Additive Manufacturing Market Report Scope and Overview:

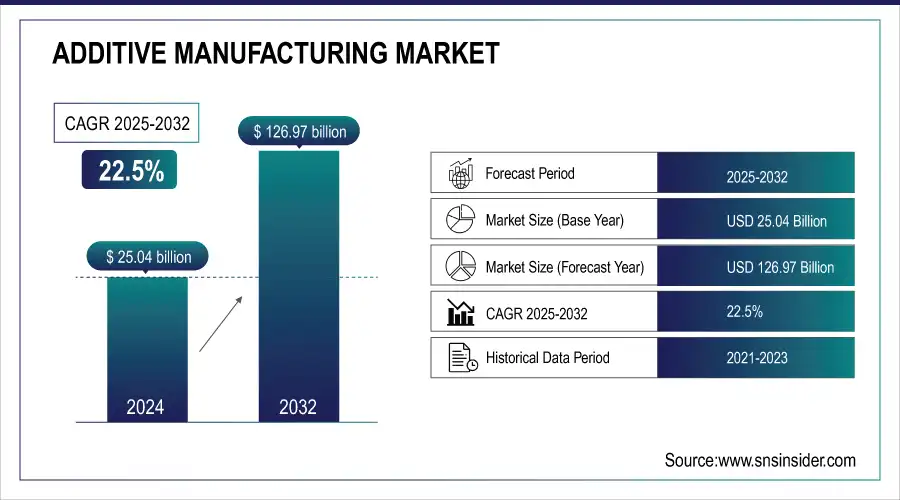

The Additive Manufacturing Market Size was valued at USD 25.04 billion in 2024 and is expected to reach USD 126.97 billion by 2032 and grow at a CAGR of 22.5% over the forecast period 2025-2032.

The additive manufacturing market growing due to several factors such as, the rise in demand of efficient prototyping, especially in healthcare, automotive, and aerospace & defense. These industries are highly depends on the rapid and cost-effective creation of prototypes for designs and conduct testing. Additive manufacturing fulfill this need by the creation of complex prototypes in a short time spam and the cost is low as compared to traditional methods. The example is the development of multi-material printing, which have the ability to create objects with a combination of functionalities in a single print. This innovative product design and lighter, stronger, and more efficient components in various sectors.

To get more information on Additive Manufacturing Market - Request Free Sample Report

For Instance, November 2023, Autodesk Inc. unveiled a new AI technology integrated in its products. This innovation, called Autodesk AI, is designed to provide users with intelligent assistance and the ability to generate creative solutions. By automating repetitive tasks and gives important suggestions, Autodesk aims to streamline workflows, reduces errors, and lead to evolve needs of its design and engineering customers.

Additive Manufacturing Market Highlights:

-

Additive manufacturing offers flexibility over traditional manufacturing, allowing design adjustments without expensive tool changes, enabling personalized products and on-demand production, which reduces stock issues and overproduction.

-

The growing demand for prototyping across industries such as healthcare, automotive, aerospace, and military, along with intensive R&D in 3D printing, is driving market expansion.

-

Advances in 3D metal printing technology and increased industrialization enable mass production with easy customization, producing high-performance components that are impossible with traditional methods.

-

Additive manufacturing increases design freedom, allows creation of lighter and stronger parts, and accelerates time-to-market, as seen in GE’s LEAP engine where 3D-printed fuel nozzles consolidated 20 parts into one, improving fuel efficiency by 15%.

-

High equipment and machinery costs, ranging from thousands to hundreds of thousands of dollars, along with expensive materials for certain applications, act as market restraints.

-

Shortage of skilled professionals with expertise in additive manufacturing design and operation limits the adoption and effective use of AM technologies.

Traditional manufacturing, additive manufacturing provides flexibility. No need of expensive tool changes for small adjustment. Additive manufacturing adjust designs and parameters on the specific customer needs. This give ability to businesses to create personalized products and adopt on-demand production, minimizing stock issues and overproduction.

The increased need for prototype applications from numerous industries and industrial verticals, including healthcare, automotive, aerospace, and military, as well as intensive research and development in 3D printing, are projected to fuel market expansion.

Additive Manufacturing Market Drivers:

-

Additive manufacturing allows for simple customization and mass production with advances in 3D metal printing technology and increased industrialization.

Development in 3D metal printing technology are rising the growth of the market. Imagine high-performance components produced for aerospace, automotive, and medical industries components which are impossible to create by using traditional methods. This with the increasing industrialization of Additive Manufacturing, increases the ability to achieve mass production and efficiency with providing easy customization for the produced parts. This rises the design freedom, of lighter and stronger parts, and also faster the time to market of new products. Additive Manufacturing is changing manufacturing practices by giving the power of scale with the benefits of creation. For Instance, the Additive Manufacturing have impact on General Electric's (GE) LEAP engine. These jet engines use 3D-printed fuel nozzles, a component is important for the fuel combustion. Also, these nozzles are assembled from approximately 20 separate pieces. Through AM, GE was able to consolidate the design into a single, lighter-weight nozzle. This innovation reduced part count and assembly time and improved fuel efficiency by 15% as compared to previous models.

