Flexographic Printing Market Size & Trends

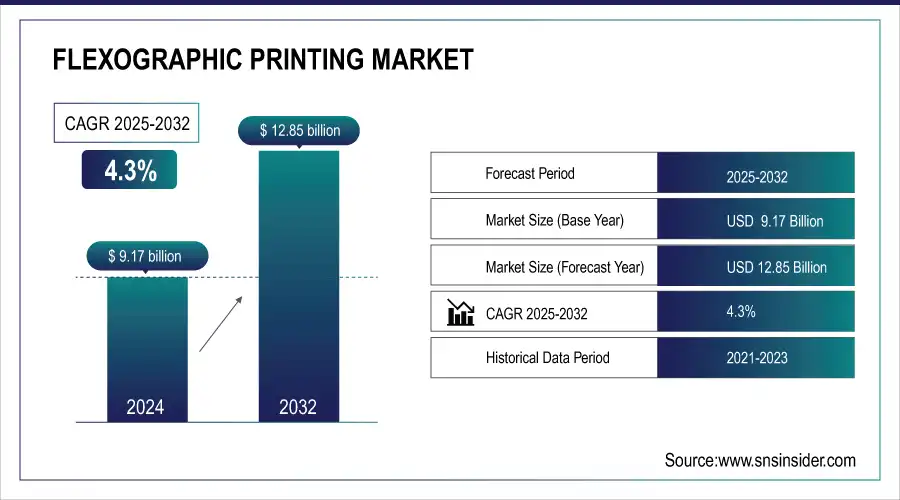

The Flexographic Printing Market size was valued at USD 9.17 billion in 2024 and is expected to grow to USD 12.85 billion at a CAGR of 4.3% by 2025-2032. The flexographic printing market is witnessing robust growth, driven by the increasing demand for efficient and high-quality printing solutions across various industries, particularly in packaging. Flexographic printing utilizes flexible relief plates to transfer ink onto a variety of substrates, making it ideal for printing on materials such as plastic, paper, and film. This technology is widely adopted for its ability to produce vibrant colors and sharp images at high speeds, catering to the evolving needs of consumer goods, food and beverage, and pharmaceuticals sectors.

Flexographic Printing Market Size and Forecast:

-

Market Size in 2024: USD 9.17 billion

-

Market Size by 2032: USD 12.85 billion

-

CAGR: 4.3% from 2025 to 2032

-

Base Year: 2024

-

Forecast Period: 2025–2032

-

Historical Data: 2021–2023

Get E-PDF Sample Report on Flexographic Printing Market - Request Sample Report

A new collaborative initiative in the flexographic printing market is setting a gold standard for sustainable packaging solutions, reflecting the growing demand from brand owners and consumers for eco-friendly manufacturing processes. This project brings together expertise across various domains, including prepress, plates, inks, substrates, sleeves, and printing technologies, aimed at enhancing the sustainability of flexible packaging production. One significant achievement of this collaboration is the creation of a colorful flexo-printed zipper bag using a seven-color extended gamut (ECG) process supported by white ink, utilizing polyethylene (PE) substrates to form a complete mono-material construction that facilitates easier recycling.

Key Flexographic Printing Market Trends:

-

Rising demand for eco-friendly packaging materials and inks driven by sustainability goals and consumer awareness.

-

Regulatory support from the European Union’s Directive on single-use plastics promoting sustainable flexographic printing practices.

-

Increasing use of water-based and environmentally friendly inks aligned with circular economy and recycling targets.

-

Integration of digital technologies such as computer-to-plate (CTP) systems to improve efficiency and reduce production costs.

-

Emergence of hybrid printing models combining flexographic and digital inkjet technologies for variable data and high-quality outputs.

