Coaxial Casing Heat Exchanger Market Size Analyis:

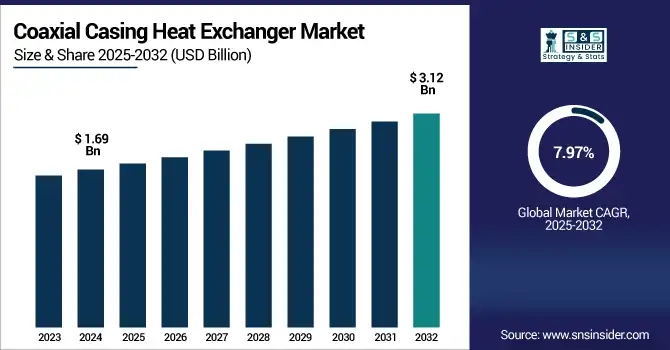

The Coaxial Casing Heat Exchanger Market Size was valued at USD 1.69 billion in 2024 and is expected to reach USD 3.12 billion by 2032 and grow at a CAGR of 7.97% over the forecast period 2025-2032. The Global Coaxial Casing Heat Exchanger Market is anticipated to grow steadily due to increasing demand from industrial as well as HVAC applications. Detailed segmentation on the basis of type, application, material, and end-user, and the comprehensive analysis of market insights are included in the report along with the regional performance and competitive landscape. It offers a holistic view of key drivers, restraints, opportunities, and challenges affecting market dynamics and provides a clear and transparent view of the market growth trajectory and future opportunities, at global level.

To Get more information on Coaxial Casing Heat Exchanger Market - Request Free Sample Report

Over 60% of industrial HVAC systems globally now incorporate coaxial heat exchangers due to their compact design and high thermal efficiency.

The U.S. Coaxial Casing Heat Exchanger Market size was USD 0.31 billion in 2024 and is expected to reach USD 0.54 billion by 2032, growing at a CAGR of 7.3% over the forecast period of 2025–2032.

U.S. Coaxial Casing Heat Exchanger Market is growing gradually owing to increase demand in industrial HVAC and oil & gas sector. This has resulted in almost double digit adoption year-over-year as optimal solution to provide efficient heat transfer in extreme operating conditions. Moreover, supportive government energy performance standards for energy equipment coupled with growing investments in industrial infrastructure modernization drives extensive adoption in mission-critical and energy-intensive applications, further establishing U.S. as a significant contributor to overall market growth.

Over 65% of new industrial chiller installations in the U.S. now utilize coaxial heat exchangers due to compact design and maintenance ease.

Implementing coaxial heat exchangers has contributed to a reduction of over 10 million metric tons of CO₂ annually across energy-intensive facilities.

Coaxial Casing Heat Exchanger Market Dynamics:

Key Drivers:

-

Efficient Heat Transfer Systems Revolutionize Oil, Gas, and Power Sectors

Oil & gas, chemical, and power generation service industrial operations are increasingly searching for implementations that can provide energy savings and thermal efficiency improvements. Coaxial casing heat exchangers provide a more efficient and space-saving alternative to traditional systems by allowing for improved heat transfer rates. With these industries striving towards sustainable production and lower emissions, the need for energy efficient thermal systems will only increase. The use of these in district heating and closed-loop cooling systems expands use cases and acts as a catalyst for widespread adoption in both industrialized and developing countries.

In recent retrofits, over 50% of district heating networks opted for coaxial casing heat exchangers for closed-loop integration.

Industrial facilities have reported up to 40% space savings in equipment layouts by switching to compact coaxial casing designs.

Restraints:

-

Lack of Global Standards Hinders Scalable Adoption of Coaxial Heat Exchangers

Lacking a common design or performance standard, manufacturers typically adhere to regional or industry standards resulting in variations in product quality and operational performance. Such difference causes procurement hurdles to global end-users who put great importance on compatibility and interchangeability. Not having a proper certification or even a technical standard makes a consumer less confident, especially when it comes to usage in applications where reliability and compliance with safety is of utmost importance. This leads to fragmented adoption and ultimately creates challenges for manufacturers to scale internationally when entering other markets.

Opportunities:

-

Industrial Growth in Developing Nations Boosts Adoption of Coaxial Casing Heat Exchangers

With fast industrialization, nations like India, Vietnam, Brazil, and Indonesia have started making heavy investments in oil & gas, chemical processing, and power sectors. Any of these industries will need strong and compact thermal systems that can endure extreme environments. Moreover, investment in infrastructure and manufacturing facilities is generating a need for modern heat transfer systems with low maintenance and operational costs. Improving awareness and availability has enabled coaxial casing heat exchangers to become differentiated options in areas where scalable and efficient heat exchange technologies are sought to deliver on infrastructure goals.

Over 60% of new thermal system installations in industrial infrastructure projects prioritize high-efficiency and low-footprint designs like coaxial casing exchangers.

Emerging markets have seen a 40% increase in the adoption of compact heat exchangers in industrial setups over the past three years.

