Automotive Carbon Brush Market Report Scope & Overview:

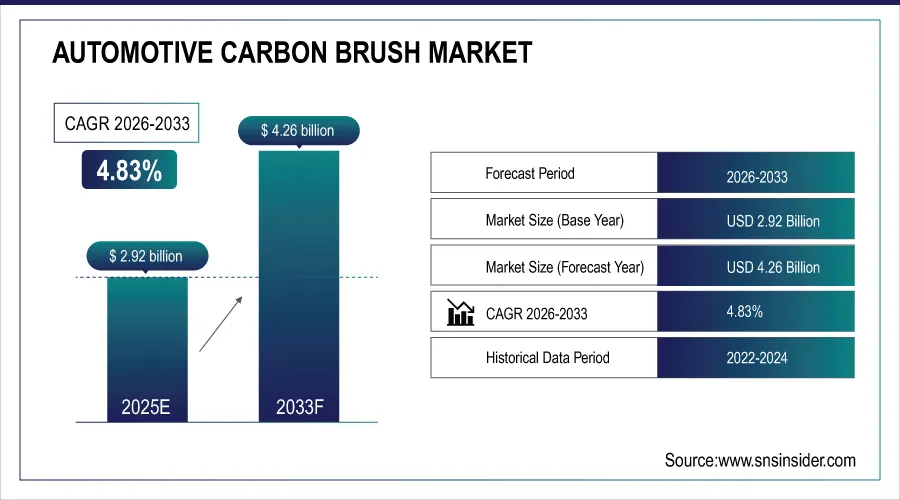

The Automotive Carbon Brush Market size was valued at USD 2.92 Billion in 2025E and is projected to reach USD 4.26 Billion by 2033, growing at a CAGR of 4.83% during 2026–2033.

To Get more information on Automotive Carbon Brush Market - Request Free Sample Report

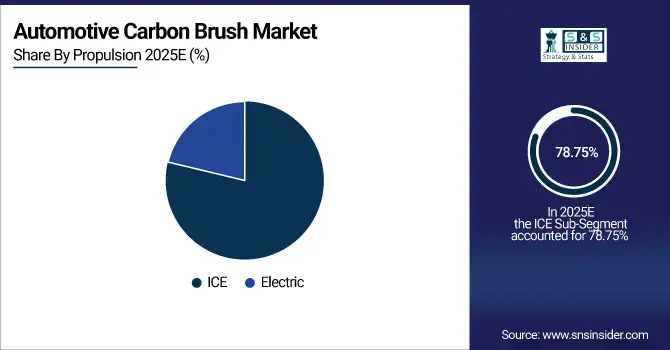

The automotive carbon brush market is experiencing steady growth, driven by rising demand for electric and hybrid vehicles, increasing automotive production, and the need for high-performance motor components. Key applications such as Safety and Chassis Electronic Systems dominate the market due to their critical role in vehicle stability, while Body Electronic Systems show the fastest growth. Electrographite remains the preferred brush grade, with Silver Graphite emerging rapidly due to efficiency demands. SUVs lead vehicle types, and ICE vehicles currently dominate propulsion, though electric vehicles are expanding quickly. Technological innovations and durable, eco-friendly designs continue to enhance motor reliability and performance.

Morgan Advanced Materials has launched the National™ S22 silver carbon brush, a high-performance, cost-effective solution designed for wind turbines, enhancing brush and slip ring longevity while reducing maintenance and operational costs. This innovative brush supports sustainable energy growth and opens new market opportunities with scalable material advancements for future carbon brush developments.

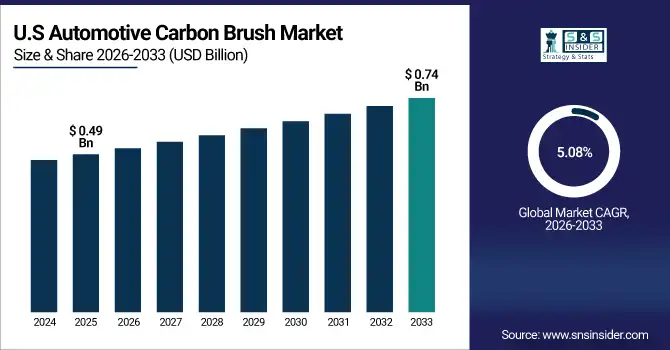

The U.S. Automotive Carbon Brush Market size was valued at USD 0.49 Billion in 2025E and is projected to reach USD 0.74 Billion by 2033, growing at a CAGR of 5.08% during 2026–2033. Growth is fueled by rising demand for electric and hybrid vehicles, increasing integration of advanced electronic systems, and continuous innovations in carbon brush materials that improve efficiency, durability, and cost-effectiveness across automotive applications.

