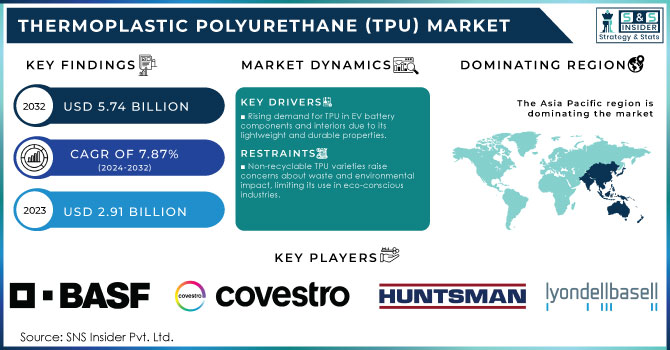

Thermoplastic Polyurethane (TPU) Market Size:

The Thermoplastic Polyurethane (TPU) Market was valued at USD 2.91 billion in 2023 and is expected to reach USD 5.74 Billion by 2032, growing at a CAGR of 7.87% from 2024-2032.

Get More Information on Thermoplastic Polyurethane (TPU) Market - Request Sample Report

Strong demand for various product attributes and potential applications integrated in numerous microwaves are committing to the development of strong and sustainable growth within the global thermoplastic polyurethanes (TPU) market. TPU is widely used in applications such as automotive components, medical products, footwear and other consumer goods, consumer electronics and industrial equipment because of its flexibility, durability and chemical resistance properties. Demand drivers include a growing automotive and transportation demand for lower-emission, lighter materials that improve fuel efficiency. The increasing penetration of electric vehicles (EVs) is additionally propelling TPU consumption in battery components and interiors with lightweight and durable products being essential. TPU is increasingly being integrated into consumer electronics such as wearables, smartphones and protective cases offering superior impact resistance and durability. TPU is particularly well-suited for smartphone and tablet covers due to its flexibility and protective qualities. Also, the market is accelerating due to footwear segment owing its elasticity and abrasion resistance properties that improve performance and comfort. TPU continues to drive product innovation, with North America boasting a greater than USD 100 billion global athletic footwear market by 2023.

Another significant market driver is the continual trend towards sustainability whereby more and more industries are opting for materials that have less of an impact on the environment. As manufacturers are trying to reduce their ecological impact, recyclable TPUs are gaining more and more popularity. Focusing on the latest trends of sustainability, Covestro (Leverkusen, Germany) a notable TPU manufacturer recently launched bio-based TPUs for low-carbon emitting production processes to meet increasing demands. TPU is also being expanded in scope to be used more often in the medical work by utilizing its biocompatibility and flexible virtual prototyping making it useful properties for such uses as catheters and tubing. The increasing healthcare infrastructure, especially in the developing region will create an inclination towards TPU for medical applications which is set to have a positive impact in 2024. Due to the growing demand for it in multiple sectors and technological advancements in its production processes, TPU market will keep thriving.

Thermoplastic Polyurethane (TPU) Market Dynamics

Drivers

-

Rising demand for TPU in EV battery components and interiors due to its lightweight and durable properties.

-

Increasing use of lightweight materials to improve fuel efficiency and reduce emissions in the automotive sector.

-

Increased use of TPU in wearables, smartphones, and protective cases due to its flexibility and impact resistance.

Thermoplastic Polyurethane (TPU), with its excellent balance of rigidity/flexibility, durability and resistance to impact, is increasingly being utilized in wearables, smartphones and protective cases. TPU is popular in consumer electronics due to its availability of hardness while being elastic.

For its flexibility, TPU is widely used in wearables including smartwatches and fitness trackers where the material can be comfortably fitted on to the wrist for bands and straps. The resistance to oil, sweat and environmental exposure adds longevity to the slate even with regular use. And, it is non-allergic to skin which is perfect for wearables as they stay on the body day in and day out. TPU is now one of the best choices for protector cases for smartphones or tablets as it absorbs most impact from a short fall and therefore reducing damage to electronic devices. That visibility enables makers to create the kind of crystal clear cases that can highlight the look of a device while still providing adequate protection. TPU is also scratch resistant, and isnill yellow not easy to turn from a clear colour cover into a doggy egg again, so its still as well loved material for durable phone case.

The versatility of TPU allows the material to take on complex shapes for use in electronics protection where it tightly molds the device and provides superior drop and physical impact protection. With the rapid growth of foldable devices and the higher penetration rate of 5G smartphones, TPU is expected to become even more popular due to its flexible design while still providing toughness needed for newer technologies.

