Conveyor Systems Market Report Scope & Overview:

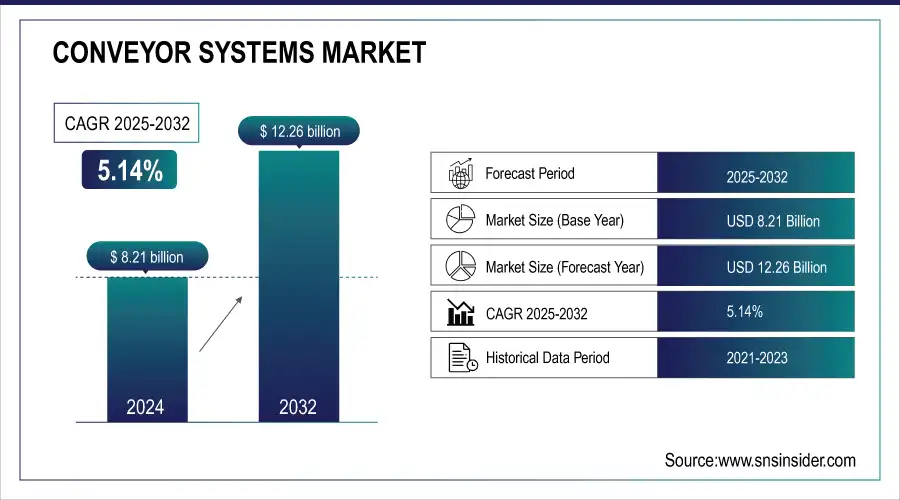

The Conveyor Systems Market was valued at USD 8.21 billion in 2025E and is expected to reach USD 12.26 billion by 2033, growing at a CAGR of 5.14% from 2026-2033.

The Conveyor Systems Market is growing due to increasing automation across industries such as manufacturing, logistics, e-commerce, and food & beverage. Rising demand for efficient material handling, faster production cycles, and cost reduction is driving adoption of advanced conveyor technologies. Integration with smart factory solutions, IoT, and robotics enhances operational efficiency, accuracy, and monitoring capabilities. Additionally, expanding warehousing and distribution infrastructure, coupled with the need for safe and ergonomic handling of materials, is fueling market growth globally. Rising investments in automation and supply chain optimization further support sustained growth.

Market Size and Forecast

-

Conveyor Systems Market Size in 2025E: USD 8.21 Billion

-

Conveyor Systems Market Size by 2033: USD 12.26 Billion

-

CAGR: 5.14% from 2026 to 2033

-

Base Year: 2025

-

Forecast Period: 2026–2033

-

Historical Data: 2022–2024

Get More Information on Conveyer Systems Market - Request Sample Report

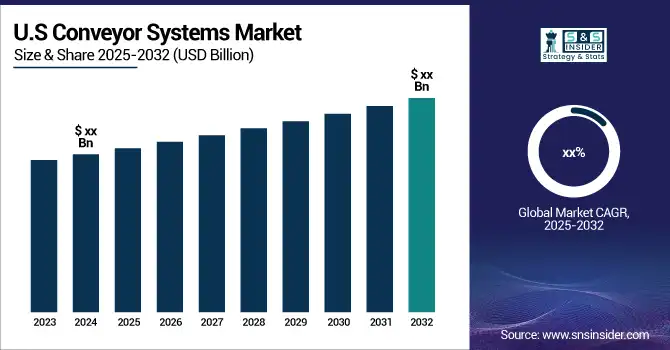

The U.S. Conveyor Systems market size was valued at an estimated USD 3.05 billion in 2025 and is projected to reach USD 4.55 billion by 2033, growing at a CAGR of 4.9% over the forecast period 2026–2033. Market growth is driven by increasing automation across manufacturing, warehousing, and logistics operations, along with the rapid expansion of e-commerce and distribution centers. Rising demand for efficient material handling solutions, labor cost optimization, and improved operational efficiency is accelerating market adoption. Technological advancements such as smart conveyor systems, integration with robotics and IoT, and growing investments in industrial automation further support the steady growth outlook of the U.S. conveyor systems market during the forecast period.

