Fluoropolymers Market Scope & Overview:

The Fluoropolymers Market size was estimated at USD 9.66 billion in 2023 and is expected to reach USD 16.20 billion by 2032 at a CAGR of 5.91% during the forecast period of 2024-2032.

Get more information on Fluoropolymers Market - Request Sample Report

The fluoropolymers market has shown steady growth, driven by their unique properties such as high chemical resistance, thermal stability, and low friction. These polymers are primarily used in applications across industries like automotive, electronics, aerospace, and chemicals. The demand for fluoropolymers has surged as industries focus on enhancing product performance and durability, particularly in harsh environments. In the automotive sector, fluoropolymers are utilized in fuel systems, electrical components, and under-the-hood applications to withstand extreme temperatures and corrosive substances. The electronics industry also contributes significantly to market growth, where fluoropolymers are used in wire coatings, insulating materials, and semiconductors, owing to their excellent electrical insulation properties.

Global fluoropolymers market trends highlight a rising shift towards sustainability, with increasing demand for environmentally friendly alternatives like bio-based fluoropolymers. Additionally, advancements in technology are pushing the boundaries of fluoropolymer applications, leading to innovations in areas such as medical devices, energy storage solutions, and coatings. Companies are focusing on creating fluoropolymers that offer superior performance in energy efficiency, corrosion protection, and resistance to UV radiation, expanding the material’s use in industries like renewable energy.

Fluoropolymers have seen widespread adoption in chemical processing due to their resistance to harsh chemicals and ability to maintain their integrity in aggressive environments. As the demand for high-performance materials in industrial applications grows, the market is expected to continue expanding. A notable trend is the increasing adoption of PTFE (polytetrafluoroethylene) in the aerospace and food processing sectors due to its superior properties.

Fluoropolymers Market Dynamics

DRIVERS

-

The automotive and aerospace industries are increasingly adopting fluoropolymers for their high-temperature resistance, chemical stability, and durability in critical applications like fuel lines, gaskets, and electrical insulation.

The automotive and aerospace industries are experiencing increased demand for fluoropolymers due to their exceptional properties, including high-temperature resistance, chemical stability, and durability. These materials are crucial in applications such as fuel lines, gaskets, seals, and coatings, where they enhance performance and longevity. The automotive sector's focus on lightweight materials to improve fuel efficiency and reduce emissions is fueling the adoption of fluoropolymers in components like hoses, cables, and bearings. Similarly, the aerospace industry benefits from fluoropolymers' ability to withstand extreme conditions, including high temperatures and aggressive chemicals. With advancements in materials technology, fluoropolymers are becoming more cost-effective, which supports their growing use in both industries. Furthermore, the rise in electric vehicles (EVs) and sustainable aviation fuel (SAF) initiatives is accelerating demand for fluoropolymers due to their role in electrical insulation and sealing applications. This trend is expected to continue as both industries seek advanced materials for next-generation vehicles and aircraft.

RESTRAIN

-

High production costs hinder fluoropolymer adoption, but growth persists due to increasing demand in high-performance sectors and advancements in manufacturing.

High production costs remain a significant challenge for the fluoropolymers market. The raw materials required, such as fluorspar and hydrofluoric acid, are often expensive and subject to supply fluctuations. Additionally, the manufacturing processes are energy-intensive, involving high-temperature techniques and specialized equipment to ensure the purity and quality of the final product. Stringent quality control measures further contribute to elevated production costs. These factors can limit the widespread adoption of fluoropolymers, particularly for small businesses or in cost-sensitive industries. Despite these challenges, the market is witnessing growth driven by the increasing demand for high-performance materials in sectors like automotive, aerospace, electronics, and medical devices. Moreover, technological advancements in manufacturing processes, such as more efficient production techniques and innovations in material formulations, are helping to mitigate some of the cost burdens, making fluoropolymers more accessible for a wider range of applications. The market is also leaning towards bio-based alternatives to address sustainability concerns.

Fluoropolymers Market Segmentation

By Product

The Polytetrafluoroethylene (PTFE) segment dominated with a market share of over 34% in 2023, commanding the largest market share due to its versatile properties and wide range of industrial applications. PTFE is renowned for its exceptional chemical resistance, making it ideal for use in harsh environments where corrosion or chemical exposure is a concern. Additionally, its high thermal stability allows it to withstand extreme temperatures, making it suitable for industries such as automotive, electronics, and chemicals. PTFE’s low friction characteristics also make it an excellent choice for coatings, gaskets, seals, and electrical insulation.

By End-User

The Industrial Equipment segment dominated with a market share of over 32% in 2023, due to the extensive use of fluoropolymers in critical industrial applications. Fluoropolymers are highly valued for their exceptional chemical resistance, thermal stability, and durability, making them ideal for use in harsh and demanding environments. These materials are widely employed in the manufacturing of seals, gaskets, and coatings, which are essential components in various industrial systems. Fluoropolymers help protect equipment from corrosion, wear, and degradation, thus enhancing the reliability and lifespan of industrial machinery. Industries such as chemicals, pharmaceuticals, and oil & gas rely heavily on fluoropolymers for their ability to withstand extreme temperatures and exposure to aggressive chemicals.

