Automotive Wiring Harness Market Size:

Get More Information on Automotive Wiring Harness Market - Request Sample Report

The Automotive Wiring Harness Market size is projected to reach USD 72.03 billion by 2032 and was valued at USD 51.05 billion in 2023. The estimated CAGR for 2024-2032 is 3.9%.

The key growth driver for the automotive wiring harness market is the increasing penetration of advanced driver-assistance systems (ADAS) and electric vehicles (EVs). Considering this increased concern for passenger safety, as many as about 65% of all the vehicles produced globally are expected to have some type of ADAS installed by 2025. It will spur the demand for advanced harnesses that would support such networks of sensors and electronic control units. This recent wave of automobile production of electrical vehicles is, therefore, another very demanding driver as electric vehicles contain up to 40% more wiring than a conventional internal combustion engine, which is also the major cause of an alarming rise in wiring harness requirements. The efforts of accelerating electrification of the automotive industry along with cutting down on carbon emissions were further encouraged for the adoption of EVs. Around 2030, it was expected to reach 30% of total vehicles sold across the globe. Use of lightweight material in wiring harnesses helps in reducing up to 15% vehicle's weight and encourages an overall vehicle efficiency further in line with strict fuel efficiency standards. The other significant factor pushing for the increasing integration of infotainment and connectivity systems is that about 75% of new vehicles are expected to come equipped with smart infotainment solutions, thereby requiring an extensive wiring network. The movement towards autonomous vehicle technologies, where an additional increase in functionality necessitates a 20-30% increase in complexity, also drives demand. Thus, important traction is being faced in the market due to a technology change, consumer preference shift, and regulatory directives that are skewed toward more improved safety and sustainability of vehicles.

Not only this, but modular and standardized harnesses are also gaining much importance, and they can bring about a reduction of almost 15% in the cost of manufacturing and much better design options. Other developments, including the use of multiplex wiring systems, have brought about a 20% reduction in total wiring length from one vehicle to another. Savings on cost and weight are therefore achieved. More connectivity, autonomous driving, and electrification will take the automotive sector further with a more complex vehicle; the wiring harness market will reform itself to enable it to manufacture smarter materials and even more refined configurations that can cope with these additional complexities.

Drivers:

-

All the increased electric vehicle adoption, rising ADAS integration, regulatory safety requirements, and demand for connected vehicles will take the automotive wiring harness market forward.

Increased Technology Advancements and Changing Regulatory Requirements Lead to a Rise in Demand for Specialized Wiring Solutions, Opportunity in the Automotive Wiring Harness Market. The driving force from increased demand for high voltage wiring harnesses within the assemblies, due to growing penetration of electric vehicles, is driving the market. Global EV sales are up 60% in 2023. Added to this is growing interest in lightweight harness materials for better vehicle efficiency; some 25% of automotive OEMs have now adopted lightweight aluminum wiring over the more traditional copper in the latest models.

The other opportunity lies in the advancement of ADAS, which requires higher-level wiring harnesses to connect the sensors and control units. Market estimates suggest that 58 percent of new vehicles sold in 2024 are expected to come equipped with Level 2 or more ADAS capabilities, increasing the demand for advanced electrical systems. Government safety norms are also witnessing the development of a demand for reliable wiring solutions. Here, more than 70% of the vehicles meet highly stringent safety compliance through reliable electrical systems, thus providing a very huge opportunity for wiring harness manufacturers to produce enhanced safety features.

Challenges:

-

The growth in automotive wiring harness market is hindered by increased complexity of EV and ADAS wiring, increasing raw material costs and labor shortages.

Automotive Wiring Harness Market faces challenges due to the increased complexity of wiring systems in latest advanced technology as used in vehicles. The high-voltage wiring requirements results in a much more complex supply chain when compared with electric vehicle customers due to the tough performance standards set for wiring, which must withstand big voltages and thus leads to more complexity in development and manufacturing at cost. About 35% of suppliers face difficulties in meeting such specialized requirements on EV wiring, thereby affecting the production timelines. This makes the wiring harness design more complex because the higher rate of data transmission coupled with increased reliability in data transmission demands more sophisticated engineering-some 40% of manufacturers of wiring harnesses report issues in optimization of weight, space and cost for vehicles with ADAS.

