Automotive Leaf Spring Market Report Scope & Overview:

Get More Information on Automotive Leaf Spring Market - Request Free Sample Report

The Automotive Leaf Spring Market Size was valued at USD 5.5 billion in 2023 and is expected to reach USD 7.50 billion by 2032 and grow at a CAGR of 3.5% over the forecast period 2024-2032.

The automotive leaf spring market is growing due to the growing demand for commercial vehicles and the rising popularity of SUVs. Although traditional steel leaf springs are prevalent, there is a growing trend towards using composite and hybrid materials, which currently make up around 15% of the market. This shift is driven by the continuous effort to decrease weight, improving fuel efficiency by an average of 3-5%. Additionally, incorporating cutting-edge manufacturing methods like laser cutting and robotic welding has increased production efficiency by 20%, ultimately reducing costs. The Asia Pacific area, specifically China and India, is becoming a central location for manufacturing, accounting for more than 60% of worldwide leaf spring production. Nevertheless, strict emission standards and safety regulations present challenges that demand technological advancements to adhere to changing industry requirements.

Furthermore, governmental encouragement of using lightweight vehicle parts has sped up the advancement of materials such as aluminum and titanium alloys, resulting in a 10% reduction in vehicle weight on average. An increased focus on eco-friendly manufacturing methods has caused a 30% increase in the utilization of recycled materials in the making of leaf springs. In addition, governments across the globe are making significant investments in infrastructure development, especially in developing economies, driving the need for durable leaf spring-equipped commercial vehicles.

MARKET DYNAMICS:

Drivers:

-

The global demand for car leaf springs will increase due to the lasting requirement for vehicle comfort.

The main driving force behind the automotive leaf spring market is a combination of factors that highlight its essential importance in vehicle suspension systems. The increasing need for commercial vehicles worldwide is a key factor driving the market. As economies expand and infrastructural development increases, there is a corresponding increase in the need for strong transportation systems, leading to a higher demand for heavy-duty trucks and trailers with leaf spring suspensions.

Opportunities:

-

The global automotive leaf spring market is expected to see a rise in adoption of lightweight components.

-

The leaf spring can be classified as a contemporary innovation in technology.

The market's growth is greatly influenced by technological advances like the incorporation of smart materials and computer-assisted design methods, providing new solutions that align with changing consumer tastes and regulations. Furthermore, the growing popularity of electric and hybrid vehicles offers a new opportunity for expansion in the automotive leaf spring market. Lightweight leaf springs made from sustainable materials are expected to be in high demand in the electric vehicle market due to the growing emphasis on sustainability and carbon emission reduction by automakers.

Challenges:

-

Fluctuations in trade policies and modifications can impede the leaf spring market for automobiles.

-

Global leaf spring market will be hindered by fluctuating raw material prices and trade policies

MARKET SEGMENTATION:

By Type:

Based on the type segment, the global market has been divided into Parabolic, Elliptic, Semi-Elliptic, and Others. During the forecast period, the parabolic-type section is expected to be dominant. It is anticipated that the semi-elliptic type segment would develop at the fastest rate in the global market for vehicle leaf springs throughout the forecast timeframe.

By Material:

The global market has been divided into metal, and composite based on the material segment. During the forecast period, metals are expected to dominate the global market in terms of value and volume. Due to their superior strength-to-weight ratio, fatigue resistance, and natural frequency, Composite Leaf Springs have grown in popularity over time.

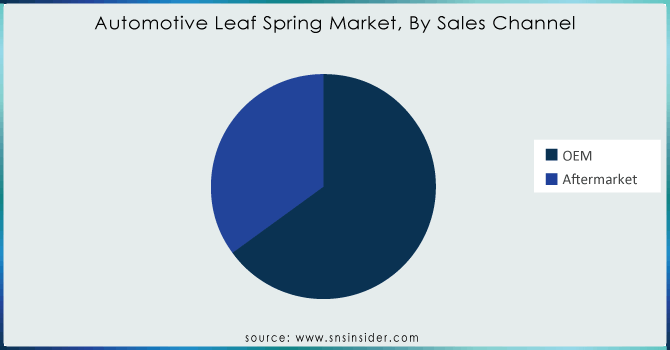

By Sales Channel:

The global market has been divided into OEM, and aftermarket based on the sales channel segment. During the time period covered by this estimate, the OEM segment is anticipated to have the majority share of the global market in terms of both value and volume. The manufacturing of light, medium, and heavy commercial vehicles has a direct correlation to the need for leaf springs from OEM.

Get Customized Report as per Your Business Requirement - Request For Customized Report

REGIONAL ANALYSIS:

Europe's leaf spring market for automobiles is mature, with a preference for high-performance and luxury vehicles. About 60% of the market is made up of commercial vehicles, especially large trucks and buses, due to strict regulations on carrying loads. On the other hand, the passenger car category is experiencing a revival because of the increased interest in restoring classic cars and enhancing their performance. The majority of material choices are in favor of steel, making up more than 85% of the market, with composite and advanced alloys becoming more popular in specific areas aiming for lighter weight and improved longevity.

The automotive leaf spring market in the APAC region is primarily led by the growing automotive production, especially in China and India. These countries represent more than 60% of worldwide vehicle manufacturing. Although the area excels in manufacturing, there is an increasing focus on technological progress. The use of composite leaf springs, which provide weight reduction and improved performance, is slowly growing, especially in luxury vehicles. Furthermore, a considerable part of the market is made up by the commercial vehicle sector, which is supported by strong logistics and infrastructure growth. Tier-1 suppliers play a significant role, accounting for more than 75% of the area's leaf spring production.

KEY PLAYERS:

Rassini (Mexico), Hendrickson USA, L.L.C. (US), Sogefi SpA (Italy), Emco Industries (India), Jamna Auto Industries (India), LITE FLEX (US), IFC Composite GmbH (Germany), NHK Springs Co. Ltd (Japan), Benteler-SGL (Austria), and OlgunCelik San. Tic. A.S (Turkey) are some of the affluent competitors with significant market share in the Automotive Leaf Spring Market.

Overview of Recent Developments:

The notable trend is the integration of lightweight materials, such as composite fibers and high-strength alloys, into leaf spring designs. Digitalization and automation are also revolutionizing the manufacturing process, streamlining production and ensuring precision engineering. The adoption of advanced simulation techniques allows for rigorous testing and validation of leaf spring designs, ensuring optimal performance and durability under varying conditions

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | US$ 5.5 Billion |

| Market Size by 2032 | US$ 7.50 Billion |

| CAGR | CAGR of 3.5% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • by Type (Parabolic, Elliptic, Semi-Elliptic, Others) • by Material (Metal, Composite) • by Sales Channel (OEM, Aftermarket) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Rassini (Mexico), Hendrickson USA, L.L.C. (US), Sogefi SpA (Italy), Emco Industries (India), Jamna Auto Industries (India), LITE FLEX (US), IFC Composite GmbH (Germany), NHK Springs Co. Ltd (Japan), Benteler-SGL (Austria), and OlgunCelik San. Tic. A.S (Turkey). |

| Key Drivers | •Increased demand for LCVs. •The long-term need for vehicle comfort will boost global demand for automobile leaf springs. |

| RESTRAINTS | •Increased demand for LCVs. •The long-term need for vehicle comfort will boost global demand for automobile leaf springs. |