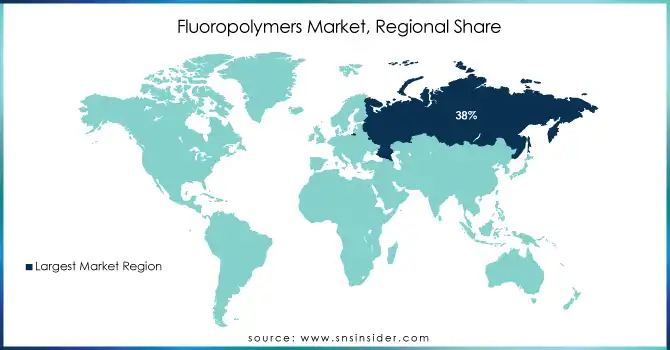

Fluoropolymers Market Regional Analysis

Europe region dominated with a global fluoropolymers market share of over 38% in 2023. The region's well-established industrial base and advanced manufacturing capabilities make it a dominant player in the market. Fluoropolymers are highly valued for their exceptional chemical resistance, high-temperature stability, and electrical insulation properties, which are essential for a wide range of applications. In the automotive sector, these materials are used in fuel systems, wiring, and seals, while in the electronics industry, they play a crucial role in the production of wires and cables.

Asia-Pacific is the fastest-growing region in the fluoropolymers market, driven by rapid industrialization and technological advancements. The region's booming automotive industry is a major contributor, with increased demand for high-performance materials like fluoropolymers used in automotive components. Additionally, the rise in electronics production, particularly in countries such as China and India, further fuels market growth, as fluoropolymers are vital for components in electrical insulation and wiring. The construction sector also contributes significantly, as these polymers are used for coatings, pipes, and seals due to their durability and resistance to high temperatures.

Get Customized Report as per your Business Requirement - Request For Customized Report

Some of the major key players of the Fluoropolymers Market

-

AGC Chemicals Americas, Inc. (AF Series Fluoropolymer, Aflas)

-

Huntsman Corporation (Hylar Fluoropolymer)

-

Dongyue Group Ltd. (FEP, PTFE)

-

Poly Fluoro Ltd. (PFA, FEP, PTFE)

-

Solvay SA (Solef PVDF, Ryton PPS)

-

The Chemours Company (Teflon, Krytox)

-

Honeywell International Inc. (Aflas)

-

Daikin Industries Limited (Daiflon PTFE, PFA)

-

Kureha Corporation (Kureha PTFE, Kureha Fluoropolymer)

-

Amco Polymers (Fluoroelastomers, FEP)

-

Saint-Gobain Performance Plastics (Fluoroloy, Norprene)

-

3M (Dyneon Fluoropolymers, 3M PTFE)

-

Arkema Group (Kynar® PVDF, Rilsan PA11)

-

Linde plc (Inovene Fluoropolymers)

-

Mitsubishi Chemical Corporation (Lumiflon)

-

Daikin America Inc. (Neoflon PTFE, PFA)

-

GFL (GFL PTFE)

-

Chongqing Changsheng Fluoro Materials Co. (PTFE, FEP)

-

Kraton Polymers (Kraton Fluoroelastomers)

-

Dynalene, Inc. (Dynalene Fluoropolymer-based solutions)

Suppliers for (innovative fluoropolymer products like PTFE, FEP, and PFA, offering advanced solutions in coatings, electrical insulation, and industrial applications) of Fluoropolymers Market

-

3M Company

-

Dupont

-

Solvay

-

Arkema Group

-

The Chemours Company

-

Honeywell International Inc.

-

Daikin Industries Ltd.

-

Saint-Gobain Performance Plastics

-

China Fluorine Chemical Co., Ltd.

-

AGC Inc.

Recent Development

In May 2024: Daikin Industries Ltd. formed a partnership with Miura, acquiring 4.67% of Miura’s shares. This collaboration is designed to broaden their solutions in various regions and support the decarbonization of manufacturing facilities.

In November 2023: Solvay and Orbia entered into a joint venture agreement to establish the largest producer of electric vehicle materials in North America. The partnership focuses on supplying materials like PVDF, essential for manufacturing electric vehicle batteries.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | US$ 9.66 Billion |

| Market Size by 2032 | US$ 16.20 Billion |

| CAGR | CAGR of 5.91% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Product (Polytetrafluoroethylene (PTFE), Polyvinylidene fluoride (PVDF), Fluorinated Ethylene Propylene (FEP), Polyvinylfluoride (PVF), Other)s • By Application (Films, Additives, Coatings, Others) • By End-Use (Industrial Equipment, Construction, Electrical & Electronics, Automotive, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | AGC Chemicals Americas, Inc., Huntsman Corporation, Dongyue Group Ltd., Poly Fluoro Ltd., Solvay SA, The Chemours Company, Honeywell International Inc., Daikin Industries Limited, Kureha Corporation, Amco Polymers, Saint-Gobain Performance Plastics, 3M, Arkema Group, Linde plc, Mitsubishi Chemical Corporation, Daikin America Inc., GFL, Chongqing Changsheng Fluoro Materials Co., Kraton Polymers, Dynalene, Inc., and Others |

| Key Drivers | • The automotive and aerospace industries are increasingly adopting fluoropolymers for their high-temperature resistance, chemical stability, and durability in critical applications like fuel lines, gaskets, and electrical insulation. |

| Restraints | • High production costs hinder fluoropolymer adoption, but growth persists due to increasing demand in high-performance sectors and advancements in manufacturing. |