Butyl Rubber Market Report Insights:

Get More Information on Butyl Rubber Market - Request Sample Report

The Butyl Rubber Market Size was valued at USD 3.9 Billion in 2023. It is expected to grow to USD 6.9 Billion by 2032 and grow at a CAGR of 6.3% over the forecast period of 2024-2032.

The rising demand for butyl rubber is attributed to the increasing demand for high-performance materials in the automotive industry. Butyl rubber is most highly regarded for certain characteristics, such as low gas permeability, outstanding heat resistance, and strong durability; tires are also a perfect application for butyl rubber. With consumers and manufacturers focusing on sustainability and cost savings, Kalrez is widely used in tire inner linings to seal air, decrease rolling resistance, and lower fuel consumption

According to the International Organization of Motor Vehicle Manufacturers (OICA), global vehicle production reached approximately 87 million vehicles in 2022, marking a significant increase after pandemic-related disruptions. This uptick in production highlights the growing demand for automotive components, including tires made with butyl rubber.

Butyl rubber demand in the medical sector has witnessed a considerable surge owing to its ability to resist chemical action, do not react, and superb sealing characteristics, making it suitable for manufacturing medical-grade products including gloves, seals and gaskets. As the pandemic led to a massive uptick in the demand for medical gloves, butyl rubber emerged as a highly desired glove material, providing an exceptional barrier and protection from contaminants. The continuous emphasis on creating sterilized spaces in hospitals and clinics also enabled the healthcare domain to demand more butyl rubber to manufacture gaskets and seals for medical devices. The global trend towards cleanliness and safety in healthcare systems will drive the demand for butyl across the medical sector, although fewer centers are likely to create a vacuum in terms of innovation in medicals among the other sectors of the utilization of butyl rubber, where the inertness of a material becomes a non-issue in health applications for butyl rubber with increasing attention.

The World Health Organization (WHO) reported the rise in demand continued post-pandemic, with healthcare spending in the U.S. reaching an all-time high of USD 4.3 trillion in 2022, according to the Centers for Medicare & Medicaid Services (CMS). This growth has continued to bolster the medical-grade products market, including those made with butyl rubber.

Butyl Rubber Market Dynamics

Drivers

-

Increasing the use of industrial and consumer goods drives the market growth.

The high-usage butyl rubber in various industrial and consumer markets is doing good business to grow the market. Butyl rubber offers flexibility, durability, and good sealing properties and therefore has been used in a variety of products since its discovery and has found a range of applications beyond automotive and medical. It has great environmental resistance against moisture, heat, and chemicals making it an obvious choice in adhesives, sealants, and gaskets for long-lasting durable function in industrial applications. Rising consumption of quality adhesives and sealants in the construction, packaging, and electronics industries has also been driving the butyl rubber marketplace. Further, butyl rubber is also utilized in the production of consumer goods such as footwear, toys, and sporting equipment, due to its durability and comfort. Moreover, butyl rubber is expected to witness steady demand from these application segments owing to rising industrialization in developing businesses and rising consumer preference for long-lasting high-quality performing products.

The U.S. Census Bureau reports that the construction industry in the U.S. alone reached a value of USD 1800 Billion in 2022, continuing to grow due to infrastructure investments and demand for residential and commercial buildings.

Restraint

-

Fluctuating raw material prices hampers the market growth.

The primary raw material for butyl rubber production, isobutene, is obtained from petroleum and natural gas, and therefore, fluctuations in raw material prices are a major restraint for the global butyl rubber market. Petroleum prices are extremely sensitive and fluctuate depending on the geopolitical situation in different parts of the world, imbalances between global supply and demand, and supply chain disruptions. Such fluctuations may increase the production cost uncertainty experienced by rubber manufacturers which makes maintaining price stability, a challenge. Higher raw material costs typically translate into pressure to increase end-product prices, such as tires and medical goods, reducing demand in price-sensitive markets. At the same time, worsening this uncertainty prevents manufacturers from predicting prices to estimate costs and makes long-term production planning more complicated, impeding investments and innovation.

Butyl Rubber Market Segmentation Analysis

By Product

In 2023, chloro butyl rubber held a dominant revenue share of 46% in the market. Chloro butyl rubber market demand is driven by the steadily growing automotive sector Owing to the high-performance vehicle production proliferation. The heat, chemical, and aging resistance of this material makes it well suited for use in float or tire inner liners and the like, and in other automotive components. Furthermore, the growing focus on fuel economy and lower emissions further fuels demand for quality tire materials such as chloro butyl rubber, as it helps maintain tire pressure and increases its lifetime. Moreover, the material demonstrates substantially improved adhesion characteristics over typical butyl rubber which ensures better bonding to a variety of substrates and materials.

By Application

The tires & lubes segment held the largest market share around 48% in 2023. The material is ideal for tire making due to its excellent air retention, durability, and aging characteristics. It helps provide long-term tire pressure maintenance, fuel economy, and longevity, making it useful particularly in traditional as well as EVs (Electric vehicles). The global automotive industry has witnessed exponential growth along with all time high vehicle production, which in turn increases the demand for high-quality tires, thereby bolstering the demand for butyl rubber. At the same time, the increased attention being paid to fuel and environmental sustainability created by the rising popularity of EVs has made for tires with low rolling resistance, another point where butyl rubber shines. Butyl rubber is primarily used in tires; however, the product is also used in lubricants, which bolster the butyl rubber market share in the segment. However, the continuous growth of the automotive industry coupled with technological innovations in tire performance, will continue to hold it as the most dominant application for the butyl rubber market, Tires & Lubes during the forecast years.

