Blow Molding Machine Market Report Scope And Overview:

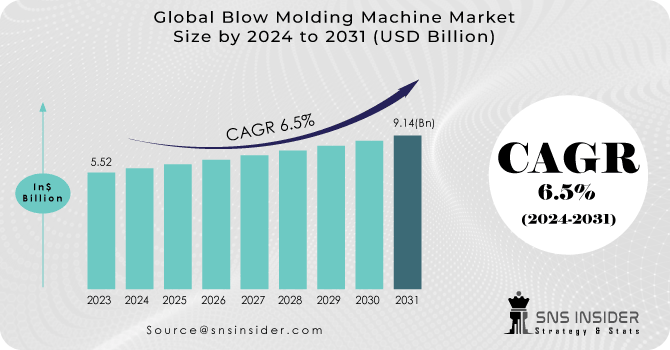

The Blow Molding Machine market size was USD 5.52 billion in 2023 and is expected to Reach USD 9.14 billion by 2031 and grow at a CAGR of 6.5% over the forecast period of 2024-2031.

Driven by continuous advancements in blow molding technology, the market is witnessing expansion, notably through the development of high-speed and energy-efficient machinery. Manufacturers are strategically investing in research and development to enhance the productivity, efficiency, and adaptability of blow molding machines, aligning with evolving customer and industry demands. Fully electric blow molding machines are opening up new business opportunities for companies. The surge in the automotive sector, particularly in affluent nations such as the U.S., Canada, UK, and Germany, is driving the demand for blow molding machines. Additionally, heightened investments in the pharmaceutical industry in countries like China and India are boosting the need for packaging products such as bottles, consequently fueling the demand for blow molding machines. The integration of computer-based technologies is playing a pivotal role in the development of efficient and automated blow molding machines, requiring minimal operator input. This offers promising prospects for market expansion.

Get More Information on Blow Molding Machine Market - Request Sample Report

MARKET DYNAMICS

KEY DRIVERS:

-

In efforts to reduce material usage and transportation costs without compromising product quality, there is a growing trend towards lightweight packaging solutions.

-

Increasing disposable incomes, urbanization rates, and economic expansion in developing countries are increasing the demand for packaged goods.

The rapid growth of urban populations is significantly influencing consumer preferences in the packaging industry. Blow molding machines play a critical role in meeting this urban need. They excel at producing a diverse range of lightweight and portable plastic containers. These containers are ideal for single-use applications and require minimal storage space, making them well-suited for urban environments.

RESTRAIN:

-

The plastics industry, encompassing blow molding, is facing increasing evaluation for its environmental impacts, particularly concerning recycling efforts and management of plastic waste.

-

Due to their prolonged operational lifespans, blow molding machines may not require frequent replacement.

OPPORTUNITY:

-

Increasing demand for lightweight containers is creating lucrative opportunities.

The blow molding machine market is experiencing significant growth, fueled in part by the continuous advancement of design and testing techniques. This trend empowers manufacturers to make crucial adjustments to equipment design, allowing them to better accommodate the specific needs of end-user industries. A recent development that aligns with the growing demand for lightweight plastic containers is Amazon's announcement of substituting traditional cardboard boxes in packaging with lightweight flexible plastic mailers.

-

Advancements in stretch blow molding technology are leading to a rise in the popularity of high-performance stretch blow machines.

CHALLENGES:

-

The anticipated hindrance to market growth stems from the processing constraints of blow molding machines and potential alternatives.

-

The blow molding machines are confined to producing hollow parts exclusively, rendering them unsuitable for solid parts manufacturing. This limitation poses a significant disadvantage for the blow molding machine market.

IMPACT OF RUSSIAN UKRAINE WAR

The Global Blow Molding Market is expected to be significantly impacted by the Russia-Ukraine Conflict and High Inflation over the long term. Ongoing research takes into account shifts in consumer behavior, disruptions in the supply chain. Similarly, the report examines the enduring political and economic uncertainties in Eastern Europe stemming from the Russia-Ukraine Conflict, and its potential repercussions on demand-supply dynamics, pricing pressures, and import/export activities. Additionally, the report delves into the effects of High Inflation on the global economy, outlining fiscal policies aimed at mitigating its impact on demand, supply, cash flow, and currency exchange rates. The geopolitical tensions may lead to shifts in demand for blow molding machines, as businesses in affected regions may prioritize other investments or adopt a more cautious approach to capital expenditures.