Additive Manufacturing Market Restraints:

-

High equipment and machinery expenditures, as well as a scarcity of experienced professionals.

Additive Manufacturing machines are expensive, ranging from a few thousand dollars for basic models to hundreds of thousands for industrial grade systems. This cost can be lower for smaller companies or those just starting Additive Manufacturing. Also, the cost of materials used in Additive Manufacturing is higher as compared to traditional manufacturing methods for certain applications. Operating and maintaining Additive Manufacturing equipment requires specialized knowledge and skilled workers. There is a current shortage of professionals with the necessary skills to design for Additive Manufacturing.

Additive Manufacturing Market Segment Analysis:

By Printer Type

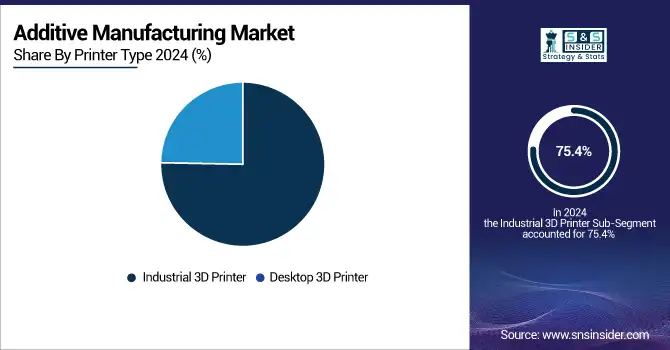

The Industrial 3D Printer dominated the segment of additive manufacturing market with more than 75.4% of market share in 2023. This dominance is due to rises the use of Industrial 3D Printer in various industries like automotive, electronics, and healthcare. From prototyping and design to creating tools, industrial 3D printers are helping in many industries, with the global adoption. These printers are user friendly and cost effective.

By Technology

The Stereolithography segment dominated the additive manufacturing market with more than 10% of market share in 2023. This segment is dominated due to, it has user-friendly nature and ability to produce high quantity of parts. High research and development activities from leading experts are constantly helps in the growth of the additive manufacturing market. These advancements are rising the new, efficient, and reliable printing technologies with unique advantages. This constant evolution definitely gives more advanced 3D printing options.

By Software

The Design Software segment dominated the additive manufacturing market with more than 35.4% of market share in 2023. Design Software segment dominated due to several factors such as, freedom in design complex geometries, incorporate internal lattices, and personalize designs. The integration with 3D printers allows direct file transfer and print, which is time saving and minimizing errors. Software can analyze design and provide suggestion about material usage and internal structures, which leads to cost savings. Teams can work on the same 3D model simultaneously, enhancing better communication and streamlining the design process.

The design software continues to evolve, it will remain a driving force of the additive manufacturing market

Additive Manufacturing Market Regional Analysis:

North America Additive Manufacturing Market Trends:

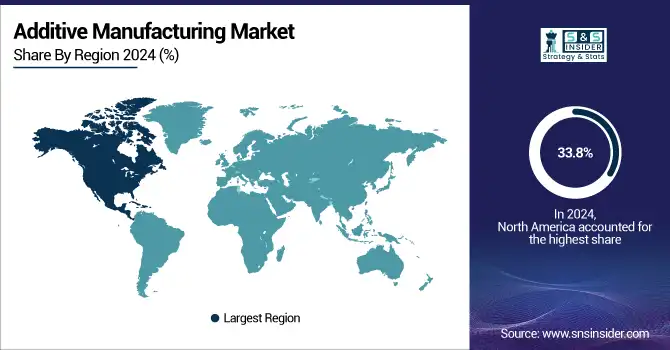

North America dominated the Additive Manufacturing Market with more than 33.8% of the market share in 2023. This dominance is due to the presence of developed countries like the US and Canada which are known for their early adoption in technologies. North America have developed healthcare infrastructure and they are very prone to adopt new technologies.

Asia-Pacific Additive Manufacturing Market Trends:

The Asia Pacific region is the fastest growing region for the additive manufacturing market. This growth is due to this region is rapidly becoming a manufacturing center for industries like automotive, healthcare, and consumer electronics. Additive Manufacturing give an opportunity to streamline and innovate production processes. Rapidly growing cities in the Asia Pacific region are rising the demand for customized and efficient solutions. 3D printing gives scope for construction and infrastructure development.

Need any customization research on Additive Manufacturing Market - Enquiry Now

Europe Additive Manufacturing Market Trends

Europe holds a significant share in the additive manufacturing market, driven by strong industrialization and technological innovation in countries like Germany, France, and the UK. The region emphasizes precision engineering, automotive, aerospace, and medical applications, encouraging the adoption of 3D printing for prototyping, production efficiency, and sustainability initiatives.

