Conveyer Monitoring Market Report Scope & Overview:

Get More Information on Conveyer Monitoring Market- Request Sample Report

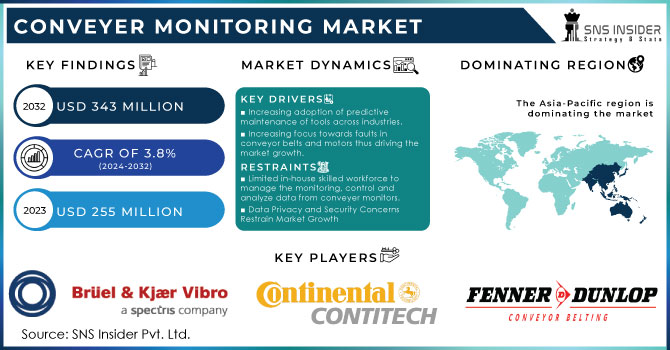

The Conveyer Monitoring Market size was valued at USD 255 million in 2023 and will reach USD 343 million by 2032, displaying a CAGR of 3.8% by 2024-2032.

The conveyor monitoring market is growing at a significant and is expected to grow considerably in the next few years. The traditional methods of conveyor monitoring were inconsistent, unreliable, labor intensive, and time-consuming.

An interruption in conveyor belts affects the productivity and damage to parts majorly belt edges and cord misalignment because of this, companies suffer from revenue losses and workflow is heavily hampered. Latest conveyor monitoring is surging in demand as it helps in the identification of failure in advance which reduces downtime and productivity of conveyors. The rise in demand for conveyor monitoring market is because of an increase in necessity of reduction in damages occurred due to human error at the time of operating processes. The key factor which is driving the market is increasing adoption of companies in order to reduce revenue loss from faults in conveyors along with growing awareness towards predictive maintenance. Also, the growing automation & Industrial IoT, cloud-based services in the market is helping in the market. Also, conveyor monitoring helps in reduction of maintenance, waste elimination. These driving factors are helping in the growth of the conveyer monitoring market.

Market Dynamics

Drivers

-

Increasing adoption of predictive maintenance of tools across industries.

Predictive maintenance is gaining popularity in industries to track the condition and performance of the machine and foresee any failure even before it appears which help manufacturers to improve thereby avoiding any breakdowns. Therefore, the popularity of predictive maintenance is driving the growth of the conveyor monitoring market.

-

Increasing focus towards faults in conveyor belts and motors thus driving the market growth.

Restraints

-

Limited in-house skilled workforce to manage the monitoring, control and analyze data from conveyer monitors.

The workforce must have knowledge and skills about monitoring solutions in order to know the health of the motor, conveyor belt, etc. Also, the team must be aware of the consequences of the failure of these systems. Skilled workforce is required for smooth operations of monitors, which increases the business cost. Thus, the shortage of skilled workforce and the increased business cost are the key factors restraining the conveyor monitoring market growth.

-

Data privacy, security concern of real time data is making a restraining factor in the market growth.

Opportunities

-

Growing penetration of automation & Industrial IoT in the market thus creating opportunities.

-

Introduction of cloud-based services with conveyer monitoring is helping in reduction of upfront cost, increasing scalability & flexibility.

Challenges

-

Lack of availability of expert personnel in remote locations is making a challenge in market growth.

-

Lack of awareness towards the possible advantages and efficiency it brings by using conveyer monitors is a challenge in the market growth.

Impact of Russia-Ukraine War

The ongoing war between Russia & Ukraine is disrupting the conveyor monitoring market. The demand and supply of the conveyer monitoring is affected by the shortage of components like sensors & chips which is causing a delay in productions, indirectly inflating equipment costs causing a dip in demand and limiting the availability of conveyer monitors. Additionally, disruptions in industries that heavily rely on conveyor operations, such as mining or steel production, could see a decrease in demand for these monitoring systems & might experience production slowdowns or shutdowns. The war has an affect several economies which might lead to decreasing investments in equipment’s which also include conveyer monitors. However, on the other side, the war might increase the importance towards supply chain security, data security & resilience among companies. The real time data can help in identification of the disruptions beforehand and minimize its impact. The focus on supply chain security lead to adoption of just-in-time manufacturing for manufacturing or those reliant on critical material transportation.

Impact of Economic Slowdown

The economic slowdown has a huge impact on conveyer monitoring market. With slowdown in the industry growth, companies might prioritize their spending over core operations rather than investing in new machines or capital. This will likely to decrease the demand of conveyer monitor systems. Industries such as manufacturing are the first to cut the investments and these industries might see a decrease in the adoption rate of monitoring systems. But, on the other side the optimization of existing systems might lead to long term benefits. The predictive maintenance feature of monitor systems helps in identification of problems beforehand leading to cost savings in the long run. The value proposition, efficiency and reduced downtime, might resonate with companies seeking to navigate a challenging economic slowdown. Moreover, the economic slowdown may act as a catalyst in the innovation within the conveyor monitoring Market, by development of more cost-effective solutions or subscription-based models might be beneficial to budget-conscious companies. Also, the return on investment (ROI) through data-driven insights and energy savings could incentivize hesitant businesses to adopt this technology.