Need Any Customization Research On Butyl Rubber Market - Inquiry Now

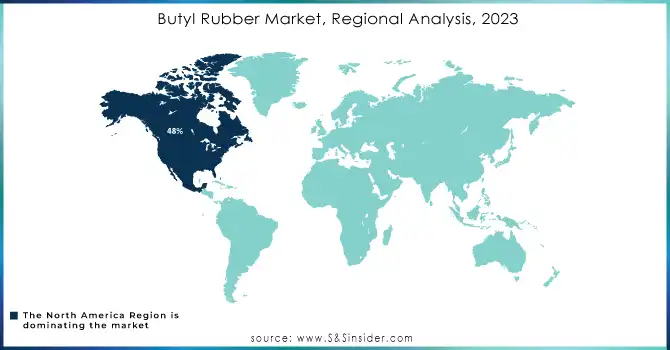

Butyl Rubber Market Regional Overview

North America held the largest market share around 48% in 2023. The USA is one of the largest producers and consumers of tires in the world and plays a major role in this dominance contributing to the production of butyl rubber as an important input in tire production. A big part of that growth in the U.S. automobile market is complemented by an ever-growing need for tires that are durable and fuel-efficient, both of which depend on butyl rubber for its unique attributes of excellent air retention and durability. Furthermore, Demand for butyl rubber in North America is mainly driven by the use of butyl rubber in medical applications especially in the manufacture of medical gloves, seals, and gaskets which became one of the prime contribution areas of the use industry and will maintain their moderately growing trend in coming years as well. In addition, the presence of a developed infrastructure in North America and the increasing use of butyl rubber in industrial applications including adhesives & sealants, supports the market in North America. Moreover, the North America market is driven by the continuous innovations in manufacturing along with the presence of the key players in the region which further aids in the growth of the North America market. North America is expected to continue to drive the butyl rubber market, as strict government regulations are focusing on the use of high standard materials in automobiles and other sectors, and the industrial activities continue to grow.

Key Players in Butyl Rubber Market

-

ExxonMobil Chemical (Butyl Rubber, Bromobutyl Rubber)

-

Lanxess AG (Butyl Rubber, Halobutyl Rubber)

-

Reliance Industries (Butyl Rubber, Chlorinated Butyl Rubber)

-

Goodyear Tire & Rubber (Butyl Rubber, High Performance Butyl Rubber)

-

Sibur Holding (Butyl Rubber, Isobutylene-Isoprene Rubber)

-

Chinese National Petroleum Corporation (CNPC) (Butyl Rubber, Chlorinated Butyl Rubber)

-

JSR Corporation (Butyl Rubber, Halobutyl Rubber)

-

Kraton Polymers (Hydrogenated Butyl Rubber, Synthetic Rubber)

-

Kumho Petrochemical (Butyl Rubber, Butyl Rubber for Tires)

-

LG Chem (Butyl Rubber, Halobutyl Rubber)

-

Marubeni Corporation (Butyl Rubber, Brominated Butyl Rubber)

-

TSRC Corporation (Butyl Rubber, Halogenated Butyl Rubber)

-

Mitsui Chemicals (Butyl Rubber, Synthetic Rubber)

-

Bridgestone Corporation (Butyl Rubber, Ultra-High Performance Butyl Rubber)

-

Tire and Rubber Products, Inc. (TRP) (Butyl Rubber, Chlorobutyl Rubber)

-

Sasol Limited (Butyl Rubber, Isobutene-Butylene Rubber)

-

Royal Dutch Shell (Butyl Rubber, Chlorinated Butyl Rubber)

-

BASF (Butyl Rubber, Synthetic Rubber)

-

Arlanxeo (Butyl Rubber, Hydrogenated Butyl Rubber)

-

Mitsubishi Chemical Corporation (Butyl Rubber, High Performance Butyl Rubber)

Recent Developments:

-

In 2023, Goodyear introduced a new line of fuel-efficient tires incorporating advanced butyl rubber compounds that improve air retention, durability, and overall performance. This initiative aligns with their strategy to meet growing demand for sustainable and energy-efficient solutions in the automotive sector, particularly with the rise of electric vehicles (EVs).

-

In 2022, ExxonMobil, a significant player in the butyl rubber market, launched an improved high-performance butyl rubber product line in 2022. This development focuses on providing better weathering resistance, enhanced durability, and low rolling resistance for tires, addressing the automotive industry’s evolving needs for eco-friendly and long-lasting products.

-

In 2023, Reliance Industries, through its subsidiary Reliance Sibur Elastomers, ramped up its production of butyl rubber at its joint venture plant in India. The company aims to cater to the growing automotive market in India and Southeast Asia, driven by increasing vehicle production and a surge in demand for tires with better durability and fuel efficiency.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | US$ 3.9 Billion |

| Market Size by 2032 | US$ 6.9 Billion |

| CAGR | CAGR of 6.3% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | •By Product (Regular Butyl, Bromo Butyl, Chloro Butyl) • By Application (Tires & Lubes, Adhesives, Sealants, Stoppers, Industrial & Medical Gloves, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe [Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | ExxonMobil Chemical, Lanxess AG, Reliance Industries, Goodyear Tire & Rubber, Sibur Holding, Chinese National Petroleum Corporation (CNPC), JSR Corporation, Kraton Polymers, Kumho Petrochemical, LG Chem, Marubeni Corporation, TSRC Corporation, Mitsui Chemicals, Bridgestone Corporation, Tire and Rubber Products, Inc. (TRP), Sasol Limited, Royal Dutch Shell, BASF, Arlanxeo, Mitsubishi Chemical Corporation. and Others |

| Key Drivers | • Increasing the use of industrial and consumer goods drives the market growth. |

| Restraints | • Fluctuating raw material prices hampers the market growth. |