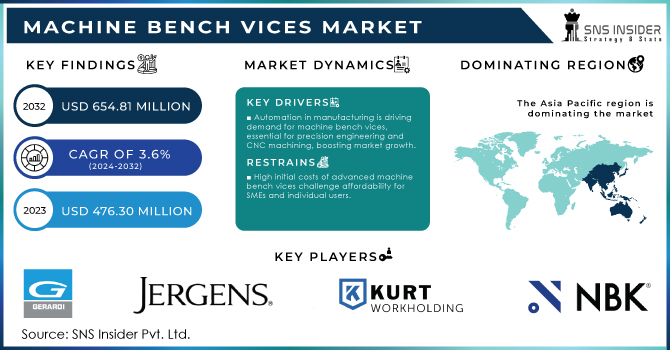

Machine Bench Vices Market Report Scope & Overview:

Get more information on Machine Bench Vices Market- Request Free Sample Report

The demand for advanced and efficient products for holding workpieces has risen due to the increasing need for high precision and quality in component production. Machine bench vices offer the stability and precision necessary for accurate machining, guaranteeing the high quality of end products. These items are used in various industrial processes, making them adaptable tools. They are utilized in machining centers, workshops, and production lines for a variety of tasks, leading to a steady demand in various manufacturing applications. The flexibility in operations and higher manufacturing output in industries drive market growth. The ability of machine bench vices to work with a variety of machining tools is an important factor in their use in different manufacturing operations like shaping steel, working with wood, cutting, drilling, removing u-joints, building, and putting things together. Machine bench vises play a crucial role in machining by securely holding workpieces during cutting, mining, grinding, and drilling.

Their ability to work well with various machining equipment, including drill presses, milling machines, lathes, and CNC machines, allows them to easily be included in various machine configurations, improving their flexibility and usefulness. Additionally, being compatible with various machining equipment improves the efficiency and productivity of machining processes. It allows machinists to easily change between various machining setups without requiring extensive reconfiguration, cutting downtime and boosting overall production.

In September 2023: Silhouette America Inc. introduced CAMEO5, CURIO2, Potrait4, and CAMEO5 PLUS cutting machines, revolutionizing the crafting sector with innovative features and tools. These machines provided accurate cutting and ability to work with various tools, in addition to a Power Carriage for improved integration.

MARKET DYNAMICS

DRIVERS

The growing use of automation in manufacturing is fueling the need for machine bench vices, crucial tools for precision engineering, CNC machining, and automated assembly lines, leading to an increase in market expansion.

The growing use of automation in manufacturing is greatly fueling the need for machine bench vices, crucial tools in precision engineering, CNC machining, and automated assembly lines. As industries aim for improved efficiency and precision, the demand for strong and dependable clamping tools such as machine bench vices becomes essential. These bad habits offer the steadiness needed for accurate tasks, guaranteeing parts are firmly grasped while milling. Machine bench vices play a vital role in CNC machining, ensuring accurate positioning of workpieces to enhance productivity and quality in operations that require precision. Furthermore, integrating machine bench vices into automated assembly lines aids in efficiently carrying out repetitive tasks, decreasing reliance on human intervention and minimizing mistakes. The shift towards automation is not just improving operational efficiency but also driving the expansion of the machine bench vices market, with companies embracing new clamping solutions to meet modern production demands. Due to continuous advancements in manufacturing automation and increasing emphasis on precision and efficiency in industrial operations, the machine bench vices market is witnessing robust growth.

The growth of the metalworking and machinery sectors is fueled by rising requirements in automotive, aerospace, and heavy machinery production, highlighting the need for top-notch bench vices in precise machining tasks.

Increased demand in the automotive, aerospace, and heavy machinery manufacturing sectors is a major factor contributing to the growth of the metalworking and machinery industries. Precision machining operations necessitate high-quality bench vices due to the need for accurate and long-lasting components in these industries. Bench vices play a vital role in automotive manufacturing processes like engine part assembly and bodywork, guaranteeing precision and steadiness. The aerospace sector requires precise bench vices to uphold strict tolerances for aircraft parts. Likewise, the heavy machinery industry depends on strong bench vices to manage big and intricate components while carrying out fabrication and upkeep tasks. As these sectors expand, the demand for sophisticated metalworking equipment like bench vices increases in order to meet production expectations and efficiency needs. Advancements in bench vice construction, like upgrades to clamping systems and superior materials, continue to meet the demand for improved performance and longevity. As a result, the metalworking and machinery industries are expanding due to the synergy between industrial growth and the need for precision tools, making high-quality bench vices essential in modern manufacturing processes.