IMPACT OF ECONOMIC SLOWDOWN

Initially, the economic slowdown led to decreased expenditure on new molding machinery by different players in the end-user industry. Shipments of injection molding and extrusion machinery in North America decelerated during the third quarter, as indicated by data collected by the Plastics Industry Association's Committee on Equipment Statistics (CES). In the third quarter, the value of shipments for injection molding machines declined by 17.1%, while shipments for single-screw extruders increased by 4.9% and twin-screw extruders surged by 12.4%. Compared to the same quarter last year, shipments for single-screw extruders decreased by 13.1%, whereas twin-screw extruders witnessed a notable increase of 19.3%. The deceleration in plastics machinery shipments during the third quarter appears to align with the moderation observed in the U.S. economy. Nevertheless, when compared to quarterly shipments in 2021 a standout year for the plastics industry, especially for plastics equipment suppliers, shipments in the third quarter of this year surpass those of the first three quarters of the previous year.

KEY MARKET SEGMENTS

By Technology Type

-

Single-step Based

-

Two-step Based

By Orientation Type

-

Rotary Type Machine

-

Linear Type Machine

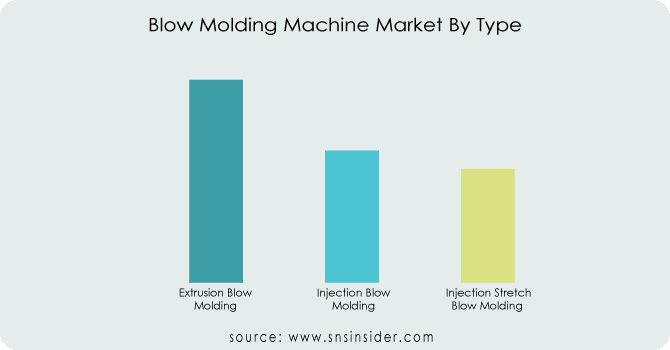

By Type

-

Extrusion Blow Molding

-

Injection Blow Molding

-

Injection Stretch Blow Molding

Get Customized Report as per Your Business Requirement - Request For Customized Report

By Raw material

-

Polyethylene (PE)

-

Polypropylene (PP)

-

Polyvinyl Chloride (PVC)

-

Polyethylene Terephthalate (PET)

-

Others

Polyethylene (PE) holds the dominant position in the raw material segment. Polyethylene (PE) is categorized as a thermoplastic material, recognized for its versatility. It is extensively utilized in various applications, including the production of containers, plastic films, geomembranes, plastic bags, and bottles. Derived from the monomer ethylene, polyethylene (PE) finds widespread use in manufacturing plastic bags, tubing, and components for computer parts, wash bottles, dispensing bottles, and molded laboratory equipment. Additionally, the expanding utilization of molded laboratory equipment by pharmaceutical companies contributes to the market's growth trajectory.

By Application

-

Packaging

-

Automotive

-

Construction

-

Others

Packaging represents the predominant segment in terms of applications. Packaging constitutes a significant portion of the continuously expanding plastic industry. Polymers and their combinations are the primary materials used in packaging. The selection of various plastic materials depends on the desired shelf life of the packaged product. The adoption of blow molding machines across numerous applications within the packaging industry is on the rise.

By End Use

-

Food & Beverage Industry

-

Personal Care & Cosmetic Industry

-

Consumer Goods Industry

-

Pharmaceuticals Industry

-

Others

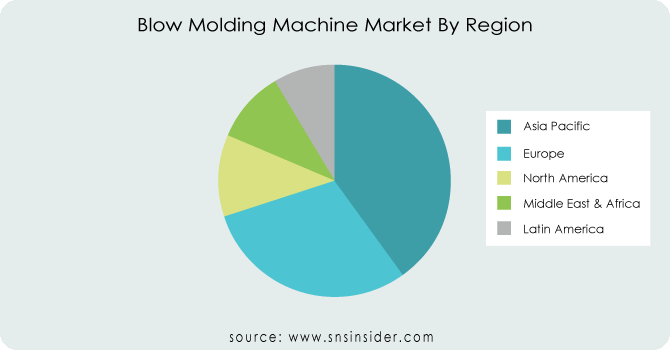

REGIONAL ANALYSIS

Asia-Pacific holds the predominant position in the global molding machine market by 40.8%. With densely populated countries such as India and China, Asia-Pacific emerges as a key market due to heightened demand for blow-molded plastic products. The region's market expansion is fueled by robust growth in economies like China, India, and Indonesia, driven by the burgeoning packaging industry and the growing preference for flexible packaging. Flexible packaging's cost-effectiveness and lightweight nature have made it popular among consumers due to its portability and easy disposal.

