Vacuum Chamber O-ring Groove Machining Market Report Scope & Overview:

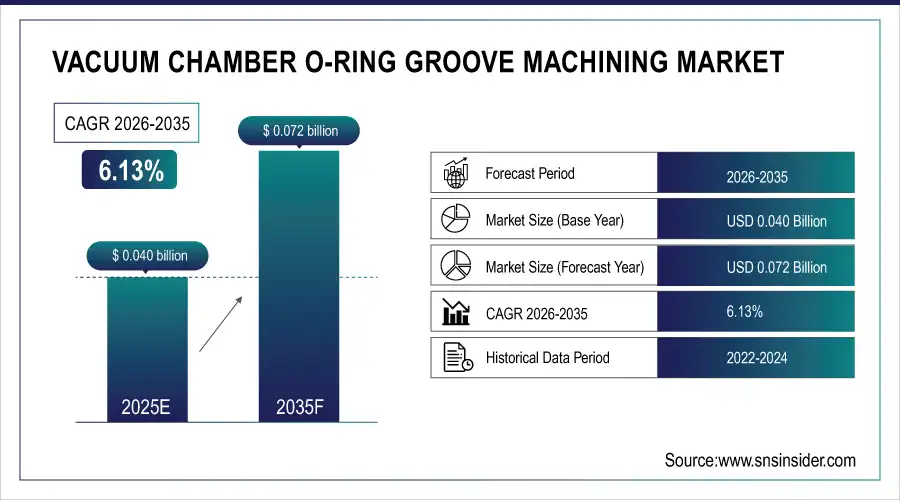

The Vacuum Chamber O-ring Groove Machining Market size was valued at USD 0.040 Billion in 2025 and is projected to reach USD 0.072 Billion by 2035, growing at a CAGR of 6.13% during 2026–2035.

The Vacuum Chamber O-ring Groove Machining market is evolving rapidly as advanced groove designs gain prominence in high-vacuum applications. Optimized O-ring retainers with dovetail grooves are improving seal stability, reducing deformation under repeated vacuum cycling, and extending component life. Innovations such as asymmetric cross-section and multi-layered O-rings are increasing the need for highly accurate, custom-machined grooves to ensure precise fitment. These developments are driving adoption of advanced CNC and simulation-assisted machining techniques. As manufacturers focus on reliability, cost reduction, and performance optimization, demand for precision groove machining continues to rise across semiconductor, electronics, and high-end industrial vacuum systems.

Researchers introduced an optimized O-ring retainer with dovetail grooves in 2025, reducing seal deformation by 25% under vacuum cycling via finite element analysis. Deep Rubber highlighted asymmetric cross-section O-rings and multi-layered designs, cutting operational costs by ₹50,000 per machine annually through better fitment in high-performance grooves.

Market Size and Growth Projection:

-

Market Size in 2025: USD 0.040 Billion

-

Market Size by 2035: USD 0.072 Billion

-

CAGR (2026–2035): 6.13%

-

Base Year: 2025

-

Forecast Period: 2026–2035

-

Historical Data: 2022–2024

To Get more information On Vacuum Chamber O-ring Groove Machining Market - Request Free Sample Report

Vacuum Chamber O-ring Groove Machining Market Highlights:

-

Increasing demand for high-precision O-ring grooves in semiconductor, aerospace, and industrial vacuum applications is driving market growth.

-

Adoption of self-lubricating and multi-layered O-rings is boosting the need for ultra-accurate machining and customized groove designs.

-

Growth of ultra-high-vacuum (UHV) systems is accelerating adoption of advanced groove machining solutions to ensure leak-free performance.

-

Rising investments in R&D and predictive maintenance technologies are creating opportunities for precision groove manufacturing.

-

Automation and CNC integration in machining processes are enhancing throughput, reducing errors, and lowering operational costs.

The U.S. Vacuum Chamber O-ring Groove Machining Market size was valued at USD 0.010 Billion in 2025 and is projected to reach USD 0.017 Billion by 2035, growing at a CAGR of 5.28% during 2026–2035, driven by expanding semiconductor fabrication, rising adoption of ultra-high-vacuum systems, and increasing demand for precision-engineered sealing solutions. Advancements in CNC machining, tighter tolerance requirements, and the shift toward advanced O-ring materials further boost demand. Additionally, investments in domestic chip manufacturing, aerospace, and research laboratories are accelerating the need for high-accuracy groove machining to ensure leak-free, reliable vacuum chamber performance.