Challenges:

-

Skill Shortage and Awareness Gaps Limit Heat Exchanger Adoption in Developing Regions

While the coaxial casing heat exchangers are highly effective, they need to be correctly installed, serviced from time to time and good deal of technical competence to yield consistently high performance. In several emerging or undeveloped markets, the deployment is constrained due to a lack of trained engineers or service providers. Along with that, decision-makers could not know the long-term savings and longevity that come with these systems. Such skills and awareness gap limits adoption in places that would be most benefitted by energy efficient and compact heat exchange solutions. Closing this gap is critical to realizing the full promise of the market.

Coaxial Casing Heat Exchanger Market Segmentation Analysis:

By Type

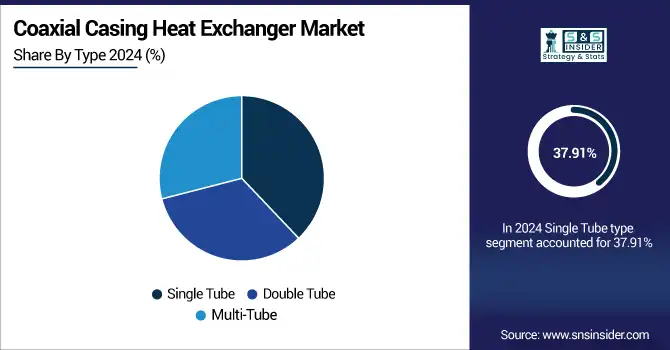

In 2024, the market size for Single Tube type segment with a market share of 37.91% is dominating the market at a rate of 7.10% during the forecast period. Increasing adoption for used in Residential and small commercial HVAC systems due to cost effective, small design and few others. Due to its simplicity of installation and maintenance, it is the most widely used option in simple heating and cooling applications. Mainstream deployments are built for durability, cost and to meet low-to-mid capacity demands, and thus are supplied by companies such as SWEP with low-cost, efficient, single tube models.

The Multi-Tube segment is anticipated to exhibit the fastest CAGR of 9.07% during the forecast period from 2024–2032, as it is especially efficient for high-capacity and industrial-level operations. Due to its higher surface area for heat transfer as well as improved thermal efficiency, it is suitable for chemical process and largescale industrial plants. Companies such as Danfoss are broadening the multi-tube portfolios to provide heavy industries with ever more reliable, scalable thermal management solutions.

By Application

The HVAC Systems segment accounted for the largest market share of 31.08% in 2024, due to increasing demand for energy-efficient climate control solutions for residential, commercial, and industrial buildings. Over the past few years, coaxial casing heat exchangers have gained widespread acceptance in HVAC systems due to their reliability and compact design. Well-known manufacturers of HVAC components (like Carrier) use these exchangers to ensure reliable heating and cooling within centralized and decentralized HVAC configurations.

The Food & Beverage segment is projected to achieve the highest CAGR of 12.65% during 2025–2032 owing to high hygiene and temperature-controlled heat exchange demand particularly in pasteurization and brewing processes. Guided by stricter regulatory standards and industry-wide pressure to prioritize sanitation, coaxial casing designs are becoming a more favored option. To facilitate this development, Alfa Laval provides dedicated exchangers designed for CIP (clean-in-place) suitability and food-grade heat transfer applications.

By Material

The stainless steel segment held 34.57% of the global industrial fittings market size in 2024, owing to better resistance against corrosion and mechanical strength, providing long-term durability in harsh applications. It continues to be the technology of choice across oil & gas, chemical processing, and power generation. Exchangers made from premium grade stainless steel for critical industries, such as those demanding both thermal reliability along with positive resistance to extreme temperatures and harsh chemicals — such as when you get Alfal Laval.

The polymer segment is predicted to achieve the highest CAGR of 9.04% from 2025–2032 owing to its lightweight, resistance to corrosion, and ability to endure some chemical and food processing surroundings. In low-pressure applications, cost benefits can also be realized with using polymers over metals. Thermal Solutions Manufacturing and such solution providers are also developing polymer-based designs for non-metal-sensitive environments, broadening their scope across niche and lower-cost market segments.

By End-User

The manufacturing sector dominates the Coaxial Casing Heat Exchanger market, holding a revenue share of 30.06% in 2024 due to extensive application for process heating, machine cooling, and industrial facility HVAC. These systems play a critical role in ensuring that large-scale operations continue to function efficiently and safely. There are many companies, such as Kelvion, that give a wide variety solutions with a great degree of customization for different industries. Hence, coaxial casing exchangers are a common sight within the manufacturing domain across the globe.

The pharmaceutical sector is expected to be the fastest-growing segment at a CAGR of 9.31% during the forecast period of 2025–2032, owing to the rising demand for sterile and efficient heat exchange in drug formulation, biotech processing, and cleanroom environments. Precision temperature control, CIP-friendly designs, etc. Demanding harsh industrial standards, companies like Tranter are answering the call with sophisticated exchanger systems designed for thermostatic free flow and energy-efficient temperature control in pharmaceutical production lines.

