Metal Embossing Machine Market Report Scope & Overview:

To get more information on Metal Embossing Machine Market - Request Free Sample Report

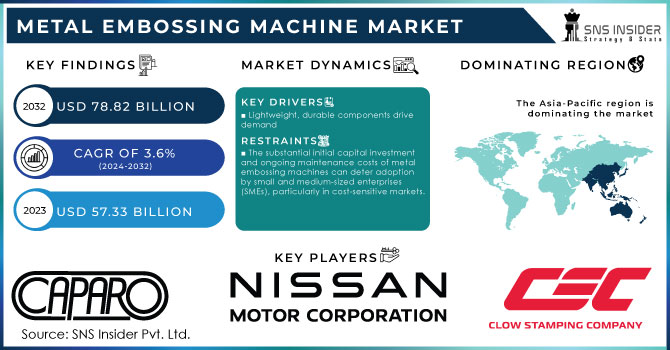

The Metal Embossing Machine Market size was valued at USD 57.33 Billion in 2023 and is expected to reach USD 78.82 Billion by 2032 with a growing CAGR of 3.6% over the forecast period 2024-2032.

The emergence of new manufacturers with new ideas and competition the imply a wider range of machines and innovative technologies, which caters to the growing demand from metal end-users. It is mainly the automotive, construction, and appliance manufacturing industries that require these machines. The demand for embossing machines is primarily in the industries utilizing such machines. They range from high-speed automation in the production of car parts to large machines. These are designed for heavy metal sheets to produce panels for architectural cladding. Except for the equipment itself, the factor on which these machines depend is the development of computer operating systems specifically designed for metals. They enable precise control over the embossing machine by utilizing a user-friendly CNC interface. The benefits of this are reduced waste and enhanced efficiency, as the automation results in faster production cycles with little labor. It also allows to save costs. Further, CNC systems can be incorporated with design software and with the help of robotic material handling. Sales of electric vehicles worldwide have to pass IEA to approximately 3.4 million. China accounted for the maximum share of 60%. Governmental support, including electric car subsidies, also providing local manufacturers of EVs to boost their presence, drives the growth of EV product, which is likely to drive the sheet metal usage during auto components production.

Automobile materials are the core materials that are used for making a vehicle. They include framework, interior and exterior structural, and transmission components. Market growth is driven by this factor during the forecast period. The market growth can be hampered as automobile manufacturers are replacing metals with plastics and carbon fiber as they help reduce the weight of vehicles. A reduction of 10% of the total weight of the vehicle results in 5% to 7% of increased fuel efficiency.

MARKET DYNAMICS

DRIVER

The metal embossing machine market is driven by the automotive and aerospace sectors' need for lightweight, durable, high-strength components to enhance performance and fuel efficiency, leading to increased demand as these industries expand.

The metal embossing machine market is growing at a quite considerable pace, primarily due to the expansion of the automotive and aerospace industries. The both spheres are increasingly committed to innovative materials assisting with the production of lightweight, highly-durable, and high-strength components. In particular, the automotive industry tends to design the parts promoting vehicle lightweighting. With reduced weight, the fuel economy of the cars can be effectively boosted as well as their overall performance. Thus, the metal embossing machines are employed in patterning and shaping metal sheets to create components that would satisfy the standards of strength and durability and be less heavy compared to their traditional alternatives.

The aerospace industry requires that component to be used in their vehicles be lightweight, durable, and withstand extreme conditions. Moreover, lightness, safety, and strength are key parameters facilitating aerospace applications. Possibly one of the key requirements for aircraft and space-related technology apart from the safety of the models is performance, more specifically fuel efficiency. The decreasing efficiency of high consumption of fuels is no longer acceptable in this era, especially considering the rising fuel costs. This results in the burgeoning production of advanced metal components capable of meeting aerospace standards to date; metal embossing machines cater to both the requirements of lightweighting parts, as well as ensuring product quality standard. Consequently, while the aerospace and automotive industry progress, they sparked an increasing demand for metal embossing machines. The need to reduce both the weight of the vehicle and the fuel consumption further increases demand.

Technological advancements, including the integration of IoT and AI for real-time monitoring and predictive maintenance, have significantly enhanced the efficiency and capabilities of metal embossing machines, driving market growth.

