Hybrid Sealants and Adhesives Market Size & Overview:

The Hybrid Sealants and Adhesives Market Size was valued at USD 8.10 billion in 2023 and is expected to reach USD 15.81 billion by 2032 and grow at a CAGR of 8.86% over the forecast period 2024-2032.

Get More Information on Hybrid Sealants and Adhesives Market - Request Sample Report

Hybrid Sealants & Hybrid Adhesives have gained popularity in recent years due to their ability to suit specific application performance criteria. Physical and chemical mixes of resins such as epoxy, acrylic, silyl-modified polyether, silyl-modified urethane, and urethanes make up these adhesives and sealants. They are chosen over traditional adhesives and sealants because of their superior adhesion and sealing abilities, remarkable mechanical and electrical insulating qualities, and chemical and heat tolerance.

The hybrid sealants and adhesives market is expanding significantly because there is a growing need for sophisticated bonding solutions with better performance attributes. The features of various chemistries, such as silicone, polyurethane, and acrylic, are combined to create hybrid sealants and adhesives, which have improved flexibility, durability, and resistance to environmental conditions.

Moreover, Ongoing research and development efforts are leading to the introduction of new and improved hybrid formulations. Innovations such as low-VOC and eco-friendly products are gaining traction, aligning with global sustainability trends.

For instance, in 2023, 3M Company introduced a new line of low-VOC hybrid adhesives designed for automotive and construction applications. This new line aligns with 3M's commitment to sustainability and innovation.

Furthermore, hybrid sealants and adhesives combine strength, flexibility, and resistance to chemicals and weathering and are appropriate for various demanding applications. Their attractiveness is increased in the aerospace, automotive, and construction sectors by their capacity to fuse disparate materials together. All these factors drive market growth.

Hybrid Sealants and Adhesives Market Dynamics

Drivers

Enhanced longevity and durability drive the market growth.

In comparison to conventional sealants and adhesives, hybrid sealants and adhesives are intended to provide greater longevity and durability. Because of their longer lifespan, they require less maintenance and replacements over time, which saves money in the long run. These cutting-edge solutions especially help the construction and automobile industries, where long-lasting performance is critical.

The aggressive environmental elements that can break down conventional sealants and adhesives, such as UV rays, extremely high or low temperatures, and chemical exposure, are not tolerated by hybrid sealants and adhesives. The longevity of hybrid products is greatly increased as a result of their durability. In the building business, for instance, a hybrid sealant might last up to 20 years, minimizing maintenance costs and downtime, whereas a normal silicone sealant may need to be replaced every 5 to 10 years.

Under the Sikaflex® trademark, Sika AG, a pioneer in specialty chemicals worldwide, has created a variety of hybrid sealants and adhesives. These goods are made to last a long time and perform well over time. For instance, in 2023 Sika AG, reported, that their hybrid adhesives used in the automobile industry have helped their clients save up to 25% on maintenance expenses. This decrease is explained by the longer lifespan and lower failure rates of hybrid products in comparison to adhesives with a traditional composition.

-

Enhanced aesthetic and functional properties have driven the hybrid sealants and adhesives market.

-

Increasing demand for lightweight materials has driven the hybrid sealants and adhesives market.

Restrain

Technical challenges in application and formulation may hinder market growth.

It can be technically difficult to develop hybrid sealants and adhesives that satisfy particular performance requirements. Extensive research and development are needed to combine several chemistries to produce the desired qualities, which can be expensive and time-consuming. Moreover, adhesion strength, flexibility, curing time, and resistance to external influences are only a few of the attributes that hybrid goods must manage. It is technically difficult to achieve this equilibrium and calls for exact formulation methods. These formulas' complexity may result in lengthier development timeframes and increased production costs. This all may hamper the market growth.

Hybrid Sealants and Adhesives Market Segmentation

By Resin

MS Polymer Hybrid resin segment held the largest market share around 38.76%in 2023. This segment is increase because of its low volatile organic compound emissions and excellent adhesion, flexibility, and durability. The market for MS Polymer hybrids is primarily being driven by the expansion of the construction industry, developments in the automobile sector, and an emphasis on sustainability. Leading businesses in this sector, including Sika AG, Henkel, and Bostik, are constantly inventing and diversifying their product lines to satisfy the changing demands of their clientele. The expansion of the construction industry, particularly in emerging markets, is driving the demand for MS Polymer hybrid sealants and adhesives. The need for durable and flexible bonding solutions in building and infrastructure projects is a significant growth driver.