Latin America Additive Manufacturing Market Trends:

Latin America is witnessing gradual growth in additive manufacturing due to increasing investments in industrial automation and technological modernization. Countries like Brazil and Mexico are exploring 3D printing for automotive, healthcare, and education sectors, aiming to improve production flexibility and reduce manufacturing costs while catering to local market needs.

Middle East & Africa Additive Manufacturing Market Trends:

The Middle East and Africa region is emerging in additive manufacturing, with growth fueled by infrastructure development, aerospace, and healthcare projects. Nations like the UAE and South Africa are adopting 3D printing technologies to accelerate construction, medical device production, and industrial innovation, addressing regional demand for customized and efficient solutions.

Additive Manufacturing Market Key Players:

-

3D Systems, Inc.

-

3DCeram

-

Arcam AB

-

Autodesk, Inc.

-

Canon, Inc.

-

Dassault Systemes

-

EnvisionTec, Inc.

-

EOS (Electro Optical Systems) GmbH

-

ExOne

-

HP Inc.

-

madeinspace.us

-

Optomec, Inc.

-

Organovo Holdings Inc.

-

Proto Labs, Inc.

-

Shapeways, Inc.

-

Tiertime

Additive Manufacturing Market Competitive Landscape:

3D Systems Inc. is a U.S.-based leader in additive manufacturing, headquartered in Rock Hill, South Carolina. Founded in 1986 by Chuck Hull, the inventor of stereolithography, the company pioneered 3D printing technologies. It offers a comprehensive portfolio of 3D printers, materials, software, and on-demand services for industries including aerospace, healthcare, automotive, and dental

-

In March 2023, 3D Systems Inc, unveiled the NextDent LCD1, a user-friendly, small-sized 3D printing platform. With printer, they introduced two innovative materials: NextDent Cast and NextDent Base.

Autodesk Inc. is a global leader in 3D design, engineering, and entertainment software, headquartered in San Francisco, California. Founded in 1982, the company is renowned for its flagship products like AutoCAD, Fusion 360, and Revit. Autodesk has been instrumental in advancing additive manufacturing by integrating generative design, simulation, and cloud-based tools into its software suite. These innovations empower industries such as aerospace, automotive, healthcare, and construction to optimize designs, reduce material waste, and enhance production efficiency.

-

In November 2023, Autodesk Inc, unveiled its new AI technology. This innovative addition integrates with existing Autodesk products, offering a powerful boost to design and manufacturing workflows.

Dassault Systèmes is a French software company specializing in 3D design, simulation, and product lifecycle management (PLM). Through its 3DEXPERIENCE platform, it integrates design, manufacturing, and simulation, enabling industries like aerospace, automotive, and healthcare to leverage additive manufacturing for innovation and efficiency. Cadence Design Systems is an American company providing electronic design automation (EDA) software and engineering services. While primarily focused on semiconductor and electronic system design, its tools support the development of components for additive manufacturing in sectors such as automotive and aerospace.

-

In February 2022, Dassault Systèmes and Cadence Design Systems announced a strategic partnership. To provide cutting-edge solutions for building complex electronic systems. This collaboration targets a large range of industries, from high-tech and healthcare to transportation and aerospace.

| Report Attributes | Details |

| Market Size in 2024 | USD 25.04 Billion |

| Market Size by 2032 | USD 126.97 Billion |

| CAGR | CAGR of 22.5% From 2025 to 2032 |

| Base Year | 2024 |

| Forecast Period | 2025-2032 |

| Historical Data | 2021-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Component (Hardware, Software, Services) • By Printer Type (Desktop 3D Printer, Industrial 3D Printer) • By Technology (Stereolithography, Fuse Deposition Modeling, Selective Laser Sintering, Direct Metal Laser Sintering, Polyjet Printing, Inkjet Printing, Electron Beam Melting, Laser Metal Deposition, Digital Light Processing, Laminated Object Manufacturing, Others) • By Software (Design Software, Inspection Software, Printer Software, Scanning Software) • By Application (Prototyping, Tooling, Functional Parts) • By Vertical Outlook (Industrial Additive Manufacturing (Automotive, Aerospace & Defense, Healthcare, Consumer Electronics, Power & Energy, Others), Desktop Additive Manufacturing (Educational Purpose, Fashion & Jewelry, Objects, Dental, Food, Others)) • By Material (Polymer, Metal, Ceramic) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]). Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia Rest of Latin America) |

| Company Profiles | 3D Systems, Inc., 3DCeram, Arcam AB, Autodesk, Inc., Canon, Inc., Dassault Systèmes, EnvisionTec, Inc., EOS (Electro Optical Systems) GmbH, ExOne, GE Additive, HP Inc., madeinspace.us, Materialise NV, Optomec, Inc., Organovo Holdings Inc., Proto Labs, Inc., Shapeways, Inc., Stratasys, Ltd, Tiertime, Voxeljet AG |