Natural Fiber Composites Market Report Scope & Overview:

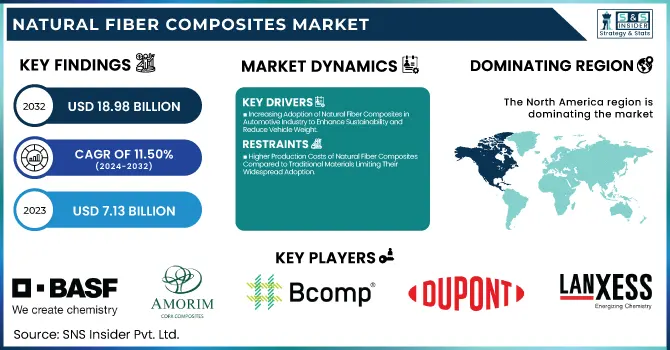

The Natural Fiber Composites Market Size was valued at USD 7.13 Billion in 2023 and is expected to reach USD 18.98 Billion by 2032, growing at a CAGR of 11.50% over the forecast period of 2024-2032.

To Get more information on Natural Fiber Composites Market - Request Free Sample Report

As the Natural Fiber Composites Market continues to grow, industries are turning towards more sustainable materials. Our report uncovers the journey of these composites, beginning with the supply chain analysis, where key suppliers and distribution networks play a crucial role. The report also focusses on the cost structure, revealing how production costs compare to traditional materials. The report dives into trade analysis, shedding light on shifting export-import trends and raw material price fluctuations. Sustainability is at the forefront, with carbon footprint metrics showing how these composites contribute to a greener future. Finally, regional trade agreements are examined, highlighting how policies shape the market’s direction. This comprehensive analysis provides a clear view of the market’s evolving landscape.

Natural Fiber Composites Market Dynamics

Drivers

-

Increasing Adoption of Natural Fiber Composites in Automotive Industry to Enhance Sustainability and Reduce Vehicle Weight

As the automotive industry focuses on enhancing durability without compromising performance, it is witnessing a transformative shift in the way that automotive manufacturers are increasingly turning to natural fiber composites to reduce the weight of their vehicles. As these materials are lighter than traditional materials including metals, they help boost fuel efficiency and also reduce emissions. Moreover, the growing emphasis on promoting sustainability in the manufacturing processes has caused a surge in the adoption of eco-friendly and renewable materials such as natural fiber composites. From automobile interior panels, door panels, to dashboards, natural fiber composites are gaining traction among automakers due to the paradigm shift towards reduced weight and fuel-efficient, and eco-friendly vehicles. As more consumers realize the environmental cost of automotive production, their appetite for sustainable alternatives is only swelling. They are being increasingly used in composites due to their good mechanical properties, lower cost, lower density, and compliance with strict environmental regulations. As the automotive sector strives to achieve lower carbon footprints and improve energy efficiency, the demand for composites is anticipated to propel market growth in the forecast period.

Restraints

-

Higher Production Costs of Natural Fiber Composites Compared to Traditional Materials Limiting Their Widespread Adoption

The incorporation of natural fibers for composite applications has numerous environmental benefits compared to synthetic fibers but still has higher production costs than standard materials such as plastics and metals. In price sensitive sectors, this discrepancy can lead some manufacturers to view the benefits of moving to natural fibre composites as impossible to justify. The extraction, processing, and treatment of natural fibers to enhance their properties incurs extra costs in the production process. In addition, the requirement for specialized production methods and equipment also add to the cost. In cost-sensitive sectors like automotive and construction, the relatively high initial expense of natural fiber composites may prove a barrier. Manufacturers need to find innovative processing technologies, scale production, and establish the supply chain efficiencies needed to lower production costs enough to make these materials commercially viable. Until these cost obstacles can be overcome, the use of natural fiber composites will be limited in several industries.

Opportunities

-

Expansion of the Natural Fiber Composites Market in Emerging Economies with Growing Industrialization and Sustainability Focus

The natural fiber composites market depicts the opportunity in the emerging economies such as Asia Pacific, Latin America, etc. As industrialization accelerates and sustainability becomes a priority, these markets demand eco-friendly materials in various sectors. Stricter legislation in those areas that regulates pollution and carbon emissions is opening a great opportunity for natural fibers composites. Furthermore, natural fibers include a wide range of different types of fibers, and such regions also have a good deal of accessibility to raw materials such as bamboo, jute, hemp, etc., which also makes them the most preferred locations for sourcing natural fibers. With the increasing awareness of consumers concerning environmental issues, it is expected that consumers and manufacturers in these emerging economies continue seeking alternatives to plastics and metals in the production of their goods, which should represent a big opportunity for natural fiber composites. Over the coming years, the rising construction of infrastructures, especially green buildings, will boost the demand for these composites in the market.

