Injection Molding Machine Market Report Scope & Overview:

To get more information on Injection Molding Machine Market - Request Free Sample Report

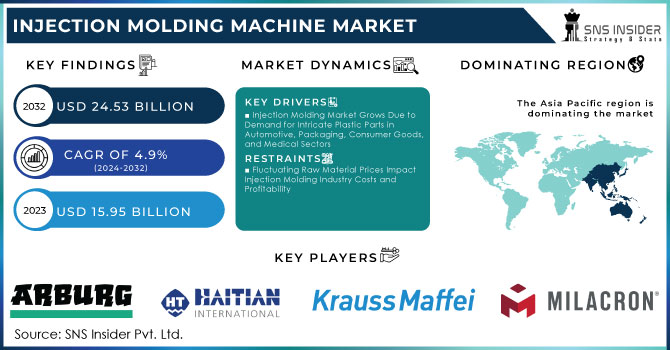

The Injection Molding Machine Market size was estimated at USD 15.95 billion in 2023 and is expected to reach USD 24.53 billion by 2032 at a CAGR of 4.9% during the forecast period of 2024-2032.

The injection molding machine market is growing steadily, boosted by the escalating incorporation of plastic components in automobile, packaging, and consumer industries, among others. The two techniques to categorize these machines include clamping force and injection pressure. Clamping force is measured in tons; to reflect the pressure the machine effectively exudes to preserve the mold during material injection. The range varies from 50 tons for small parts to over 3000 tons for industrial parts. Injection pressure, is measured in megapascals and indicates the pressure exerted on the molten to permeate the mold. The range varies from 30 MPa to over 200 MPa for the low and high viscosities, respectively. The leading growth driver in the United States is the escalading demand for on-the-go packages spurred by increasing consumer purchasing power and burgeoning busy lifestyles. This increase has drastically enhanced the packaging industry, consequently stimulating the demand for injection-molded packaging. The estimated share of the U.S. injection molding machine market is currently over 60.2% primarily due to the availability of cutting technologies, competent workforce, advanced processing, and heightened R&D investments.

The major policy changes are an increase in manufacturing sector incentives, rather significant ones, with measures to be taken collectively to include incentives under the Production-Linked Incentive or PLI scheme. Apart from that, there is a significant increase in grants for high-tech production, the use of new, more eco-friendly technologies, and, finally, encouragement for more domestic production rather than importing goods from other nations.

The increasing applicability of automation and robotics in inject molding is also steering unprecedented growth. The incorporation of the industry 4.0 network in these machines is also fueling the growth of machines’ capabilities and consequently demanding by providing latest features, including monitoring, predictive maintenance, and energy consumption. Furthermore, the injection molding machine market is benefiting from the constant trend towards sustainable and eco-friendly practices. This scenario is invigorated by the utilization of the machines in partnership with biodegradable and recycled products.

MARKET DYNAMICS

DRIVERS

The automotive, packaging, consumer goods, and medical sectors' growing need for intricate plastic parts is driving market growth through the efficient mass production capabilities of injection molding.

The Need for intricate plastic parts is rising in various industries due to which the injection molding machine market is on the trend. This technology has the potential to mass produce complex plastic components with high efficiency. From an automotive perspective, injection molding machine market is flourishing as the technology is used widely for producing lightweight dashboards, aerodynamic components, and precise engine parts, such as intricate plastic gears and mirror housings of the cars. Volume of production is high along with accuracy, which seems ideal for the automotive industry. From a packaging perspective, injection molding machine market is in demand as various containers, bottles, and closures are made from it. For example, single-use beverage bottles are made using this technology as the bottles are produced in masses and maintaining the quality is important. Consumer goods sector is also one of the promising sectors for the injection molding machine market as the technology is used for producing intricate plastic components for electronics, toys, and household appliances. An example of the usage of this technology is the production of colorful interlocking bricks of popular children’s building toy systems as these bricks need high precision and functionality. From the healthcare industry, overdose of plastic products can be found with the use of this technology, as disposable and durable medical products like syringes, needle housings, and surgical instruments and prosthetic components require high accuracy making the clean room facilities essential. Injection molding and production volumes of medical instruments produce a strong fit. In other words, rise in demand for complex plastic parts from different industries along with technological advancements implies that the injection molding machine market will have a strong growth rate.

Advancements in injection molding machines, including automation, robotics, real-time monitoring, predictive maintenance, and energy efficiency, are enhancing capabilities and driving market growth.