Conveyor Systems Market Trends

-

Growing demand for automation and efficient material handling is driving conveyor systems adoption.

-

Expansion in e-commerce, manufacturing, and logistics sectors is boosting market growth.

-

Integration with IoT, robotics, and AI is enhancing real-time monitoring, predictive maintenance, and workflow optimization.

-

Increasing need for safety, energy efficiency, and customizable solutions is shaping market trends.

-

Adoption of modular and automated conveyors is improving scalability and operational flexibility.

-

Rising investments in smart warehouses and distribution centers are fueling demand.

-

Collaborations between OEMs, technology providers, and end-users are accelerating innovation and advanced system deployment.

Conveyor Systems Market Growth Drivers:

-

Surging Demand for Automation in Industries Including Automotive, E-commerce, Food & Beverage, and Logistics is Driving the Market Growth

By automating material handling processes, conveyor systems have become critical in improving operational efficiency and reducing dependence on manual labor. For assembly lines in the automotive sector, conveyors are a fundamental component for increasing the speed and precision of manufacturing. Due to the increasing need for speed and accuracy to fulfill orders for e-commerce and logistics companies, converters are employed to assist in sortation and shipping operations. In food and beverage, these systems are used to package products and move them through processing stages while ensuring hygiene and efficiency. The automated conveyor systems industry benefits from the fact that companies are continuously looking to improve their supply chains and be more productive, which boosts demand for these systems.

Conveyor Systems Market Restraints:

-

Higher Initial Investment Costs of Purchasing and Installation of the Conveyor Systems Can Hinder Market Growth

These systems normally have high capital expenditure, both on the equipment and its installation, integration, and infrastructure upgrades. For large-scale setups, the cost may be justified considering the jump in productivity and long-term efficiency. However, for SMEs with smaller budgets, the cost of such an investment can be a huge barrier to entry for adopting conveyor systems despite providing potentially huge operational ROI. And needing staff to build, run, and maintain these systems only multiplies it. This in turn raises the entry cost and many SMEs are unable to adopt advanced automation for better operational efficiencies.

Conveyor Systems Market Opportunities:

-

Growing Prioritization Eco-friendly and Energy-efficient Solutions by Businesses and Industries Can Create Better Growth Opportunities

The demand for green technologies is rising, with organizations seeking conveyor systems that help reduce environmental impacts. These systems focus on minimizing energy consumption, lowering carbon emissions, and using recyclable or sustainable materials in their components. Conveyor systems that incorporate energy-saving features including variable speed drives or efficient motors, allow businesses to lower their operational costs while adhering to environmental standards. Moreover, with global sustainability regulations becoming more stringent, manufacturers are focusing on developing systems that are both efficient and environmentally responsible. This shift is not only driven by regulatory requirements but also by consumer preference for environmentally-conscious companies. As a result, eco-friendly conveyor systems are becoming a competitive advantage, leading to higher demand and providing opportunities for companies to innovate in the conveyor systems industry.

Conveyor Systems Market Challenges:

-

Lack of Trained and Qualified Labor May Challenge Market Expansion

Advanced conveyor systems are critical and proper, trained use both an operator and maintenance personnel and technicians needed, to all to make such systems work effectively. Conveyor systems require sophisticated technology, including automatic controls, sensors, and integrated computer software, and manufacturing worker must be technically skilled for the smooth operation of the conveyor system. Lack of this knowledge can make it difficult to troubleshoot problems, not perform maintenance tasks, or adjust the performance of the system.

High requirement for skilled labor, especially in countries where technical education and training is inadequate, will in turn slow the deployment of conveyor systems and hinder their long-term sustainability. All of these can lead to a downtime, higher maintenance cost, or lower operational efficiency for the company. This challenge can, however, be resolved by investing in training programs to develop a skilled workforce, as the optimal use of conveyor systems and the ability to maintain them in the right way will help drive the conveyor systems market growth.