Automotive Carbon Brush Market Size and Forecast:

-

Market Size in 2025 USD 2.92 Billion

-

Market Size by 2032 USD 4.26 Billion

-

CAGR of 4.83% from 2026 to 2033

-

Base Year 2025E

-

Forecast Period 2026-2033

-

Historical Data 2022-2024

Automotive Carbon Brush Market Highlights:

-

Rising demand for durable and high-performance carbon brushes driven by automotive electrification and industrial automation.

-

Advanced brush materials and holder systems enhance power transmission, reduce wear, and extend maintenance intervals.

-

High manufacturing costs and raw material supply constraints limit adoption, especially in cost-sensitive segments.

-

Shift toward brushless motors and alternative propulsion technologies reduces dependency on traditional carbon brushes.

-

Stringent environmental and safety regulations increase compliance costs, impacting production and pricing.

-

Growing demand for material substitutes like graphite, electrographite, and silver composites creates new market opportunities.

Automotive Carbon Brush Market Drivers:

-

Rising Demand for Durable and High-Performance Carbon Brushes

The increasing adoption of renewable energy, particularly wind power, is driving demand for durable and high-performance carbon brushes in automotive and industrial applications. Companies like Schunk are developing advanced brush materials and holder systems that ensure reliable power transmission, low wear, and extended maintenance intervals, even under extreme environmental conditions. This innovation supports OEMs in optimizing efficiency and reducing operational costs. As automotive electrification and industrial automation expand, the need for robust, long-lasting carbon brushes grows, positioning advanced material technology as a key driver of market growth in the global automotive carbon brush sector.

In 2024, Schunk Carbon Technology highlighted its advanced carbon brushes and brush holder systems for wind turbines, offering high efficiency, low wear, and long maintenance intervals even under extreme environmental conditions. These solutions optimize power transmission in onshore and offshore generators, supporting OEMs with both standard and customized applications.

Automotive Carbon Brush Market Restraints:

-

High carbon and composite costs limit adoption, slowing market growth.

The automotive carbon brush market faces challenges that could hinder growth despite rising demand. High manufacturing costs for advanced carbon and composite materials limit adoption in cost-sensitive segments. Additionally, the increasing shift toward brushless motors and alternative propulsion technologies reduces dependency on traditional carbon brushes in certain automotive applications. Supply chain disruptions for raw materials such as high-purity graphite and silver can affect production continuity and pricing. Furthermore, stringent environmental and safety regulations require manufacturers to invest in compliance, increasing operational costs. These factors collectively act as restraints, potentially slowing market expansion despite growing EV and industrial motor applications.

Automotive Carbon Brush Market Opportunities:

-

Automotive Carbon Brush Market Trends Driven by Material Substitutes

Restrictions on carbon fiber usage in vehicles are driving demand for alternative materials in automotive applications. Safety concerns from conductive dust and disposal issues push automakers to adopt high-performance, durable, and compliant solutions. This trend encourages the use of graphite, electrographite, and silver composite brushes, which offer reliable electrical conductivity and extended service life. Companies developing cost-effective and efficient carbon brush technologies can meet evolving automotive and industrial requirements, ensuring consistent motor and generator performance while addressing regulatory and operational challenges associated with traditional carbon fiber components.

In April 2025, the European Union proposed classifying carbon fiber as a hazardous material under the End-of-Life Vehicles Directive, potentially limiting its use in new cars by 2029. This move, aimed at addressing disposal and safety concerns from conductive carbon dust, could impact automotive carbon fiber applications, particularly in EVs and high-performance vehicles, affecting manufacturers and suppliers globally.

Automotive Carbon Brush Market Segment Highlights:

-

By Application: Dominant – Safety and Chassis Electronic System: 49.25% in 2025E, Fastest-growing – Body Electronic System: 6.29% CAGR

-

By Brush Grade: Dominant – Electrographite: 34.63% in 2025E, Fastest-growing – Silver Graphite: 9.40% CAGR

-

By Vehicle Type: Dominant – SUVs: 39.75% in 2025E, Fastest-growing – HCV: 9.79% CAGR

-

By Propulsion: Dominant – ICE vehicles: 78.75% in 2025E, Fastest-growing – Electric vehicles: 8.78% CAGR

Automotive Carbon Brush Market Segment Analysis:

By Application, Safety and Chassis Systems Lead as Body Electronics Accelerate Growth

The Safety and Chassis Electronic System segment dominates, reflecting its critical role in vehicle stability and safety. Meanwhile, the Body Electronic System is the fastest-growing segment, driven by increasing demand for advanced comfort, convenience, and smart vehicle features.

By Brush Grade, Electrographite Dominates While Silver Graphite Gains Momentum

Electrographite holds a dominant position, widely preferred for its excellent conductivity and durability. Meanwhile, Silver Graphite is gaining momentum as the fastest-growing brush grade, driven by increasing demand for high-performance motors and enhanced electrical efficiency in electric and hybrid vehicles.