The metal embossing machines market has undergone significant changes due to technological progress, with the development of the Internet of Things and Artificial Intelligence playing major roles in the current growth of the sector. The former allow machines to be connected to networks, transmitting and analyzing data in real time. As a result, the work of the machines is constantly monitored to identify potential deviations and provide recommendations. Built-in sensors allow for the tracking of multiple parameters, including temperature, pressure, and vibration, with the data on these being sent to a corporate system. AI algorithms then analyze the information to determine if failures are imminent, allowing for the scheduling of timely maintenance. This in turn minimizes production losses and equipment repair expenditures. As a result, timely prevention measures are the most long-term and cost-effective, preventing the occurrence of unpredictable equipment breakdowns and achieving the longest possible machinery life cycles. This has the potential to largely eliminate the need for reactive maintenance work, which is typically costlier and leads to the stoppage of production. As a result, the machines perform embossing with greater precision and uniformity, resulting in higher product quality and less material waste. Finally, the use of IoT and AI technologies in such applications enables the accumulation of data to improve enterprise decision-making and future operations planning. As a result, combining these two solutions achieves greater efficiency and lowers costs in a variety of ways. It is no surprise that manufacturers use these technologies in their work to keep up with the times and obtain a competitive advantage by offering superior quality and lower prices. As a result, with the rapid rise of digitalization in business, the integration of AI and IoT in embossing machines is a major factor of the metal embossing machines market.

RESTRAIN

The substantial initial capital investment and ongoing maintenance costs of metal embossing machines can deter adoption by small and medium-sized enterprises (SMEs), particularly in cost-sensitive markets.

High requirement for initial capital investment that relates to metal embossing machine creates a strong obstacle for small and medium enterprises that may operate in cost-sensitive markets. Due to the demand for considerable investment in order to purchase and install this type of factory, a burden in for of maintenance and repair costs is also substantial. For SMEs, constantly paying both depends on success in operation, which complicates their financial management. For them, it is complicated to maintain investment in metal embossing machines while guaranteeing high levels of profit. As a result, SMEs may find it difficult to invest in advanced metal embossing technologies because of their high investment needs and need to pay repair and maintenance costs after the investment. In the end, these obstacles can prevent SMEs from employing advanced technologies related to metal embossing and reducing their level of competitiveness in the market.

The operation and maintenance of metal embossing machines require skilled labor and technical expertise, presenting challenges due to scarcity of operators and the involved technical complexity, particularly for companies lacking necessary expertise and resources.

The operation and maintenance of metal machines have a very high level of skilled and technical labor requirement. These make the machines technically very complicated and challenge for many companies. Besides this, the operators of these metal embossing machines need special handling, calibration, and troubleshooting of the equipment. The skill level required to operate these machines is specialized which makes the machines technically complicated. Because of these challenges, since the operator must be trained, they are very few found who run these machines and are also skilled in the establishing of uncouth parts. The machines high skilled labor requirement is a challenge for many companies especially when hiring operators who have high negotiated wage rates from the company. The training requirement by these machines is expensive as well considering the hiring of experienced operators exposing the company to increasing cost. The machines frequently require the maintenance and repairing of uncouth parts as a result of the frequent breakdown caused by the low technical knowledge of the participants. Many of these metal embossing companies are smaller and less experienced forcing them to act as and when a problem strikes.

KEY SEGMENTATION ANALYSIS

By Product Type

The Manual Metal Embossing Machines held the largest share of over 62% in 2023 in terms of volume and value, as manual machines are generally less costly compared to the automatic ones. They are also considered to be user-friendly and therefore suitable for small workshops or for personal use.

The automatic machine is expected to be the fastest-growing segment over the forecast period, with an estimation that, in future these machines are projected to replace so much of the human effort, that is guaranteed to drive long-term productivity which eliminates manual labor and these machines can be operated automatically and they are best for large production.

By End-Use

The Low and Medium Volume dominated the market over 58% share in 2023. This is due to the demand in product manufacturing in various industries, Automotive, Aerospace, and other industries where three-dimensional patterns are required on metal products.

The High Volume, this segment is expected to grow but at relatively slower rate compared to low and medium volume. High volume embossing is used for mass production in the industries such as, Appliance manufacturing, Building materials etc.

