Epitaxial Wafer Market Size & Growth:

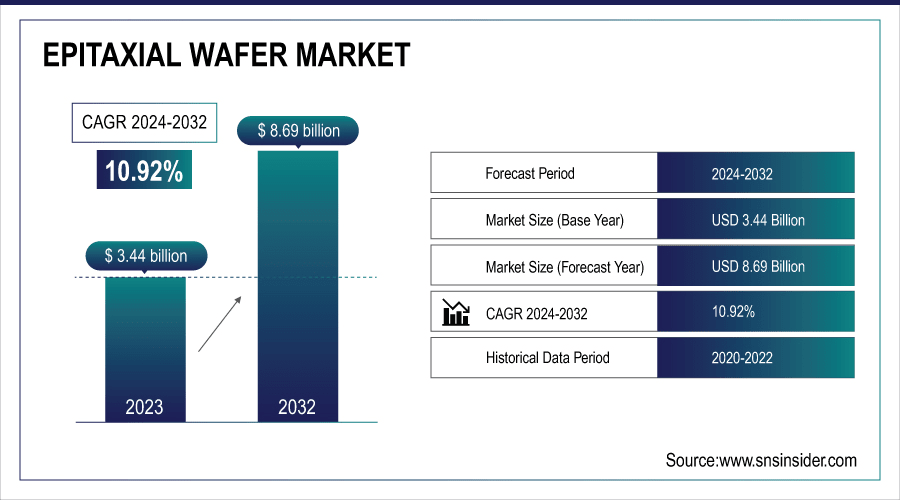

The Epitaxial Wafer Market was valued at USD 3.44 billion in 2023 and is anticipated to expand to USD 8.69 billion by the year 2032, with a CAGR of 10.92% in the forecasted period of 2024 to 2032.

To Get More Information On Epitaxial Wafer Market - Request Free Sample Report

This expansion is being fueled by the rising need for high-performance semiconductors in industrial automation, electric vehicles, and consumer electronics. Epitaxial wafers play a vital role in improving device efficiency and reliability, especially in power semiconductors and LED applications. Technological innovations and growth in 5G and IoT are also driving market demand. The region that innovates first is North America, but Asia-Pacific is still the largest manufacturing hub.

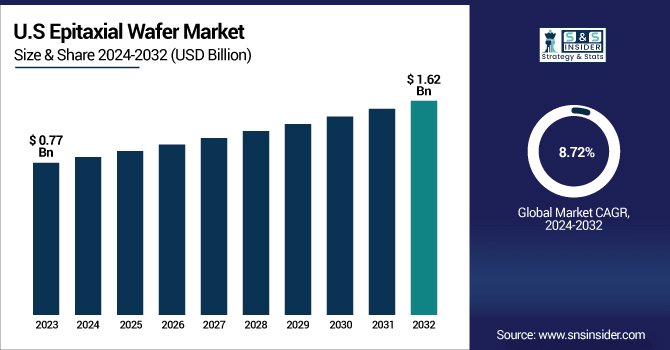

The U.S. Epitaxial Wafer Market size was USD 0.77 billion in 2023 and is expected to reach USD 1.62 billion by 2032, growing at a CAGR of 8.72% during the forecast period from 2024 to 2032.

This expansion is driven by rising needs for sophisticated semiconductor technology in industries like automotive, consumer products, aerospace, and defense. The U.S. is still a leading innovator of semiconductor R&D, with major investments backing local chip production. Increased use of electric cars and AI and 5G infrastructure developments also help fuel the growth of the market within the United States.

Epitaxial Wafer Market Dynamics

Key Drivers:

-

Increasing Use of Advanced Semiconductor Materials in Power Electronics and Automotive Applications Accelerates Epitaxial Wafer Market Growth

The wide application of new semiconductor materials like silicon carbide (SiC) and gallium nitride (GaN) in power electronics and automotive industries is largely contributing to the expansion of the epitaxial wafer market. These materials, when integrated into epitaxial wafers, improve device efficiency, heat conduction, and voltage tolerance and are hence suitable for electric vehicles (EVs), fast chargers, and power management devices. With demand for EVs mounting and governments forcing cleaner transport options, automakers are committing deeply to new-era semiconductor technology dependent on epitaxial layering. Also driving the market now are consumer gadgets and factory control systems, demanding more efficient and high-reliability components designed to run long hours at high-frequency and high-power operations. The application of epitaxial wafers in supporting the performance is rapidly becoming invaluable. Governments and the private sector are both funding R&D efforts and infrastructure creation to increase the production of epitaxial wafers, further fueling the market's strong and consistent growth worldwide.