Flexographic Printing Market Growth Drivers:

-

Sustainable Packaging Solutions Fueling Growth in the Flexographic Printing Market

The flexographic printing industry is experiencing robust growth driven by the rising demand for eco-friendly packaging materials and inks, alongside increasing consumer awareness of environmental concerns. As businesses shift toward sustainable practices, flexographic printing has emerged as a preferred choice due to its capability to print on a diverse range of substrates, including biodegradable plastics, recycled paper, and plant-based materials. The urgency of transitioning from traditional packaging to more sustainable alternatives is underscored by the European Union's Directive on single-use plastics, which aims to mitigate the environmental impact of these products through regulatory measures. This framework promotes the use of flexographic printing in sustainable packaging solutions by utilizing water-based and environmentally friendly inks that align with EU sustainability goals. The directive targets ten specific single-use plastic items, prompting manufacturers to explore innovative alternatives, thereby fostering growth in the flexographic printing sector.

-

Improving Efficiency and Customization through Digital Transformation in Flexographic Printing Market

The integration of digital technologies into the flexographic printing market is fundamentally transforming the industry by enhancing efficiency, flexibility, and quality. Traditionally celebrated for its speed and cost-effectiveness in high-volume production, flexographic printing is now benefiting from digital advancements that address the evolving demands of the market. Digital prepress technologies, such as computer-to-plate (CTP) systems, streamline workflows by minimizing setup times and reducing errors, ultimately lowering production costs. This technological shift facilitates quicker turnaround times, enabling brands to swiftly adapt to market trends and consumer preferences.

Flexographic Printing Market Restraints:

-

Navigating Material Price Volatility in the Flexographic Printing Market

The flexographic printing market is increasingly challenged by fluctuating prices of raw materials, which directly impact production costs and profitability. Key materials such as inks, substrates, and printing plates are subject to price instability due to various factors, including supply chain disruptions, geopolitical tensions, and environmental regulations. For instance, the rising cost of petroleum-based products affects the pricing of many inks and substrates, while increased demand for eco-friendly materials can further strain supply chains. This volatility necessitates that flexographic printers adopt more strategic procurement practices and foster strong relationships with suppliers to ensure stable material costs. Additionally, the shift towards sustainable packaging amplifies the need for alternative materials, which can often come at a premium. As companies navigate these challenges, they are compelled to innovate by seeking cost-effective substitutes and optimizing their printing processes to maintain competitiveness.

Flexographic Printing Market Segmentation Insights:

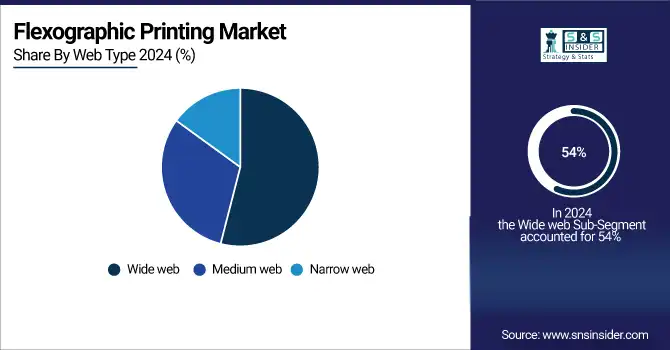

by Web Type

In the Flexographic printing market, the wide web segment captured the largest revenue share, accounting for 54% in 2024, primarily due to its extensive application in packaging materials, labels, and flexible films. This growth is driven by the increasing demand for high-quality printing and faster production speeds in various industries, including food and beverage, personal care, and pharmaceuticals. Leading companies are actively launching innovative products to capitalize on this trend. For instance, Bobst introduced the M1 and M5 series, advanced wide web flexographic printing presses that offer enhanced precision and efficiency, catering to the evolving needs of the packaging sector. Similarly, Mark Andy unveiled its HD Flexo technology, which combines high-definition imaging with wide web capabilities, enabling converters to achieve exceptional print quality while reducing waste.

by Application

In the Flexographic printing market, flexible packaging emerged as the leading application, capturing 44% of the revenue share in 2024. This dominance can be attributed to the increasing demand for lightweight, convenient, and sustainable packaging solutions across various sectors, particularly in food and beverage, personal care, and pharmaceuticals. Flexible packaging offers significant advantages, such as extended shelf life, reduced material usage, and enhanced product protection, making it a preferred choice for manufacturers aiming to improve sustainability and reduce costs.Companies in the flexographic printing industry are actively launching innovative products and technologies to cater to this growing demand. For instance, Sealed Air launched its Cryovac brand of flexible packaging solutions, which incorporates advanced barrier technologies to enhance food preservation and reduce spoilage.

