Calcined Bauxite Market Report Scope & Overview:

The Calcined Bauxite Market size was USD 1.7 billion in 2023 and is expected to reach USD 2.5 billion by 2032 and grow at a CAGR of 4.1% over the forecast period of 2024-2032.

Get E-PDF Sample Report on Calcined Bauxite Market - Request Sample Report

Calcined bauxite is becoming increasingly important in road surfacing due to its very high friction properties, where its presence significantly increases safety in the exposed zones. It is especially important to use anti-skid surfaces for highways to maintain vehicle traction, especially in bad weather conditions. Likewise, calcined bauxite is used on airport runways to avoid skidding when aircraft take off or land, allowing for safe functioning in wet or frozen circumstances. The great resilience of the material as well as the polish resistance allows the material to be used in surfaces where long-lasting applications are desired and in high traffic zones too. With governments and transportation authority working to improve the safety of roads and runways, the consumption of calcined bauxite for this application is expected to increase.

The Federal Highway Administration (FHWA) has reported that HFST can lead to significant reductions in vehicular crashes. Specifically, studies indicate an estimated 83% reduction in wet crashes and a 57% decrease in total crashes following HFST application.

In advanced ceramics and abrasives, calcined bauxite is vital for improving the performance of renewable energy technologies. High-performance & durable components are necessary for solar panel production which is manufactured using advanced ceramics derived from calcined bauxite as they provide superior thermal stability & strength required in photovoltaic cells. Likewise, abrasives from calcined bauxite are key to the precision machining and finishing of turbine blades in wind turbines, enabling optimal aerodynamic performance and structural integrity. The world is rapidly accelerating investment in renewable energy to meet its decarbonization targets creating demand for these unique materials. In addition, calcined bauxite is being significantly adopted in essential renewable energy applications as governments and industries worldwide are focusing on sustainable energy solutions.

This growth is closely linked to the expansion of renewable energy infrastructure. For instance, in 2022, annual U.S. renewable energy generation surpassed coal for the first time in history. By 2025, domestic solar energy generation is expected to increase by 75%, and wind by 11%.

Calcined Bauxite Market Dynamics

Drivers

-

High demand across various industries like refractories, abrasives, welding, and ceramics drives market growth.

Calcined Bauxite market growth is high on their considerable demand in various industries including refractory abrasives welding ceramic and others. Calcined bauxite is an essential raw ingredient in the production of heat-resistant materials used in furnaces and kilns, helping to manufacture durable materials for use in the industry, most commonly, steel and cement production, therefore it is widely used in refractory items. Its extreme hardness and longevity have made it suitable for grinding, polishing, and cutting applications in abrasives., In the welding industry, calcined bauxite is used in the composition of fluxes enabling cleaner and stronger results and the ceramics industry used the alumina in the bauxite for high-performance ceramics with enhanced thermal and mechanical properties. High growth in these industries and the wide spectrum of industrial applications collectively drive demand for calcined bauxite globally.

in May 2022, US Ceramics LLC's calcination plants, including two manufacturing facilities in Wrens and Andersonville, Georgia, with respective production capabilities of 250 kilotons and 100 kilotons, were purchased by First Bauxite.

Restraint

-

High production costs associated with calcined bauxite may hamper the market growth.

The high cost of production is a prominent challenge for the calcined bauxite market, which is expected to hinder market growth. A key challenge for the calcined bauxite market, which is expected to hinder market growth calcination is an energy-intensive process that uses a huge amount of heat to convert bauxite to the final calcined product. Manufacturers face huge energy consumption and expensive operation overhead. The expense also covers activities such as raw bauxite, transportation, and environmental compliance. The production costs of calcined bauxite however are likely to be higher, as energy prices go up and the regulatory standards tighten, which may render calcined bauxite a less favorable option for certain industries, especially those seeking low-cost substitutes. This may constrain market expansion, particularly in price-sensitive markets.

