Cellulose Ether & Derivatives Market Report Scope & Overview:

Get E-PDF Sample Report on Cellulose Ether & Derivatives Market - Request Sample Report

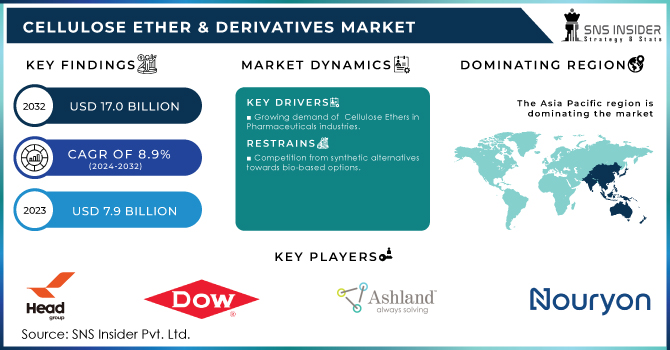

The Cellulose Ether & Derivatives Market Size was valued at USD 7.9 billion in 2023 and is expected to reach USD 17.0 billion by 2032 and grow at a CAGR of 8.9% over the forecast period 2024-2032.

The cellulose ether & derivatives market is a vital segment within the chemical industry, driven by the increasing demand across a variety of end-use applications, including construction, pharmaceuticals, food & beverages, and personal care. Key market dynamics shaping this industry include the growing need for environmentally sustainable products, rising consumer preference for natural ingredients, and an expanding demand for high-performance additives in construction materials. The shift toward green building practices and the growing adoption of cellulose-based products in the food and pharmaceutical sectors are significantly influencing market trends. Additionally, cellulose ethers, such as methylcellulose, hydroxypropyl cellulose, and carboxymethyl cellulose, offer essential properties like thickening, binding, and stabilizing, which are critical in improving the quality and performance of products across multiple industries.

Recent developments further highlight the innovation and evolution of the cellulose ether & derivatives market. For instance, advancements in the production of high-purity derivatives are enabling better formulations in pharmaceuticals and food products, responding to the growing demand for clean-label and organic ingredients. In the construction industry, the trend of producing eco-friendly and energy-efficient building materials has accelerated the use of cellulose ethers as additives in cement, plaster, and wall coatings. Furthermore, the rising global interest in personal care and cosmetics has expanded the usage of cellulose derivatives due to their natural origins, enhancing their appeal in formulations for skincare, haircare, and makeup products. Companies are also focusing on expanding their production capacities and enhancing the quality of cellulose ethers to meet diverse customer demands. Investments in research and development have led to the introduction of new variants of cellulose ethers, catering to specific needs, such as improved solubility or enhanced viscosity, to address the evolving requirements of modern industries.

Cellulose Ether & Derivatives Market Dynamics:

Drivers:

-

Increasing Demand for Sustainable and Green Building Materials Drives the Adoption of Cellulose Ethers in Construction Industry

The growing trend of sustainability and eco-friendly practices in construction has significantly impacted the demand for cellulose ethers. These derivatives are increasingly used in cement, plaster, and wall coatings due to their natural, biodegradable properties. Cellulose ethers like hydroxyethyl cellulose and methyl cellulose enhance the workability, water retention, and adhesion properties of construction materials, making them ideal for use in energy-efficient and sustainable building solutions. As the construction sector moves toward reducing its environmental impact, cellulose ethers are gaining prominence for their ability to improve the performance and durability of building materials while maintaining sustainability. Additionally, the demand for low-VOC (volatile organic compound) products, which are considered safer for the environment and human health, has further fueled the adoption of cellulose ether-based products in construction.

-

Surge in Demand for Natural Ingredients in Personal Care and Cosmetics Products Boosts the Cellulose Derivatives Market

-

Pharmaceutical Industry’s Focus on Safe and Effective Excipients Drives the Growth of Cellulose Derivatives

-

Rising Adoption of Cellulose Derivatives in the Food and Beverage Industry to Meet Clean Label Demands Fuels Market Growth

-

Technological Advancements in Cellulose Derivatives Production Enhance Their Application Scope Across Industries

Restraint:

-

Limited Raw Material Availability and High Cost of Production Pose Challenges to Cellulose Ether & Derivatives Market Growth

Despite the significant demand for cellulose ethers and derivatives, their market growth is hindered by the limited availability of raw materials and the high cost of production. Cellulose, the primary raw material, is derived from plant sources like wood and cotton, which can be subject to supply chain disruptions, especially with seasonal variations or environmental factors impacting harvests. The refining and processing of cellulose into high-quality derivatives require advanced manufacturing techniques and specialized equipment, which increases production costs. This can lead to higher prices for cellulose-based products, limiting their adoption in price-sensitive applications. Furthermore, the fluctuating costs of raw materials, such as wood pulp and cotton, can further strain the supply chain and add volatility to market pricing.