Vacuum Chamber O-ring Groove Machining Market Drivers:

-

Increased Demand for High-Precision Vacuum Chamber O-Ring Groove Machining

Advancements in self-lubricating rubber materials are emerging as a key market driver for vacuum chamber O-ring groove machining. These next-generation materials, designed to reduce friction while maintaining sealing performance under low-lubrication conditions, require extremely precise groove dimensions and surface finishes. Any deviation in groove geometry can compromise sealing efficiency, vacuum integrity, and component lifespan. As semiconductor, electronics, and advanced manufacturing industries increasingly adopt such high-performance sealing solutions, demand rises for CNC-based, ultra-precision groove machining. This trend accelerates investments in advanced machining technologies to support reliability, process stability, and extended maintenance intervals.

In May 2024, NOK and Eneos jointly developed self-lubricating rubber, reducing friction in O-rings and seals by up to 40% while maintaining sealing performance, enabling more efficient vacuum and industrial applications.

Vacuum Chamber O-ring Groove Machining Market Restraints:

-

High Production Costs Limiting Expansion in Vacuum Chamber O-ring Groove Machining

The Vacuum Chamber O-ring Groove Machining market faces significant challenges due to high precision manufacturing costs, which limit adoption among small and medium-sized fabs and laboratories. Complex machining processes, stringent quality standards, and the need for advanced materials increase capital expenditure and operational costs. Additionally, skilled labor shortages and long production lead times constrain market growth. Fluctuating raw material prices and maintenance requirements for high-vacuum and ultra-high-vacuum systems further hinder profitability. These factors collectively slow market expansion despite rising demand from semiconductor, aerospace, and industrial sectors.

Vacuum Chamber O-ring Groove Machining Market Opportunities:

-

Rising Semiconductor Precision Demands Driving Growth in Vacuum Chamber O-ring Groove Machining

The increasing complexity of semiconductor and high-tech manufacturing processes is creating a significant growth opportunity for the Vacuum Chamber O-ring Groove Machining market. As fabs and advanced research facilities demand ultra-clean, contamination-free vacuum environments, precision O-ring grooves become critical for maintaining optimal vacuum performance and system reliability. Rising adoption of high-vacuum and ultra-high-vacuum chambers, coupled with the need for seamless integration with predictive maintenance and process optimization systems, drives demand. Manufacturers offering advanced, high-precision machining solutions can capitalize on this trend, enabling improved fab uptime, reduced operational costs, and enhanced overall process efficiency.

In Dec 2025 – Pfeiffer Vacuum+Fab Solutions showcased its semiconductor vacuum portfolio, including the UltiDry pump and ARGOS predictive maintenance, at SEMICON Europa 2025 in Munich, enhancing fab uptime and process efficiency

Vacuum Chamber O-ring Groove Machining Market Segment Highlights:

-

By Material Type: Dominant – Elastomer O-rings (71.30% → 65.70%); Fastest-Growing – Metallic O-rings (28.70% → 34.30%, CAGR 8.25%)

-

By Chamber Type: Dominant – High Vacuum Chambers (67.40% → 62.60%); Fastest-Growing – Ultra-High Vacuum (UHV) Chambers (32.60% → 37.40%, CAGR 7.59%)

-

By End-Use Industry: Dominant – Semiconductor & Electronics Manufacturing (42.40% → 45.60%); Fastest-Growing – Semiconductor & Electronics Manufacturing (CAGR 6.90%)

-

By Machining Type: Dominant – CNC Precision Milling (61.50% → 57.50%); Fastest-Growing – Laser or EDM Machining (23.40% → 26.60%, CAGR 7.49%)

By Material Type: Elastomer O-rings Dominating and Metallic O-rings Fastest-Growing

Elastomer O-rings remain the dominant segment in the Vacuum Chamber O-ring Groove Machining market, driven by high demand from semiconductor, electronics, and industrial applications for flexible, reliable sealing solutions. Metallic O-rings are the fastest-growing segment, supported by rising adoption in high-temperature, high-vacuum, and advanced precision manufacturing environments.

By Chamber Type: High Vacuum Chambers Dominating and Ultra-High Vacuum (UHV) Chambers Fastest-Growing

High Vacuum Chambers remain the dominant segment in the Vacuum Chamber O-ring Groove Machining market, driven by widespread use in semiconductor, aerospace, and industrial applications requiring reliable vacuum performance. Ultra-High Vacuum (UHV) Chambers are the fastest-growing segment, supported by increasing adoption in advanced research, high-precision fabrication, and next-generation semiconductor manufacturing.