Conveyor Systems Market Segment Analysis

By Type, Flat Belt Conveyor dominates the market

The Flat Belt Conveyor segment dominated with a market share of over 32% in 2025, due to their higher usage within multi-purpose applications which are most cost-effective with simple design and can be adopted in a wide range of industries. Freight transport is widely used in industries including automotive, food and beverage, and logistics, where the transport of goods is a critical process that needs reliable and efficient transportation. A flat belt conveyor consists of a flat, continuous belt, and is best for transporting products short and long distances. These benefits include simple designs, low maintainability, and flexibility in handling both fragile or packaged goods.

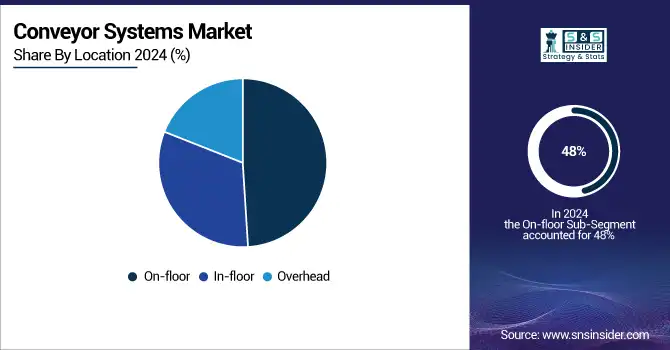

By Location, On-floor conveyors dominate the market

The On-floor segment dominated with a market share of over 48% in 2025, due to its wide adoption in sectors including automotive, food and beverage, e-commerce, and others. This makes them ideal for companies looking for an efficient solution to material handling these systems are very flexible, adaptable to many configurations, and cost-effective. On-floor conveyors are very easy to incorporate into a current production line, providing the perfect amount of versatility in any application including sorting, assembly, and packaging. Along with ever-decreasing labor costs and higher throughput, they bring seamlessly flowing processes and higher productivity.

By Load, Bulk Load conveyors dominate the market.

The Bulk Load segment dominated with a market share of over 62% in 2025. For these industries, mass needs to be moved in bulk volume, and that is the reason bulk-load conveyors are irreplaceable. These types of Conveyors are mass Conveyors designed to accommodate loose or bulk amounts of materials such as coal, grains, sand, and other types of raw materials. Their unrivaled ability to transport bulky, massive, long-distance loads with lightweight & inexpensive material handling equipment is the key to their leadership in the high-volume material handling industry.

By Application, Manufacturing dominates the market.

The Manufacturing segment dominated with a market share of over 32% in 2025, owing to the rise in automation and efficiency requirements in manufacturing lines. Conveyor systems play a crucial role in facilitating the seamless flow of materials in various industries, including automotive, electronics, and industrial goods, which help to reduce labor costs and improve productivity. A few examples include Industry 4.0 and its focus on smart automation, IoT-enabled systems, and AI-driven logistics for manufacturers, all of which continue propelling demand further. Moreover, high existing infrastructure and high-quality standards for manufacturing units enable the adoption of conveyor solutions across various industries.

