Powder Compacting Pressers Market Size & Overview:

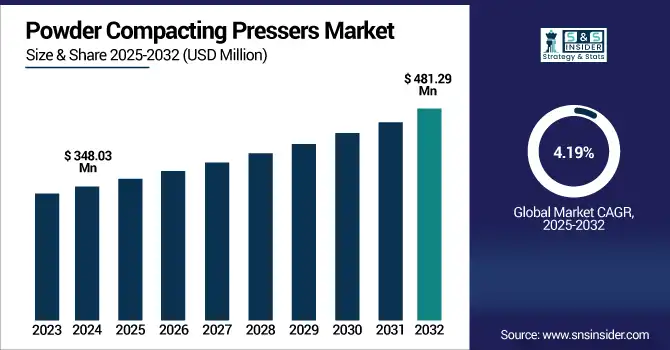

The Powder Compacting Pressers Market size was valued at USD 348.03 Million in 2024 and is expected to reach USD 481.29 Million by 2032, growing at a CAGR of 4.19% over the forecast period of 2025-2032.

To Get more information on Powder Compacting Pressers Market - Request Free Sample Report

The demand for powder compacting presses from manufacturing industries is mainly driven by the need for precision, automation, and energy-efficient systems. Automotive and aerospace sectors, where light and high-strength components are a must, are slowly adopting the market. New servo-hydraulic and electric presses are improving manufacturing speed and precision. Increasing investments in smart manufacturing and Industry 4.0 initiatives are accelerating the powder compacting pressers market share as well. As per the Analysis, manufacturers are adopting IoT and predictive maintenance capabilities for improved equipment uptime, whereas modular machine designs enable scalability and customizability across industries.

“For instance, in August 2024, Osterwalder released a game-changing powder compacting presser, having delivered its first 1000kN multi-plate servo-electric press, ushering in a new era of high-power precision, energy efficiency, and automation.”

The U.S. powder compacting pressers market size was valued at USD 84.84 Million in 2024 and is expected to reach USD 108.81 Million by 2032, growing at a CAGR of 3.21% over the forecast period of 2025-2032.

Powder compacting pressers market trends in US underscore the growing stimulation of adoption in automotive, defense, and medical component manufacturing for the precision required durable parts. Due to this, technology innovation and automation are increasing productivity. Focus on Customization, Energy Efficiency, Smart Factory System Integration to lead in the U.S. powder compacting pressers market.

Powder Compacting Pressers Market Dynamics:

Drivers:

-

Rising Demand for High-Precision Components in Automotive and Aerospace Accelerates the Powder Compacting Pressers Market Growth

Factors, such as rising demand for high-precision, lightweight, and durable components in the automotive and aerospace industries are driving the powder compacting pressers market. Powder compacting presses are being put to efficient work in industries that need precision in geometry and depend on the strength of the material. With the boom in electric vehicle sales and aerospace advancements, manufacturers are replacing their older presses with more modern technology, including servo-hydraulic and electric presses. Moreover, the further decrease in the use of materials and the improvement in the uniformity of components also encourage the use of powder compacting presses. Such demand is a direct indication that production needs are changing along with performance standards, forcing manufacturers to boost capacity and incorporate more complex systems globally.

In August 2023, SMS Group announced the delivery of a new press for compacting powder, aimed at improving efficiency and precision in the production of metal components. These heavy-duty operations and monthly verification build on the capabilities of existing machinery and will take global industry compacting processes to the next level, a boon for sustainable manufacturing.”

-

Growing Integration of Smart Manufacturing and IoT Drives the Expansion of Powder Compacting Pressers Market Share

Increase in smart manufacturing systems, IoT-enabled monitoring, and automation tools developed for different types of machinery has been a prominent catalyst in driving the growth of the market share. The adoption of these technologies by manufacturers is growing, as they need real-time performance tracking, predictive maintenance, and lower downtime. Adopting Industry 4.0 enables improved control and flexibility within full production lines, particularly in environments delivering high output. Such capabilities are becoming increasingly necessary to remain competitive, particularly in industries, such as medical, defense, and electronics, where precision and reliability are required. As digital transformation is driven higher, organizations investing in intelligent press systems are giving themselves a present-day strategic advantage, and this will lead to increased adoption throughout the manufacturing ecosystem.