Opportunity:

-

Expanding Use of Cellulose Derivatives in Renewable and Bio-Based Packaging Solutions Offers Market Growth Potential

The rising demand for sustainable and biodegradable packaging solutions presents a significant opportunity for the cellulose ether & derivatives market. As environmental concerns regarding plastic waste grow, companies are exploring renewable and bio-based alternatives, with cellulose derivatives offering an eco-friendly option. Cellulose ethers can be used to create films, coatings, and adhesives that help improve the performance of biodegradable packaging while maintaining strength and integrity. This trend is particularly strong in industries like food and beverage packaging, where there is an increasing push for materials that do not harm the environment. The transition towards renewable packaging alternatives is expected to create substantial growth opportunities for cellulose ether manufacturers, especially as governments and consumers push for more sustainable practices.

-

Increasing Demand for Biodegradable and Environmentally Friendly Personal Care Products Fuels Market Expansion

-

Expanding Applications of Cellulose Derivatives in the 3D Printing Industry Opens New Market Frontiers

Challenge:

-

Fluctuating Raw Material Prices and Environmental Regulations Pose Threats to Cellulose Derivatives Market Stability

A significant challenge for the cellulose ether & derivatives market is the fluctuation in the prices of raw materials, such as wood pulp and cotton. These materials are subject to supply chain disruptions and environmental factors, such as weather conditions and natural disasters, which can lead to price volatility. Additionally, stricter environmental regulations related to forest management and the sustainable sourcing of raw materials can limit the availability of cellulose, further impacting market stability. As companies strive to balance demand with environmental compliance, the rising cost of raw materials and compliance with regulations could hinder market growth and affect profitability for manufacturers.

| Market Trend | Description | Impact on Market |

|---|---|---|

| Increasing demand for sustainable and eco-friendly products | Consumers are increasingly seeking products that are natural, biodegradable, and environmentally friendly. Cellulose ethers, derived from renewable sources, meet these preferences. | Growing demand for cellulose ethers in industries such as personal care, food, and packaging. |

| Rising adoption of pharmaceuticals | Cellulose ethers are used as excipients in drug formulations, and their adoption is expanding due to their functional properties like controlled release and gel formation. | Boosting market growth in the pharmaceutical sector, particularly for tablet and capsule formulations. |

| Shift towards personalized and specialized formulations | Customization in product offerings, such as unique viscosities or specific functional properties, is gaining traction. | Manufacturers are developing tailored cellulose ether solutions for niche industries like cosmetics and food. |

| Growing interest in plant-based and clean-label products | As consumers focus on healthier and cleaner ingredients, there is a rise in the preference for plant-based products. Cellulose ethers cater to this shift. | Increased use in clean-label foods, cosmetics, and personal care products that prioritize transparency and health. |

| Expansion in emerging markets | Rising industrialization and urbanization in regions such as Asia-Pacific and Latin America are driving demand for cellulose ethers in construction and consumer goods. | Creating new growth opportunities for cellulose ethers in construction, adhesives, and household products. |

Cellulose Ether & Derivatives Market Segmentation Overview

By Type

In 2023, Hydroxypropyl Methylcellulose (HPMC) dominated the Cellulose Ether & Derivatives market, holding a market share of approximately 40%. HPMC is extensively used in the pharmaceutical, construction, and food industries due to its excellent water retention, thickening, and gelling properties. For example, in the pharmaceutical industry, it is a key component in controlled-release formulations, while in construction, it is commonly used in tile adhesives and cement-based products for its water-retention properties that improve workability. HPMC's versatility and widespread demand across multiple sectors make it the leading segment in the market.

By Application

In 2023, the Adhesives segment dominated the Cellulose Ether & Derivatives market with a market share of 35%. This dominance is primarily attributed to the increasing use of cellulose ethers like HPMC and CMC in adhesive formulations for various applications, such as in the construction, automotive, and packaging industries. For example, cellulose ethers are used in high-performance adhesives for their ability to modify the rheological properties of the product, ensuring better bond strength and durability. The growing demand for eco-friendly and water-based adhesives further supports the growth of this segment, contributing to its leadership in the market.

By End Use

In 2023, the Construction segment dominated the largest market share in the Cellulose Ether & Derivatives market, with a share of around 45%. The significant demand in construction is driven by the increased use of cellulose ethers in products like cement, plaster, wall putty, and tile adhesives. These products benefit from cellulose ether's properties such as improved workability, water retention, and enhanced adhesion. For example, in construction, Hydroxyethyl Methylcellulose (HEMC) and Hydroxypropyl Methylcellulose (HPMC) are used in plaster and mortar for their ability to extend the open time, allowing better application. The booming construction industry, especially in emerging economies, continues to drive the dominance of this segment in the market.