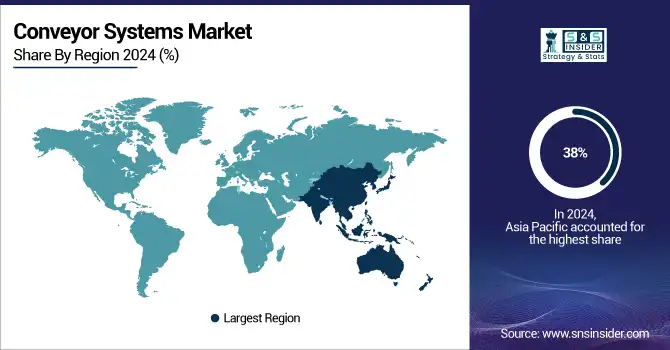

Conveyor Systems Market Regional Analysis

Asia Pacific Conveyor Systems Market Insights

The Asia Pacific region dominated with a market share of over 38% in 2025, owing to the rapid industrialization, high manufacturing activities, and increasing demand for automation. The emergence of global manufacturing giants, such as China, Japan, and India, underscores the growing necessity for superior conveyor systems to improve production processes. Market growth will also be supported by a stable industrial base in the region of automotive, electronics and food processing leading the way. Moreover, the design of large infrastructure facilities such as smart factories, warehouses, and logistics hubs is projected to continue driving up the demand for conveyor systems to optimize material handling.

Ask for a Customized Report as per Your Business Requirement - Enquiry Now

Europe Conveyor Systems Market Insights

Europe is the fastest-growing region in the Conveyor Systems Market, owing to rising automation demand in various sectors. With businesses striving to improve efficiency and productivity, conveyor systems are key for providing smooth operations. The demand for sophisticated conveyor solutions is further accelerated by the increase in automation technology, particularly the fusion of AI, robotics, and IoT. Various sectors including automotive, food and beverage, logistics, and e-commerce are implementing these systems with rising consumer demand and improving supply chain management.

North America Conveyor Systems Market Insights

North America holds a significant position in the Conveyor Systems Market, driven by advanced manufacturing infrastructure, high adoption of automation, and strong logistics and e-commerce sectors. The region’s focus on Industry 4.0, smart factories, and IoT-enabled material handling solutions is accelerating demand. Investments in warehouse modernization, efficient production lines, and automated distribution systems further boost market growth, making North America a key hub for innovative and high-performance conveyor system deployment.

Middle East & Africa and Latin America Conveyor Systems Market Insights

The Middle East & Africa and Latin America are emerging markets in the Conveyor Systems Market, fueled by growing industrialization, expanding e-commerce, and investments in infrastructure and logistics. Increasing adoption of automated material handling solutions in manufacturing, warehousing, and distribution centers is driving growth. Government initiatives supporting smart manufacturing and efficient supply chain operations, coupled with rising awareness of productivity and safety benefits, position these regions as high-potential markets for conveyor system deployment.

Conveyor Systems Market Competitive Landscape:

GSE

GSE is a global leader in ink logistics and workflow automation, offering innovative solutions for the printing industry. The company specializes in designing systems that enhance productivity, accuracy, and safety in ink handling processes, including color preparation, storage, and distribution. Its technologies streamline operations for package printing facilities, optimizing efficiency and ergonomics while reducing manual handling errors and improving overall operational performance.

-

In September 2024, GSE unveiled an innovative modular conveyor system designed to transport ink containers automatically, securely, and efficiently throughout the ink kitchen. This advanced system enhances workflow productivity and ergonomics by optimizing the color preparation process for production in package printing facilities.

Murata Machinery USA, Inc.

Murata Machinery USA, Inc. is a leading provider of advanced automation solutions, specializing in material handling, storage, and retrieval systems for diverse industries. Its portfolio includes high-density automated storage and retrieval systems (AS/RS), robotics, and other material handling technologies that enhance operational efficiency, reduce labor costs, and optimize warehouse space. The company focuses on compact, flexible, and scalable automation solutions tailored to customer needs.

-

In February 2023, Murata Machinery USA, Inc. revealed the Ledger A3 mini-load, a high-density automated storage and retrieval system (AS/RS) featuring a four-tote carriage, designed for compact product storage and retrieval.

SIMATIC

SIMATIC, part of Siemens’ industrial automation portfolio, provides cutting-edge control, visualization, and software solutions for manufacturing operations. Its product suite includes PLCs, HMI panels, SCADA systems, and industrial software designed to optimize process control, improve monitoring capabilities, and enable digital integration across production lines. SIMATIC emphasizes reliability, flexibility, and seamless integration, supporting smart manufacturing and Industry 4.0 initiatives globally.