Challenge

-

Lack of Standardization and Consistent Quality Control for Natural Fiber Composites Limiting Widespread Adoption

Lack of standardized processes for manufacturing and quality control is a major challenge for the natural fiber composites market. There are no universal standards for natural fiber composites as there are for metals and plastics, so there are no conservation production guidelines for the composite products. Different processing methods and raw material conditions along with variations in treatment processes cause inconsistencies to natural fiber composites which make them less attractive and a less desired candidate for industrial processes that require solid quality and reliability. The absence of standardization results in ambiguity for end-users as well as producers, restraining the commercial acceptance of natural fiber composites. There is an industry need for standards around what your identity constitutes, as well as standards around the authentication / certification procedures that you will go through. Such initiatives will contribute to ensuring consistency, durability, and performance of natural fibre composites and promote greater confidence in their application in different sectors.

Natural Fiber Composites Market Segmental Analysis

By Raw Material

In 2023, wood segment dominated the natural fiber composites market and accounted for the largest share of about 52.10%. Wood is the most commonly available and economical material for softwood, displaying optimal properties in terms of mechanical resistance, stiffness, and low density, leading to widespread usage in composite applications. Wood fibers are commonly used in the automotive, construction, and furniture industries, because of their sustainability and lower environmental impact. This growth in the use of wood-based natural fiber composites has also been driven by support from associations such as the European Composites Industry Association (EuCIA), as well as favourable government policies aimed at encouraging sustainable manufacturing. Adhesive-based wood composites also enable industries to meet sustainability goals further driving the segment growth.

By Resin

Polypropylene (PP) dominated the Natural Fiber Composites market in 2023, and held 48.3% of the share. This dominance is due to the benefits of polypropylene, such as being low cost and offering great chemical resistance and ease of processing, making it an obvious choice for the production of composites with natural fibers. Polypropylene based composites provide excellent durability, which makes them more preferable in the manufacturing of interiors panels, bumpers, and dashboards of the automotive sector. There is also a growing emphasis on sustainability in the automotive sector whether in the form of regulatory oversight or through initiatives like the European Union's push towards greener automotive production, which further contributes to the increasing demand for polypropylene-based natural fiber composites.

By Matrix Type

The Inorganic Compound dominated the Natural Fiber Composites market and accounted for a market share of about 54.2% share in 2023. Inorganic compounds like glass fiber and mineral-based composites are generally preferred, as they offer high strength, superior thermal stability, and better fire resistance. Such properties have made inorganic compounds ideal for use in the automotive and construction industries where safety and durability are of utmost importance. Moreover, compared to organic matrices, inorganic matrices are less susceptible to moisture absorption, which improves the performance of natural fiber composites in demanding environments. Porous silica has dominated the inorganic and access to high performance applications has been the main driving force behind the market share.

By Technology

The injection molding dominated the Natural Fiber Composites market with a 46.90% share in 2023. This technology is widely used due to its rapid, cost-effective mass production capability, as well as its ability to create intricate shapes capitalizing on the elements of the automotive and consumer goods sectors. The ability of injection molding to accurately control the fiber distribution and resin matrix results in enhanced mechanical properties of the obtained composites. Its major share in the global market is attributed to the increasing adoption of injection molding in automotive manufacturing, with a corresponding demand for lightweight and durable parts. The American Composites Manufacturers Association (ACMA) and other industry groups still tout the benefits of injection molding in making quality natural fiber composite components.

By End-use Industry

In 2023, the automotive industry dominated the Natural Fiber Composites based on end use and accounted for 58.70% market share. A huge driving force in automotive manufacturing is the need for lightweight, durable, and sustainable materials. Natural fiber composites find wide application in automotive components, including interior panels, bumpers, and door trims, where they are employed to reduce vehicle weight and improve fuel economy. These favorable factors are complemented by stricter automotive regulations, including CO2 emissions in the European Union, that encourage the use of innovative materials, including natural fiber composites, to reduce the carbon footprint of the automotive sector. These trends help retain the automotive industry as the major consumer for natural fiber composites.