Restrain:

-

High Capital Investment Requirements for Manufacturing Facilities Limit Small Players from Entering the Epitaxial Wafer Market

The epitaxial wafer market requires a heavy capital outlay to set up manufacturing units. The manufacturing process for epitaxial wafers consists of sophisticated deposition technologies, precise temperature control systems, and ultraclean environments, all of which require high initial investments. Moreover, the need to uphold quality standards and yield efficiency with different wafer sizes adds more operational complexity and cost.

Consequently, most small and medium-sized businesses (SMEs) are unable to access the market, resulting in high market concentration among a few large players. These cost obstacles also limit innovation and scale in developing markets, where high-tech semiconductor infrastructure funding is usually scarce. Additionally, the long return on investment gestation period in this category discourages new entrants and decreases market competitiveness. As demand is increasing, the stringent entry barrier is still a critical factor limiting the overall growth and diversification of the global epitaxial wafer market.

Opportunities:

-

Emerging Demand for Epitaxial Wafers in 5G Infrastructure and Smart Devices Presents Significant Growth Opportunities Worldwide

The mass deployment of 5G networks and the growing penetration of smart devices are creating new opportunities for growth in the epitaxial wafer market. Epitaxial wafers are required to produce high-frequency and high-speed components utilized in 5G base stations, RF front ends, and smart sensors. These usages require superb material quality and performance, both of which epitaxial wafer technology provides. With increasing global demand for quick and dependable connectivity, telecom operators and OEMs are investing in newer infrastructure, hence fueling the consumption of wafers.

Further, smart home, industrial Internet of Things, wearable technology, and autonomous technology need small, power-efficient chips created with epitaxial wafers. The change in the trend of consumer and industrial electronics offers a bright growth prospect to wafer producers to diversify their product mix and increase their presence globally. Cooperation with telco giants and chipset makers should be expected to speed up adoption and innovation in epitaxial wafer-based solutions in 5G-upcoming ecosystems.

Challenges:

-

Supply Chain Instability and Dependence on Limited Material Sources Challenge Global Epitaxial Wafer Production and Distribution

The epitaxial wafer industry is under severe threat from supply chain volatility and dependence on restricted sources of raw materials. Silicon, silicon carbide (SiC), and gallium nitride (GaN), the fundamental materials employed in epitaxial wafer production, are frequently supplied by a handful of international suppliers. Interruptions in the mining, processing, or exportation of any of these raw materials can cause crucial production bottlenecks. In addition, geopolitical tensions, export controls, and transportation disruptions make the global supply chain even more complicated. They not only influence material availability but also lead to volatile pricing and long lead times for wafer makers. As demand increases from several end-use industries, supply interruption can drastically impact production cycles and delivery promises. Firms are now trying to diversify supply chains, establish regional fabs, and invest in recycling technologies for materials, but such initiatives take time and a huge amount of money. Until such time, supply chain vulnerability continues to be an integral operational problem.

Epitaxial Wafer Market Segment Analysis

By Type

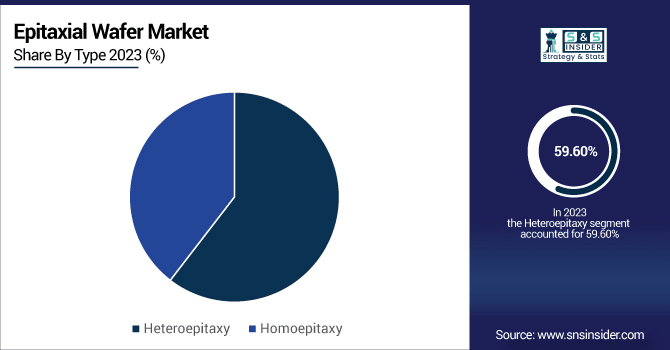

In 2023, the Heteroepitaxy segment held the highest revenue share of 59.60% in the epitaxial wafer market due to its extensive use in sophisticated semiconductor devices. Players such as IQE have been at the forefront of this growth; IQE's manufacturing of epitaxial wafers from materials like gallium arsenide (GaAs) and gallium nitride (GaN) is for high-performance applications in microLED displays and electro-optic devices. Also, Nexperia's partnership with Mitsubishi Electric to design silicon carbide (SiC) power semiconductors highlights the emphasis of the industry on heteroepitaxial technologies for efficient power conversion.

