Mining Drill Bits Market Report Scope & Overview:

To get more information on Mining Drill Bits Market - Request Free Sample Report

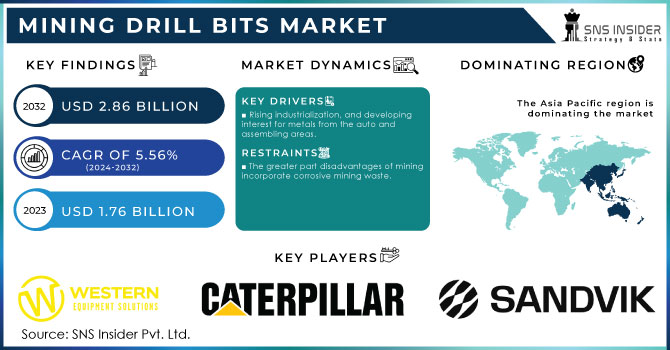

The Mining Drill Bits Market Size was valued at USD 1.76 Bn in 2023 and is expected to reach USD 2.86 Bn by 2032 with a growing CAGR of 5.56 % over the forecast period 2024-2032.

Mining drill bits apparatus are utilized in oil and gas activities to penetrate and make openings for oil and gas extraction. The mining drill bits are pivoting device that is comprised of the hardest materials and sharp surface to cut into a stone and dregs. The fundamental motivation behind the drilling tools is to crush, cut, scratch, and smash the stone at the lower part of the well. The bores business is changing quickly with new assembling innovations and the rising utilization of new materials in the boring apparatus creation process. Oil and gas being the foundation of the worldwide energy industry, bores are the essential apparatus for oil and gas extraction processes. Mining drill bits are devices comprising of hard materials like steel, tungsten carbide, or jewel for enduring more noteworthy tension. These pieces are broadly utilized for investigation and mineral extraction.

New item dispatches and acquisitions by driving players in the market combined with mechanical advancement have expanded the interest across the globe. The boring tools are accessible in six breadths going from 6.75 crawls to 12.25 inches. The boring tools are created to offer longer life through the joining of intensity therapy innovation and a high-level air-cooled bearing plan.

MARKET DYNAMICS

KEY DRIVERS

-

The financial development in non-industrial nations.

-

Rising industrialization, and developing interest for metals from the auto and assembling areas.

-

Rising interest in regular assets, mechanical progressions, and critical interests in innovative work.

RESTRAINTS

-

The greater part disadvantages of mining incorporate corrosive mining waste.

-

cyanide and mercury spill in the water streams, and air and water quality license infringement.

-

This environmental downside is expected to thwart the market development.

OPPORTUNITIES

-

Mechanical advancements.

-

Technological advancement in Man-made reasoning (Al) and AI (ML).

CHALLENGES

-

Expansion in buying cost of mining drill bits

-

Development in awareness in regards to ecological harm

-

The burden of many standards and guidelines on the mining business players by the legislatures.

IMPACT OF COVID-19

The COVID-19 pandemic desperately affected each area. The business has experienced critical harm because of the commitment to severe standards, like countrywide lockdowns, to restrict the spread of the infection. Hence, the flare-up of the infection has adjusted the interest in mining boring tools. As the market is significantly reliant upon the mining business. Which is an essential industry, the greatest disappointment looked by the mining business has affected the interest in investigation and creation of mining exercises. This has straightforwardly affected the interest in boring exercises and diminished the requirement for mining drill bits, including the bores.

MARKET ESTIMATION

ON THE BASIS OF TYPE

The mining drill bits market by type is extensively sorted into rotational pieces, DTH hammer pieces, and others. Revolving pieces are additionally ordered into fixed shaper pieces and roller cone bits. Rotating pieces have a wide assortment of utilization and can be utilized for different stone arrangements. Steel roller cone pieces are for the most part used to penetrate milder arrangements, while Tungsten Carbide embeds are utilized for boring hard rock developments. Fixed shaper pieces are regularly utilized for penetrating at different profundities.

Into the-opening (DTH) hammer pieces are utilized for DTH hammers that drill openings through different stone arrangements. DTH hammer bits have a splined drive to pivot the cycle in the ground. With expanding investigation exercises, these pieces are filling sought after. The other market fragments represent the lesser-utilized wing, etch, anchor, button, and crosspiece.

ON THE BASIS OF MATERIAL TYPE

The mining drill bits market by the material is comprehensively sorted into PDC precious stone, tungsten carbide, steel, and others. PDC jewel bits have better strength than cut different materials. They are fake and subsequently, nearly modest. Their high hardness, strength, and intensity steadiness drive their interest. Tungsten carbide has a Moh's hardness of 8.5 to 9, making it very intense. Their capacity to fit little measurements in hard rock developments drives the market's tungsten carbide bits. Processed tooth steel pieces are by and large utilized for delicate stone arrangements. Another section represents mining boring apparatus materials like stable precious stones, surface set jewels, and framework.