By Vehicle Type, SUVs Lead as HCVs Drive Fastest Growth

SUVs dominate the vehicle type segment, reflecting their widespread adoption and demand in both personal and commercial transportation. Meanwhile, Heavy Commercial Vehicles (HCVs) are the fastest-growing segment, driven by increasing logistics, transportation needs, and the expansion of commercial fleets requiring durable, high-performance motor components.

By Propulsion, ICE Vehicles Dominate as Electric Vehicles Accelerate Growth

ICE vehicles dominate the propulsion segment, reflecting their continued prevalence in global transportation. Meanwhile, electric vehicles are the fastest-growing segment, driven by increasing adoption of EVs, government incentives, and the demand for high-performance, efficient motor components in the rapidly expanding electric mobility sector.

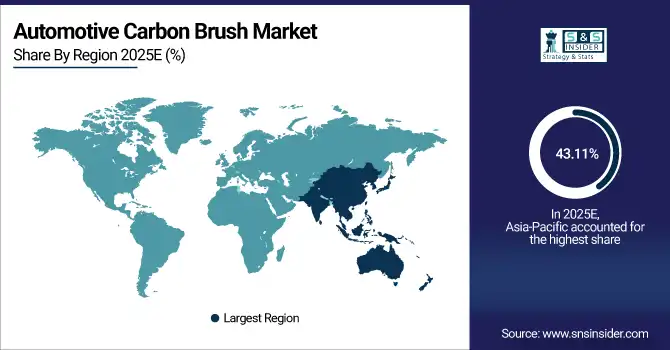

Automotive Carbon Brush Market Regional Highlights:

-

By Region – Dominating: Asia-Pacific (43.11% in 2025E → 41.04% in 2033, CAGR 5.27%)

-

Fastest-Growing Region: North America (25.55% in 2025E → 27.96% in 2033, CAGR 7.12%)

-

Europe: 20.44% → 21.97% (CAGR 6.88%)

-

South America: 6.00% → 5.02% (CAGR 3.55%, declining)

-

Middle East & Africa: 4.89% → 4.02% (CAGR 3.32%, declining)

Automotive Carbon Brush Market Regional Analysis:

Asia-Pacific Automotive Carbon Brush Market Trends:

The Asia-Pacific automotive carbon brush market is experiencing dominant growth, driven by rising electric vehicle adoption, expanding automotive production, and increased industrial automation. Key trends include advanced carbon materials, eco-friendly brushes, and high-performance designs for EV motors. Rapid urbanization and supportive government policies further fuel demand across the region.

Get Customized Report as per Your Business Requirement - Enquiry Now

-

China Automotive Carbon Brush Market Insights:

China dominates the Asia-Pacific automotive carbon brush market, driven by its large-scale automotive manufacturing industry and rapid adoption of electric vehicles. Strong government support for EV infrastructure, combined with growing demand for high-performance automotive components, has positioned China as the leading market in the region, fueling innovation and expansion in carbon brush production and technology.

North America Automotive Carbon Brush Market Trends:

The North America automotive carbon brush market is experiencing fastest growing, driven by increasing electric vehicle adoption, technological advancements in automotive electronics, and rising demand for high-performance motors. Key trends include the development of durable, low-resistance carbon brushes, eco-friendly materials, and innovative designs that enhance motor efficiency, reliability, and lifespan across passenger and commercial vehicle applications.

-

U.S Automotive Carbon Brush Market Insights:

The United States is dominating the North America automotive carbon brush market, driven by its advanced automotive manufacturing sector, rapid adoption of electric and hybrid vehicles, and strong R&D focus on high-performance automotive components.

Europe Automotive Carbon Brush Market Trends:

The Europe automotive carbon brush market is experiencing steady growth, driven by the increasing adoption of electric and hybrid vehicles, stringent emission regulations, and advancements in automotive electronics. Key trends include the use of high-performance, durable carbon materials, eco-friendly brush designs, and innovations that enhance motor efficiency and reliability across passenger and commercial vehicles.

-

Germany Automotive Carbon Brush Market Insights:

Germany is dominating the European automotive carbon brush market, driven by its strong automotive manufacturing industry, advanced electric vehicle adoption, and continuous innovation in high-performance automotive components.

Latin America Automotive Carbon Brush Market Trends:

The Latin America automotive carbon brush market is an emerging market, driven by increasing automotive production, rising adoption of electric and hybrid vehicles, and growing demand for durable, high-performance motor components. Key trends include the use of advanced carbon materials, eco-friendly brushes, and innovative designs that enhance motor efficiency, reliability, and lifespan across passenger and commercial vehicle applications.