The other challenge is the rise in the raw materials price such as that of copper, which is approximately 60% of the normal composition of a wiring harness. Due to growing global copper prices, manufacturing costs increase by 15% on average. Apart from the historically mentioned labor shortages in the field, availability of skilled technicians is also one of the main challenges for manufacturers since wiring harness assembly is still substantially a labor-intensive activity; today, as much as 48% of the manufacturers claim difficulties in finding enough skilled labor.

Segment Analysis:

By Component

The Automotive Wiring Harness Market can be mainly bifurcated into its sub-components like electric wires, connectors, terminals, and others. Electric wires take the major share in the market, approximately 45%. Increased adoption of electric and hybrid vehicles opens avenues for growth opportunities for manufacturers through the demand for high-quality wires that can bear a higher voltage. Another significant portion is connectors that guarantee the secure connection between different vehicle systems. This is approximately 25% of the market. With the increasing amount of wiring going inside the vehicle, to accommodate more and more advanced infotainment systems and ADAS, the demand for special connectors rises continually. Terminals are 15% of the segment and play a very critical role in guaranteeing secure electrical connection, especially in high-stress environments. Recently, terminals of new material designs are perceived as gaining traction due to light weight and energy-efficient automotive designs. Other category holds approximately 15 percent of the market share with protective coverings, relays and fuses. These components are essential for any system to have protection and reliability-more so as wiring harnesses tend to become increasingly complex.

By Electric Vehicle

In this market, the traditional BEV segment holds a majority market share of around 65%, primarily because of increasing consumer demand for zero-emission vehicles and support from various governments towards being sustainable. The requirement for high-voltage wiring harnesses for that size of a battery and electrical systems application puts a call for innovation with regard to lighter and more efficient materials from manufacturers. PHEVs, with around a 35% market share, are also significant because of the ability that they offer to switch between their primary electric and backup conventional power sources. Since PHEVs require wiring harnesses to connect all the electric and internal combustion engine components, there is increased complexity both in design and manufacturing. Again, due to governmental incentives for hybrid technology as an intermediate step towards full electrification, PHEVs are also one of the important market drivers.

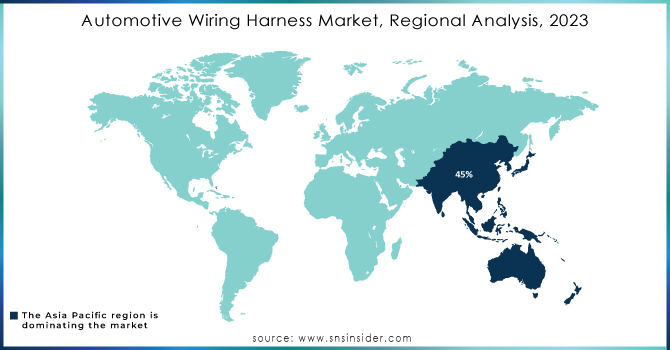

Regional Analysis:

The Automotive Wiring Harness Market has significant regional dynamics with Asia Pacific regions leading by a market share of about 45%. This is because most of the major automotive manufacturers are located in countries in China, Japan, and South Korea; meanwhile, this region accounts for the fastest growth of electric vehicles. High-performance wiring harnesses become the need of the hour with growing production of regular and electric vehicles, new technologies in vehicles, and a high trend towards innovation in engineering and improving safety standards. It also has a good representation of renowned automotive OEMs and Tier 1 suppliers besides the strong focus on innovation in engineering, ensuring a well-placed 25% share of North America.

Europe takes up about 20 percent of the market share, wherein this region's concern about reducing carbon emissions and promoting eco-friendly mobility is another driver factor. Advanced driver assistance systems and electric vehicles have been very early adopting countries in Europe, which in turn, propels the demand for sophisticated wiring harnesses.