The Homoepitaxy market is expected to grow at a fast rate, with a CAGR of 12.43% over the forecast period, due to its high crystal quality and lower defect densities. The growth is represented by developments such as Infineon Technologies' partnership with SK Siltron CSS for the manufacture of 150-mm silicon carbide wafers, which are critical in high-voltage applications.

Furthermore, the growing demand for high-efficiency SiC epitaxial wafers in the solar cell industry, as designed by firms such as United Silicon Carbide Inc., is an indicator of the growing applications of homoepitaxial wafers in renewable energy industries. These developments show a clear move towards homoepitaxial technologies to satisfy the strict performance demands of future semiconductor devices.

By Wafer Size

The 9–12-inch wafer size category ruled the epitaxial wafer market in 2023, generating 53.71% of the market revenue. Its popularity can be explained by the universal adoption of bigger wafers in large-volume semiconductor production, which raises efficiency and decreases costs. The likes of Siltronic AG have played a key role in this category by manufacturing 300mm (12-inch) silicon wafers through a collaborative effort with Samsung Electronics in Singapore. These wafers are critical to high-end applications in consumer electronics and automotive markets. The growing need for high-performance devices and the miniaturization trend have further driven the expansion of this segment, cementing its market leadership position.

The 5–8-inch wafer size segment is also expected to register the Fastest CAGR of 14.45% during the forecast period. This is attributable to increasing demand for medium wafers in applications including MEMS-based devices, power semiconductors, and LEDs. Firms such as IQE have extended their manufacturing capabilities to cover 8-inch gallium arsenide (GaAs) and gallium nitride (GaN) epitaxial wafers for use in microLED displays and electro-optic devices. The multiple uses and the low cost of 5–8 inch wafers render them versatile enough for use in a wide variety of applications, hence the rampant growth in the epitaxial wafer business.

By Application

In 2023, the LED application segment dominated the epitaxial wafer industry, accounting for 35.61% of the overall revenue. This is due to the extensive use of LEDs across a number of applications, such as consumer electronics, automotive lighting, and general lighting. Organizations like IQE have played a major role in the growth, as they manufacture 8-inch gallium arsenide (GaAs) and gallium nitride (GaN) epitaxial wafers, which are critical to microLED display and other optoelectronic applications. The ongoing developments in LED technology, combined with the need for energy-efficient lighting, have driven the demand for high-quality epitaxial wafers, further solidifying the segment's market leadership.

The Power Semiconductor segment is estimated to have the Fastest CAGR of 13.00% through the forecast period. It is spurred by a growing demand for effective power management solutions in renewable energy systems, industrial applications, and electric vehicles (EVs). It has been Transphorm and such other companies at the forefront who have been manufacturing gallium nitride (gan) power transistors of improved performance profile, including an increased short-circuit withstand time, to match the requirements of contemporary power electronics. The addition of advanced epitaxial wafers within power semiconductor products guarantees increased efficiency, lower losses in energy, and smaller footprint, all for the global quest for sustainable energy-efficient technologies.

By Industry Vertical

In 2023, the Consumer Electronics industry dominated the epitaxial wafer market, accounting for 42.30% of the overall revenue. This is fueled by the growing demand for high-performance devices like smartphones, tablets, and wearable technology, which need sophisticated semiconductor components. Players such as IQE have played a key role in this growth, manufacturing 8-inch gallium arsenide (GaAs) and gallium nitride (GaN) epitaxial wafers for microLED displays and other optoelectronic applications. The relentless innovation in consumer electronics, as well as the demand for energy-efficient and space-saving components, has driven the use of epitaxial wafers, further solidifying the segment's dominant position in the market.

The Automotive industry is anticipated to witness the maximum CAGR of 14.29% throughout the forecast period. It is driven by the growing adoption of sophisticated semiconductor devices in electric vehicles (EVs), autonomous vehicles, and in-car infotainment.

In March 2023, Resonac Corporation's silicon carbide (SiC) epitaxial wafers for its new inverter's driver elements, which will be mounted in Toyota's new BEV model, "LEXUS RZ."

The use of SiC-based inverters offers increased vehicle energy efficiency and expanded driving ranges, indicating the paramount importance of epitaxial wafers in contemporary automobile applications.

