Dimethyl Carbonate Market Report Scope & Overview:

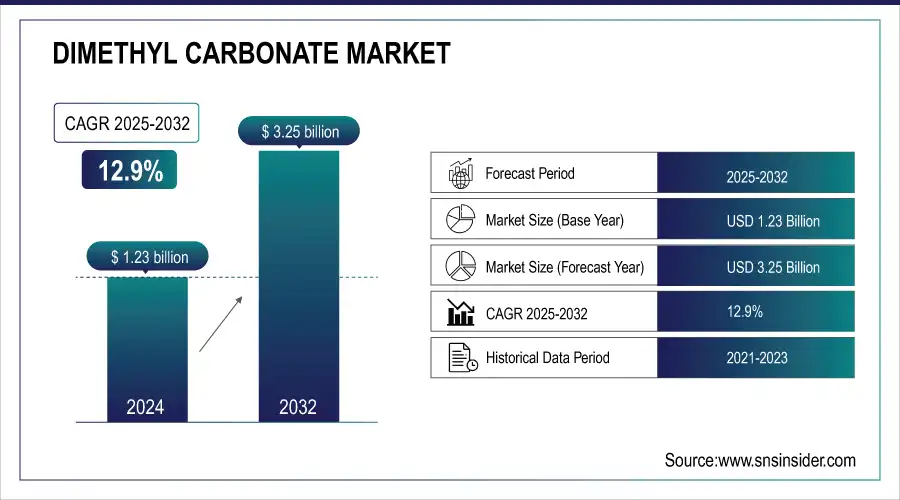

The Dimethyl Carbonate Market Size was USD 1.23 Billion in 2024 and is expected to reach USD 3.25 Billion by 2032, growing at a CAGR of 12.9% from 2025-2032.

The growth of the Dimethyl Carbonate (DMC) market is driven by the growing demand from automotive and electronics industries. DMC is valued for its high solubility and used as a solvent in battery electrolytes for lithium-ion batteries found in electric vehicles (EVs). With the global automotive industry transitioning to electric mobility, this growing demand for lithium-ion batteries is spurring demand for DMC. Moreover, DMC is a high-purity grade solvent frequently utilized in the electronics industry for the production of semiconductors, printed circuit boards (PCBs), displays, and other electronic parts.

Get More Information on Dimethyl Carbonate Market - Request Sample Report

For instance, policy frameworks like the U.S. Inflation Reduction Act and the EU's Net Zero Industry Act are driving investments in EV and battery technologies. These policies have already spurred nearly USD 500 billion in investment announcements between 2022 and 2023.

Dimethyl carbonate (DMC) is an intermediate used to make polycarbonate, a high-performance plastic that is commonly used in automotive, electronics, and construction. Polycarbonate is used in automotive components including headlights, dashboards, and glazing systems due to these properties being lightweight, durable, and impact-resistant reducing weight needed to improve fuel efficiency, reduce emissions, etc. Polycarbonate is used in housing for electronic devices, optical discs, and connectors in the electronics sector because of the electrical insulation properties of polycarbonate.

Market Size and Forecast:

-

Market Size in 2024 USD 1.23 Billion

-

Market Size by 2032 USD 3.25 Billion

-

CAGR of 12.9% From 2025 to 2032

-

Base Year 2024

-

Forecast Period 2025-2032

-

Historical Data 2021-2023

Dimethyl Carbonate Market Trends:

-

Growing adoption of polycarbonate in automotive, electronics, and construction due to its lightweight, high-performance, and recyclable properties.

-

Increasing emphasis on sustainability and circular economy practices driving the use of recyclable polymers like polycarbonate.

-

Regulatory support in Europe and North America promoting recycling and eco-friendly materials adoption.

-

Rising use of dimethyl carbonate (DMC) as an oxygenated fuel additive to improve combustion efficiency and reduce emissions.

-

Stricter global emissions regulations accelerating demand for cleaner, low-emission fuel additives and sustainable material solutions.

Dimethyl Carbonate Market Growth Drivers:

-

Growing demand for polycarbonate as a green revolution for a sustainable shift will drive market growth.