Recent Developments:

Leoni AG: Up 21% so far for this year as of June 2024. Leoni has increased its capacity in the production lines of high-voltage wiring harnesses and rising support to electric vehicles. The company issued a press release on opening up its new manufacturing facility in Eastern Europe for lightweight and flexible wiring solutions designed specifically for electric and hybrid vehicles.

Marelli April 2024: Marelli has developed a modular wiring harness system aimed at maximizing connectivity within the minimum overall weight. The modular wiring harness system is here to further efficiency in the assembly phase and decrease installation complexity for automotive manufacturers mainly on electric and connected vehicles.

Sumitomo Electric Industries: Launches New Series of Connectors for High Voltage Applications in Electric Vehicles New Connections from Sumitomo Electric Can Face Extreme Temperatures and Hostile Environments, Improving Reliability and Safety in EV Applications.

Need Any Customization Research On Automotive Wiring Harness Market - Inquiry Now

Key Players:

-

Leoni AG: (High-Voltage Wiring Harnesses, Modular Wiring Systems)

-

Yazaki Corporation: (Automotive Wiring Harnesses, Eco-Friendly Wiring Solutions)

-

Sumitomo Electric Industries: (High-Voltage Connectors, Automotive Wiring Harnesses)

-

Denso Corporation: (Wiring Harnesses for Autonomous Vehicles, High-Speed Data Transmission Systems)

-

Marelli: (Modular Wiring Harness Systems, Lightweight Wiring Solutions)

-

Kromberg & Schubert: (Custom Wiring Harnesses, Smart Wiring Solutions)

-

Aptiv PLC: (Connected Vehicle Wiring Systems, ADAS Wiring Harnesses)

-

Lear Corporation: (Electrical Distribution Systems, High-Performance Wiring Harnesses)

-

Furukawa Electric Co., Ltd.: (High-Voltage Wiring Harnesses, Standard Automotive Wiring Harnesses)

-

TE Connectivity: (Automotive Connectors, Custom Wiring Harness Solutions)

-

Belden Inc.: (High-Speed Data Cables, Specialty Wiring Harnesses)

-

Eaton Corporation: (Electrical Distribution Systems, Automotive Wiring Solutions)

-

Wiring Harness Manufacturer’s Association (WHMA): (Manufacturing Standards, Certification Programs)

-

AVX Corporation: (Automotive Capacitors, High-Frequency Wiring Solutions)

-

Molex LLC: (High-Speed Automotive Connectors, Wiring Harness Solutions for Electric Vehicles)

-

Amphenol Corporation: (Automotive Interconnect Systems, Custom Wiring Harnesses)

-

Nexans: (Wiring Harnesses for Electric Vehicles, Specialty Automotive Cables)

-

SABIC: (Engineering Thermoplastics, Lightweight Wiring Insulation Materials)

-

Aisin Seiki Co., Ltd.: (Electrical Systems for Vehicles, Wiring Harnesses for Hybrid Vehicles)

-

Corning Incorporated: (Fiber Optic Cables, Advanced Electrical Materials)

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 51.05 Billion |

| Market Size by 2032 | USD 72.03 Billion |

| CAGR | CAGR of 3.9% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Component: (Electric Wires, Connectors. Terminals, Others) • By Application: (Body Harness, Chassis Harness, Engine Harness, HVAC Harness, Sensors Harness) • By Electric Vehicle: (Battery Electric Vehicle (BEV), Plug-in Hybrid Electric Vehicle (PHEV)) • By Vehicle: (Light Vehicle, Heavy Vehicle) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Leoni AG, Yazaki Corporatio, Sumitomo Electric Industries, Denso Corporation, Marelli, Kromberg & Schubert, Aptiv PLC , Lear Corporation and others |

| Key Drivers | • All the increased electric vehicle adoption, rising ADAS integration, regulatory safety requirements, and demand for connected vehicles will take the automotive wiring harness market forward. |

| RESTRAINTS | • The growth in automotive wiring harness market is hindered by increased complexity of EV and ADAS wiring, increasing raw material costs and labor shortages |