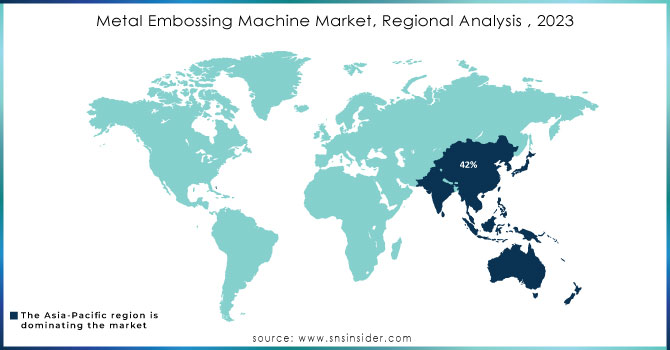

REGIONAL ANALYSIS

In 2023, Asia-Pacific dominated the metal embossing machine market in 2023 with a market share 42%. The development of manufacturing plants and increased investments could support the ongoing demand of such machines in the region. Chinese manufacturers, such as Harsle present cost-effective alternatives for the metal embossing machines. The reduced costs are primarily attributable to subsized labour and production. Therefore, such options could be especially attractive to budget-conscious customers rare to medium-complex machines. Meanwhile, the country is a hub for manufacturing domestic and export-oriented products that require metal embossing machines. Subsequently, China becomes a large market for Harsle, enabling the company to benefit from higher economies of scale and further reduce production costs. At the same time, since China is the key location of such machine manufacturers, the growth in demand for them is also expected in the region.

North America is anticipated to grow at the fastest rate, and its industrial growth is a major element driving the metal embossing machine market. metal embossing is a technique used in a range of industries to create shapes, reliefs, designs, and patterns. The United States and Canada have well-established ‘manufacturing’ across industries, such as automotive, construction, appliances, and aerospace, driving the growth of the metal embossing machines market. decorative purposes, to impart raised designs for aesthetics or for an impression of increased thickness and rigidity, or for functional foil embossing, which is an alternative to heat exchange in refrigerators or air conditioning, several metal embossing machines can emboss several colors in a single piece. The North American infrastructure is aging, including overpasses, bridges, and tunnels, which need renovation or replacement. The construction industry uses embossed metal products in roofing sheets, siding panels, and architectural panels, among other construction materials. Governments instill mandatory guidelines on product labeling, product safety, and quality.

Need any customization research on Metal Embossing Machine Market - Enquiry Now

KEY PLAYERS

The major key players are Caparo, Nissan Motor Company, Ltd, Kenmode, Inc., Acro Metal Stamping Co, Manor Tool & Manufacturing, D&H Industries, Inc., Klesk Metal Stamping Co., Clow Stamping Company, Goshen Stamping Company, Tempco Manufacturing Company, Inc., INTERPLEX HOLDINGS PTE. LTD., AAPICO Hitech Public Company Limited, Klesk Metal Stamping Co., and others.

RECENT DEVELOPMENT

In February 2024: Bosch Rexroth, this company might have showcased a new CNC-controlled embossing press at a trade show. This indicates a focus on automation and efficiency in the market.

|

Report Attributes |

Details |

|---|---|

|

Market Size in 2023 |

US$ 57.33 Billion |

|

Market Size by 2032 |

US$ 78.82 Billion |

|

CAGR |

CAGR of 3.6% From 2024 to 2032 |

|

Base Year |

2023 |

|

Forecast Period |

2024-2032 |

|

Historical Data |

2020-2022 |

|

Report Scope & Coverage |

Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

|

Key Segments |

• By Product Type (Manual Metal Embossing Machine and Automatic Metal Embossing Machine) |

|

Regional Analysis/Coverage |

North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

|

Company Profiles |

Caparo, Nissan Motor Company, Ltd, Kenmode, Inc., Acro Metal Stamping Co, Manor Tool & Manufacturing, D&H Industries, Inc., Klesk Metal Stamping Co., Clow Stamping Company, Goshen Stamping Company, Tempco Manufacturing Company, Inc., INTERPLEX HOLDINGS PTE. LTD., AAPICO Hitech Public Company Limited, Klesk Metal Stamping Co. |

|

Key Drivers |

• The metal embossing machine market is driven by the automotive and aerospace sectors' need for lightweight, durable, high-strength components to enhance performance and fuel efficiency, leading to increased demand as these industries expand. |

|

RESTRAINTS |

• The substantial initial capital investment and ongoing maintenance costs of metal embossing machines can deter adoption by small and medium-sized enterprises (SMEs), particularly in cost-sensitive markets. |