Calcined Bauxite Market Segmentation

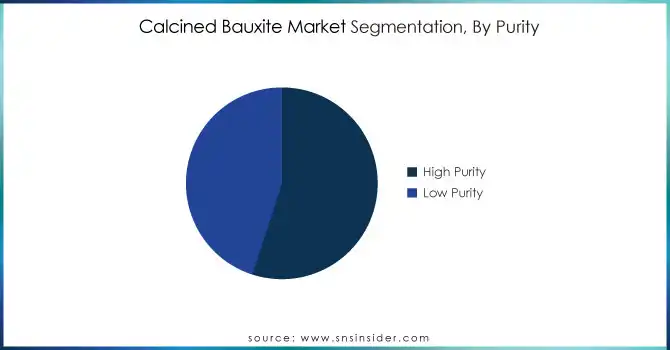

By Purity

The high-purity segment dominated the Calcined Bauxite Market with a revenue share of more than 55% in 2023 owing to its crucial role in demanding applications like refractories, ceramics, and abrasives. This segment's dominance was fueled by the growing emphasis on quality and performance standards across industries, compelling a shift towards materials with higher purity levels. Additionally, the exceptional properties of high-purity calcined bauxite, including superior strength and thermal resistance, further solidified its position as the market leader. The growing need for high-performance materials in sectors like abrasives, ceramics, and advanced coatings has further driven the demand for high-purity calcined bauxite. Its ability to withstand extreme conditions makes it the preferred choice for high-end applications, contributing to its dominance in the market.

By Type

The aggregate segment held the largest market share in the calcined bauxite market around 58% in 2023 due to its widespread use in various industrial applications. Calcined bauxite in its aggregate form is prized for its hardness, durability, and resistance to wear, making it ideal for use in the production of refractories, abrasives, and road surfacing materials. In refractories, aggregate calcined bauxite is a key component in the creation of heat-resistant materials used in high-temperature processes, such as steel and cement production. Its use in anti-skid road surfaces, particularly for highways and airport runways, also contributes to its dominant position in the market. The aggregate segment’s ability to cater to such diverse and high-demand industries is a major factor driving its significant market share.

By Application

The calcined bauxite market for metallurgy accounted for the largest share of the overall market, as calcined bauxite is an important raw material to produce alumina which in turn is used for various metallurgical processes. Calcined bauxite is the main raw material for producing alumina, which in turn serves as the raw material for aluminum, the most broadly applied metal in the world. In the steel sector, calcined bauxite is very important in generating high-grade refractories for lining furnaces and kilns, enabling them to bear extreme temperatures and chemical reactions during metal production. Growing global demand for metals like aluminum, steel, and other metals, and their application in automobile, construction, aerospace, and packaging industries is expected to continue to boost the growth of this segment on the metallurgy end. Such widespread industrial demand and the essential aspect of calcined bauxite in these processes make it a key player in the market.

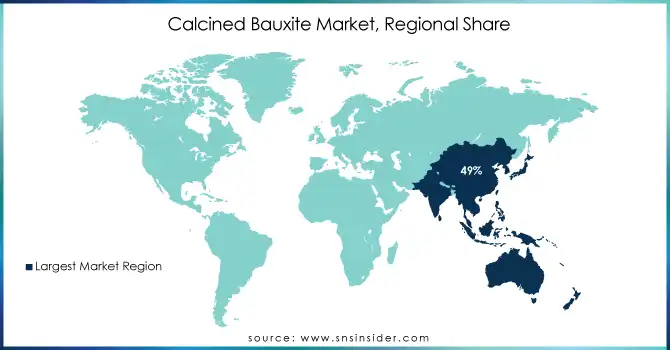

Calcined Bauxite Market Regional Analysis

Asia Pacific held the largest market share around 49% in 2023 owing to the presence of a strong industrial base along with increasing demand for bauxite-based products across key application segments in the region. High calcined bauxite demand in this region is the result of one of the largest production capacities of aluminum in the world, where the construction sector, steel, aluminum, and cement industries are continuously growing across the globe for economic expansion and infrastructure development. An impact of this scale of calcined bauxite is in primarily consumer countries such as China and India, where more and more bauxite is used for alumina production, in refractories, and in road surfacing. In addition, the critical industrialization as well as urbanization embraced by nations such as China, and India together with Southeast Asia market expansion, the need for top-notch materials in the construction, automotive, and energy industry has influenced the industry growth. This, together with the presence of large manufacturing capacity, well-established infrastructure, and proliferating industrial activities, is supporting Asia Pacific on the path to patent the global calcined bauxite market.