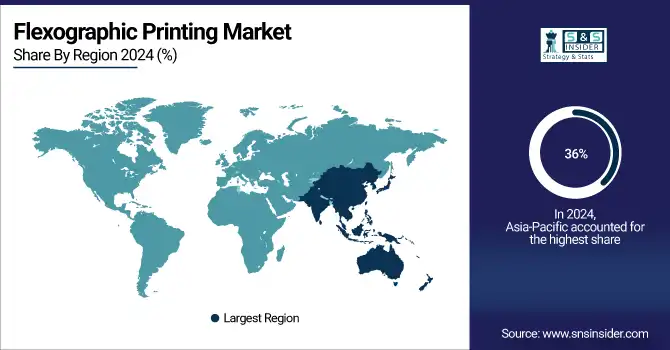

Flexographic Printing Market Regional Analysis:

Asia Pacific Flexographic Printing Market Insights

In 2024, the Asia-Pacific region dominated the flexographic printing market, capturing 36% of the share revenue. This dominance is largely driven by rapid industrialization, a booming packaging sector, and increasing demand for flexible packaging solutions across various industries such as food and beverage, pharmaceuticals, and consumer goods. Countries like China and India are witnessing significant growth due to rising urbanization, changing consumer preferences, and advancements in printing technology. Major players in the region are responding to this demand with innovative product launches. For instance, Hindustan Aeronautics Limited (HAL) unveiled its new Flexo Print Technology, designed to enhance the efficiency and quality of printing processes for flexible packaging.

Get Customized Report as Per Your Business Requirement - Request For Customized Report

North America Flexographic Printing Market Insights

In 2024, North America emerged as the second fastest-growing region in the flexographic printing market, driven by technological advancements, a robust packaging industry, and increasing consumer demand for sustainable packaging solutions. The region is witnessing significant investments in research and development, leading to innovations that enhance printing efficiency and quality. Major companies are actively launching new products to capture market opportunities. For example, Mark Andy introduced the P7E Flexographic Press, designed to optimize workflow and reduce waste, which has gained traction among converters looking for efficient solutions. Similarly, DIC Corporation launched a new line of eco-friendly inks that meet stringent environmental regulations while maintaining high-quality print standards, appealing to brands focusing on sustainability. Moreover, MacDermid Graphics Solutions unveiled advanced photopolymer plates that provide superior print quality and durability, catering to the increasing demand for flexible packaging.

Europe Flexographic Printing Market Insights

The Europe Flexographic Printing Market is experiencing growth driven by rising demand for sustainable and eco-friendly packaging solutions. Increasing consumer awareness of environmental concerns and regulatory frameworks, such as the EU single-use plastics directive, are promoting the use of water-based and UV-curable inks. Flexographic printing’s versatility across substrates, including biodegradable plastics and recycled materials, supports packaging, labeling, and commercial printing applications. Technological advancements, digital-flexo integration, and demand for high-quality, cost-efficient, and flexible printing solutions are further boosting market expansion.

Latin America (LATAM) and Middle East & Africa (MEA) Flexographic Printing Market Insights

The LATAM and MEA Flexographic Printing markets are growing due to increasing demand for sustainable and high-quality packaging solutions across food, beverage, and consumer goods sectors. Rising awareness of environmental regulations and adoption of eco-friendly inks, such as water-based and UV-curable formulations, drive market expansion. Flexographic printing’s versatility across diverse substrates, coupled with digital integration and technological advancements, enables efficient, cost-effective, and visually appealing printing. Government initiatives and industrial growth further support the adoption of flexographic printing in these regions.

Key Flexographic Printing Companies are:

-

Allstein GmbH

-

Bobst

-

Codimag

-

Comexi

-

Flint Group

-

Heidelberger Druckmaschinen AG

-

Koenig & Bauer AG

-

Komori Corporation

-

Mark Andy Inc.

