Concrete Pump Market Report Scope & Overview:

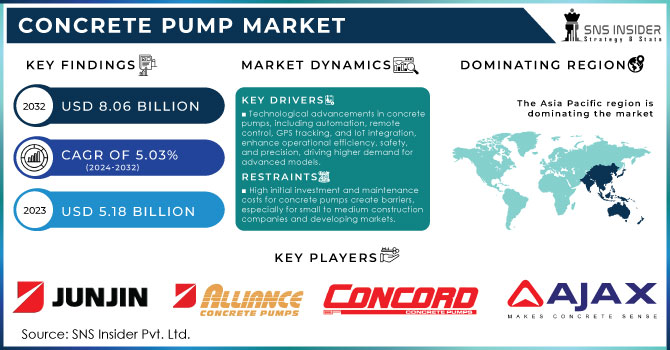

The Concrete Pump Market size was valued at USD 5.18 Billion in 2023 and is projected to reach USD 8.06 Billion by 2032, enlisting a CAGR of 5.03 % from 2024 to 2032.The Concrete Pump Market is rapidly growing, as global construction activities and urbanization increase. As construction projects get bigger and more complicated, the need for efficient, sustainable solutions grows. Concrete pumps are an excellent alternative to the traditional manual method, as they are faster, more precise, and cost-effective. For large high-rise buildings and industrial structures too, manual labor and other current conventional methods are not feasible. A surge in residential, commercial, and industrial construction is also fueling the boom, with a boost from urbanization, notably in developing economies. Governments all over the world are also investing heavily in new highways, railway lines, bridges, and airports, which will further help the market’s technological developments.

To get more information on Concrete Pump Market - Request Sample Report

The industry innovations comprise equipment with remote controls that are able to provide the most precise concrete placement in such. Another one is the eco-friendly design of equipment with lower energy consumption and emissions. It is beneficial in terms of adhering to the global environmental protection policies imposed by the governments and support sustainable development regulations. In the case of high capacity, the need for the delivery of concrete for large public works infrastructure projects are the main contributors. This facilitates the transportation of concrete to long distances for mega highway, airport, and bridge construction. For the urban market, where space constraints are such that the erection of stationary or static equipment requires large space and is not practical for smaller and medium-sized construction projects. due to high cost, truck-mounted are required. The U.S. is likely to be the North America region’s largest market due to its extensive modernization work and a high proportion of high-rise and other industry projects.

In July 2024: Hindustan Infrastructure Solution has introduced a state-of-the-art concrete pump for the SOBHA Dream Heights project in Gujarat. This advanced equipment is designed to enhance efficiency in delivering concrete to high elevations, addressing the challenges associated with high-rise construction. The new pump reflects the increasing demand for modern solutions in vertical construction projects, such as the prominent SOBHA Dream Heights development.

MARKET DYNAMICS

DRIVERS

-

Technological advancements in concrete pumps, including automation, remote control, GPS tracking, and IoT integration, enhance operational efficiency, safety, and precision, driving higher demand for advanced models.

Technologic innovations of concrete pumps help to advance their operational efficiency, safety, and preciseness. Consequently, the inflow of new, technologically advanced models of concrete pumps drives the surge in demand for such devices. The first type of technological innovation is related to the utilization of automation, which helps to streamline the process of concrete pumping. It diminishes the labor time because manual help is not required, enhancing the evenness and preciseness of concrete delivering. The second time involves the implementation of a remote command and control system, which assists in preventing operators and other workers on site from savage conditions or toxic substances. In addition, the use of GPS Vehicle Tracking makes it easier to determine the exact location and functionality of the pump, driving the efficiency of the devices and provide the opportunity to respond faster to a shortage of concrete to be delivered. The third innovation involves the involvement Internet of Things technology and comprehensive software, dedicated to the data collection, processing, and transmission, allowing for flaws and shortages identification and predictive maintenance. These technological innovations make process of concrete pumping more efficient and increase the overall efficiency of the process. Such concreting trends also improve the safety of workers and preciseness. These factors are highly important to developers and construction companies working on large-scale projects. Thus, it is expected that with the further development of the construction technologies, the demand for high-tech concrete pumps is expected to grow.

-

The surge in high-rise construction projects worldwide, including landmarks like Dubai’s Burj Khalifa, has driven demand for concrete pumps due to their efficiency in delivering concrete at elevated heights with less labor.

The global surge in high-rise construction projects, exemplified by iconic structures like Dubai’s Burj Khalifa, has significantly increased the demand for concrete pumps. These projects require the efficient and precise delivery of concrete to great heights, where traditional methods would be labor-intensive and less effective. Concrete pumps are specifically designed to handle such challenges by efficiently transporting concrete up to elevated levels, minimizing the need for extensive manual labor and reducing the time required for construction. Their ability to deliver concrete quickly and accurately to high-rise floors ensures a smoother construction process and enhances overall productivity. As skyscrapers and tall buildings become more prevalent worldwide, the reliance on advanced concrete pumping technology continues to grow, reflecting the industry's need for efficient and reliable solutions in managing complex and large-scale construction projects.

RESTRAINTS

-

High initial investment and ongoing maintenance costs for concrete pumps pose a significant barrier, particularly for small and medium-sized construction companies and in developing markets with limited financial resources.

