Dual Flap Dispensing Closure Market Report Scope & Overview:

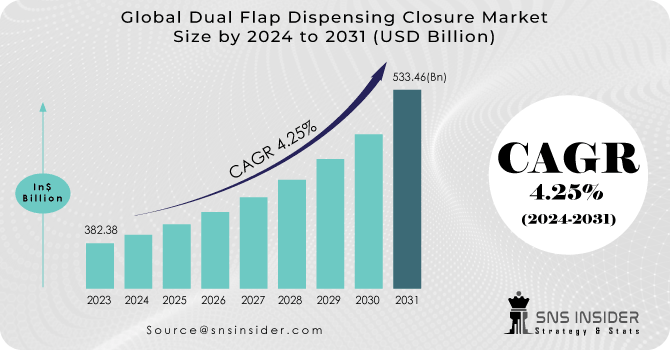

The Dual Flap Dispensing Closure Market size was USD 382.38 billion in 2023 and is expected to Reach USD 533.46 billion by 2031 and grow at a CAGR of 4.25 % over the forecast period of 2024-2031.

Increasing demand for efficient and user-friendly packaging solutions is driving the growth of the dual flap dispensing closure market. Expanding the food and beverage industry and increasing awareness about their environmental benefits create the need for innovative packaging solutions. The demand for dual flap dispensing closures, including the rise of innovative packaging, a growing focus on consumer convenience, and stricter regulations for product safety and hygiene is further boosting the market growth. The increased usage of seasonings and sweeteners has elevated the growth of the dual flap dispensing closure market.

Get More Information on Dual Flap Dispensing Closure Market - Request Sample Report

The future demand landscape for the dual flap dispensing closure market is poised for growth, driven by several key factors like consumers are increasingly prioritizing both convenience and hygiene, especially when it comes to dispensing liquids or semi-liquids. Dual flap dispensing closures find applications across various industries, including food and beverage, personal care, household products, and automotive fluids. With the expansion of these industries, driven by population growth, urbanization, and changing lifestyles, the demand for reliable and efficient dispensing solutions is projected to increase. There is a growing emphasis on sustainable packaging solutions due to environmental concerns and regulatory pressure. Consolidation activities like mergers and acquisitions can benefit investors by creating larger companies with economies of scale and a broader market reach, making them more attractive investment targets.

MARKET DYNAMICS

KEY DRIVERS:

-

Consumer Demand for Clean and Efficient Dispensing:

The rise in consumer demand for tidy and spill-free dispensing solution fuels the market growth of dual flap dispensing closures, which excel at minimizing mess and waste. The increasing consumer preference for clean and mess-free dispensing experiences, driven by heightened awareness of hygiene and sustainability.

-

Brand emphasis on innovative packaging, such as dual flap dispensing closures, establishes product differentiation.

RESTRAIN:

-

Due to complex design and materials, dual flap closures can be costlier for small businesses compared to traditional options.

For small and medium-sized businesses may find it more expensive compared to traditional closures. Manufacturing dual flap dispensing closures involves more intricate designs and specialized materials, which can increase production expenses.

-

Manufacturers must check the compatibility with existing packaging infrastructure.

OPPORTUNITY:

-

Expanding the market penetration of dual flap dispensing closure globally

Emerging markets with rising disposal incomes and changing consumer preferences represent untapped opportunities for dual flap dispensing closure manufacturers to introduce their products and expand their global footprint. Dual flap dispensing closures find applications in wide range of industries. This versatility allows manufacturers to target multiple markets and cater to diverse consumer needs. Regulatory requirements mandating tamper-evident packaging and child-resistant closures in certain industries create opportunities for dual flap dispensing closures. Their ability to incorporate safety features while maintaining user accessibility positions them as compliant solutions for manufacturers navigating regulatory landscapes.

-

Increase in Packaging Innovation

CHALLENGES:

-

Huge educational efforts required to familiarize consumers with their benefits, usage instructions, and disposal practices.

-

Sustainability concerns adds challenge in demand of dual flap dispensing closure

IMPACT OF RUSSIAN UKRAINE WAR

The war zone disrupts the flow of raw materials and manufactured goods, potentially impacting the availability and cost of materials used in dual flap closures. Disruptions continue to jam shipping lanes, leaving stockpiles of plastic clogging warehouses. The cost of pallets skyrockets on top of already outrageous shipping fees, pressuring resin producers. The conflict can lead to higher oil prices, which can affect the cost of plastic resins used in closures. Substantial polypropylene (PP) and polyethylene (PE) price hikes and a 30% diminishment of production capacity added to the burden. The war triggered a mass exodus of over 300 major Western companies from Russia and Ukraine, leading to widespread closures of packaging and production facilities.

IMPACT OF ECONOMIC SLOWDOWN

Due to economic slowdown consumers often tighten their budget and reduce discretionary spending. This can lead to decreased demand for consumer products, including those equipped with dual flap dispensing closures. It can also cause the reduction in industrial activity, including manufacturing and production processes. Industries reliant on closures, such as beverage bottling plants and manufacturing facilities, may scale back operations, leading to decrease in demand for closure. Economic downturns can disrupts supply chains, causing delays in the procurement of raw materials. Consumers and businesses can lead to more price sensitive and may seek lower-cost alternatives. Economic uncertainty delays the investments in innovation initiatives among closure industry. Companies may revaluate their strategies and prioritize cost-saving measures, which could impact long-term demand pattern for dual flap dispensing closure though the economy recovers.

