Concrete Repair Mortars Market Report Scope & Overview:

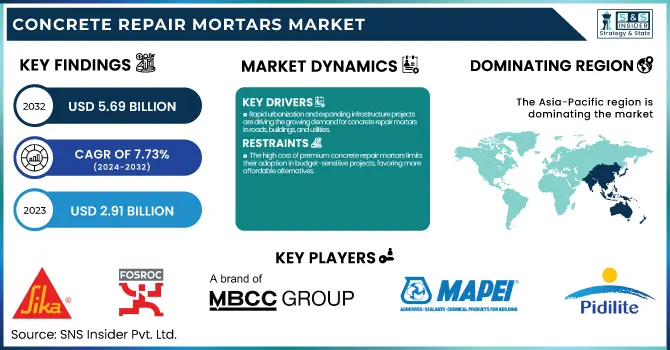

The Concrete Repair Mortars Market size was esteemed at USD 2.91 billion in 2023 and is supposed to arrive at USD 5.69 billion by 2032 and develop at a CAGR of 7.73% over the forecast period 2024-2032.

To get more information on Concrete Repair Mortars Market - Request Free Sample Report

This report offers a detailed overview of the concrete repair mortars market, focusing on regional manufacturing output, utilization rates, and maintenance and downtime metrics. It highlights technological adoption trends, including the shift towards automation and eco-friendly formulations, as well as regional export/import dynamics. Additionally, it examines the growing preference for high-performance, fast-curing mortars in the construction industry, reflecting broader sustainability trends in material development.

MARKET DYNAMICS

DRIVERS

-

Rapid urbanization and expanding infrastructure projects are driving the growing demand for concrete repair mortars in roads, buildings, and utilities.

The demand for concrete repair mortars is being significantly driven by the ongoing trend of rapid urbanization and infrastructure development. With the growth of cities and the expansion of infrastructure projects roads, bridges, buildings, utilities, etc. The demand for maintenance and repair solutions to preserve structure integrity and longevity continues to rise. Every concrete surface face wear and tear from traffic loads and the environment, as well as natural aging, which drives the development of high-quality repair materials. Repair mortars are critical tools for repairing cracked infrastructure surfaces, structures, and various forms of deterioration. Moreover, the increase in government funding for large infrastructural projects and urban renewal projects also drives the demand for effective and durable repair solutions. With urbanization and increasing infrastructure development, the demand for concrete repair mortars is anticipated to keep growing, making it an essential aspect of the construction and maintenance sectors.

RESTRAINT

-

The high cost of premium concrete repair mortars limits their adoption in budget-sensitive projects, favoring more affordable alternatives.

The high cost of premium concrete repair mortars is a significant restraint in the market, particularly for low-budget or cost-sensitive projects. High-performance mortars, engineered for exceptional durability, rapid curing times, and improved defense against environmental influences, are typically more expensive than standard options. The production costs of these products are typically high due to the use of advanced materials polymers, resins, or additives. These premium solutions deter the long facilitation and increased lifespan of structures however, they may not become an option for smaller or budget-conscious construction projects. This price point often contributes to the preference for cheaper but less long-lasting alternatives, which in turn restricts the adoption of advanced repair methods especially in developing areas or among smaller contractors. This makes it difficult for manufacturers and consumers to strike a balance between performance and affordability in the concrete repair mortars market.

OPPORTUNITIES

-

Rising urbanization and infrastructure growth in emerging markets are driving the demand for concrete repair mortars to maintain and enhance existing structures.

The rising demand for concrete repair mortars in emerging markets is largely driven by rapid urbanization and the growth of infrastructure in developing economies. Infrastructure is critical for society, and as cities grow and demand for strong infrastructure increases, existing infrastructure, including roads, bridges, and buildings, must be maintained and repaired regularly. Governments and private companies in these areas are spending heavily on infrastructure allowing them to house a growing population and promoting economic growth. This has led to an increase in demand for concrete repair mortars, which help to maintain and extend the life of these structures. Furthermore, the increasing pace of urbanization has led to a need for more durable and sustainable buildings, which also supports the demand for high-performance repair materials. A great opening for the suppliers to bring in new and cost-effective concrete repair solutions to serve this rapidly growing market, by providing long-term solutions to infrastructure maintenance.

CHALLENGES

-

Environmental concerns in concrete repair mortars arise from the use of harmful chemicals and energy-intensive production processes, despite the growing shift towards eco-friendly alternatives.