Restraints:

-

Limited Skilled Workforce and Technical Know-How Restrict the Growth of Powder Compacting Pressers Market in Emerging Economies

Use of powder compacting presses would require specialist, technically educated personnel to operate and optimise the process, which is not always available in emerging economies. Insufficiently skilled operators reduce productivity and also increase the chances of machine misuse and downtimes. The truth is, new technologies including servo or hybrid presses are complex to maintain, and non-experts within a manufacturing organization generally shy away from them. This critical bottleneck, therefore, lies in training and knowledge diffusion. These limitations create significant development hindrances within the market in underprivileged regions and drastically cap the climax of overall powder compacting pressers market trends, realizing of enticing business across the global markets.

Powder Compacting Pressers Market Segmentation Analysis:

By Product Type

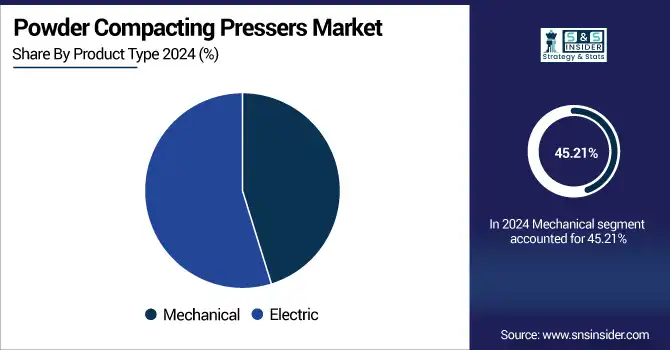

In 2024 Mechanical segment leading the powder compacting pressers market attained a revenue share of about 45.21% due to its proven track record of cost-effectiveness and reliable heavy-duty performance. Mechanical presses are generally faster and require less maintenance than other types, they are the favored choice for fast, long-lasting performance for manufacturers. The dominance is also supported by established companies in the Industry dealing with the mechanical solution segment, making this segment dominate in the Industry.

The electric segment is poised to grow at a substantial CAGR of approximately 5.24% over 2025–2032. Electric presses can provide better control over pressing parameters and lower operating costs due to their lower energy consumption. This is in sync with growth trends of the emerging powder compacting pressers market, which are more sustainable and automated at the same time, attracting investments in advanced electric technology and driving the segment, thus boosting market growth and continuing to proliferate in the powder compacting pressers market value.

By Application

The powder metallurgy segment was the biggest revenue shareholder of the powder compacting pressers market during 2024, as it serves manufacturers across different industries that need to produce metal parts with a considerable level of precision. Compact pressers for these applications are in large demand owing to the versatility and cost advantages of powder metallurgy processes. This segment is also set to lead due to the presence of strong powder compacting pressers companies that provide specialized solutions. This dominance overall portrays the importance of powder metallurgy in the powder compacting pressers market analysis.

The Ceramic & Cement segment is projected to witness the highest growth during2025-2032, owing to factors, such as increasing industrialization and infrastructure development worldwide. The growing demand for powder compacting solutions is due to the increased adoption of advanced ceramics and cement products in construction and electronics applications. Advancements in materials and compacting techniques, along with diverse focused emerging market growth, are positioning the ceramic & cement segment as the fastest growing in the powder compacting pressers industry.

By End Use

The automotive segment held the highest revenue share in 2024 due to an upsurge in the production of high-strength and precise automotive components. With these powder compacting pressers, manufacturers can comply with stringent quality norms without compromising on the manufacturing cycle. The growth of the segment can be attributed to high ongoing demand for light-weight and durable components, coupled with major companies focusing on automotive applications, which is also one of the prominent market trends.

The medical segment will reach a substantial CAGR over 2025-2032 with increasing need for rigorously fabricated implants as well as medical devices. The capability of powder metallurgy and compacting technology enables the production of pieces necessary for the health area, and that meet biocompatibility and high performance. Demand is further fueled by increasing healthcare infrastructure investment and the new trend of aging populations globally. Innovation and specialization are creating new opportunities in the powder exact pressers industry, and this rapid expansion of this segment is indicative of market growth in general.