Natural Fiber Composites Market Regional Outlook

In 2023, North America dominated the Natural Fiber Composites market, holding a significant market share of around 39.2%. The region accounted for a large percentage of the global market, driven by robust demand in the automotive, construction, and consumer goods industries. In particular, the United States has been a key player, with the automotive industry leading the charge in adopting sustainable materials. The U.S. government’s support for eco-friendly manufacturing through initiatives like the Clean Energy Standard and increasing investments in sustainable technologies have propelled the demand for natural fiber composites. Additionally, leading companies in North America, such as Trex Company, Inc., have pushed the use of wood-based composites in decking and building materials, further enhancing regional market growth. North America’s high level of awareness regarding sustainability, coupled with regulatory support, solidifies its dominance in the market.

On the other hand, Asia Pacific emerged as the fastest-growing region in the Natural Fiber Composites market, with a significant growth rate in the forecast period. The growth is primarily fueled by the rapid industrialization and urbanization in countries such as China, India, and Japan, which have led to an increasing demand for sustainable materials in various sectors. For instance, China’s automotive industry is adopting natural fiber composites to reduce vehicle weight and meet stricter emissions regulations. Furthermore, India’s growing focus on sustainable construction materials has driven the demand for natural fiber composites in the building and infrastructure sector. The rapid expansion of industries like automotive and construction, coupled with the region’s push toward eco-friendly manufacturing practices, has made Asia Pacific a key growth area for natural fiber composites. This region’s favorable government policies and large manufacturing base further contribute to its significant growth.

Get Customized Report as per Your Business Requirement - Enquiry Now

Key Players

-

A B Composites Pvt. Ltd. (Natural Fiber Composites, Bio-based Resin Composites)

-

Amorim Cork Composites S.A. (Cork Composites, Cork Panels)

-

BASF SE (Ecovio, Ultramid)

-

Bcomp Ltd. (AmpliTex, PowerRibs)

-

DuPont (Hytrel, Sorona)

-

Fibre Extrusion Technology Ltd. (Natural Fiber Filament, Bio-based Fibers)

-

FlexForm Technologies (Ecoflex, FlexForm Natural Fiber Composites)

-

Green Dot Bioplastics (Terratek SC, Terratek C3)

-

Green Dot Bioplastics Inc. (Terratek SC, Terratek C3)

-

JELU-WERK J. Ehrler GmbH & Co. KG (JELUwood, JELU Fiber)

-

JNC Corporation (JNC Biocomposite, Natural Fiber Reinforced Plastics)

-

Lanxess AG (Tepex, Durethan)

-

Lingrove Inc. (Ekoa, Ecores)

-

Owens Corning (Owens Corning Natural Fiber Composites, Flexural Composite Panels)

-

Plasthill Oy (Biofiber Composites, Sustainable Natural Fiber Products)

-

Polyvlies Franz Beyer GmbH (Biofiber Nonwoven Fabrics, Polyvlies Composites)

-

Procotex (Natural Fiber Yarns, Fiber Reinforced Plastics)

-

Solvay S.A. (Amodel, Technyl)

-

TECNARO GMBH (Arboform, Arbosheet)

-

Trex Company, Inc. (Trex Decking, Trex Transcend)

Recent Highlights

-

May 2024: Toray Advanced Composites added capacity and capability for continuous fiber thermoplastic composites in response to increasing customer demand in aerospace and automotive markets. To boost production efficiency and product performance and consolidate its presence in the advanced composites market, Toray is now investing in additional new machinery.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 7.13 Billion |

| Market Size by 2032 | USD 18.98 Billion |

| CAGR | CAGR of 11.50% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | •By Raw Material (Wood, Cotton, Flax, Kenaf, Hemp, Others) •By Resin (Polypropylene (PP), Polyethylene (PE), Polyamide (PA), Others) •By Matrix Type (Inorganic Compound, Natural Polymer, Synthetic Polymer) •By Technology (Injection Molding, Compression Molding, Pultrusion, Others) •By End-use Industry (Automotive, Electronics, Sporting Goods, Construction, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Trex Company, Inc., Bcomp Ltd., TECNARO GMBH, UPM, DuPont, Toray Industries, Inc., Solvay S.A., BASF SE, Owens Corning, Lanxess AG and other key players |