The high initial cost and the cost of sustaining of the equipment including concrete pumps are a significant barrier for small and medium-size construction firms, as well as a constraint for the market of developing countries. Concrete pumps play an essential role in efficient and accurate concrete laying; due to the nature of the technology, their cost can be rather high. This imposes costs on both the purchase of the equipment and the cost of training and familiarizing the workers with the use of such technology. The obligation to spend such resources can discourage small unenterprising from attempting to recoup them. The high cost of maintaining the equipment and servicing the pumps to ensure that the infrastructure is operational is also likely to impose additional costs that could affect the willingness of limited businesses to keep the pumps. In developing countries, the pressure of the constraints could potentially keep construction firms from adopting novel construction approaches that use sophisticated construction equipment.

KEY MARKET SEGMENTATION

By Type

-

Truck-mounted Concrete Pumps

-

Stationary Concrete Pumps

-

Specialized Concrete Pumps

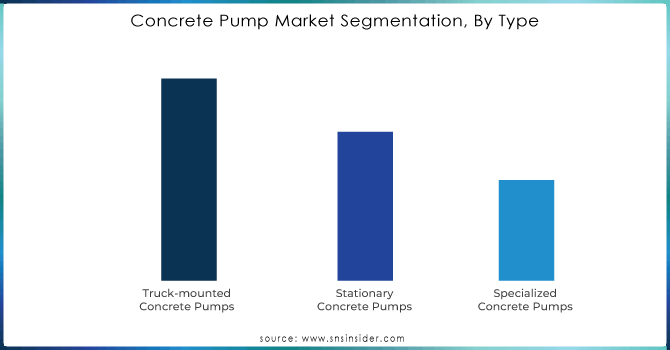

The truck-mounted Concrete pumps dominated the market with a share of around 62.04% in 2023. Truck Mounted Concrete Pumps are widely used in large scale constructions. These pumps have several unique characteristics which include mobility, moving large amounts of concrete at high speeds and an arm that can be remote-controlled. They are also used in electrical sealing activities, for reaching inaccessible levels. These factors propel the growth of the Concrete Pumps Market during the projected period.

Need any customization research on Concrete Pump Market - Enquiry Now

By Vertical

-

Industrial

-

Commercial

-

Domestic

REGIONAL ANALYSIS

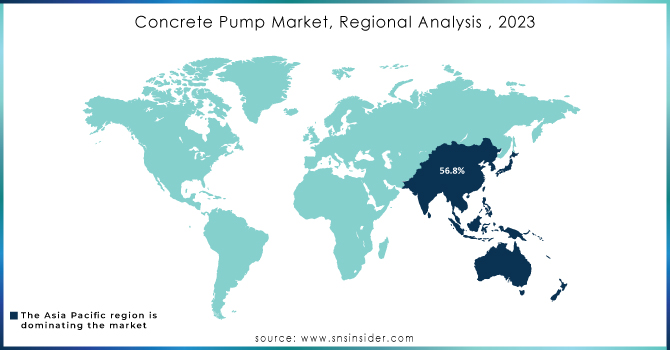

Asia Pacific dominated the market with a share of around 56.8% in 2023. The market growth of the region is attributed to the rapid increase of the population in the area leading to a surge in demand for construction activities. In addition, an increase in the government spending and more focus in developing infrastructure in this area. The growing economies including India, China, and Indonesia have substantial foreign direct investments, which increases demand for heavy pumps in infrastructure and construction projects in a wide range of industries.

KEY PLAYERS

The major key players are Ajax Fiori Engineering, Alliance Concrete Pumps, Concord Concrete Pumps, DY Concrete Pumps, Junjin, Liebherr, PCP Group, Sany, Schwing Stetter, Sebhsa, Zoomlion Heavy Industry Science & Technology Co., Ltd. and Other Players

RECENT DEVELOPMENT

In October 2022: Liebherr Company presented its new 36 XXT truck-mounted concrete pump for the first time. It was sold to Betonpumpenunion GmbH & Co. KG. The machine has features such as low unfolding height along with an innovative XXT support system.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 5.18 Billion |

| Market Size by 2032 | USD 8.06 Billion |

| CAGR | CAGR of 5.03% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By type (Truck-mounted Concrete Pumps, Stationary Concrete Pumps, Specialize Concrete Pumps), by vertical (Industrial, Commercial, Domestic) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | BEUMER GROUP, Daifuku Co., Ltd., Honeywell International, Inc., KION GROUP AG, Mecalux, S.A, Murata Manufacturing Co., Ltd., SSI SCHAEFER, Swisslog Holding AG, TOYOTA INDUSTRIES CORPORATION, Vanderlande Industries B.V. |

| Key Drivers | • Technological advancements in concrete pumps, including automation, remote control, GPS tracking, and IoT integration, enhance operational efficiency, safety, and precision, driving higher demand for advanced models. • The surge in high-rise construction projects worldwide, including landmarks like Dubai’s Burj Khalifa, has driven demand for concrete pumps due to their efficiency in delivering concrete at elevated heights with less labor. |

| RESTRAINTS | • High initial investment and ongoing maintenance costs for concrete pumps pose a significant barrier, particularly for small and medium-sized construction companies and in developing markets with limited financial resources. |