Powder Compacting Pressers Market Regional Outlook:

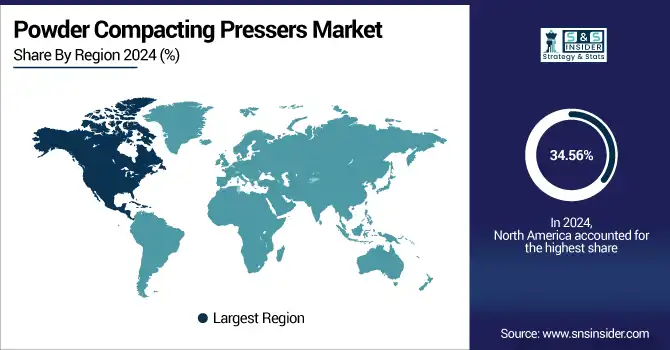

In 2024, North America held the largest revenue share in the global powder compacting pressers market at approximately 34.56%, owing to the presence of robust manufacturing infrastructure along with the high concentration of global powder compacting pressers companies. The region is characterized by early adoption of technologies, strong investment in R&D, and high-level quality standards that propel the demand for precision compacting solutions. Moreover, the developed automotive and aerospace industries also play a major role in market growth, which makes North America a dominant region in the powder compacting pressers market analysis across the globe.

Asia-Pacific currently has the fastest CAGR by value at 5.55% during 2025-2032, due to its rapid industrialization, increasing manufacturing base, and high demand from emerging markets, such as China and India. Growing investments in infrastructure, automotive, and electronics sectors drive the demand for efficient technologies for powder compacting. Government policies are also favorable, and the presence of micro compacting pressers companies in local markets is growing, which helps to grow the local market as well. The rapid expansion is a direct reflection of major powder compacting pressers market trends influencing the industry across the region.

Europe powder compacting pressers market is mainly propelled are progressive production technologies and innovation together with Germany dominating the country-wide market. The recent inventions have mainly stressed issues like automation and energy efficiency in presses, perfecting output while reducing the cost of operations. The positive development of the automotive and industrial sectors also underlines the stable growth of the market in the region.

Get Customized Report as per Your Business Requirement - Enquiry Now

Key Players in the Powder Compacting Pressers Market are:

The major players operating in the market are: Komage Gellner Maschinenfabrik KG, SMS group GmbH, Osterwalder AG, Maschinenfabrik Lauffer GmbH & Co. KG, Gasbarre Products, Inc., Ajax CECO Erie Press, Beckwood Press, Digital Press, DORST Technologies GmbH & Co. KG, and Cincinnati Incorporated.

Recent Developments:

-

November 2024 - Komage has started shipping its new HMI system for powder compacting presses, enhancing user interface and operational efficiency, marking a significant advancement in powder compacting technology and industry automation.

-

June 2022 - Gasbarre launched advanced CNC powder compaction presses in June 2022, offering enhanced precision, automation, and efficiency for high-volume metal powder manufacturing, boosting productivity in the Powder Compacting Pressers Market.

-

October 2023 - Ajax-CECO Erie Press introduces advanced powder compacting solutions, enhancing efficiency and precision in metal forming processes. Their innovative press technology supports diverse industrial applications, driving growth in the powder compacting market.

| Report Attributes | Details |

|---|---|

| Market Size in 2024 | USD 348.03 Million |

| Market Size by 2032 | USD 481.29 Million |

| CAGR | CAGR of 4.19% From 2025 to 2032 |

| Base Year | 2024 |

| Forecast Period | 2025-2032 |

| Historical Data | 2021-2023 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Product (Hydraulic, Electric, Hybrid, Mechanical, Servo-hydraulic) • By Application (Powder Metallurgy, Ceramic & Cement, Carbon & Carbide, Others) • By End Use (Automotive, Machining, Energy & Electricity, Equipment, Medical, Military, Construction, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Germany, France, UK, Italy, Spain, Poland, Turkey, Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (UAE, Saudi Arabia, Qatar, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Rest of Latin America) |

| Company Profiles | Komage Gellner Maschinenfabrik KG, SMS group GmbH, Osterwalder AG, Maschinenfabrik Lauffer GmbH & Co. KG, Gasbarre Products, Inc., Ajax CECO Erie Press, Beckwood Press, Digital Press, DORST Technologies GmbH & Co. KG, Cincinnati Incorporated |