Environmental concerns in the concrete repair mortars market arise due to the use of certain chemicals in traditional repair products. Some of the concrete repair mortars contain toxins such as Solvents, volatile organic compounds (VOCs), and non-biodegradable polymers, while the industry is taking a step towards sustainable and eco-friendly solutions. These substances can also cause pollution air, pollute the environment, and are potentially harmful to the health of workers who carry out the application process. The production of the mortars could also be energy-intensive, adding to carbon emissions. With the increased demand for eco-friendly building practices, eco-friendly building companies are exploring alternatives with reduced effects on the environment. It broadly encompasses using sustainable raw materials, lowering emissions, and making sure the final products can be recycled or composted. Nonetheless, the struggle will persist for manufacturers to compromise performance with eco-friendliness to satisfy market and regulatory needs.

SEGMENTATION ANALYSIS

By Type

Polymer Modified Cementitious (PMC) Mortars segment dominated with the market share of over 72% in 2023, due to their widespread use and versatility in a variety of applications. These mortars are used because they have improved adhesion, flexibility, and cracking resistance properties, allowing for the repair of structural and non-structural concrete. The specific performance requirements of the surface will dictate the type of PMC mortar to be used, although, in general, they provide improved workability, bond strength, and durability under multiple environmental conditions. They are widely used in building, road infrastructure and utility applications, as well as resurfacing and patching. They also have a dominant role in the market due to their adaptability in various environments, cost-effectiveness, and ease of application for both residential and industrial applications. Their continuing dominance in the market stems from their wide-ranging applicability across various industries.

By Application

The Hand/Troweling application segment dominated the Concrete Repair Mortars Market, accounting for 42% of the market share in 2023. This segment is still the most common solution for the repair of concrete by volume, thanks to its versatility, simplicity, and effectiveness in small to medium scale applications. Hand/troweling is used for surface repairs, patching and finishing, which makes it suitable for residential and commercial construction projects. Used in areas that are hard to access or for smaller damaged surfaces that cannot accommodate larger machines, this method has gained wide popularity due to its precision, micro-level accurate and mechanized repair process. The simplicity of the application process and cost-effectiveness further drive its dominance in the market, especially for smaller repair jobs and DIY applications.

By Grade

The Structural grade segment dominated the concrete repair mortars market with a 68% market share in 2023, Structural repair mortars have been engineered to recover the integrity of buildings, bridges, highways, and other infrastructure faced with heavy loads, environmental stress, and aging. This segment benefits from a growing need for maintenance and repair of infrastructure in both developed and emerging economies. Structural repair mortars are known for their durability, strength characteristics, and long-lasting performance, making them the preferred option in projects that will require long-term solutions. The increasing concern for safety, regulatory standards, and the necessity to prolong the service life of old infrastructure is pushing the demand for structural repair products and etching its leadership position in the market.

By End-Use

The Road Infrastructure segment dominated the concrete repair mortars market with a 52% market share in 2023, due to the extensive need for maintenance and repair of roads, highways, and bridges. With the continued trend towards urbanization and increased vehicular traffic, road surfaces are being subjected to increasing wear and tear, creating a strong need for effective repair solutions. Rain, sunshine, heavy vehicle loads, and environmental elements cause damage to our road infrastructures over time, and so they need to require frequent repairs. Moreover, governments globally are making significant investments in the renovation and enhancement of transportation networks, which is also driving this segment with an increasing demand for concrete repair mortars. The emphasis on durability, safety, and economical solutions are foregoing road infrastructure to the leading position in the concrete restoration market.

KEY REGIONAL ANALYSIS

The Asia-Pacific region is dominated by a market share of over 38% in 2023, due to rapid urbanization and significant infrastructure development, particularly in countries like China, India, and Southeast Asian nations. This means that roads, bridges, commercial buildings, and residential complexes are all under construction, greatly increasing the demand for concrete repair solutions that will make these buildings last longer. Furthermore, the increasing emphasis on improving and preserving worn-out infrastructure in developed regions like Japan and South Korea also aids in the pool of market leaders. New economies are also channeling funds for infrastructure, giving a boost to market development. Hence, concerning the ever-increasing construction, the Asia-Pacific region not only profits from the construction boom but also from the immediate requirement of concrete repair mortars, which is both durable and cost-effective.