KEY SEGMENTATION ANALYSIS

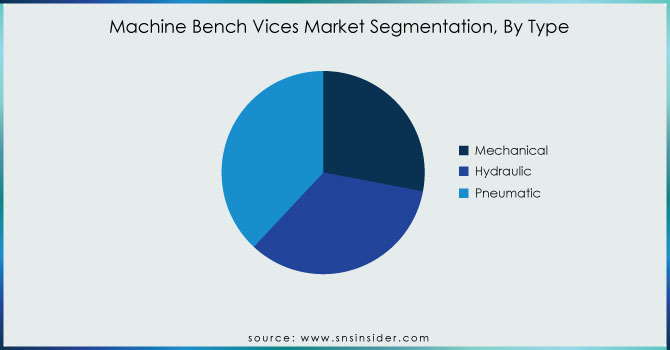

By Type

In 2023, the pneumatic sector held the largest market share at approximately 38.06%. The identical sector will also experience significant growth within the machine bench vices industry. The wide variety of products from many different manufacturers plays a key role in the excellent performance of the segment in the worldwide market. The high market share is also influenced by the reliability of operations and the precision and accuracy in handling workpieces. Pneumatic products have become more popular in the global market due to their significantly reduced maintenance expenses.

Get Customized Report as per your Business Requirement - Request For Customized Report

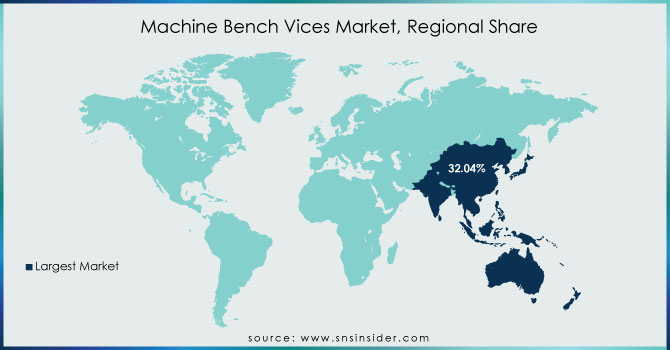

KEY REGIONAL ANALYSIS

Asia Pacific led the market in 2023 with the market share of 32.04%, owing to its manufacturing prowess. The region is identified as a manufacturing powerhouse, with a substantial export of machine bench vices across Europe and North America. Established manufacturing clusters in China and Japan, and constant efforts of India to position itself as a prominent manufacturer of industrial goods and attract global manufacturers, are crucial factors contributing to the consistent growth and rise in the machine bench vices market share.

North America is experiencing fastest growth during the forecasted period, as the food and beverage, chemicals, pharmaceuticals, and e-commerce sectors, among others, are actively turning to automation and technological advancements. The demand for effective packaging solutions has grown, as machinery became more advanced and met consumer expectations and compliance with stringent regulatory standards.

KEY PLAYERS

The major Key players are Gerardi SPA, Jergens, Inc., Kurt Workholding, Nabeya Co., Ltd., BISON USA Corp., International Machine Tools and Equipment Inc., Palmgren, STARK Spannsysteme GmbH, JPW Industries, Inc., TSUDAKOMA Corp., Rohm GmbH and others.

RECENT DEVELOPMENT

In August 2023: Kurt Workholding launched Kurt TriLock product link, featuring a 3-in-1 vice with integrated quickchange dovetail jaws from recently acquired CARVESMART. Six-inch Kurt triLock vices speedily convert between double-station or single-station configurations and three vice sizes.

In July 2023: Roemheld, a German work-holding equipment manufacturer, launched a centric machine vice that operates mechanically at its stand during the forthcoming EMO 2023 metalworking trade show in Hannover.

| Report Attributes | Details |

|---|---|

| Market Size in 2024 | US$ 476.30 Million |

| Market Size by 2032 | US$ 654.81 Million |

| CAGR | CAGR of 3.6% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Type (Mechanical, Hydraulic and Pneumatic) • By End-use Industry (Mining, Food & Beverage, Oil & Gas, Energy and Power, and Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Gerardi SPA, Jergens, Inc., Kurt Workholding, Nabeya Co., Ltd., BISON USA Corp., International Machine Tools and Equipment Inc., Palmgren, STARK Spannsysteme GmbH, JPW Industries, Inc., TSUDAKOMA Corp., Rohm GmbH |

| Key Drivers | • The growing use of automation in manufacturing is fueling the need for machine bench vices, crucial tools for precision engineering, CNC machining, and automated assembly lines, leading to an increase in market expansion.

• The growth of the metalworking and machinery sectors is fueled by rising requirements in automotive, aerospace, and heavy machinery production, highlighting the need for top-notch bench vices in precise machining tasks. |

| RESTRAINTS | • Although the price is justified by the advanced features and durable materials, the high initial cost of top-notch machine bench vices can pose a major hurdle for small and medium-sized enterprises (SMEs) and individual users. |