and digital tools streamline manufacturing processes, leading to higher output rates and reduced production time. |

|

Improved Quality Control |

Advanced monitoring systems utilize real-time data analytics to detect defects early, ensuring higher quality products. |

|

Greater Customization Capabilities |

Digital technologies enable more flexible production systems, allowing for easier customization of Tow Prepreg to meet specific customer needs. |

|

Data-Driven Decision Making |

Analytics and machine learning help manufacturers analyze production data to optimize processes, forecast demand, and improve inventory management. |

|

Increased Supply Chain Transparency |

Digital platforms enhance visibility across the supply chain, improving collaboration and coordination among suppliers, manufacturers, and customers. |

Digitalization is revolutionizing Tow Prepreg production by introducing advanced technologies that enhance various aspects of the manufacturing process. Enhanced production efficiency is achieved through automation and digital tools that streamline operations, enabling higher output rates and reducing production times. Improved quality control is facilitated by real-time data analytics, which allows manufacturers to detect defects early, thereby ensuring higher product quality. Moreover, the integration of digital technologies offers greater customization capabilities, enabling manufacturers to adapt their Tow Prepreg products to specific customer requirements easily. Data-driven decision-making becomes possible as manufacturers leverage analytics and machine learning to optimize production processes, forecast demand, and enhance inventory management. Finally, increased supply chain transparency is another significant impact of digitalization, as digital platforms provide improved visibility, fostering better collaboration and coordination among suppliers, manufacturers, and customers. This transformation ultimately leads to more efficient, flexible, and responsive Tow Prepreg production processes.

Tow Prepreg Market Segments

By Resin Type

In 2023, the epoxy resin segment dominated the Tow Prepreg Market with a market share of approximately 55%. Epoxy resins are favored for their excellent mechanical properties, high adhesion, and durability, making them ideal for demanding applications in various industries. For instance, in the aerospace sector, epoxy-based tow prepregs are commonly used for structural components, where high strength and resistance to environmental factors are critical. Additionally, the automotive industry utilizes epoxy resins in the production of lightweight components that enhance fuel efficiency and performance. The versatility of epoxy resins in different processing methods, such as autoclave and out-of-autoclave curing, further solidifies their leading position in the market.

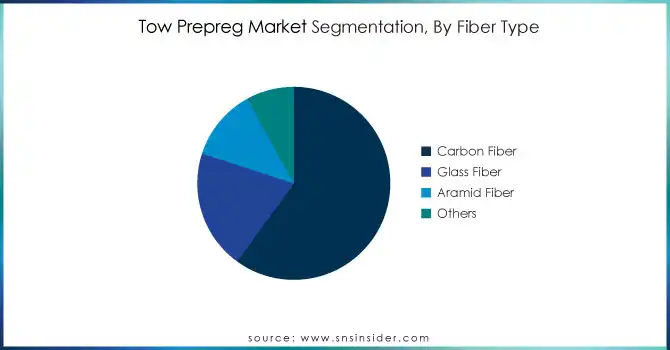

By Fiber Type

The carbon fiber segment dominated the Tow Prepreg Market in 2023, capturing a market share of around 60%. Carbon fibers are renowned for their superior strength-to-weight ratio, making them an ideal choice for high-performance applications across various sectors. For example, in the aerospace industry, carbon fiber tow prepregs are used extensively in the construction of aircraft components, such as wings and fuselage sections, where reducing weight while maintaining structural integrity is crucial. Furthermore, the automotive sector is increasingly adopting carbon fiber materials in vehicle designs to improve performance and fuel efficiency. This high demand in critical applications underscores the dominance of carbon fibers in the tow prepreg market.

By Application

In 2023, the pressure vessels segment dominated the Tow Prepreg Market, with a market share of approximately 45%. Pressure vessels, including tanks and cylinders used in various industries, benefit from the high strength and lightweight characteristics of tow prepregs. For instance, in the oil and gas sector, composite pressure vessels made from tow prepregs are used for storing and transporting gases safely and efficiently. Additionally, these materials are essential in the renewable energy sector for manufacturing high-performance components that withstand high pressures and temperatures. The growing demand for safe and efficient storage solutions in these industries drives the preference for tow prepregs in pressure vessel applications.

By End-use Industry

The aerospace and defense segment dominated the Tow Prepreg Market in 2023, accounting for a market share of approximately 50%. This industry relies heavily on advanced composite materials to achieve weight reduction and enhanced performance in aircraft and defense systems. For instance, tow prepregs are utilized in the construction of critical components such as wing structures, fuselage, and internal support structures, where high strength-to-weight ratios are essential for improving fuel efficiency and overall performance. Additionally, the increasing focus on developing lightweight and fuel-efficient aircraft has further fueled the demand for tow prepregs in the aerospace and defense sectors. The continued innovation and investment in this field reinforce the leading position of the aerospace and defense industry in the tow prepreg market.