North America is experiencing rapid growth in the concrete repair mortars market, primarily fueled by substantial investments in infrastructure maintenance and renovation. The demand for high-performance concrete repair solutions is driven by the need for frequent repair and restoration of aging infrastructure, including bridges, highways, and buildings, in various regions. Furthermore, the growing adoption of cutting-edge repair technologies like high-early-strength and long-lasting repair mortars is accelerating market expansion. Heeding the region's axis on sustainability and strict environmental regulations has also created a demand for developing and utilizing environmentally repair products. In addition, the increasing focus on infrastructure resilience, especially against extreme weather events and natural disasters, is fuelling the demand for durable and permanent concrete repair products in North America.

Need any customization research on Concrete Repair Mortars Market - Enquiry Now

Some of the major key players in the Concrete Repair Mortars Market

-

Sika AG – SikaRepair and Sikadur product lines

-

Fosroc International Ltd. – Renderoc, Nitobond, and Conbextra range

-

MBCC Group – MasterEmaco and MasterFlow

-

Mapei S.p.A – Mapegrout, Mapecem, and Planitop

-

Saint-Gobain Weber S.A. – Weber Repar and Weber Dry

-

Pidilite Industries Ltd. – Fevicol and Dr. Fixit product range

-

Remmers Baustofftechnik GmbH – Remmers Concrete Repair Mortars and Renovation Mortars

-

Flexcrete Technologies Ltd. – Flexcrete Repair Mortars and Protective Coatings

-

The Euclid Chemical Co. – EucoRepair and EucoGuard products

-

Adhesive Technology Corp. – ATC Repair Mortars and Patching Compounds

-

LATICRETE International Inc. – LATICRETE Concrete Repair Systems

-

BASF SE – MasterEmaco and MasterTop solutions

-

Ardex Group – Ardex Repair Mortars and Finishing Products

-

Cemex S.A.B. de C.V. – Cemex Concrete Repair and Restoration Products

-

Bostik Ltd. – Bostik Concrete Repair Solutions

-

Rheomix by Bostik – Advanced Concrete Repair Mortars

-

MAPEI India Pvt. Ltd. – Mapei Repair Systems

-

Knauf – Knauf Repair Mortars and Finishing Products

-

H.B. Fuller – Fuller Concrete Repair and Maintenance Solutions

-

Kryton International Inc. – Krystol Repair Mortars and Waterproofing Solutions

Suppliers for (comprehensive repair and protection systems for buildings and infrastructure) on Concrete Repair Mortars Market

-

Sika AG

-

Fosroc International Ltd.

-

MBCC Group

-

Mapei S.p.A

-

Saint-Gobain Weber S.A.

-

Pidilite Industries Ltd.

-

Remmers Baustofftechnik GmbH

-

Flexcrete Technologies Ltd.

-

The Euclid Chemical Co.

-

Adhesive Technology Corp.

RECENT DEVELOPMENT

In June 2023: Fosroc appointed Mannai Trading Co. WLL as its exclusive distributor in Qatar. This collaboration is set to deliver high-performance construction chemicals to the expanding market, with an emphasis on sustainable and eco-friendly practices.

In May 2023: Sika AG acquired MBCC Group to broaden its global footprint and enhance its portfolio of products and services, covering every stage of the construction lifecycle. This acquisition was aimed at solidifying Sika's position in the global market.

| Report Attributes | Details |

| Market Size in 2023 | USD 2.91 Billion |

| Market Size by 2032 | USD 5.69 Billion |

| CAGR | CAGR of 7.73% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Type (Polymer Modified Cementitious (PMC) Mortars, Epoxy Based Mortars) • By Application (Hand/Troweling, Pouring, Spraying) • By Grade (Structural, Non-Structural) • By End-use (Building & Carparks, Road Infrastructure, Utility, Marine) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Sika AG, Fosroc International Ltd., MBCC Group, Mapei S.p.A, Saint-Gobain Weber S.A., Pidilite Industries Ltd., Remmers Baustofftechnik GmbH, Flexcrete Technologies Ltd., The Euclid Chemical Co., Adhesive Technology Corp., LATICRETE International Inc., BASF SE, Ardex Group, Cemex S.A.B. de C.V., Bostik Ltd., Rheomix by Bostik, MAPEI India Pvt. Ltd., Knauf, H.B. Fuller, Kryton International Inc. |