Injection molding has become a new way with some cutting-edge technology leading the way. Modern injection molding is well equipped with automation and robotics. This feature has not only propelled the task done but also increased the speed of carrying out the unloading of moldings and other optimization tasks. The humans are made to have an easy time seeing that the machines can even detect any human error and have them rectified. As their output rate has increased due to the same machine, the machines have an ensured uptime which means that the professional employees who used to do the same work can now attend to more demanding tasks. The machines have a real-time monitoring system that monitors the crucial features of the machine. Some of the detector’s sensor the heat of the machine or even that of the scheduled product and can have it corrected. Such is the same with pressure. The system is crucial to the continuous production of good quality products and fewer halts by virtue of the same sensors detecting hitches before the product itself is released. The machines may however have hitches like any other types of machines. For these, the machines have predictive repair abilities that integrate a number of previous data and make what is known as advanced algorithms. The system causes a doubt that the machinery needs repair based on the same. The repairs are carried out and unnecessary costs or even major breakdowns of machinery. The machines are also variable in power consumption and come along with power saving aids and drives that include reduced output of the machine and inbuilt regenerative braking systems. Some of the repeating of the same model can be carried out with the aid of memory which ensures that the machines are in good shape.

RESTRAIN

Fluctuating raw material prices, driven by changes in oil prices and other factors, significantly impact production costs and profitability for manufacturers in the injection molding industry, necessitating pricing adjustments or reduced margins.

In the injection molding industry, production costs and profitability are both strongly affected by fluctuating raw material prices. At the foremost among such materials is plastic resin, whose price changes are driven by oil costs and other market fluctuations. Being a petroleum-based product, resin is directly impacted by the extreme market dynamism of oil price swings. High resin prices mean higher production costs for manufacturers, ultimately leading to profit margins being eaten away. There are limited ways for manufacturers to adjust to these changes, most of them involving altering pricing strategies to handle the increased costs. For some manufacturers, a possible solution may be increasing their prices accordingly, which would allow them to avoid loss of margins. However, in many markets, this solution may be unfeasible due to the frequent competitiveness of the field. In such cases, companies may be forced to eat the cost, losing parts of their profit margins as a result. The other challenge that extremely volatile resin prices pose is in terms of company budgeting and financial planning. Companies need to be able to maintain profitability without compromising the quality or consistency of the products they offer.

KEY MARKET SEGMENTATION

By Material

The plastic segment dominated the market with the largest revenue share of approx. 76.9% in 2023. The growing consumption of plastic parts in the automotive industry is fueling the segment growth. These plastic parts are much lighter in weight and are cheaper. The product provides great precision and high repeatability, with a low cost-per-part. The machine also produces complex geometry parts which are difficult with other methods. The plastic injection molding production process of the machine is also faster and has a reduced cost of labour as compared to other convention ways.

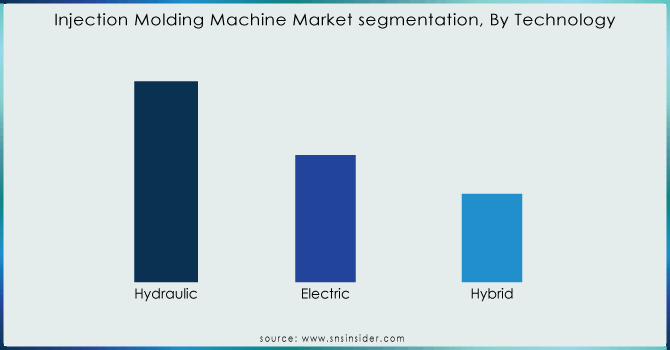

By Technology

The Hydraulic was the leading segment and held the maximum revenue share of 51.4% in 2023. There are several factors that are driving the demand for hydraulics including minimized production of large quantities of parts, intricate parts for the automotive industry, lower initial costs, production of precise molds, high wear and tear resistance of hydraulic parts, and the machines are widely used in the automotive, marine, and aerospace industries where heavy force is required.

The electric machine is energy-efficient, startup time is shorter, and the energy usage only occurs when the machine is in movement. The electric segment is digitally controlled and supervision is not required making the process efficient. The electric segment has highly accurate control and monitoring systems and the molding condition is stabilised. The electric injection molding machine is digitally controlled and delivers high speed. It is more effective throughout the entire production process because the independent motors control the whole process from injection to extruder to clamping and ejection.

Need any customization research on Injection Molding Machine Market - Enquiry Now

By End-Use

The automotive segment accounted for the largest revenue share of approx. 29.4% in 2023. Injection molding machines are used to manufacture a wide range of components for vehicles, including exterior body panels, bumpers, dashboards, spoilers, and electrical housings. Several parts of automobiles are manufactured using plastic injection molding. These include instrumentation components, glove boxes, interior surfaces, dashboard faceplates, air vents, etc. The increased demand for automotive components across the globe has been driving the global production of automobiles. Moreover, the demand for injection-molded parts in the automotive industry has been surging. This, in turn, is expected to help the automotive segment continue its dominance over the forecast period.

