AI In Packaging Market Report Scope And Overview:

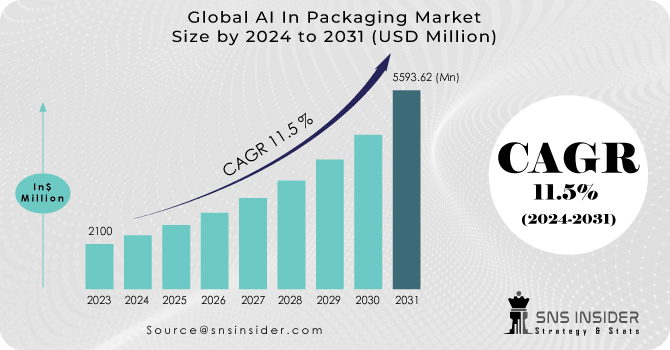

The AI In Packaging Market Size was valued at USD 2100 million in 2023 and is expected to reach USD 5593.62 million by 2031 and grow at a CAGR of 11.5 % over the forecast period 2024-2031.

The surging demand for intelligent and sustainable packaging, coupled with a heightened emphasis on environmental considerations, has created fertile ground for AI-driven innovations. Artificial intelligence emerges as a pivotal catalyst in shaping intelligent packaging solutions that not only meet these demands but also elevate overall product safety, traceability, and consumer engagement. AI applications in packaging offer a range of functions. Active monitoring systems, driven by AI algorithms, oversee factors such as temperature and humidity to maintain ideal storage conditions for sensitive products. Temperature-sensitive labels, another AI-driven innovation, enable precise temperature tracking throughout the supply chain, particularly valuable for maintaining the quality of items like pharmaceuticals and perishable goods.

Get More Information on AI In Packaging Market - Request Sample Report

Looking towards the future, the trajectory of the AI in packaging market appears promising from 2023 to 2032. The continuous adoption of AI is anticipated as businesses recognize its intrinsic value in transforming the packaging landscape. Forecasts indicate an intensified impact of AI on quality control, leveraging integrated technologies like computer vision and machine learning for more precise and efficient inspection processes. Furthermore, AI's role in supply chain management is positioned to expand, optimizing inventory, forecasting demand, and refining logistics. Through data analysis, AI algorithms will empower companies with actionable insights, enabling informed decision-making and operational streamlining.

MARKET DYNAMICS

KEY DRIVERS:

-

Quality assurance through computer vision

Sophisticated computer vision algorithms have the capability to swiftly and precisely detect product defects, guaranteeing a uniform standard of quality and diminishing the necessity for manual inspections.

-

Growing demand for personalized and sustainable packaging solutions.

RESTRAIN:

-

High implementation costs pose a significant barrier, especially for smaller enterprises.

The initial investment required for integrating AI technologies into packaging processes can be significant. This financial barrier may hinder smaller companies from adopting AI in packaging.

-

Data privacy and security concerns, stemming from the extensive data AI systems require and the challenges of integrating AI into existing infrastructures, pose significant hurdles.

OPPORTUNITY:

-

AI technologies allow for advanced quality control, offering the chance to improve product quality by swiftly identifying defects and maintaining consistency in manufacturing processes.

-

Virtual reality is set to become a common feature in the customer experience and packaging design of numerous companies.

As interactive VR headsets, such as the Oculus Rift and HTC Vive, become increasingly cost-effective, smaller businesses are gaining access to immersive virtual reality experiences.

CHALLENGES:

-

Adhering to evolving regulations and standards related to AI and packaging poses a challenge.

Impact of Russia Ukraine War

The packaging industry, notably in Ukraine, has been profoundly affected by the Russia-Ukraine war, disrupting a sector that played a vital role in the global packaging supply chain. Ukraine, previously recognized for its substantial production of PET beverage bottles, transport packaging, and glass bottles, leveraging rich natural resources like timber and metals, is now grappling with the severe consequences of the conflict. The invasion has caused a virtual standstill in Ukraine's packaging sector, exemplified by the challenges faced by companies such as PACK TECHNOLOGY Ukraine. Logistical hurdles and operational standstills have become acute issues due to the occupation and blockade of cities.