Coaxial Casing Heat Exchanger Market Regional Outlook:

The North America Coaxial Casing Heat Exchanger market would be driven by the strong demand from HVAC, oil & gas and industrial sectors. An efficient infrastructure, tough energy efficiency standards, and technology innovation all contribute to the advantages this region enjoys. Canada and Mexico are also gaining traction with expanding industrial hubs and development of cross-border energy infrastructure, but the U.S. continues to dominate the market as major manufacturers expand capabilities across the marke.

-

The U.S. dominates the North American market due to its extensive industrial base, strong presence of leading manufacturers, and high adoption of advanced HVAC and energy systems across commercial, residential, and heavy industries.

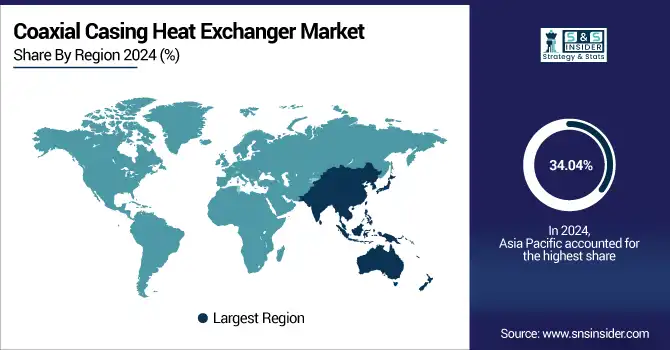

Asia Pacific held the largest revenue share of about 34.04% in the Coaxial Casing Heat Exchanger Market in 2024 owing to fast industrialization, rising energy infrastructure, and substantial demand from HVAC and manufacturing industries in China, India, and Southeast Asia. Asia Pacific is projected to have the highest CAGR of 9.05% during the forecast period from 2024–2032, due to scaling urbanization, favorable government initiatives, and the growth of various chemical and food processing industries choosing low-cost and high-performance heat exchange technologies.

-

China leads the Asia Pacific market owing to rapid industrialization, expansive manufacturing infrastructure, and significant investments in energy, HVAC, and chemical processing sectors driving widespread use of heat exchanger technologies.

Europe’s Coaxial Casing Heat Exchanger Market is driven by stringent energy efficiency regulations, advanced industrial infrastructure, and growing adoption in HVAC and renewable energy systems. Countries like Germany, France, and the UK are key contributors. The region emphasizes sustainable technologies and emission reduction, encouraging industries to adopt compact, efficient heat exchangers across manufacturing, power generation, and food processing applications.

-

Germany dominates the European market due to its advanced industrial base, strong engineering expertise, and high demand for energy-efficient systems. Its focus on sustainability and widespread use in automotive, chemical, and HVAC sectors further strengthens its leadership in the region.

Saudi Arabia dominates the Middle East & Africa Coaxial Casing Heat Exchanger Market, with factors including high oil & gas share and industrial investments in the region. Brazil reigns over Latin America, having a steadily developing industrial base, growing food processing sector as well as increasing need for energy-efficient HVAC systems in cities.

Get Customized Report as per Your Business Requirement - Enquiry Now

Key Players:

The Coaxial Casing Heat Exchangers Companies are SWEP International AB, Danfoss A/S, Alfa Laval AB, Kelvion Holding GmbH, Tranter Inc., Hisaka Works Ltd., Kaori Heat Treatment Co., Ltd., HRS Heat Exchangers, API Heat Transfer, Xylem Inc and others.

Recent Developments:

-

In March 2025, ISH Frankfurt, SWEP showcased its Sealix coating and double-wall coaxial exchanger portfolio, designed for tap water systems and district energy applications. These innovations enhance corrosion resistance, reduce scaling, and boost thermal performance in sustainable heating and cooling infrastructure.

-

In June 2024, Kelvion introduced a 3D-printed coaxial sleeve heat exchanger line using additive manufacturing to create custom geometries that enhance thermal efficiency. These exchangers are optimized for modular renewable energy systems and high-demand process industries, offering design flexibility and faster production times.

| Report Attributes | Details |

|---|---|

| Market Size in 2024 | USD 1.69 Billion |

| Market Size by 2032 | USD 3.12 Billion |

| CAGR | CAGR of 7.87% From 2025 to 2032 |

| Base Year | 2024 |

| Forecast Period | 2025-2032 |

| Historical Data | 2021-2023 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Type (Single Tube, Double Tube, Multi-Tube) • By Application (Oil & Gas Industry, Power Generation, HVAC Systems, Chemical Processing, Food & Beverage) • By Material (Stainless Steel, Carbon Steel, Nickel Alloys, Copper Alloys, Polymer) • By End-User (Manufacturing, Pharmaceutical, Pulp and Paper, Mining and Metals, Textile Industry) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Germany, France, UK, Italy, Spain, Poland, Turkey, Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Singapore, Australia,Taiwan, Rest of Asia Pacific), Middle East & Africa (UAE, Saudi Arabia, Qatar, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Rest of Latin America) |

| Company Profiles | SWEP International AB, Danfoss A/S, Alfa Laval AB, Kelvion Holding GmbH, Tranter Inc., Hisaka Works Ltd., Kaori Heat Treatment Co., Ltd., HRS Heat Exchangers, API Heat Transfer, Xylem Inc. |