-

Brazil Automotive Carbon Brush Market Insights:

Brazil is dominating the Latin America automotive carbon brush market, driven by its large automotive manufacturing sector, increasing electric and hybrid vehicle adoption, and rising demand for high-performance automotive components.

Middle East & Africa Automotive Carbon Brush Market Trends:

The Middle East & Africa automotive carbon brush market is steadily growing, driven by increasing automotive production and rising adoption of electric and hybrid vehicles in the region. Key trends include the use of advanced carbon materials, durable and eco-friendly brush designs, and innovations that enhance motor efficiency, reliability, and lifespan across passenger, commercial, and industrial vehicles.

-

Saudi Arabia Automotive Carbon Brush Market Insights:

Saudi Arabia is dominating the Middle East & Africa automotive carbon brush market, driven by its growing automotive industry, increasing adoption of electric and hybrid vehicles, and rising demand for high-performance motor components across passenger and commercial vehicles.

Automotive Carbon Brush Market Competitive Landscape:

Helwig Carbon Products, Inc., established in 1919, is a leading manufacturer of high-performance carbon brushes and brush holders for automotive, industrial, and power generation applications. Known for innovations like Multi-Flex and Tri-Flex brushes with Red Top Pad technology, the company enhances motor efficiency, reduces wear, and extends brush life, delivering durable, high-quality solutions worldwide.

-

In March, 2024: Helwig Carbon’s Multi-Flex and Tri-Flex brushes offer superior performance over solid brushes by increasing contact points on uneven commutators, reducing circulating currents, and improving brush and commutator life. Their patented Red Top Pad dampens vibration, prevents chipping, and evenly distributes spring force for high-voltage and high-stress motors.

SKF Aktiebolaget is a global leader in bearing, seal, and lubrication solutions, serving automotive, industrial, and aerospace markets. Established in 1907, SKF specializes in innovative technologies like hybrid bearings and conductive brush rings, enhancing performance, reliability, and longevity in electric vehicle powertrains and other high-precision applications worldwide.

-

In April 2024: SKF developed the Conductive Brush Ring for EV powertrains, providing reliable electrical grounding and reducing parasitic currents. Combined with Hybrid ceramic ball bearings, it enhances eAxle lifetime, lowers friction, and improves reliability in high-performance electric vehicle systems.

Automotive Carbon Brush Market Key Players:

-

MERSEN

-

Helwig Carbon Products, Inc.

-

OMNISCIENT INTERNATIONAL

-

Toyo Tanso Co., Ltd.

-

Morgan Advanced Materials

-

Schmidthammer Elektrokohle GmbH

-

AVOCarbon

-

Schunk Carbon Technology

-

Carbon Brush Company Pvt. Ltd.

-

Shree Auto Electronics

-

PanTrac

-

CEET Carbon

-

Graphite India Limited

-

Donnelly Carbon

-

Seoyon E-Hwa

-

Futaba Corporation

-

Shanghai Carbon Industry Co., Ltd.

-

Carbone Lorraine

-

Nippon Carbon Co., Ltd.

-

Asahi Carbon Co., Ltd.

| Report Attributes | Details |

|---|---|

| Market Size in 2025 | USD 2.92 Billion |

| Market Size by 2032 | USD 4.26 Billion |

| CAGR | CAGR of 4.83% From 2026 to 2033 |

| Base Year | 2025E |

| Forecast Period | 2026-2033 |

| Historical Data | 2022-2024 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Application (Engine Electronic System, Comfort System, Safety and Chassis Electronic System, Body Electronic System) • By Brush Grade (Carbon Graphite, Electrographite, Graphite, Metal Graphite, Silver Graphite) • By Vehicle Type (Hatchback/Sedan, SUVs, LCV, HCV) • By Propulsion (ICE, Electric) |

| Regional Analysis/Coverage | North America (US, Canada), Europe (Germany, UK, France, Italy, Spain, Russia, Poland, Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Australia, ASEAN Countries, Rest of Asia Pacific), Middle East & Africa (UAE, Saudi Arabia, Qatar, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Mexico, Colombia, Rest of Latin America). |

| Company Profiles | MERSEN, Helwig Carbon Products, Inc., OMNISCIENT INTERNATIONAL, Toyo Tanso Co., Ltd., Morgan Advanced Materials, Schmidthammer Elektrokohle GmbH, AVOCarbon, Schunk Carbon Technology, Carbon Brush Company Pvt. Ltd., Shree Auto Electronics, PanTrac, CEET Carbon, Graphite India Limited, Donnelly Carbon, Seoyon E-Hwa, Futaba Corporation, Shanghai Carbon Industry Co., Ltd., Carbone Lorraine, Nippon Carbon Co., Ltd., Asahi Carbon Co., Ltd. |