By End-Use Industry: Semiconductor & Electronics Manufacturing Dominating and Fastest-Growing

Semiconductor & Electronics Manufacturing remains both the dominant and fastest-growing end-use segment in the Vacuum Chamber O-ring Groove Machining market, fueled by rapid expansion of semiconductor fabs, electronics production, and high-precision manufacturing, driving consistent demand for advanced vacuum chamber sealing and machining solutions.

By Machining Type: CNC Precision Milling Dominating and Laser/EDM Machining Fastest-Growing

CNC Precision Milling continues to dominate the Vacuum Chamber O-ring Groove Machining market due to its high accuracy and wide industrial adoption. Laser and EDM Machining are the fastest-growing segment, driven by rising demand for complex geometries, high-precision features, and faster production in semiconductor and aerospace applications.

Vacuum Chamber O-ring Groove Machining Market Regional Highlights:

-

North America: 37.70% → 35.30% in 2035, Leading Share in 2025 with Gradual Decline (CAGR 5.43%)

-

Asia-Pacific: 30.50% → 34.50% in 2035, Fastest-Growing Region and Rising Dominance (CAGR 7.44%)

-

Europe: 24.80% → 23.20% in 2035, Moderate Share with Slow Decline (CAGR 5.42%)

-

Latin America: 4.90% → 4.10% in 2035, Small Share with Moderate Decline (CAGR 4.24%)

-

Middle East & Africa: 2.10% → 2.90% in 2035, Emerging Region with Rapid Growth (CAGR 9.55%)

North America Vacuum Chamber O-ring Groove Machining Market Insights:

The North America Vacuum Chamber O-ring Groove Machining market dominates globally, driven by advanced semiconductor, aerospace, and industrial manufacturing sectors. Strong technological infrastructure, high adoption of precision vacuum systems, and ongoing R&D investments contribute to market leadership, while gradual regional growth reflects maturity and continued demand for high-performance, reliable vacuum solutions.

Get Customized Report as per Your Business Requirement - Enquiry Now

U.S. Vacuum Chamber O-ring Groove Machining Market Insights:

The U.S. leads the North America Vacuum Chamber O-ring Groove Machining market, driven by advanced semiconductor, aerospace, and industrial sectors, robust R&D, precision manufacturing adoption, and strong technological infrastructure.

Asia-Pacific Vacuum Chamber O-ring Groove Machining Market Insights:

The Asia-Pacific Vacuum Chamber O-ring Groove Machining market is experiencing robust growth, fueled by expanding semiconductor, electronics, and industrial manufacturing sectors. Rising investments in advanced vacuum technologies, government initiatives, and increasing adoption of precision machining solutions are driving market expansion, positioning the region as the fastest-growing and emerging hub globally.

China Vacuum Chamber O-ring Groove Machining Market Insights:

The China Vacuum Chamber O-ring Groove Machining market is expanding steadily, driven by growing semiconductor, electronics, and industrial manufacturing sectors, increasing investments in precision vacuum technologies, and rising adoption of advanced machining solutions.

Europe Vacuum Chamber O-ring Groove Machining Market Insights:

The Europe Vacuum Chamber O-ring Groove Machining market is growing moderately, supported by steady demand in semiconductor, aerospace, and industrial sectors. Technological advancements, ongoing R&D, and adoption of precision vacuum systems contribute to consistent market expansion, while mature infrastructure and regulatory frameworks shape stable growth across the region.

Germany Vacuum Chamber O-ring Groove Machining Market Insights:

Germany’s Vacuum Chamber O-ring Groove Machining market is expanding steadily, driven by strong industrial manufacturing, semiconductor, and aerospace sectors, along with technological advancements, precision machining adoption, and ongoing research and development initiatives.

Latin America Vacuum Chamber O-ring Groove Machining Market Insights:

The Latin America Vacuum Chamber O-ring Groove Machining market is witnessing steady growth, driven by increasing industrial automation, adoption of precision manufacturing technologies, and rising demand from semiconductor, aerospace, and electronics sectors. Strategic investments and gradual technological upgrades across the region are supporting consistent market expansion.

Brazil Vacuum Chamber O-ring Groove Machining Market Insights:

Brazil is the dominant country in the Vacuum Chamber O-ring Groove Machining market, driven by strong industrial, aerospace, and electronics sectors, increasing adoption of precision manufacturing, and growing investments in advanced vacuum technologies.