KEY MARKET SEGMENTS

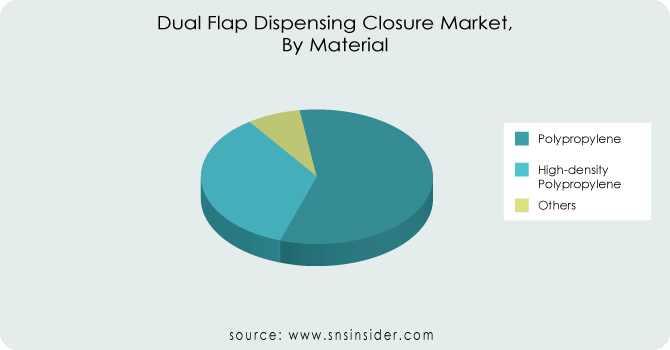

By Material

-

Polypropylene

-

High-density Polypropylene

-

Others

Dual flap closures go beyond the typical cap, offering a winning combination of features are made from robust plastics like PP and HDPE, they're durable and long-lasting. Their lightweight design makes them easy to handle and transport without sacrificing functionality. The market share for Polypropylene is 57.6% in 2023.

Get Customized Report as per Your Business Requirement - Request For Customized Report

By Liner type

-

Heat Induction Seal Foil Liner

-

Pressure Sensitive Liner

By Application

-

Spices, Condiments & Seasonings

-

Sweeteners

-

Confectionery & Bakery Products

-

Others

These closures are especially popular for spices, condiments, and seasonings, as they help keep them fresh and prevent them from clumping. Dual flaps are also finding their way onto containers for various baked goods, offering a convenient way to sprinkle or drizzle without the frustration of traditional closures. The market share of Spices, Condiments, and Seasonings is 46.1% in 2023.

By End Use Industry

-

Food Service Outlets

-

Households

-

Theatres & Malls

REGIONAL ANALYSIS

The Asia Pacific region stands out as a leader in dual flap dispensing closures due to its massive population across many countries. This large and growing consumer base creates significant demand for various beverage packaging closure solutions.

The United States leads the charge in both the production and utilization of dual flap dispensing closures. While the market may seem saturated, projections indicate a steady growth trajectory with sales expected to increase.

Being the leader in the European dual flap dispensing closure market, Germany still expects a considerable rise in demand for this product over the next decade. The United Kingdom market for dual flap dispensing closures is on the rise, driven by consumers' preference for convenient and mess-free products. In response, manufacturers are prioritizing user-friendly designs and ensuring compatibility with various products to meet these evolving customer demands.

China is the frontrunner in this region.This growth is driven by two main factors are, the widespread use of spices and condiments, which often require convenient and secure closures.,The increasing popularity of food service retail chains, which creates a demand for tamper-evident and easy-to-use closures for takeout and packaged food.

India is expected to be a major player in the dual flap dispensing closure market, fueled by the country's love for spices. This growth is driven by two key factors are, the rising demand for spices, which benefit from the secure and convenient dispensing offered by dual flap closures. The increasing preference for products with user-friendly features, which aligns perfectly with the ease of use that dual flap closures provide.

REGIONAL COVERAGE:

North America

-

US

-

Canada

-

Mexico

Europe

-

Eastern Europe

-

Poland

-

Romania

-

Hungary

-

Turkey

-

Rest of Eastern Europe

-

-

Western Europe

-

Germany

-

France

-

UK

-

Italy

-

Spain

-

Netherlands

-

Switzerland

-

Austria

-

Rest of Western Europe

-

Asia Pacific

-

China

-

India

-

Japan

-

South Korea

-

Vietnam

-

Singapore

-

Australia

-

Rest of Asia Pacific

Middle East & Africa

-

Middle East

-

UAE

-

Egypt

-

Saudi Arabia

-

Qatar

-

Rest of Middle East

-

-

Africa

-

Nigeria

-

South Africa

-

Rest of Africa

-

Latin America

-

Brazil

-

Argentina

-

Colombia

-

Rest of Latin America

Key players

The major key players are MOCAP, Cap & Seal, O. Berk Company LLC, Aaron Packaging Inc., Feldman Industries Inc., FLOCON, Inc., Mold-Rite Plastics, Kaufman Container, Alameda Packaging LLC, Illing Company and others.

Berk Company LLC-Company Financial Analysis

RECENT DEVELOPMENT

-

In January 2023, MJS Packaging unveiled dual flap and shake dispensing closures tailored for spices, seasonings, and various products. The company has offered a wide selection of sizes, colors, liners and combinations, enabling customers to select the options that best align with their requirements.

-

Borealis and Menshen, Leaders in plastic closure and packaging solutions, unveiled a groundbreaking recycling technology in September 2020. Known AS Ten Package Closures, this innovative solution transforms polyolefin waste streams into adaptive goods, adding significant value to the recycling process.

| Report Attributes | Details |

| Market Size in 2023 | US$ 382.38 Billion |

| Market Size by 2031 | US$ 533.46 Billion |

| CAGR | CAGR of 4.25% From 2024 to 2031 |

| Base Year | 2023 |

| Forecast Period | 2024-2031 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Material (Polypropylene, High-Density Polypropylene, Others) • By Liner Type (Heat Induction Seal Foil Liner, Pressure Sensitive Liner) • By Application (Spices, Condiments, Seasonings, Sweeteners, Confectionery & Bakery Products, Others) • By End Use Industry (Food Service Outlets, Households, Theatres & Malls) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | MOCAP, Cap & Seal, O. Berk Company LLC, Aaron Packaging Inc., Feldman Industries Inc., FLOCON, Inc., Mold-Rite Plastics, Kaufman Container, Alameda Packaging LLC, Illing Company |

| Key Drivers | • Consumer Demand for Clean and Efficient Dispensing: • Brand emphasis on innovative packaging, such as dual flap dispensing closures, establishes product differentiation. |

| Market Opportunities | • Expanding the market penetration of dual flap dispensing closure globally • Increase in Packaging Innovation |