Injection Molded Plastics Market Report Scope & Overview:

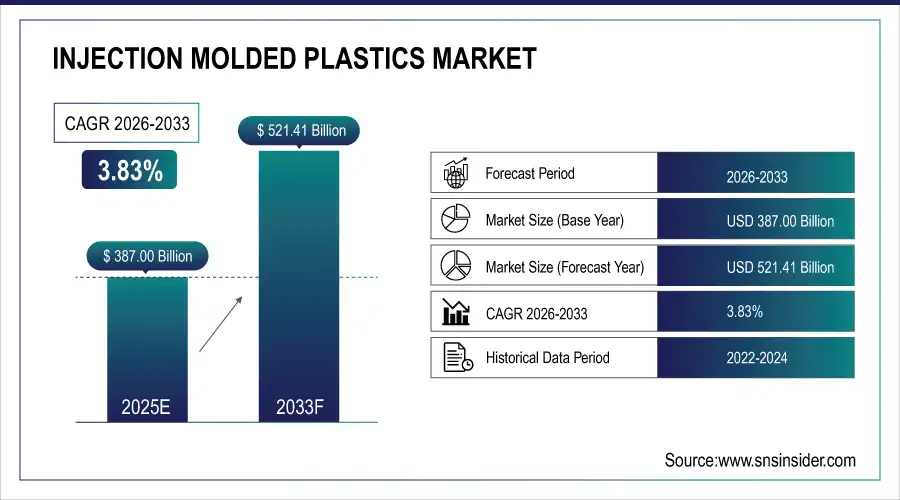

The Injection Molded Plastics Market size was valued at USD 387.00 Billion in 2025E and is projected to reach USD 521.41 Billion by 2033, growing at a CAGR of 3.83% during the forecast period 2026–2033.

The Injection Molded Plastics Market analysis is driven by demand from automotive, electronics, packaging, and healthcare sectors. Market growth is driven by the increasing use of lightweight, durable plastic products in end-use industries, growing economic stability and accelerated GDP growth rates in developing countries are other factors driving demand.

Injection molded plastics production reached 105 million tons in 2025, driven by automotive, electronics, packaging, and healthcare demand.

Market Size and Forecast:

-

Market Size in 2025: USD 387.00 Billion

-

Market Size by 2033: USD 521.41 Billion

-

CAGR: 3.83% from 2026 to 2033

-

Base Year: 2025

-

Forecast Period: 2026–2033

-

Historical Data: 2022–2024

To Get more information On Injection Molded Plastics Market - Request Free Sample Report

Injection Molded Plastics Market Trends:

-

The increasing requirement for lightweight, durable and cost-effective materials usage has led to the rising application of injection molded plastics in automotive, electronics and consumer goods industry.

-

Product performance, design flexibility and manufacturing efficiency are all now being improved through breakthrough multi-material injection molding technology and precision.

-

Spending on special plastic components is rising in healthcare, packaging and industrial applications.

-

Growing emphasis on recyclability, bio-based plastics and environmentally friendly manufacturing will impact both material selection and processing.

-

Trade competition has become increasingly fierce in a variety of fields, such as high-performance environment-friendly and personalized plastic products which occupy the market.

U.S. Injection Molded Plastics Market Insights:

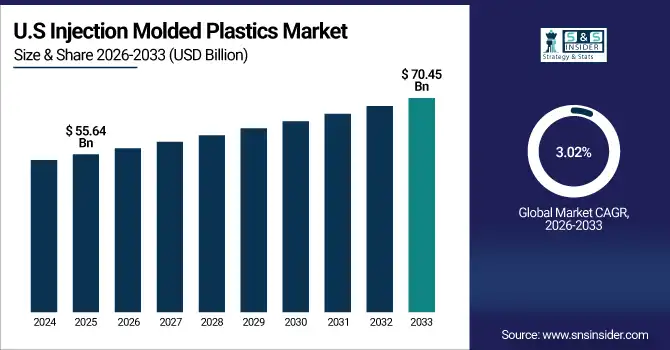

The U.S. Injection Molded Plastics Market is projected to grow from USD 55.64 Billion in 2025E to USD 70.45 Billion by 2033, at a CAGR of 3.02%. Increasing application in the automotive, electronics, packaging and healthcare sectors coupled with an emphasis on light weight, durable and sustainable plastics will fuel demand.

Injection Molded Plastics Market Growth Drivers:

-

Increasing automotive and electronics demand for lightweight, durable components is accelerating growth in the Injection Molded Plastics market.