Middle East & Africa (MEA) Vacuum Chamber O-ring Groove Machining Market Insights:

The Middle East & Africa Vacuum Chamber O-ring Groove Machining market is growing gradually, fueled by increasing industrialization, rising investments in semiconductor and aerospace sectors, and adoption of precision vacuum technologies. Emerging economies and infrastructure development are driving steady demand, positioning the region as a promising market for future expansion.

Saudi Arabia Vacuum Chamber O-ring Groove Machining Market Insights:

Saudi Arabia is the dominant country in the Middle East & Africa (MEA) Vacuum Chamber O-ring Groove Machining market, driven by industrial development, semiconductor investments, and adoption of advanced manufacturing technologies.

Vacuum Chamber O-ring Groove Machining Market Competitive Landscape:

Pfeiffer Vacuum, established in 1890, is a global leader in vacuum technology, providing vacuum pumps, leak detectors, contamination management, and gas abatement solutions for semiconductor, industrial, and research applications. Known for innovation and reliability, Pfeiffer serves advanced manufacturing markets worldwide, supporting high-performance and energy-efficient vacuum systems.

-

In July 2025, Pfeiffer Vacuum+Fab Solutions showcased UltiDry vacuum pumps, gas abatement, and leak detection at SEMICON India 2025, supporting India’s semiconductor growth. They also introduced predictive maintenance (ARGOS) and expanded solutions at SEMICON Southeast Asia, Europa, and Korea 2025.

ULVAC, Inc., established in 1952, is a global leader in vacuum and thin-film technologies, providing deposition, etching, and vacuum equipment for semiconductor, MEMS, and industrial applications. The company drives innovation in advanced electronics, supporting sustainable, high-precision manufacturing solutions worldwide through equipment, services, and collaborative R&D projects.

-

June 2025 – ULVAC, Inc. continues participation in the "Lab-in-Fab" project to advance piezoMEMS technology, providing deposition and etching solutions for commercialization. The collaboration with STMicroelectronics, ASTAR, and NUS aims to develop environmentally friendly, cost-effective sensors and actuators for next-generation devices.

Vacuum Chamber O-ring Groove Machining Companies are:

-

Moorfield Nanotechnology Limited

-

MKS Instruments, Inc.

-

Leybold GmbH

-

Pfeiffer Vacuum Technology AG

-

ULVAC, Inc.

-

Plasmionic Technologies

-

Kurt J. Lesker Company

-

Huntington Mechanical Laboratories, Inc.

-

Evans Vacuum Engineering

-

VAT Group AG

-

Advanced Vacuum Company

-

Thermionics Vacuum Products

-

LACO Technologies

-

RANVAC Technologies

-

Atlas Technologies (Enhanced Vacuum Technology)

-

GPR Company, Inc.

-

Schmalz GmbH

-

INFICON

| Report Attributes | Details |

|---|---|

| Market Size in 2025 | USD 0.040 Billion |

| Market Size by 2035 | USD 0.072 Billion |

| CAGR | CAGR of 6.13% From 2026 to 2035 |

| Base Year | 2025 |

| Forecast Period | 2026-2035 |

| Historical Data | 2022-2024 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Material Type(Elastomer O-rings and Metallic O-rings) • By Chamber Type(High Vacuum Chambers and Ultra-High Vacuum (UHV) Chambers) • By End Use Industry(Semiconductor & Electronics Manufacturing, Aerospace & Defense, Research & Laboratories and Pharmaceutical & Chemical Processing) • By Machining Type (CNC Precision Milling, Laser or EDM Machining and Conventional Milling / Turning) |

| Regional Analysis/Coverage | North America (US, Canada), Europe (Germany, UK, France, Italy, Spain, Russia, Poland, Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Australia, ASEAN Countries, Rest of Asia Pacific), Middle East & Africa (UAE, Saudi Arabia, Qatar, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Mexico, Colombia, Rest of Latin America). |

| Company Profiles | Applied Vacuum Engineering, Moorfield Nanotechnology Limited, MKS Instruments, Inc., Leybold GmbH, Pfeiffer Vacuum Technology AG, Angstrom Sciences, Inc., ULVAC, Inc., Plasmionic Technologies, Kurt J. Lesker Company, Huntington Mechanical Laboratories, Inc., Evans Vacuum Engineering, VAT Group AG, Advanced Vacuum Company, Thermionics Vacuum Products, LACO Technologies, RANVAC Technologies, Atlas Technologies (Enhanced Vacuum Technology), GPR Company, Inc., Schmalz GmbH, INFICON. |