Advantages of TPU

|

Feature |

Benefit in Wearables |

Benefit in Smartphones/Protective Cases |

|---|---|---|

|

Flexibility |

Comfortable fit for wristbands and straps |

Enables snug fitting and flexible phone cases |

|

Impact Resistance |

Protects against daily wear and tear |

Absorbs shock, protecting devices from damage |

|

Durability |

Resistant to sweat, oils, and environmental factors |

Long-lasting protection from scratches and drops |

|

Hypoallergenic Properties |

Suitable for prolonged skin contact |

Safe for regular handling by users |

With these advantages, TPU’s use in wearables, smartphones, and protective cases will continue to grow as consumer electronics become more integrated into daily life. Its versatility and protective features make it a material of choice for companies seeking durable, flexible, and aesthetic solutions for their products.

Restraints

-

Non-recyclable TPU varieties raise concerns about waste and environmental impact, limiting its use in eco-conscious industries.

-

TPU can degrade or lose its properties when exposed to high temperatures, restricting its use in high-heat environments.

-

Raw material shortages or logistical challenges can affect TPU production and availability in global markets.

Raw material shortages and logistical issues significantly affect the production and availability of Thermoplastic Polyurethane (TPU) in global markets. TPU's versatility stems from its composition, primarily consisting of polyols and diisocyanates, which are critical raw materials. Disruptions in the supply chain for these components can lead to production delays and increased costs, ultimately impacting the availability of TPU products. One major cause of raw material shortages is the fluctuation in global demand for polyols and diisocyanates. These materials are also used in various applications, such as coatings, adhesives, and elastomers, which can create supply strain during periods of high demand. For example, during economic recovery or post-pandemic periods, surges in demand for construction and automotive parts can intensify competition for the same raw materials, resulting in shortages for TPU manufacturers.

Logistical challenges, including transportation delays and rising shipping costs, further exacerbate these shortages. The COVID-19 pandemic highlighted vulnerabilities in global supply chains, leading to disruptions caused by port congestion, labor shortages, and container availability. These logistical hurdles can result in longer lead times for TPU manufacturers, forcing them to either delay production or raise prices to maintain profit margins. Moreover, these challenges may hinder manufacturers' ability to meet contractual commitments, potentially resulting in lost business and strained relationships with clients. Companies may need to find alternative suppliers or materials, which could compromise product quality or performance.

To address these risks, TPU manufacturers are increasingly diversifying their supplier networks, investing in local sourcing, and implementing effective inventory management strategies to ensure a steady supply of raw materials. However, navigating these complexities remains a challenge in the ever-evolving global marketplace, influencing the overall growth trajectory of the TPU market.

Thermoplastic Polyurethane (TPU) Market Segment Analysis

By Type

In 2023, the polyester segment led the thermoplastic polyurethane market. Polyester-based thermoplastic polyurethane is extensively used in applications that necessitate resistance to water, oils, and fuels. Its excellent transparency makes it especially favored in the construction and engineering sectors. The increasing demand for polyether types in the automotive industry is anticipated to drive growth in this segment throughout the forecast period.

The polycaprolactone segment of the Thermoplastic Polyurethane (TPU) market is expected to experience significant growth driven by its superior toughness, abrasion resistance, and biodegradability. Increasing applications in biomedical fields, particularly in bone tissue engineering and drug delivery systems, are fueling demand. The rising emphasis on sustainable materials also supports polycaprolactone's adoption. Future forecasts indicate that advancements in processing techniques and expanding application areas will further enhance market opportunities, leading to a robust growth trajectory for the polycaprolactone segment in the coming years.

By Application

The footwear segment led the thermoplastic polyurethane market in 2023. Increasing adoption of TPU in athletic and casual footwear due to a growing demand for lightweight, flexible, and durable materials is driving the growth of the segment. With its combination of excellent abrasion resistance and comfort that improves shoe performance, it is a go-to for manufacturers. Moreover, increasing inclination towards green and sustainable products is driving the brands to use TPU as it can be recycled. Technological advances in manufacturing are adding further support to the growth of the segment.

The automotive segment is projected to experience the fastest CAGR during the review period, driven by a growing demand for TPU in various parts and components, such as rocker panels, body-side trim cladding, and ditch covers.

In the construction sector, the increasing demand for thermoplastic polyurethane as an insulator to improve the aesthetics and durability of buildings will facilitate market growth. TPU's exceptional tensile strength and shock absorption characteristics have led to a heightened preference for the polyester type in engineering applications. Additionally, the rising need for thermoplastic polyurethane tubes, hoses, and pipes in consumer goods is expected to drive growth in the hose and tubing segment. Furthermore, the rapidly advancing electronics industry is likely to enhance the use of TPU in wire and cable applications throughout the forecast period.