Increasing demand in automotive and electronics sectors is the primary driver of Injection Molded Plastics market growth. Increasing craze for lightweight and affordable, durable components is enhancing its utilization in consumer good, healthcare, industrial etc. Product performance has been improved with the development of precision moldings, multi-material molding technology and the design freedom it provides. Increasing emphasis on sustainability, recyclability, and performance of plastics is also accelerating the utilization and is positively influencing overall market development.

Injection molded plastics demand grew by 3.9% in 2025, driven by rising automotive, electronics, and packaging applications.

Injection Molded Plastics Market Restraints:

-

Fluctuating polymer prices and stringent environmental regulations are restricting large-scale production and adoption of injection molded plastics.

Fluctuating polymer prices and strict environmental regulations are key factors restraining the growth of the Injection Molded Plastics market. Reliance on petrochemical-derived resins leaves manufacturers vulnerable to volatility of raw material pricing & supply chain risk. Adherence to environmental standards; waste disposal and recycling obligations burden the cost of production. Smaller players could find it difficult to invest in advanced molding technologies or sustainable materials, curtailing their capacity to scale up and tap into increasing demand from automotive, electronics or packaging markets.

Injection Molded Plastics Market Opportunities:

-

Rising demand for sustainable, high-performance plastics offers innovation opportunities across automotive, electronics, healthcare, and packaging industries.

There is significant opportunity in the Injection Molded Plastics market due to growing need for sustainable and high-performance plastics. Sophisticated polymer formulations, bio-based resins and novel molding technologies can offer end users improved durability, reduced weight and increased design freedom in automotive, electronics, medical devices and packaging applications. Growing attention toward recyclability, sustainable raw materials and compliance with environmental standard enables manufacturers to develop new products, enter into new end-use industries, and foster long-term market growth and penetration.

High-performance zinc alloys and compounds for 18% of industrial material innovations in 2025, driven by demand in construction, automotive, and renewable energy applications.

Injection Molded Plastics Market Segmentation Analysis:

-

By Type, Polypropylene (PP) held the largest market share of 28.47% in 2025, while Polycarbonate (PC) is expected to grow at the fastest CAGR of 5.12%.

-

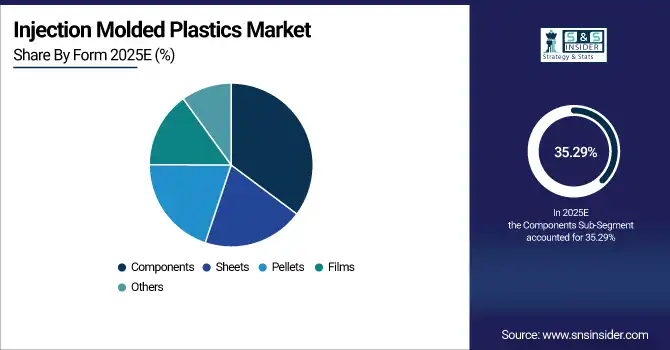

By Form, Components dominated with a 35.29% share in 2025, while Films are projected to expand at the fastest CAGR of 5.45%.

-

By Manufacturing Process, Standard Injection Molding accounted for the highest market share of 52.18% in 2025, and Overmolding Molding is projected to record the fastest CAGR of 6.03%.

-

By End-Use Industry, Automotive held the largest share of 29.76% in 2025, while Healthcare & Medical is expected to grow at the fastest CAGR of 5.98%.

By Type, Polypropylene Dominates While Polycarbonate Expands Rapidly:

Polypropylene (PP) segment dominated the market owing to its lightweight, durable and cost-effective nature is being used in automotive, packaging, consumer goods applications. With its established supply base and flexible properties, it’s the recommended choice for high volume. The polycarbonate is the fastest growing segment due to the requirement of high performance, impact-resistant component in electronic, healthcare, and advanced automotive applications. Emerging formulations for PCs and green alternatives are also speeding up adoption.

