Cryogenic Tanks Market Report Scope & Overview:

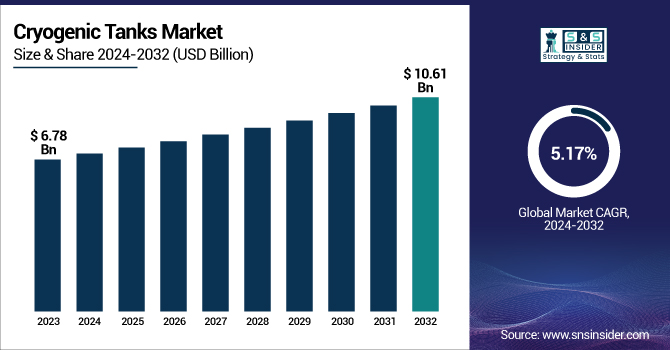

The Cryogenic Tanks Market Size was valued at USD 6.78 Billion in 2023 and is expected to reach USD 10.61 Billion by 2032 and grow at a CAGR of 5.17% over the forecast period 2024-2032.

To Get more information on Cryogenic Tanks Market - Request Free Sample Report

The Cryogenic Tanks Market is witnessing strong growth as demand for liquefied gases is increasing in industries like healthcare, energy, and manufacturing. The tanks are necessary for the storage and transportation of gases such as LNG, liquid nitrogen, oxygen, and hydrogen at extremely low temperatures. Advances in insulation and material strength are improving efficiency and safety. The demand is fueled by higher LNG consumption, growing industrial uses, and increasing medical oxygen demand.

The Cryogenic Tanks Market was valued at USD 1.08 Billion in 2023 and is expected to reach USD 1.87 Billion by 2032, growing at a CAGR of 6.36% from 2024 to 2032. The U.S. Cryogenic Tanks Market is growing on account of growing demand for liquefied gases in industries including healthcare, energy, and manufacturing. The increased use of LNG as a less polluting fuel, as well as the augmented demand for industrial gases and medical oxygen, is boosting market growth. The well-established oil & gas infrastructure in the country and improvements in technology related to cryogenic storage strengthen market opportunities. Government policies that encourage clean energy adoption also enhance the demand for LNG storage.

Cryogenic Tanks Market Dynamics

Key Drivers:

-

Increasing Adoption of LNG as a Cleaner Alternative to Conventional Fossil Fuels Drives Cryogenic Tanks Market Growth

The increasing trend towards liquefied natural gas (LNG) as a cleaner fuel is largely fueling demand for cryogenic tanks. With strict carbon emission policies and a growing emphasis on sustainable energy solutions, industries are investing in LNG infrastructure, increasing storage and transportation needs. The U.S. and other developed countries are increasing LNG export terminals, further fueling the cryogenic tank market. Also, industries such as power generation, shipping, and transportation are embracing LNG to lower their carbon footprint. This increased use of LNG requires cutting-edge cryogenic storage solutions, paving the way for technological innovations in tank design, insulation, and security.

Restraint:

-

High Initial Investment and Maintenance Costs Hinder the Expansion of the Cryogenic Tanks Market Globally

The large capital outlay needed for cryogenic tank production, installation, and upkeep is a significant limitation. The equipment materials and insulation technologies required to ensure ultra-low temperatures contribute substantially to the costs of production. Regulatory requirements for cryogenic storage safety compliance, which are stringent, also contribute to operational costs. Sectors with limited budgets, particularly in developing countries, can be challenged to implement cryogenic tanks on a large scale. Maintenance and regular inspections are also expensive, as maintaining structural integrity and temperature stability requires constant monitoring. These aspects make it difficult for small and medium-sized enterprises (SMEs) to enter the market.

Opportunity:

-

Technological Advancements in Cryogenic Storage and Insulation Materials Create Growth Potential for the Cryogenic Tanks Market

Ongoing innovations in cryogenic insulation, light materials, and energy-saving designs are creating new avenues for the growth of the cryogenic tanks market. Developments like vacuum-insulated storage tanks, composite materials, and Internet of Things-enabled temperature sensing enhance performance, safety, and cost-effectiveness. Moreover, research into hydrogen storage technologies for fuel cell usage is fuelling demand for future cryogenic tanks. As businesses increasingly focus on energy efficiency and sustainability, new cryogenic storage technologies with reduced energy use and longer lifespan are gaining momentum. Businesses investing in intelligent cryogenic systems and automated monitoring will reap rewards from growing applications in the healthcare, aerospace, and clean energy industries.

Challenge:

-

Stringent Government Regulations and Safety Compliance Requirements Pose Operational Challenges in the Cryogenic Tanks Market

The market for cryogenic tanks is stringently regulated because of safety issues related to liquefied gas storage and transportation at very low temperatures. Governments impose stringent compliance requirements on tank design, material, and procedural operations to avert dangers like leaks, explosions, and pressure failures. Complying with these rigid certification demands, such as ASME, DOT, and ISO, adds expenses and prolongs production cycles. Furthermore, changing environmental laws regarding greenhouse gas emissions affect LNG transportation and storage. Firms have to spend on ongoing compliance upgrades and safety improvements, which makes market entry and growth challenging for new entrants and small firms in the sector.