The European region has experienced a notable surge in the adoption of blow molding machines, primarily due to their superior quality and energy-efficient characteristics. For instance, ARBURG specializes in a variety of blow molding machines, including hydraulic, hybrid, electric, cube-mold, and vertical-type machines. The economic progress observed in Europe has resulted in a larger consumer base, consequently benefiting the overall molded plastics market and driving the blow molding machines market forward. A significant trend in the North American blow molding machine industry is the development of new product lines specifically designed to address the demands of the global plastic market.

The emerging regions encompassing Latin America, the Middle East, and Africa, is experiencing increased demand for blow molding machinery due to heightened needs for molded plastic products in the area.

REGIONAL COVERAGE:

North America

-

US

-

Canada

-

Mexico

Europe

-

Eastern Europe

-

Poland

-

Romania

-

Hungary

-

Turkey

-

Rest of Eastern Europe

-

-

Western Europe

-

Germany

-

France

-

UK

-

Italy

-

Spain

-

Netherlands

-

Switzerland

-

Austria

-

Rest of Western Europe

-

Asia Pacific

-

China

-

India

-

Japan

-

South Korea

-

Vietnam

-

Singapore

-

Australia

-

Rest of Asia Pacific

Middle East & Africa

-

Middle East

-

UAE

-

Egypt

-

Saudi Arabia

-

Qatar

-

Rest of Middle East

-

-

Africa

-

Nigeria

-

South Africa

-

Rest of Africa

-

Latin America

-

Brazil

-

Argentina

-

Colombia

-

Rest of Latin America

Key players

Major players in Blow Molding Machine market are R&B Plastics Machinery, LLC, Zhejiang Huangyan Lingma Plastic Machinery, Pet All Manufacturing Inc., Nissei asb company, SIPA North America, Inc., Jomar Corporation, Tech-Long Inc., KHS GmbH, Sacmi Imola, KENPLAS Industry Ltd. and others.

Zhejiang Huangyan Lingma Plastic Machinery-Company Financial Analysis

RECENT DEVELOPMENT

-

In October 2022, Huntsman's experts in elastomers provided support to blow molding equipment manufacturer Ossberger during the debut of its latest Pressblower machine at K2022. During the trade exhibition, Ossberger will showcase the Pressblower SB2-260, an advanced injection blast molder designed specifically for producing gaiters utilized in automotive air springs.

-

During the K2019 event held on July 22, 2019, Bekum Maschinenfabrik GmbH launched Concept 808, a cutting-edge blow molding machine. This innovative equipment is equipped with Bekum Control 8.0, an intuitive touchscreen interface, and is capable of handling multi-cavity three-layer applications.

| Report Attributes | Details |

| Market Size in 2023 | US$ 5.52 Billion |

| Market Size by 2031 | US$ 9.14 Billion |

| CAGR | CAGR of 6.5 % From 2024 to 2031 |

| Base Year | 2023 |

| Forecast Period | 2024-2031 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Technology Type (Single-Step Based, Two-Step Based) • By Orientation Type (Rotary Type Machine, Linear Type Machine) • By Type(Extrusion Blow Molding, Injection Blow Molding, Injection Stretch Blow Molding) • By Raw Material (Polyethylene (PE),Polypropylene (PP), Polyvinyl Chloride (PVC), Polyethylene Terephthalate (PET), Others) • By Application (Packaging, Automotive, Construction, Others) • By End Use (Food & Beverage Industry, Personal Care & Cosmetic Industry, Consumer Goods Industry, Pharmaceuticals Industry, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | R&B Plastics Machinery, LLC, Zhejiang Huangyan Lingma Plastic Machinery, Pet All Manufacturing Inc., Nissei asb company, SIPA North America, Inc., Jomar Corporation, Tech-Long Inc., KHS GmbH, Sacmi Imola, KENPLAS Industry Ltd. |

| Key Drivers | • In efforts to reduce material usage and transportation costs without compromising product quality, there is a growing trend towards lightweight packaging solutions. • Increasing disposable incomes, urbanization rates, and economic expansion in developing countries are increasing the demand for packaged goods. |

| Restraints | • The plastics industry, encompassing blow molding, is facing increasing evaluation for its environmental impacts, particularly concerning recycling efforts and management of plastic waste. • Due to their prolonged operational lifespans, blow molding machines may not require frequent replacement. |