By Form, Components Dominate While Films Expand Rapidly:

Components segment dominated the market, as these are vital to automotive, electronics and industrial equipment facilitating mass production. Their easy availability and usability with various molding operations help you penetrate the market. Films is the fastest growing segment, driven by increasing demand for flexible packaging, medical devices and specialty industrial applications. Growth is being supported by innovation in thin-gauge molding and defying plastic films, particularly in areas with strong packaging and healthcare consumption:

By Manufacturing Process, Standard Injection Molding Dominates While Overmolding Expands Rapidly:

Standard injection molding segment dominated the market owing to its cost effectiveness, efficiency and high-volume production for automotive, electronics and consumer goods. It is the bedrock of the industry, due to its scales and mature technology. Overmolding is the fastest growing segment, providing designers with complex designs of multi-components, now it’s possible to include functionality will add value to a production line. Growing use in medical devices, electronics and high-end automotive applications is underpinning growth.

By End-Use Industry, Automotive Dominates While Healthcare & Medical Expands Rapidly:

Automotive segment dominated the market due to the rising consumption lightweight, durable plastic materials in automotive to enhance fuel efficiency & performance. It's the established lines, and the high volume demands that keep a stranglehold on it. Healthcare & Medical is the fastest growing segment, pushed by demand for precision-molded products, diagnostic products and eco-friendly medical packaging. Biocompatible plastics and regulatory adherence are pushing adoption in this growing market.

Injection Molded Plastics Market Regional Analysis:

Asia-Pacific Injection Molded Plastics Market Insights:

The Asia-Pacific Injection Molded Plastics Market dominated with a 43.25% market share in 2025, owing to robust automotive, electronics and consumer goods production. The plastic parts are widely used, high acceptance for lightweight-weight durable and lower-cost components in China, India Japan mention all trading partner and market leadership. Rapid industrialization, urbanization, and growing demand for sustainable and high-performance plastics across the healthcare, packaging & industrial applications have added to its hegemony in the regional market.

Get Customized Report as per Your Business Requirement - Enquiry Now

China Injection Molded Plastics Market Insights:

China is dominated the Injection Molded Plastics by the presence of large automotive, electronics and consumer goods manufacturers. Increasing industrialization, urbanization, and emergence of light-weight, durable, low-cost plastics are some major factors surging the growth of market which open up possibilities for manufacturers in the region thus boosting its position as an important injection molded plastics regional hub.

Europe Injection Molded Plastics Market Insights:

Europe Injection Molded Plastics Market is the fastest-growing, expanding at a CAGR of 5.35% as there is an increasing demand for lightweight, strong and high-performance plastic parts over the automotive, electronics and healthcare sectors. Important markets are Germany, France and the UK. Expansion is backed by state-of-the-art molding techniques, sustainability drives, recyclability emphasis and rising uptake of plastics in industry product, medical essentials and packages, which reinforce the region’s market presence.

Germany Injection Molded Plastics Market Insights:

Germany is significant market for Injection Molded Plastics due to automotive, electronics and industrial applications. Robust manufacturing, cutting-edge molding technologies and increased emphasis on lightweight, strong and sustainable plastics are driving the industry forward. Growing integration in medical equipment, packages and industrial devices further strengthen Germany market dominance and expansion.

North America Injection Molded Plastics Market Insights:

North America is one of the major growth regions for the Injection Molded Plastics, where demand leverage on all end use materials type including automotive, electronics, packaging, medical equipment. Growth is driven by technological advances in molding processes, expanded use of lightweight and durable plastics, and rising industrial and infrastructure spending. Emphasis on green, high performance and recyclable plastics along with robust processing capacities is enhancing growth prospects in industrial/consumer/specialty applications.

U.S. Injection Molded Plastics Market Insights:

The U.S. Injection Molded Plastics market on the basis of end use is classified as automotive, consumer goods, packaging, electronics and medical among others. Rising industrial, infrastructure and consumer applications, advancement in the molding technologies, sustainable plastics and advancements with respect to recyclable and bio-based materials are likely to drive the market.

Latin America Injection Molded Plastics Market Insights:

The Latin America Injection Molded Plastics Market is on a rise, largely supported by the demand for automotive, electronics, packaging and industrial applications. Growth is being driven by the expansion of manufacturing capacities, infrastructure development, and growing use of lightweight, durable and sustainable plastics. Advancements in molding processes and green materials are opening up opportunities in Brazil, Mexico and Argentina.

Middle East and Africa Injection Molded Plastics Market Insights:

Middle East & Africa Injection Molded Plastics Market are anticipated to see moderate growth due to the demand in automotive, construction and industrial application. Growth is supported by investment in infrastructure, urbanisation and the use of light, durable plastics. Regional market growth is supported by government initiatives, sustainable production and growing industrial applications.