Polycarbonate is becoming a key driver for market expansion and is likely to witness an increase in demand due to the shift in focus of various industries towards sustainability. In the global race to serve ecologically friendly alternatives, polycarbonate a high-performance, lightweight, tough, and recyclable polymer plays an important role. The range of uses in automotive, electronics, and construction reflects its versatility and promise to supplant less sustainable materials, such as glass and metal. This type of material is used to manufacture lightweight automotive components which aid in fuel efficiency and lower the carbon footprint. In addition, because polycarbonate can be recycled, this also adheres to a circular economy, which is exactly what many companies are looking for to minimize the impact on the environment. Additionally, regulations to promote the use of sustainable materials are also driving its adoption while governments and environmental agencies are also promoting the use of polycarbonate. This transition secures polycarbonate and its contribution towards developing a greener narrative as a defining pillar of the green revolution needed to accomplish global sustainability goals.

Dimethyl Carbonate Market Restraints:

-

High production cost associated with its synthesis which may hamper the market growth.

The high cost of production during spectating the synthesis of Dimethyl Carbonate (DMC) may restrain the market growth adversely. Current DMC production pathways example, oxidative carbonylation of methanol, need the use of homogeneous catalysts, high energy input and complex high-tech processes. This explains the high manufacturing costs relative to other chemicals and solvents that are simpler to produce. Moreover, methanol, an important DMC production feedstock, can be subject to great price fluctuations, contributing to cost unpredictability. Consequently, the high costs associated with DMC may prevent manufacturers from providing the solution at an affordable price point, potentially restricting DMC adoption, particularly across cost-sensitive market segments. DMC is considered an environment-friendly product with a green image that can replace phosgene-based solvents; however, the higher cost of DMC as compared to its substitute products is a major factor that may hinder the extensive use of DMC in many end-users, which in turn is limiting the overall growth of the DMC market, as stated in the study.

Dimethyl Carbonate Market Opportunities:

-

Dimethyl carbonate is growing as a green fuel for cleaner burning gasoline and diesel.

Dimethyl carbonate (DMC) is a popular method for cleaner air. This versatile compound is suitable for gasoline and diesel fuels. By joining forces with these fuels, DMC becomes an "oxygenated additive," boosting combustion efficiency. Think of it as a tiny cheerleader inside the engine, urging the fuel to burn more completely. This translates to a significant reduction in harmful emissions like carbon monoxide (CO), unburnt hydrocarbons (HC), and those pesky soot particles known as particulate matter (PM). But DMC's benefits go beyond just a pep talk. With stricter emissions regulations being rolled out by governments worldwide to combat air pollution and climate change, vehicles need all the help they can get.

Dimethyl Carbonate Market Segment Analysis:

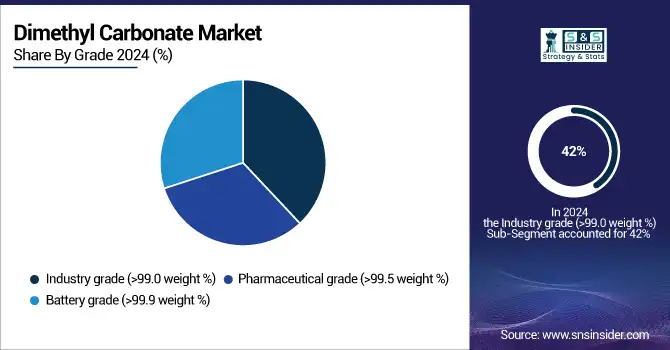

By Grade

The industry grade (>99.0 weight %) held the largest market share around 42% in 2024. This is mainly because its high-performance properties in various applications are set at the higher end of the market, where the material in industry-grade purity class is>99.0 %. This grade boasts a similar high purity and is thus an extremely competitive solution for industrial applications ranging from lithium-ion batteries to coatings, to pharmaceuticals. For lithium-ion batteries, DMC is used as a solvent in electrolyte formulation, but it requires high purity concerning its quality for better efficiency and stability of battery performance. It is also considered ideal as the better purity result also renders it suitable for sensitive processes such as coatings and adhesives that should not be influenced by even trace impurities that may affect the quality of the final product.