-

In June 2023, SIMATIC introduced WinCC Unified V18, the latest visualization system within the TIA Portal. This release brings ongoing enhancements to the WinCC Unified System software, improving support for panels and runtime systems, as well as vertical integration capabilities.

Key Players

Some of the major key players of the Conveyor Systems Market

-

Daifuku Co., Ltd. (Automated Conveyor Systems, Material Handling Systems, Warehouse Automation Solutions)

-

Fives (Industrial Automation, Conveyor Systems, Robotics Solutions)

-

Interroll Group (Roller Conveyors, Pallet Conveyors, Modular Conveyors)

-

Kardex (Automated Storage and Retrieval Systems, Conveyor Systems, Vertical Lift Modules)

-

Kuka AG (Robotic Conveyor Systems, Automation Solutions)

-

Mahindra Tsubaki (Chain Conveyors, Automated Conveyor Systems, Power Transmission Solutions)

-

Conveyor Systems Pvt. Ltd. (Belt Conveyors, Roller Conveyors, Slat Conveyors)

-

Murata Machinery, Ltd. (Automated Conveyor Systems, Storage Solutions, Robotic Systems)

-

Siemens (Material Handling Systems, Automated Conveyor Solutions, Automation Technology)

-

Taikisha Ltd. (Automated Conveyor Systems, Assembly Line Systems, Industrial Robots)

-

Caterpillar (Mining Conveyor Systems, Heavy-Duty Conveyors, Material Handling Equipment)

-

Dematic (Automated Guided Vehicles, Conveyor Systems, Warehouse Automation Solutions)

-

Swisslog (Automated Conveying, Warehouse Solutions, Robotics)

-

TGW Logistics Group (Automated Conveyor Systems, Sorting Systems, Warehouse Automation)

-

Vanderlande (Airport Baggage Handling Systems, Automated Conveyor Systems, Sorting Systems)

-

Honeywell Intelligrated (Conveyor Systems, Material Handling, Robotics, Automated Storage)

-

Schneider Electric (Automated Conveyor Solutions, Industrial Automation)

-

Mecalux (Automated Storage and Retrieval Systems, Conveyor Systems, Warehouse Solutions)

-

Beumer Group (Conveyor Systems, Parcel Handling, Bulk Material Handling)

-

Bastian Solutions (Automated Conveyor Systems, Warehouse Automation, Robotics Solutions)

Suppliers for (Integration of conveyor systems with robotic automation, and high-speed sorting technologies) on Conveyor Systems Market

-

Daifuku Co., Ltd.

-

Fives

-

Interroll Group

-

Kardex

-

Kuka AG

-

Mahindra Tsubaki

-

Conveyor Systems Pvt. Ltd.

-

Murata Machinery, Ltd.

-

Siemens

| Report Attributes | Details |

|---|---|

|

Market Size in 2025E |

USD 8.21 billion |

|

Market Size by 2033 |

USD 12.26 billion |

|

CAGR |

CAGR of 5.14% From 2026 to 2033 |

|

Base Year |

2025 |

|

Forecast Period |

2026-2033 |

|

Historical Data |

2022-2024 |

|

Report Scope & Coverage |

Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

|

Key Segments |

• By Type (Roller, Flat Belt, Wheel, Vertical, Others (Pneumatic and others)) |

|

Regional Analysis/Coverage |

North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

|

Company Profiles |

Daifuku Co., Ltd., Fives, Interroll Group, Kardex, Kuka AG, Mahindra Tsubaki, Conveyor Systems Pvt. Ltd., Murata Machinery, Ltd., Siemens, Taikisha Ltd., Caterpillar, Dematic, Swisslog, TGW Logistics Group, Vanderlande, Honeywell Intelligrated, Schneider Electric, Mecalux, Beumer Group, Bastian Solutions. |