Injection Molded Plastics Market Competitive Landscape:

Berry Global based in the U.S., produces plastic packaging and engineered products for a variety of industries including healthcare, personal care, and food & beverage. With an extensive range of products and the continuous advancement of sustainable and high-performance plastics, the company prides itself on being a competent partner offering such tailored solutions. Heavy emphasis on R&D, operational excellence and supply chain expertise have kept it among the elite in injection molded plastics.

-

In May 2025, Berry Global unveiled its patented roll-on deodorant ball technology, delivering faster output and minimal material waste. This innovation enhances production efficiency and reduces environmental impact, aligning with the company's commitment to sustainability and operational excellence.

Husky Injection Molding Systems, Canada-based supplier of injection molding equipment and services to the plastics industry. With decades of experience in high-precision construction, efficient hot-runner systems and customer-mould products that enhance productivity, the company has set out to conquer the market. Husky's focus on technology leadership, process optimization, and our customized solutions for packaging, automotive and medical markets has made us the world’s leading provider of injection molding systems.

-

In October 2025, Husky Injection Molding Systems showcased its next-generation packaging molding platform at KShow 2025 in Düsseldorf. The platform integrates advanced architecture, hot runner and mold controllers, plus the Advantage+Elite™ real-time monitoring service, enhancing efficiency and supporting sustainable, high-performance plastics production.

ENGEL Machinery Inc. of Austria is one of the world's largest suppliers of plastics injection molding machines and automation. It dominates the market with its focus on innovation, energy-efficient solutions and customized products for automotive, packaging, and medical applications. By bringing advanced technology, custom automation and customer service to the differentiating elements in injection molded plastics manufacturing, ENGEL ushers value added performance where it matters most: on the production floor.

-

In October 2025, ENGEL presented the world premiere of its tie-bar-less Victory Electric 220 injection molding machine at K 2025. The machine features advanced design enhancements and integrates "Inject AI," combining artificial intelligence and digital tools to optimize injection molding processes, increasing precision, efficiency, and sustainability in production.

Injection Molded Plastics Market Key Players:

Some of the Injection Molded Plastics Market Companies are:

-

Berry Global, Inc.

-

Husky Injection Molding Systems

-

Engel Machinery Inc.

-

Arburg GmbH + Co KG

-

KraussMaffei Group

-

Nissei Plastic Industrial Co., Ltd.

-

Sumitomo (SHI) Demag

-

Milacron Holdings Corp.

-

JSW Plastics Machinery Inc.

-

Fanuc Corporation

-

Toshiba Machine Co., Ltd.

-

Sungplastic

-

Mack Molding

-

EVCO Plastics

-

The Rodon Group

-

Seaway Plastics Engineering

-

Xometry Inc.

-

PTI Engineered Plastics, Inc.

-

Curbell Plastics, Inc.

-

Crescent Industries Inc.

| Report Attributes | Details |

|---|---|

| Market Size in 2025E | USD 387.00 Billion |

| Market Size by 2033 | USD 521.41 Billion |

| CAGR | CAGR of 3.83% From 2026 to 2033 |

| Base Year | 2025E |

| Forecast Period | 2026-2033 |

| Historical Data | 2022-2024 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Type (ABS, Polypropylene, Polycarbonate, Nylon, PET, Others) • By Form (Sheets, Pellets, Components, Films, Others) • By Manufacturing Process (Standard Injection Molding, Micro Injection Molding, Gas-Assisted Injection Molding, Overmolding, Others) • By End-Use Industry (Automotive, Electronics, Consumer Appliances, Healthcare, Packaging, Industrial Equipment, Others) |

| Regional Analysis/Coverage | North America (US, Canada), Europe (Germany, UK, France, Italy, Spain, Russia, Poland, Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Australia, ASEAN Countries, Rest of Asia Pacific), Middle East & Africa (UAE, Saudi Arabia, Qatar, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Mexico, Colombia, Rest of Latin America). |

| Company Profiles | Berry Global, Inc., Husky Injection Molding Systems, Engel Machinery Inc., Arburg GmbH + Co KG, KraussMaffei Group, Nissei Plastic Industrial Co., Ltd., Sumitomo (SHI) Demag, Milacron Holdings Corp., JSW Plastics Machinery Inc., Fanuc Corporation, Toshiba Machine Co., Ltd., Sungplastic, Mack Molding, EVCO Plastics, The Rodon Group, Seaway Plastics Engineering, Xometry Inc., PTI Engineered Plastics, Inc., Curbell Plastics, Inc., Crescent Industries Inc. |