North America is estimated to grow at the highest CAGR during the forecast period of 2024-2032 attributed to the region's accelerating adoption of calcined bauxite in diverse industrial applications, including construction, automotive, and aerospace. This growth is propelled by increasing infrastructural investments, stringent regulatory standards, and technological advancements driving demand for high-performance materials like calcined bauxite. Additionally, a shift towards sustainable practices and initiatives further stimulates market expansion in the region.

Get Customized Report as per Your Business Requirement - Enquiry Now

Key Players:

-

Sinocean Industrial Limited (Calcined Bauxite, Refractory Bauxite)

-

Great Lakes Minerals, LLC (Refractory Grade Bauxite, Calcined Bauxite)

-

Boud Minerals Limited (Calcined Bauxite, High Alumina Bauxite)

-

LKAB (Bauxite for Refractories, Alumina Production Bauxite)

-

Saurashtra Calcine Bauxite (Refractory Bauxite, Calcined Bauxite)

-

First Bauxite LLC (Refractory Bauxite, Calcined Bauxite)

-

EK-COMPANY AG (High-Purity Bauxite, Abrasive Bauxite)

-

Bosai Group (Bauxite for Metallurgy, Calcined Bauxite)

-

Allied Industries Ltd (Refractory Bauxite, Calcined Bauxite)

-

UAE Calcined Bauxite (Metallurgical Bauxite, Abrasive Grade Bauxite)

-

Alcoa Corporation (Bauxite for Alumina, Metallurgical Bauxite)

-

China Hongqiao Group Limited (Metallurgical Grade Bauxite, Calcined Bauxite)

-

Jining Bauxite Industrial (Refractory Bauxite, Calcined Bauxite)

-

Arc Minerals Ltd (Calcined Bauxite, Alumina)

-

Ashapura Minechem Ltd (Refractory Bauxite, Calcined Bauxite)

-

Global Bauxite (Calcined Bauxite, Abrasive Bauxite)

-

Yunnan Tin Company Limited (Calcined Bauxite, Alumina)

-

Rio Tinto Group (Bauxite for Alumina Refining, Refractory Grade Bauxite)

-

Guangxi Huayan Bauxite Group (Bauxite for Metallurgical Use, Calcined Bauxite)

-

Zibo Honghe Chemical Co. Ltd (Calcined Bauxite, High Alumina Bauxite)

Recent Development:

-

In Jan 2023: State-owned lithium-ion battery mineral company in Sweden, LKAB, finds giant rare earth oxides deposit in Kiruna, in far northern Sweden. This deposit, which contains rare earth minerals, is the largest known deposit in Europe and is estimated to be nearly 1 million tonnes in size.

-

In October 2022, Koch Minerals & Trading, a subsidiary of Koch Industries, made a USD 252 million preferred equity investment in Compass Minerals, a leading global provider of essential minerals. Combine this news with it being an expansion and growth opportunity overseas thus the cash will give Compass Minerals strength in the vertical.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 1.7 Billion |

| Market Size by 2032 | USD 2.5 Billion |

| CAGR | CAGR of 4.1% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Purity (High Purity and Low Purity) • By Type (Aggregate and Powder) • By Application (Abrasives, Refractory Materials, Road Surfacing, Metallurgy, and Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Sinocean Industrial Limited (China), Great Lakes Minerals, LLC(US), Boud Minerals Limited (UK), LKAB (Sweden), Saurashtra Calcine Bauxite, First Bauxite LLC (US), EK-COMPANY AG (Germany), Bosai Group (China), Allied Industries Ltd (India) |

| Key Drivers | • High demand across various industries like refractories, abrasives, welding, and ceramics drives the market growth. |

| Restraints | • High production cost associated with calcined bauxite may hamper the market growth. |