By Application

Polycarbonate synthesis held the largest market share around 43% in 2024. It is attributed to its increasing acceptance in numerous demand-driven sectors like automotive, electronics, construction, and healthcare. Polycarbonate has exceptional characteristics, combined with a high impact, optical clarity, and lightweight, especially suitable for durable and safety applications. Polycarbonate is used in automotive lighting, for making lightweight components to reduce the weight of the vehicles and vice versa, better vehicle fuel economy ratio, to meet stringent environmental regulations for low carbon emissions. In the electronic industry, polycarbonate transparency and toughness are vital for the production of such items as optical discs, LCDs, and device housing.

By End-User Industry

Paint and coatings held the largest market share around 28% in 2024. This is leading to an increase in preference for DMC in this industry as it serves as a greener solvent which aids in lowering the VOC emissions, an important factor of attraction as several governments across the globe impose stringent regulations on air pollution as well as solvents-based chemicals. Due to growing user inclination towards eco-friendly and less toxic substitutes, it is gradually becoming a commonly used solvent in paint & coating formulation, particularly in automotive, construction, and industrial segments.

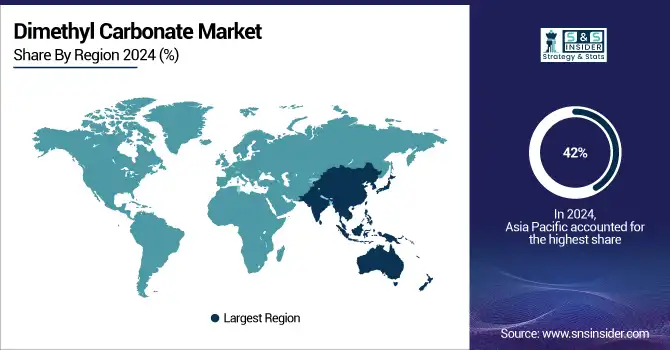

Dimethyl Carbonate Market Regional Analysis:

Asia Pacific Dimethyl Carbonate Market Insights

Asia Pacific held the highest market share around 42% in 2024. It is because of a synergy of factors including; industrial growth, manufacturing scale, and demand for sustainable solutions across multiple sectors. One of the largest production and consumption markets for Dimethyl Carbonate (DMC) is also based in this region, particularly in the automotive, electronics, and paints & coatings industries. DMC is an important material for high-performance materials such as polycarbonate, and the fast industrial development and infrastructural advancement in a few regions including China, India, and Japan, will drive the growth for the consecutive years. Moreover, the rapid adoption of eco-friendly substitutes like DMC in paints & coatings in the region, along with strict environmental regulations toward lessening VOC emissions followed by green techs will further drive regional growth.

Get Customized Report as per Your Business Requirement - Request For Customized Report

North America Dimethyl Carbonate Market Insights

The North America DMC market is driven by stringent emissions regulations, rising demand for cleaner fuels, and the adoption of sustainable materials in automotive and industrial applications. Growth is supported by environmental policies, advanced fuel additive technologies, and increasing awareness of eco-friendly solutions across the transportation and chemical sectors.

Europe Dimethyl Carbonate Market Insights

Europe’s DMC market is expanding due to strong focus on green fuels, sustainable chemical processes, and compliance with strict emission and environmental regulations. Growing adoption in automotive, industrial, and chemical industries, coupled with government initiatives promoting recyclable and low-emission solutions, fuels market growth across the region.

Latin America (LATAM) and Middle East & Africa (MEA) Dimethyl Carbonate Market Insights

The LATAM and MEA DMC markets are gradually growing, supported by rising demand in automotive, industrial, and chemical applications. Increasing adoption of fuel additives for emission control, sustainable practices, and government initiatives promoting environmental protection create opportunities for market expansion in these regions.

Dimethyl Carbonate Market Key Players:

-

UBE Corporation (UBE Dimethyl Carbonate, UBE DMC Solvent)

-

Guangzhou Tinci Materials Technology Co., Ltd. (Tinci DMC, Tinci Green Solvent)

-

Tokyo Chemical Industry Co., Ltd. (TCI Dimethyl Carbonate, TCI DMC Reagent)

-

Merck KGaA (DMC Reagent, Sigma-Aldrich DMC)

-

Shandong Shida Shenghua Chemical Group Co., Ltd. (Shida DMC, Shida DMC Solvent)

-

Thermo Fisher Scientific Inc. (Thermo Scientific DMC, Fisher Chemical DMC)