Tow Prepreg Market Regional Analysis

In 2023, North America dominated the Tow Prepreg Market, with a market share of approximately 40%. The region’s strong performance can be attributed to the high demand for advanced composite materials in aerospace, automotive, and defense applications. The United States, in particular, played a significant role in driving this growth, as it is home to major aerospace companies like Boeing and Lockheed Martin, which extensively use tow prepregs in the production of aircraft components. The U.S. aerospace industry’s continuous push for fuel-efficient, lightweight, and high-performance materials has further contributed to the increasing adoption of tow prepregs. Additionally, the automotive sector in North America has been leveraging tow prepregs for manufacturing lightweight components, contributing to fuel efficiency and overall vehicle performance. The defense sector in the U.S. also uses these materials for producing advanced military equipment, such as aircraft and armored vehicles, where high strength and durability are essential. In Canada, the aerospace industry has similarly experienced growth in the use of tow prepregs, driven by the presence of key manufacturers and suppliers of composite materials. The growing emphasis on sustainability and energy efficiency in the region also pushes demand for these materials in various applications, making North America the dominant region in the market.

Moreover, Asia-Pacific emerged as the fastest-growing region in the Tow Prepreg Market in 2023, with a CAGR of around 8%. This growth is primarily driven by the expanding aerospace and automotive industries in countries like China, Japan, and South Korea. China, the largest player in the region, has been investing heavily in its domestic aerospace sector, increasing the demand for high-performance materials such as tow prepregs for aircraft manufacturing. The Chinese government’s support for the aviation sector and its ambitious goals for the production of both commercial and military aircraft have led to a surge in the use of advanced composite materials in the country. In Japan, leading companies such as Mitsubishi Heavy Industries have been incorporating tow prepregs into their manufacturing processes for aircraft components and automotive applications. South Korea’s aerospace industry is also expanding, with companies like Korea Aerospace Industries (KAI) making strides in the production of lightweight, high-strength materials. Additionally, the automotive sector in the Asia-Pacific region is adopting tow prepregs to reduce vehicle weight, improve fuel efficiency, and meet increasingly stringent environmental regulations. This combination of expanding aerospace and automotive sectors, along with the region’s ongoing investment in advanced technologies, positions Asia-Pacific as the fastest-growing region in the Tow Prepreg Market.

Get Customized Report as per your Business Requirement - Request For Customized Report

Recent Developments

-

March 2024: Hexcel launched HEXTOW IM9 24K intermediate modulus carbon fiber, offering higher tensile strength for aerospace and industrial applications, catering to the growing demand for advanced composite materials.

Key Players:

-

ARISAWA Mfg. Co., Ltd. (Carbon Tow Prepreg, Glass Fiber Prepreg)

-

Cytec Solvay Group (Cycom 5320-1, MTM45-1)

-

Gurit Holding AG (Gurit Prepreg, Sipprep)

-

Hexcel Corporation (HexTow Carbon Fiber Prepreg, HexPly Prepreg)

-

Huntsman Corporation (Araldite Prepreg, EPON Resin Prepreg)

-

Mitsubishi Chemical Holdings Corporation (Diane Prepreg, MR60 Prepreg)

-

JXTG Holdings, Inc. (JXTG Carbon Fiber Prepreg, JXTG Glass Fiber Prepreg)

-

Olin Corporation (Olin Tow Prepreg, Olin Fiber Prepreg)

-

Owens Corning (Owens Corning Prepreg, OC Flexwound Prepreg)

-

Porcher Industries (Porcher Prepreg, Polyester Prepreg)

-

Red Composites Ltd. (Red Tow Prepreg, RedFlex Prepreg)

-

SGL Carbon SE (SGL Carbon Prepreg, SGL Tow Prepreg)

-

Teijin Limited (Teijin Tow Prepreg, Tenax Prepreg)

-

TCR Composites, Inc. (TCR Prepreg, Carbon Prepreg)

-

Toray Industries, Inc. (Toray Prepreg, T700 Carbon Fiber Prepreg)

-

UMO Group (UMO Tow Prepreg, UMO Carbon Prepreg)

-

Zoltek Companies, Inc. (Zoltek Prepreg, Zoltek Carbon Fiber Prepreg)

-

Hexion Inc. (Hexion Resin Prepreg, Hexion Thermoset Prepreg)

-

BASF SE (BASF Prepreg, BASF Carbon Fiber Prepreg)

-

Solvay Group (Solvay Prepreg, MTM Prepreg)

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | US$ 534.6 Million |

| Market Size by 2032 | US$ 1526.0 Million |

| CAGR | CAGR of 12.4% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | •By Resin Type (Epoxy Resin, Phenolic Resin, BMI Resin (Bismaleimide), Polyimide Resin, Others) •By Fiber Type (Carbon Fiber, Glass Fiber, Aramid Fiber, Others) •By Application (Pressure Vessels, Scuba Tanks, Oxygen Cylinders, Others) •By End-use Industry (Aerospace & Defense, Automotive & Transportation, Sports & Recreational, Oil & Gas, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | TCR Composites, Inc., SGL Carbon SE, HEXCEL Corporation, VITECH COMPOSITES., ARISAWA Mfg. Co., Ltd., Mitsubishi Chemical Holdings Corporation, JXTG Holdings, Inc., Red Composites Ltd., Teijin Limited, Porcher Industries and other key players |

| Key Drivers | •Rising Applications of Tow Prepregs in Wind Energy Sector Boosts Market Growth •Increasing Investment in Research and Development of Composite Materials Encourages Tow Prepreg Market Growth |

| RESTRAINTS | •High Production Costs and Complexity in Manufacturing Tow Prepregs Limit Market Growth |