The conflict has triggered extensive closures of packaging and production facilities in both Ukraine and Russia. Martial law imposition in Ukraine has compelled numerous establishments, including major players like Karpatneftekhim (the country's largest PET plant), to halt operations. Vetropack, a significant glass packaging provider, faced operational halts and sent employees home due to severe facility damage. Supply chain disruptions, infrastructure damage, and the mass departure of businesses and labour from conflict zones have exacerbated an already challenging situation for the packaging industry, resulting in a complex operating environment post-conflict.

Impact of Economic Slowdown

The current economic slowdown has exerted a notable impact on the AI in packaging market across several dimensions. Firstly, the downturn has led to delayed investments as companies, amid financial uncertainty, adopt a cautious approach towards spending. This caution affects the willingness of businesses to invest in cutting-edge technologies like AI, resulting in the postponement or scaling back of projects related to the integration of AI in the packaging sector.

Additionally, budget constraints arising from the economic downturn compel companies to prioritize essential operations over investments in advanced technologies. The financial limitations hinder the allocation of funds specifically earmarked for AI in packaging, and smaller businesses may face particular challenges in securing resources for technological advancements. Maintain core operations while carefully integrating AI technologies. For example, IBM's strategic emphasis on AI and cloud computing has played a pivotal role in stabilizing its business model amidst market fluctuations.

Furthermore, economic uncertainties contribute to a slower rate of adoption of AI in packaging. Businesses, wary of perceived risks and costs associated with implementing AI solutions in their packaging processes, exhibit hesitancy in embracing these innovative technologies during periods of economic instability.

The shift in consumer spending habits is another significant consequence of the economic slowdown. Changes in consumer priorities and reduced disposable income can influence product demand and, consequently, impact packaging requirements. Brands are prompted to reevaluate their packaging strategies to align with altered consumer preferences and purchasing behaviours, reflecting an adaptation to the evolving economic landscape.

KEY MARKET SEGMENTS

By Technology Type

-

Computer Vision

-

Predictive Analytics

-

Machine Learning

-

Natural Language Processing

Machine learning dominates the market with share 42.8%. Machine learning models play a crucial role in facilitating efficient quality control and supply chain optimization within the packaging industry. Packaging firms are anticipated to predict equipment breakdowns or maintenance needs through the application of machine learning.

By Application

-

Supply Chain Optimization

-

Quality Control and Inspection

-

Smart Packaging

-

Packaging Design and Customization

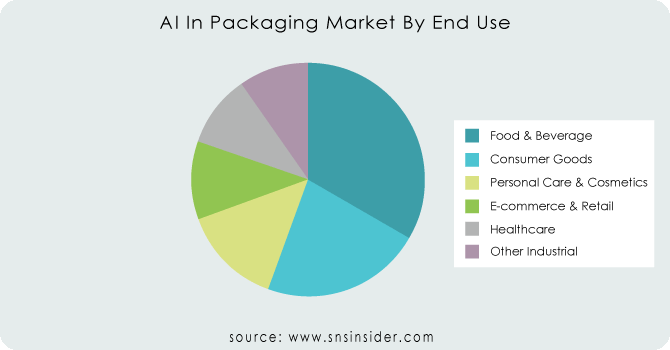

By End Use

-

Personal Care & Cosmetics

-

Food & Beverage

-

Consumer Goods

-

Healthcare

-

Other Industrial

-

E-commerce & Retail

The prevalence of quality control and inspection applications remains dominant in the industry. AI-supported quality control methods are diminishing error risks and enhancing process efficiency. AI technologies enable real-time monitoring of packaging operations, providing continuous feedback on both the final product's quality and the process's efficiency.

Get Customized Report as per Your Business Requirement - Request For Customized Report

REGIONAL ANALYSIS

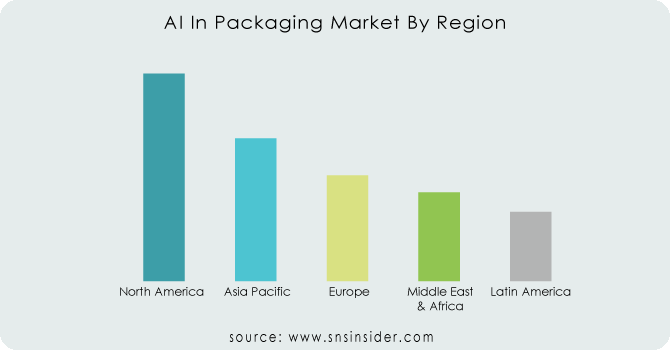

North America stands as a frontrunner, projecting dominance in the global market. The region's sustained economic growth, coupled with a robust technological infrastructure, fosters an environment conducive to the adoption of AI in packaging. The rising prevalence of AI technologies within the packaging industry, driven by a penchant for innovation, positions North America as a key contributor to the market's expansion.