Cellulose Ether & Derivatives Market Regional Analysis

In 2023, the Asia-Pacific region dominated the Cellulose Ether & Derivatives market, holding a market share of around 45%. This dominance is primarily driven by rapid industrial growth, particularly in the construction, pharmaceutical, and food industries. China, India, and Japan are key players in this region, contributing significantly to the market share. For instance, China is a major manufacturer of construction materials, and the demand for cellulose ethers like Hydroxypropyl Methylcellulose (HPMC) in cement, plaster, and tile adhesives is soaring due to the country’s massive infrastructure and urbanization projects. Similarly, India’s booming pharmaceutical sector, which uses cellulose ethers for controlled drug delivery systems, is fueling market growth. Japan, with its advanced technology in food and personal care products, is also a major contributor. The availability of low-cost raw materials, robust manufacturing capabilities, and increasing demand for eco-friendly construction and pharmaceutical products are the key factors driving the dominance of the Asia-Pacific region in this market.

Get Customized Report as per your Business Requirement - Request For Customized Report

Recent Developments

January 2024: Dow's PO/PG and polyols manufacturing facility in Freeport, Texas received ISCC PLUS certification, solidifying their commitment to sustainable practices.

January 2024: ACI Annual Meeting and Industry Convention held in Orlando, Florida, Nouryon unveiled Berol® Nexus surfactant, their latest game-changer designed to revolutionize the North American cleaning product market. This innovative, multifunctional hydrotrope promises to significantly improve cleaning performance.

Key Players in Cellulose Ether & Derivatives Market

-

Ashland Global Holding Inc. (Methocel, Aquacoat, Klucel)

-

Colorcon (Opadry, Klucel, Pharmacoat)

-

Dow Chemical Company (Methocel, Cellosize, Walocel)

-

Fenchem (Methyl Cellulose, Hydroxypropyl Methylcellulose, Carboxymethyl Cellulose)

-

LOTTE Fine Chemicals (LotteCell, Lotte Hydroxypropyl Methylcellulose, Lotte Methyl Cellulose)

-

Nouryon Chemical Holdings (METHOCEL, Walocel, Ethercell)

-

Rayonier Advanced Materials (Cellulose Ether, Redispersible Powder, Hydroxypropyl Cellulose)

-

Shangdong Head Co. Ltd (Methyl Cellulose, Hydroxypropyl Methylcellulose, Carboxymethyl Cellulose)

-

Shin Etsu Chemicals Co Ltd (Hydroxypropyl Methylcellulose, Methyl Cellulose, Hydroxyethyl Methylcellulose)

-

Zibo Hailan Chemicals Co. Ltd (Carboxymethyl Cellulose, Hydroxypropyl Methylcellulose, Methyl Cellulose)

-

AkzoNobel N.V. (Keltrol, Cellosize, Epolene)

-

Anhui Sunhere Pharmaceutical Excipients Co., Ltd. (Methylcellulose, Hydroxypropyl Methylcellulose, Ethylcellulose)

-

BASF SE (Cellosize, Walocel, Tylose)

-

Chongqing Shuangfu Chemical Co., Ltd. (Methylcellulose, Hydroxypropyl Methylcellulose, Carboxymethyl Cellulose)

-

Clariant AG (Laponite, Kollidon, Klucel)

-

Daicel Corporation (Methyl Cellulose, Hydroxypropyl Methylcellulose, Cellulose Acetate)

-

Jiangsu Chizhou Yongtai Chemical Co., Ltd. (Methyl Cellulose, Hydroxypropyl Methylcellulose, Carboxymethyl Cellulose)

-

Kao Corporation (Methylcellulose, Hydroxypropyl Methylcellulose, Ethylhydroxyethyl Cellulose)

-

Luoyang Fushi Biotechnology Co., Ltd. (Carboxymethyl Cellulose, Hydroxypropyl Methylcellulose, Methyl Cellulose)

-

Mitsubishi Chemical Corporation (Cellulose Ether, Hydroxypropyl Methylcellulose, Methyl Cellulose)

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | US$ 7.9 Billion |

| Market Size by 2032 | US$ 17.0 Billion |

| CAGR | CAGR of 8.9% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Type (Methyl Cellulose (MC),, Hydroxypropyl Methylcellulose (HPMC), Hydroxymethyl Methylcellulose (HMC), Carboxymethyl Cellulose (CMC)) • By Application (Ceramic Processing, Adhesives, Household Products, Textiles, Others) • By End User (Construction, Pharmaceuticals, Paints & Coatings, Foods & Beverages, Drilling Fluids, Personal Care) |

| Regional Analysis/Coverage |

North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia Rest of Latin America |

| Company Profiles | Shandong Head Co., Ltd, J.M. Huber Corporation, FENCHEM, The Dow Chemical Company, Colorcon, LOTTE Fine Chemicals, J. RETTENMAIER SOHNE GmbH + Co KG, Shin-Etsu Chemical Co., Ltd, Rayonier Advanced Materials Inc., Nouryon Chemical Holdings B.V, Ashland Global Holdings, Inc, and other players. |

| DRIVERS | • It is a sustainable product because it comes from wood. • Increasing Use in End-Use Industries • Carboxymethyl cellulose is being used more and more in the mini flotation process. |

| Restraints | • Dangerous air pollutants (HAPs) released during production • Risks of Fire and Explosion |