Epitaxial Wafer Market Regional Overview

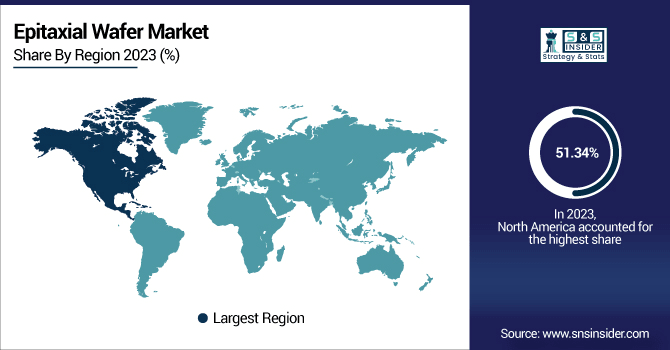

North America dominated the global epitaxial wafer market in 2023, at 51.34% of the total revenue. The reasons include a strong semiconductor ecosystem in the region as well as investments in EVs, aerospace, and defense industries. GlobalFoundries signed a strategic partnership with General Motors to provide U.S.-made semiconductor chips to boost domestic chip-making capability.

Get Customized Report as Per Your Business Requirement - Enquiry Now

Moreover, Wolfspeed also opened a world-class silicon carbide (SiC) production plant in Marcy, New York, with strong federal support, to address the growing need for power semiconductors in EVs and renewable energy technologies. All these initiatives highlight North America's dedication to driving semiconductor technologies, thus solidifying its position in the epitaxial wafer industry.

Asia Pacific is expected to grow with the highest CAGR of 14.63% in the market for epitaxial wafers in the forecast period. The growth is fueled by the expansion of consumer electronics, IoT devices, and 5G infrastructure. In 2023, LG Siltron began mass production of 6-inch silicon carbide epitaxial wafers to meet the skyrocketing demand in power electronics. In addition, United Silicon Carbide Inc. created high-efficiency SiC epitaxial wafers for the solar cell industry, which corresponds to the region's drive towards renewable energy alternatives. These innovations, combined with huge investments in semiconductor production, make the Asia Pacific a key player in the global epitaxial wafer market.

Key Companies Listed in the Epitaxial Wafer Market Report are:

-

Epistar Corporation – (AlGaInP High-Brightness LED Chips, Mini/Micro LED Chips)

-

GlobalWafers (Sino-American Silicon) –(300mm Silicon-On-Insulator (SOI) Wafers, 200mm Epitaxial Wafers)

-

II-VI Incorporated – (Silicon Carbide (SiC) Epitaxial Wafers, Semiconductor Lasers for LiDAR)

-

IntelliEPI (GaAs-Based Epitaxial Wafers, InP-Based Epitaxial Wafers)

-

Jenoptik AG (Silicon Epitaxial Wafers, Optoelectronic Components)

-

Nichia Corporation (High-Purity Gallium, Vacuum Evaporation Materials)

-

Silicon Valley Microelectronics Inc. – (Silicon Epitaxial Wafers, Silicon-On-Insulator (SOI) Wafers)

-

Siltronic AG (Wacker Chemie AG) – (300mm Silicon Epitaxial Wafers, Float Zone Silicon Wafers)

-

Sumco Corporation – (Polished Silicon Wafers, Silicon-On-Insulator (SOI) Wafers)

Epitaxial Wafer Market Trends

-

In December 2024, the U.S. Commerce Department finalized $406 million in subsidies for GlobalWafers to enhance silicon wafer production in Texas and Missouri. This initiative aims to establish the first high-volume U.S. production of 300-mm wafers for advanced semiconductors and expand silicon-on-insulator wafer production.

-

In September 2024, Coherent Corp. announced the launch of its 200 mm Silicon Carbide Epitaxial Wafers, marking a significant advancement in their epitaxial wafer manufacturing capabilities.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 3.44 Billion |

| Market Size by 2032 | USD 8.69 Billion |

| CAGR | CAGR of 10.92 % From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | •By Type – ( Heteroepitaxy, Homoepitaxy ) •By Wafer Size – ( 2-4 Inch,5-8 Inch,9-12 Inch, Others ) •By Application – ( LED ,Power Semiconductor ,MEMS-Based Devices, Others) •By Industry Vertical – (Consumer Electronics, Automotive, Healthcare, Industrial) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Electronics And Materials Corporation Limited, Epistar Corporation, GlobalWafers (Sino-American Silicon), II-VI Incorporated, IntelliEPI, Jenoptic AG, Nichia Corporation, Silicon Valley Microelectronics Inc., Siltronic AG (Wacker Chemie AG), Sumco Corporation. |