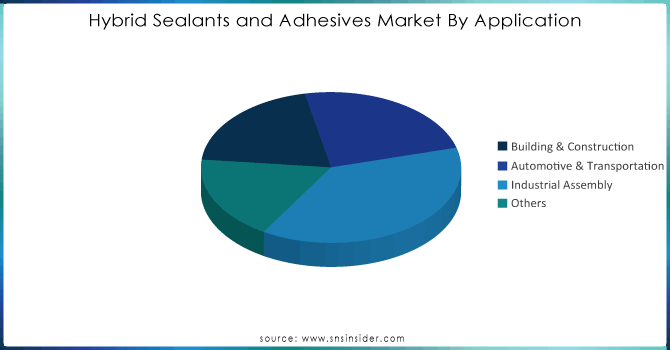

By Application

The Automotive & Transportation segment held the largest market share around 40.87% in the application segment in 2023. In the automotive sector, adhesive longevity is essential to guaranteeing the longevity and safety of automobiles. Applications for hybrid adhesives include joining trim pieces, sealing windshields, and bonding structural elements. According to a study conducted by the European Adhesive Bonding Association, bonded joints' lifespan can be up to 30% longer when hybrid adhesives are used in car assembly as opposed to regular adhesives. For automakers, this lifespan means fewer recalls and warranty claims in addition to higher consumer satisfaction.

Get Customized Report as per Your Business Requirement - Request For Customized Report

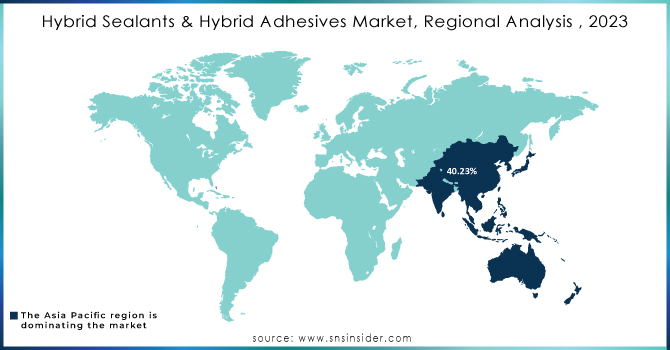

Hybrid Sealants and Adhesives Market Regional Outlook

Asia Pacific dominated the market and held the largest market share approx. 40.23% in 2023. Due to increased industrialization and construction activity in the region, Asia-Pacific currently dominates the hybrid adhesive & sealant market and is expected to grow at the fastest rate during the forecast period. This might be ascribed to the increased usage of hybrid adhesives and sealants over silylated polymers for acoustic ceiling panels, window frames, decorative films, prefinished panels ceramic tile installation, and other applications due to their improved mechanical qualities and UV resistance. The region's prosperity is being supplemented by the rising hospitality sector, which includes the construction of hotels and healthcare centers. Furthermore, the expanding usage of technologically improved adhesives with greater durability and resistance in the growing automotive sectors, from structural bonding to assembly of electronic components, is a factor.

The company has been concentrating on growing its market share in the Asia-Pacific area, which is a significant area of growth for adhesives and hybrid sealants. To meet the growing demand in the area, For instance, Sika stated in 2023 that a new manufacturing site will open in China. Additionally, the business is putting sustainability first by creating environmentally friendly goods.

Key players:

Bostik, Sika AG, Henkel AG & Co., KGaA, Illinois Tool Works Incorporation, Kisling AG, Soudal, H.B. Fuller, Wacker Chemie AG, Tremco illbruck GmbH & Co., 3M Company, and others.

Recent Development:

-

In 2023, Wacker Chemie AG the company introduced a new series of hybrid sealants designed for high-performance applications in the construction and automotive industries. Wacker Chemie is also investing in sustainable manufacturing practices.

-

In 2023, Henkel launched a new range of Loctite hybrid adhesives featuring advanced formulations that provide superior adhesion and flexibility. These products are designed for demanding applications in automotive and industrial settings.

-

In 2022, Henkel acquired a leading manufacturer of hybrid sealants, enhancing its product offerings and market reach. The company is also investing in R&D to develop next-generation hybrid adhesives with improved performance characteristics.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | US$ 8.10 Billion |

| Market Size by 2032 | US$ 15.81 Billion |

| CAGR | CAGR of 8.86% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Resin (MS Polymer Hybrid, Epoxy-Polyurethane Epoxy-cyanoacrylate, Others) • By Application (Building & Construction, Automotive & Transportation, Industrial Assembly, Others) |

| Regional Analysis/Coverage | North America (USA, Canada, Mexico), Europe (Germany, UK, France, Italy, Spain, Netherlands, Rest of Europe), Asia-Pacific (Japan, South Korea, China, India, Australia, Rest of Asia-Pacific), The Middle East & Africa (Israel, UAE, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Rest of Latin America) |

| Company Profiles | Bostik, Sika AG, Henkel AG & Co. KGaA, Illinois Tool Works Incorporation, Kisling AG, Soudal, H.B. Fuller, Wacker Chemie AG, Tremco illbruck GmbH & Co. KG, 3M Company, and others. |

| Drivers | • Enhanced aesthetic and functional properties have driven the hybrid sealants and adhesives market. • Increasing demand for lightweight materials has driven the hybrid sealants and adhesives market. |

| Restraints | • Technical challenges in application and formulation may hinder market growth. |