-

MPS Systems B.V.

-

Nilpeter A/S

-

Nuova Gidue

-

Omet Group

-

Rotatek

-

Tresu Group

-

Uteco

-

Windmoller & Holscher

-

Xeikon

Competitive Landscape for Flexographic Printing Market:

Mark Andy Inc. is a leading U.S.-based manufacturer in the flexographic printing market, specializing in narrow- and mid-web presses. Known for its P7E and Performance Series, the company delivers innovative, efficient, and versatile flexo solutions. Mark Andy supports sustainable packaging trends, hybrid technologies, and digital-flexo integration to meet evolving industry demands.

-

In June 2024, Mark Andy Inc. announced a strategic partnership with RotoMetals, a company known for producing high-precision rotary tooling solutions specifically for the flexographic printing industry. This collaboration aims to combine RotoMetals' tooling expertise with Mark Andy’s advanced printing technology to create innovative solutions that improve the quality, efficiency, and productivity of flexographic printing. by focusing on cutting-edge tooling innovations and joint research and development, the partnership seeks to address industry challenges and meet the evolving needs of flexographic printers.

Amcor plc is a global leader in packaging solutions, actively shaping the flexographic printing market through its focus on sustainable and innovative designs. Leveraging advanced flexo technologies, Amcor produces high-quality flexible packaging on eco-friendly substrates, aligning with global sustainability goals and regulatory frameworks while meeting diverse consumer and industry needs.

-

In May 2024, Amcor plc inaugurated its European Innovation Center (AICE) in Ghent, Belgium. This center is part of Amcor’s global expansion of packaging innovation hubs, which already include locations in Latin America, the U.S., and Asia-Pacific. The AICE is dedicated to developing advanced material technologies and designs, aimed at making packaging more sustainable, efficient, and visually appealing. Collaborating with brands and retailers across Europe, the center will work to create packaging solutions that enhance both consumer experience and environmental outcomes.

Reproflex3 is a UK-based specialist in prepress and flexographic printing solutions, recognized for its expertise in packaging graphics and print quality optimization. The company leverages advanced flexo plate technologies, workflow automation, and sustainable practices to deliver consistent, high-definition results, supporting brand owners and printers with innovative, cost-efficient, and eco-conscious packaging solutions.

-

In August 2023, Reproflex3, a UK-based prepress and flexographic plate manufacturer, revealed the purchase of ANF, a manufacturer of flexographic printing plates for the packaging sector. This decision was made to increase the company's market share in European corrugated packaging and pharmaceutical industries.

| Report Attributes | Details |

|---|---|

| Market Size in 2024 | USD 9.17 Billion |

| Market Size by 2032 | USD 12.85 Billion |

| CAGR | CAGR of 4.3% From 2025 to 2032 |

| Base Year | 2024 |

| Forecast Period | 2025-2032 |

| Historical Data | 2021-2023 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Type (Water-based Inks, Solvent-based Inks, Energy-curable Inks) • By Offering (Flexographic Printing Machine, Flexographic Printing Ink) • By Method (Inline Type press, Central Impression press, Stack Type press) • By Web Type (Narrow web, medium web, Wide web) • By Application (Corrugated Packaging, Flexible Packaging, Labels & Tags, Cartons, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Germany, France, UK, Italy, Spain, Poland, Turkey, Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Singapore, Australia, Taiwan, Rest of Asia Pacific), Middle East & Africa (UAE, Saudi Arabia, Qatar, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Rest of Latin America) |

| Company Profiles | Allstein GmbH ,Amcor PLC, Bobst ,Codimag ,Comexi ,Flint Group ,Gallus ,Heidelberger Druckmaschinen AG ,Koenig & Bauer AG ,Komorik,Corporation ,Mark Andy Inc. ,MPS Systems B.V. ,Nilpeter A/S ,Nuova,Gidue ,Omet Group ,Rotatek ,Tresu Group ,Uteco ,Windmoller & Holscher & Xeikon. |