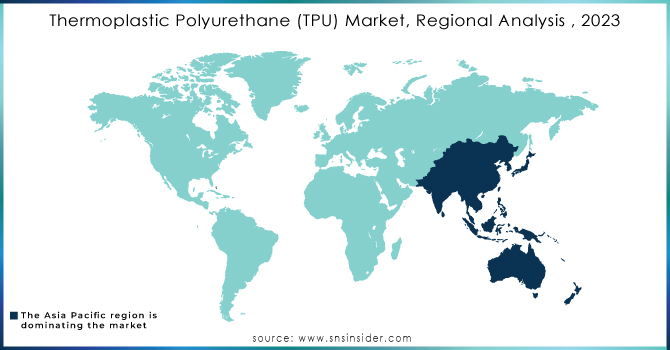

Thermoplastic Polyurethane (TPU) Market Regional Outlook

The Asia Pacific dominated the market in 2023, with countries like China and India experiencing significant industrialization and urbanization. This rapid development, along with industry consolidations and population growth, has spurred innovation, positioning Asia Pacific as a global industrial hub. The increasing demand for high-performance materials has driven the need for thermoplastic polyurethane in sectors such as automotive, construction, and consumer goods. Additionally, ongoing infrastructure projects and the rising demand for insulating materials in construction are expected to further boost growth in China's thermoplastic polyurethane market.

In North America, the growing emphasis on sustainable and eco-friendly materials has resulted in a significant rise in demand for bio-based and recycled thermoplastic polyurethane formulations that offer better environmental performance. The increasing need for polyester-based products in the electronics sector is also likely to strengthen the market in this region.

In Europe, the rapidly growing automotive industry in countries like Germany, France, and the U.K. is anticipated to drive market expansion. Furthermore, technological advancements by manufacturers aimed at improving product characteristics such as UV resistance, chemical resistance, and flame retardancy will open up a wider array of application opportunities.

Need Any Customization Research On Thermoplastic Polyurethane (TPU) Market - Inquiry Now

Key Players

The major key players are

-

BASF SE - Elastollan TPU

-

Covestro AG - Desmopan TPU

-

Huntsman Corporation - Irogran TPU

-

Wanhua Chemical Group Co., Ltd. - YUANFENG TPU

-

Mitsubishi Chemical Corporation - MCH TPU

-

LyondellBasell Industries N.V. - Amdel TPU

-

Eastman Chemical Company - Eastman TPU

-

Kraton Corporation - Kraton G TPU

-

PolyOne Corporation (now Avient Corporation) - Versaflex TPU

-

Teijin Limited - Teijin TPU

-

RTP Company - RTP 2000 TPU

-

Hexpol AB - HEXPOL TPE

-

China National Chemical Corporation (ChemChina) - ChemChina TPU

-

DOW Inc. - Adiprene TPU

-

Lubrizol Corporation - Estane TPU

-

Albis Plastic GmbH - ALBIS TPU

-

SABIC (Saudi Basic Industries Corporation) - SABIC TPU

-

Rohm and Haas Company (a subsidiary of Dow) - DOW TPU

-

Tosoh Corporation - Tosoh TPU

-

Kraiburg TPE GmbH & Co. KG - KLINGERSIL TPU

Raw Material Supplier

-

BASF YPC Company Ltd.

-

Bayer AG

-

BASF SE

-

Mitsui Chemicals, Inc.

-

SABIC

-

Huntsman Corporation

-

Kraton Polymers

-

Huntsman Corporation

-

Mitsubishi Gas Chemical Company, Inc.

-

BASF SE

-

Evonik Industries AG

-

SABIC

-

Covestro AG

-

LyondellBasell Industries N.V.

-

Dow Inc.

-

Mitsubishi Chemical Corporation

-

Huntsman Corporation

Recent Developments

In February 2023, Covestro AG revealed its plans to build its largest thermoplastic polyurethane manufacturing plant in Zhuhai, South China. The expansion will occur in three phases, with the initial phase slated for completion by late 2025. Upon full operation, the facility will have a production capacity of 20,000 tons of TPU per year.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 2.91 Billion |

| Market Size by 2032 | USD 5.74 Billion |

| CAGR | CAGR of 7.87% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | •By Type (Polyester, Polyether, Polycaprolactone and Others) •By Application (Automotive, Construction, Engineering, Footwear, Hose & Tubing, Wire & Cable, Medical, Synthetic Leather and Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | BASF SE, Covestro AG, Huntsman Corporation, Wanhua Chemical Group Co., Ltd., Mitsubishi Chemical Corporation, LyondellBasell Industries N.V., Eastman Chemical Company, Kraton Corporation, PolyOne Corporation (now Avient Corporation),Teijin Limited |

| Key Drivers | •Rising demand for TPU in EV battery components and interiors due to its lightweight and durable properties. •Increasing use of lightweight materials to improve fuel efficiency and reduce emissions in the automotive sector. |

| Restraints | •Non-recyclable TPU varieties raise concerns about waste and environmental impact, limiting its use in eco-conscious industries. •TPU can degrade or lose its properties when exposed to high temperatures, restricting its use in high-heat environments. |