ON THE BASIS OF SIZE

In view of the size, the market is isolated into under 8 inches, 8 inches - 11 inches, or more 11 inches. By and large, the more modest boring apparatus are utilized for investigation penetrating exercises. Boring apparatus are even just about as little as 1 mm. The 8 creeps to 11 inches portion are the most broadly utilized boring tool size for creation penetrating. The bigger boring apparatus are for the most part utilized for creation penetrating at more noteworthy profundities. Boring tools of different sizes, materials, and types are dissected to penetrate explicit stone arrangements.

ON THE BASIS OF THE APPLICATION

The market by application is comprehensively classified into surface mining and underground mining. Surface mining is by and large used to mine sand, rock, squashed stone, phosphates, coal, copper, iron, and aluminum. This sort of mining is utilized significantly because of its simplicity of activity. Subsequently, mining boring tools are tremendously utilized in surface mining. Minerals of gold, iron, zinc, tin, lead, and unrefined oils are significantly mined underground.

KEY MARKET SEGMENTATION

BY TYPE

-

Rotary bits

-

Fixed cutter bits

-

Roller cones bits

-

DTH Hammer bits

-

Others

BY MATERIAL

-

PDC Diamond

-

Tungsten carbide

-

Steel

-

Others

BY SIZE

-

Below 8 inches

-

8 to11 inches

-

Above 11 inches

BY APPLICATION

-

Surface mining

-

Underground Mining

REGIONAL ANALYSIS:

The Asia Pacific overwhelmed the worldwide market in 2021. Expanding oil and gas investigation, developing interest for mineral investigation and rising foundation advancement support the development of the mining drill bits market in the area. The modern development in nations like China, India, and Japan, reinforcing the car business, and expanding interest in oil recuperation drive the development of this locale. Developing interests in innovative work exercises, an extension of global players around here, and mechanical headways are a few variables ascribed to the development of this provincial portion.

Need any customization research on Mining Drill Bits Market - Enquiry Now

REGIONAL COVERAGE:

-

North America

-

USA

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

UK

-

France

-

Italy

-

Spain

-

The Netherlands

-

Rest of Europe

-

-

Asia-Pacific

-

Japan

-

south Korea

-

China

-

India

-

Australia

-

Rest of Asia-Pacific

-

-

The Middle East & Africa

-

Israel

-

UAE

-

South Africa

-

Rest of Middle East & Africa

-

-

Latin America

-

Brazil

-

Argentina

-

Rest of Latin America

-

KEY PLAYERS

The major key players are Rockmore International, Western Drilling Tools Inc, CATTERPILLAR INC., Robit Plc,Epiroc AB, Sandvik AB, Brunner & Lay Inc., Xiamen Prodrill Equipment Co. Ltd., Mitsubishi Materials Corporation, MICON-Drilling GmbH, Boart Longyear, DATC Group, Changsha Heijingang Industrial Co., Ltd.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | US$ 1.76 Billion |

| Market Size by 2032 | US$ 2.86 Billion |

| CAGR | CAGR of 5.5% From 2024 to 2032 |

| Base Year | 2022 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • by Type (Rotary bits, DTH Hammer bits, others) • by Material (PDC Diamond, Tungsten carbide, Steel, Others) • by Size (Below 8 inches, 8 to11 inches, Above11inches) • by Application (Surface mining, Underground Mining) |

| Regional Analysis/Coverage | North America (USA, Canada, Mexico), Europe (Germany, UK, France, Italy, Spain, Netherlands, Rest of Europe), Asia-Pacific (Japan, South Korea, China, India, Australia, Rest of Asia-Pacific), The Middle East & Africa (Israel, UAE, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Rest of Latin America) |

| Company Profiles | Rockmore International, Western Drilling Tools Inc, CATTERPILLAR INC., Robit Plc,Epiroc AB, Sandvik AB, Brunner & Lay Inc., Xiamen Prodrill Equipment Co. Ltd., Mitsubishi Materials Corporation, MICON-Drilling GmbH, Boart Longyear, DATC Group, Changsha Heijingang Industrial Co., Ltd. |

| Key Drivers | • The financial development in non-industrial nations. • Rising industrialization, and developing interest for metals from the auto and assembling areas. |

| RESTRAINTS | • The greater part disadvantages of mining incorporate corrosive mining waste. • cyanide and mercury spill in the water streams, and air and water quality license infringement. |