The packaging industry has been witnessing significant growth across the globe. Increasing purchasing power, busy lifestyles, and hence growing demand for packaged products have been supporting market growth. The market is expected to witness an increasing preference for product packaging with functional, convenient, and eco-friendly products. Injection molding is used extensively in the manufacturing of packaging products, and hence the growth of packaging or end-use industries is expected to support the growth of the market over the forecast period.

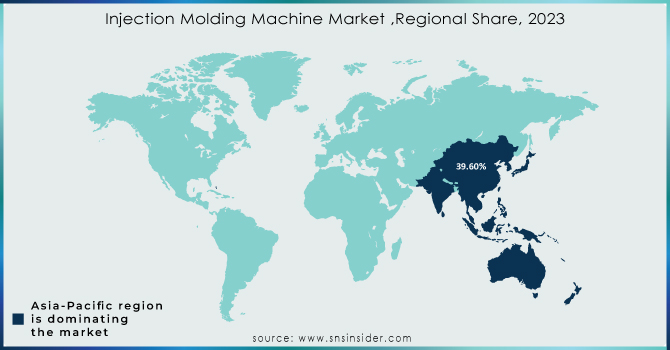

REGIONAL ANALYSES

The Asia Pacific is expected to dominate the market, with a revenue share of approx. 39.6% in 2023. The market growth can be attributed to the increasing demand from the healthcare sector, rapid industrialization in emerging economies such as China, India, and Japan, and the increasing need for plastic molds in electric vehicles. Moreover, the rapid growth of automotive and packaging industries in Asia Pacific is expected to propel the demand for injection molding machines over the forecast period.

North America is anticipated to exhibit the fastest CAGR of 3.95% from 2024 to 2032. The market growth in this region can be ascribed to a remarkable growth in the manufacturing sector, on the ground of the industrial dynamics and commodity abundance of its countries. The demand for packaged food products, increasing immigration rate, and technologically advanced machineries, such as automation, are responsible for the growth of the market in this region.

Key Players

The major key players are Arburg GmbH + Co KG, Haitian International Holdings Limited, Milacron, Nissei Plastic Industrial Co., Limited, Engel Austria GmbH, Sumitomo (SHI) Demag Plastics Machinery GmbH, Chen Hsong Holdings Limited, Toyo Machinery & Metal Co., Ltd, Husky Injection Molding Systems Ltd, Japan Steel Works Limited, KraussMaffei Group and others

RECENT DEVELOPMENT

In December 2023: Husky Technologies opened a cutting-edge service center in Jeffersonville, Indiana. The facility provides a wide array of readily accessible OEM parts, demonstrating the company's dedication to its customers in the Americas region

In November 2023: ARBURG expanded its global footprint with the inauguration of a new subsidiary in Vietnam. The primary objective was to enhance accessibility to ARBURG products and services for customers in Vietnam. The establishment of this subsidiary reflects the company's commitment to providing products and services with increased convenience, efficiency, and dependability

In June 2023: Haitian International opened an advanced manufacturing facility in Mexico with the strategic objective of enhancing local production capacity, reducing delivery times, and delivering superior solutions to meet the technical needs of customers in North and South America

| Report Attributes | Details |

|---|---|

| Market Size in 2024 | US$ 15.95 Billion |

| Market Size by 2032 | US$ 24.53 Billion |

| CAGR | CAGR of 4.9% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | •By Material (Plastics, Metals, Others) •By Technology (Hydraulic, Electric, Hybrid) •By End-Use (Automotive, Consumer Goods, Packaging, Electronics, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Arburg GmbH + Co KG, Haitian International Holdings Limited, Milacron, Nissei Plastic Industrial Co., Limited, Engel Austria GmbH, Sumitomo (SHI) Demag Plastics Machinery GmbH, Chen Hsong Holdings Limited, Toyo Machinery & Metal Co., Ltd, Husky Injection Molding Systems Ltd, Japan Steel Works Limited, KraussMaffei Group |

| Key Drivers | • The automotive, packaging, consumer goods, and medical sectors' growing need for intricate plastic parts is driving market growth through the efficient mass production capabilities of injection molding. • Advancements in injection molding machines, including automation, robotics, real-time monitoring, predictive maintenance, and energy efficiency, are enhancing capabilities and driving market growth. |

| RESTRAINTS | • Fluctuating raw material prices, driven by changes in oil prices and other factors, significantly impact production costs and profitability for manufacturers in the injection molding industry, necessitating pricing adjustments or reduced margins. |