-

Kishida Chemical Co. Ltd. (Kishida DMC, Kishida DMC Solvent)

-

Lotte Chemical (Lotte DMC, Lotte Green Solvent)

-

Arrow Chemical Group Corp. (Arrow DMC, Arrow Carbonate)

-

Kowa Company Ltd. (Kowa DMC, Kowa Carbonate)

-

Haike Chemical Group (Haike DMC, Haike Dimethyl Carbonate)

-

Panax Etec (Panax DMC, Panax Dimethyl Carbonate)

-

Changzhou Yabang Chemical Co., Ltd. (Yabang DMC, Yabang Dimethyl Carbonate)

-

Jiangsu Sopo Chemical Co., Ltd. (Sopo DMC, Sopo Dimethyl Carbonate)

-

Zibo Jinguang Chemical Co., Ltd. (Jinguang DMC, Jinguang Green Solvent)

-

Mitsui Chemicals, Inc. (Mitsui DMC, Mitsui Dimethyl Carbonate)

-

SK Innovation Co., Ltd. (SK DMC, SK Dimethyl Carbonate)

-

Sinochem International Corporation (Sinochem DMC, Sinochem Green Solvent)

-

Evonik Industries AG (Evonik DMC, Evonik Solvent)

-

Dow Chemical Company (Dow DMC, Dow Dimethyl Carbonate)

Competitive Landscape for Dimethyl Carbonate Market:

UBE Corporation is a leading chemical manufacturer specializing in Dimethyl Carbonate (DMC) production, offering high-purity DMC for applications in fuel additives, pharmaceuticals, and organic synthesis. The company’s focus on sustainable, low-toxicity, and eco-friendly solvents positions it strongly in the growing DMC market, meeting global demand for cleaner fuels, safer chemical processes, and environmentally responsible industrial solutions.

-

In February 2024: UBE, a major player, announced the construction of a new US plant. This powerhouse will churn out a significant 100,000 metric tons of DMC annually, along with a bonus of 40,000 metric tons of DMC-derived EMC per year. This expansion reflects the growing demand for DMC and positions UBE to meet that need.

Merck KGaA is a global leader in specialty chemicals and life sciences, offering high-quality Dimethyl Carbonate (DMC) for applications in pharmaceuticals, organic synthesis, and fuel additives. With a focus on sustainable, eco-friendly solutions, Merck supports cleaner processes and efficient production, driving growth in the expanding DMC market worldwide.

-

In June 2023: Merck announced an expansion of their production capacity for high-purity reagents at their Chinese facility. While not directly DMC-related, this investment highlights the growing importance of high-quality control and testing materials, particularly for the biopharmaceutical industry.

| Report Attributes | Details |

|---|---|

| Market Size in 2024 | USD 1.23 Billion |

| Market Size by 2032 | USD 3.25 Billion |

| CAGR | CAGR of 12.9% From 2025 to 2032 |

| Base Year | 2024 |

| Forecast Period | 2025-2032 |

| Historical Data | 2021-2023 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | •By Grade (Industry Grade (>99.0 Weight %), Pharmaceutical Grade (>99.5 Weight %)Battery Grade (>99.9 Weight %)) •By Application (Polycarbonate Synthesis, Battery Electrolyte, Solvents, Reagents, Others) •By End-Use Industries (Plastics, Paints & Coating, Pharmaceutical, Battery, Agrochemicals, Others) |

| Regional Analysis/Coverage | North America (US, Canada), Europe (Germany, UK, France, Italy, Spain, Russia, Poland, Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Australia, ASEAN Countries, Rest of Asia Pacific), Middle East & Africa (UAE, Saudi Arabia, Qatar, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Mexico, Colombia, Rest of Latin America). |

| Company Profiles | UBE Corporation (Japan), Guangzhou Tinci Materials Technology Co., Ltd. (China), Tokyo Chemical Industry Co., Ltd. (Japan), Merck KGaA (Germany), Shandong Shida Shenghua Chemical Group Co., Ltd. (China), Thermo Fisher Scientific Inc. (US), Kishida Chemical Co. Ltd. (Japan), Lotte Chemical (South Korea), Arrow Chemical Group Corp., Kowa Company Ltd. (Japan), Haike Chemical Group, Panax Etec |