Key Market Segmentation

By Type

-

Conveyor Motor Monitoring

-

Conveyor Belt Monitoring

By Conveyor Belt Monitoring Market

-

Electromagnetic

-

X-ray

-

Optical Sensors

The Conveyor Belt Monitoring is dominating the market in this segment. Conveyor belts often suffer from faults such as belt wear and tear, longitudinal crack, damages to belt edges, and belt overlapping on pulleys thus, hampering the productivity. Belt monitoring consists of X-ray, electromagnetic, and optical. These are designed to increase production by monitoring the condition of the conveyor belt monitoring system.

By Technology

-

Vibration Monitoring

-

Thermography

-

Corrosion Monitoring

-

Ultrasound Emission Monitoring

-

Motor Current Analysis

By Offering

-

Hardware

-

Software

By Deployment Type

-

On-premise

-

Cloud

By Industry

-

Mining Industry

-

Power Generation

The Mining industry is dominating the market. Also, with the adoption of automation among industries providing safety, wear & tear minimization, increased reliability & quality is making mining industry a dominating industry to have implementing these. The increased safety of workforce in mining is also helping in maintaining the dominating nature. The setting up of stringent rules & regulations for the safety of workforce is driving in adoption of conveyer monitors in the market growth.

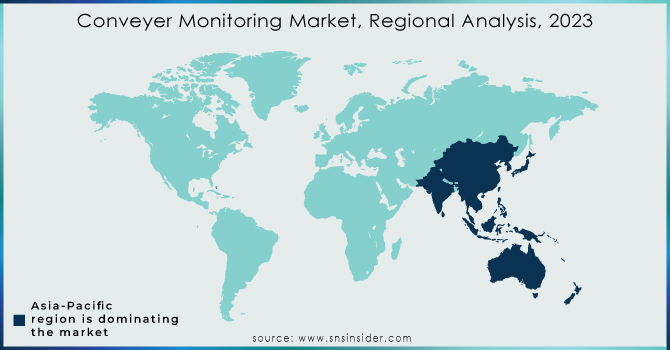

Regional Analysis

The Asia-Pacific region dominated the market with a share of 48% of the total market. Because of the growing industries such as mining, steel, cement, and food and beverage industries, etc. The regions increasing population & urbanization is also making a dominating place for cements, food & processing industries, steel which in-turn increases the demand of conveyer monitoring.

Need any customization research on Conveyor Monitoring Market - Enquiry Now

Regional Outlook

North America

-

US

-

Canada

-

Mexico

Europe

-

Eastern Europe

-

Poland

-

Romania

-

Hungary

-

Turkey

-

Rest of Eastern Europe

-

-

Western Europe

-

Germany

-

France

-

UK

-

Italy

-

Spain

-

Netherlands

-

Switzerland

-

Austria

-

Rest of Western Europe

-

Asia Pacific

-

China

-

India

-

Japan

-

South Korea

-

Vietnam

-

Singapore

-

Australia

-

Rest of Asia Pacific

Middle East & Africa

-

Middle East

-

UAE

-

Egypt

-

Saudi Arabia

-

Qatar

-

Rest of the Middle East

-

-

Africa

-

Nigeria

-

South Africa

-

Rest of Africa

-

Latin America

-

Brazil

-

Argentina

-

Colombia

-

Rest of Latin America

Key Players

The major players are Fenner Dunlop, PHOENIX CBS GMBH, ContiTech Conveyor Belt Group, SKF, Bruel and Kjaer, Beltscan Systems Pty, Yellowtec, Honeywell International, Emerson Electric, Parker Hannifin and others.

Recent Development

-

In April 2024, Honeywell announced the launch of its next-generation conveyor monitoring system, the "Honeywell Sentinel XL." This system boasts improved wireless sensor capabilities for easier installation and enhanced data security features for secure remote monitoring.

-

Siemens recently partnered with a cloud computing platform provider to offer a cloud-based version of its conveyor monitoring solution, "Simatic MineMonitor." This cloud-based system is expected to be launched in third quarter of 2024 and will cater to companies seeking a scalable and cost-effective monitoring solution.

| Report Attributes | Details |

|---|---|

| Market Size in 2024 | US$ 255 Million |

| Market Size by 2032 | US$ 343 Million |

| CAGR | CAGR of 3.8% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Type • By Conveyor Belt Monitoring Market • By Technology • By Offering • By Deployment Type • By Industry |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Fenner Dunlop, PHOENIX CBS GMBH, ContiTech Conveyor Belt Group, SKF, Bruel and Kjaer, Beltscan Systems Pty, Yellowtec, Honeywell International, Emerson Electric, Parker Hannifin |

| Key Drivers | • Increasing adoption of predictive maintenance of tools across industries. • Increasing focus towards faults in conveyor belts and motors thus driving the market growth. |

| Restraints | • Limited in-house skilled workforce to manage the monitoring, control and analyze data from conveyer monitors. • Data privacy, security concern of real time data is making a restraining factor in the market growth. |