In Europe, the AI in packaging market is influenced by a strong emphasis on sustainability and stringent regulations. The region's commitment to eco-friendly practices and circular economy models shapes innovations in packaging materials, driving the integration of AI to optimize sustainability efforts. European countries, with their mature economies, are at the forefront of leveraging AI for packaging solutions, aligning with evolving consumer expectations.

Asia-Pacific emerges as a significant growth hub, propelled by rapid urbanization, a burgeoning e-commerce sector, and a proactive approach towards technological adoption. Countries like China, Japan, and South Korea are witnessing increased integration of AI in packaging operations, driven by the need for efficiency and the rising demand for personalized and sustainable packaging solutions.

In developing regions, the adoption of AI in packaging is influenced by economic considerations, technological readiness, and the pace of industrialization. Latin America and the Middle East & Africa showcase potential growth as industries explore opportunities to enhance efficiency and competitiveness through AI-driven packaging solutions.

REGIONAL COVERAGE:

North America

-

US

-

Canada

-

Mexico

Europe

-

Eastern Europe

-

Poland

-

Romania

-

Hungary

-

Turkey

-

Rest of Eastern Europe

-

-

Western Europe

-

Germany

-

France

-

UK

-

Italy

-

Spain

-

Netherlands

-

Switzerland

-

Austria

-

Rest of Western Europe

-

Asia Pacific

-

China

-

India

-

Japan

-

South Korea

-

Vietnam

-

Singapore

-

Australia

-

Rest of Asia Pacific

Middle East & Africa

-

Middle East

-

UAE

-

Egypt

-

Saudi Arabia

-

Qatar

-

Rest of Middle East

-

-

Africa

-

Nigeria

-

South Africa

-

Rest of Africa

-

Latin America

-

Brazil

-

Argentina

-

Colombia

-

Rest of Latin America

Key players

Some of the major players in the AI In Packaging Market are SteriPack Group, West Rock Company, Constantia Flexibles GmbH, Uflex Ltd, ACG Pharmapack Pvt. Ltd, Winpak Ltd, Amcor plc, Klockner Pentaplast Group, Sonoco Products Company, Honeywell International, Inc., Berry Global and other players.

SteriPack Group - Company Financial Analysis

RECENT TRENDS

-

ABB Robotics and Zume entered into a cooperation agreement in November 2021. ABB supplies Zume with the world's constant packaging production, which reduces its dependence on traditional plastics.

-

The Sea Vision Group is launching its newest technology using AI to optimize packaging solutions.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | US$ 2100 Million |

| Market Size by 2031 | US$ 5593.62 Million |

| CAGR | CAGR of 11.5 % From 2024 to 2031 |

| Base Year | 2023 |

| Forecast Period | 2024-2031 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Technology Type (Computer Vision, Predictive Analytics, Machine Learning, Natural Language Processing) • By Application (Supply Chain Optimization, Quality Control And Inspection, Smart Packaging, Packaging Design And Customization) • By End Use (Personal Care & Cosmetics, Food & Beverage, Consumer Goods, Healthcare, Other Industrial, E-Commerce & Retail) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | SteriPack Group, West Rock Company, Constantia Flexibles GmbH, Uflex Ltd, ACG Pharmapack Pvt. Ltd, Winpak Ltd, Amcor plc, Klockner Pentaplast Group, Sonoco Products Company, Honeywell International, Inc., Berry Global |

| Key Drivers | • Quality assurance through computer vision • Growing demand for personalized and sustainable packaging solutions. |

| Opportunities | • AI technologies allow for advanced quality control, offering the chance to improve product quality by swiftly identifying defects and maintaining consistency in manufacturing processes. • Virtual reality is set to become a common feature in the customer experience and packaging design of numerous companies. |