Cryogenic Tanks Market Segments Analysis

By Cryogenic Liquid

The Liquid Natural Gas industry dominates the market for cryogenic tanks with a 32.25% share in revenues by 2023, buoyed by global growth in demand for clean energy and enhanced adoption of LNG as fuel in power production, transport, and industry usage. Organizations such as Chart Industries and Linde Plc are putting capital in high-tech storage and transportation units for LNG and huge capacity terminals for LNG storage. In 2023, Chart Industries introduced its HLNG vehicle tank to enable heavy-duty trucking for LNG. U.S. and European LNG export facility expansion, as well as government incentives for low-carbon fuel, is boosting demand for cryogenic storage systems, solidifying market growth.

Liquefied Nitrogen is growing with the highest CAGR of 5.96% due to growing applications across healthcare, pharmaceuticals, and food processing industries. The growing need for cryopreservation, storage of medical gas, and freezing of food has been driving the market growth. Advanced cryogenic storage tanks were introduced by Air Products and Chemicals Inc. for biomedical and lab use recently, improving efficiency and reliability. High-capacity tanks for industrial distribution of gas, specifically nitrogen tanks, were launched by Cryolor as well. The increasing emphasis on R&D in biotechnology, semiconductor cooling, and aerospace further drives demand for high-performance cryogenic tanks, further driving the liquefied nitrogen segment's fast market growth.

By Application

The Storage segment accounted for the highest revenue share of 63.94% in 2023 due to the increasing demand for LNG, liquid nitrogen, oxygen, and hydrogen in various industries. The growing use of large-scale cryogenic storage tanks in healthcare, energy, and manufacturing has driven market growth. Players like Chart Industries launched sophisticated vacuum-insulated cryogenic storage tanks to improve efficiency and minimize energy losses. INOX India also increased the production of cryogenic tanks to address increasing storage requirements for LNG. The increasing emphasis on clean energy and storage of medical oxygen has further boosted this segment, which has become the pillar of the cryogenic tank market globally.

The Transportation segment is also expected to develop at the highest CAGR of 5.71% with growing demand for LNG and hydrogen transport in energy and industrial applications. With growing global LNG commerce, players such as Cryolor and Linde have launched high-capacity cryogenic trailers to improve efficiency in long-distance gas transport. Air Products also rolled out hydrogen transport tanks to meet the expanding hydrogen economy. Growing applications of cryogenic ISO containers and on-site cryogenic solutions for medical oxygen and industrial gas supply further increase this segment. As industries switch to low-carbon energy, demand for cryogenic transport solutions will keep increasing market growth at a faster pace.

By End-Use

Manufacturing dominated the market for cryogenic tanks in 2023, accounting for 34.46% of the revenues, supported by the growing usage of liquefied gases like nitrogen, oxygen, and argon in industry applications. The growing use of metal fabrication, chemical processing, and electronic manufacturing has also spurred the demand for effective cryogenic storage technology. Players such as Chart Industries and Air Products have introduced next-generation cryogenic tanks with improved insulation technology for industrial gas storage. Cryolor has also introduced high-capacity cryogenic tanks to address manufacturing requirements. With industrial automation increasing, the demand for high-purity cryogenic gases is driving investment in next-generation cryogenic storage solutions for precision manufacturing.

The Healthcare industry is seeing the highest growth in the market for cryogenic tanks at a CAGR of 6.08%, due to increasing demand for medical oxygen and liquid nitrogen for cryopreservation and medical procedures. Demand for medical-grade oxygen storage picked up speed during the COVID-19 pandemic, and companies such as Linde and Air Liquide began increasing their cryogenic tank offerings. Portable cryogenic tanks for hospitals were introduced by INOX India, increasing on-site oxygen availability. Technological advances in cryogenic biobanking and regenerative medicine are additionally driving market expansion.

By Raw Material

The Steel segment led the Cryogenic Tanks Market in 2023 with the highest revenue share because of its strength, durability, and resistance to harsh temperatures. Top players such as Chart Industries and Linde Plc have launched sophisticated cryogenic storage products made of stainless steel to address the increasing demand for LNG, medical gases, and industrial processes. In 2023, Cryofab introduced an upgraded stainless steel cryogenic tank line with enhanced insulation performance. The dominance of the steel segment is fueled by its widespread application in massive LNG storage and transportation, in line with the increasing global energy demand and medical gas distribution networks.

The Nickel Alloy segment is expected to achieve the highest CAGR in the Cryogenic Tanks Market through the forecast period due to its higher corrosion resistance and thermal stability. Air Products and VRV S.p.A. are among the companies that have created advanced nickel alloy-based cryogenic tanks for harsh environments, such as hydrogen storage and aerospace. Air Liquide launched in 2024 high-performance nickel alloy cryogenic tanks, specifically designed for storing liquid hydrogen and backing the worldwide hydrogen economy. The high-speed uptake of nickel alloy materials is driven by the growth in investment in hydrogen infrastructure and the move toward clean energy solutions.

Cryogenic Tanks Market Regional Outlook

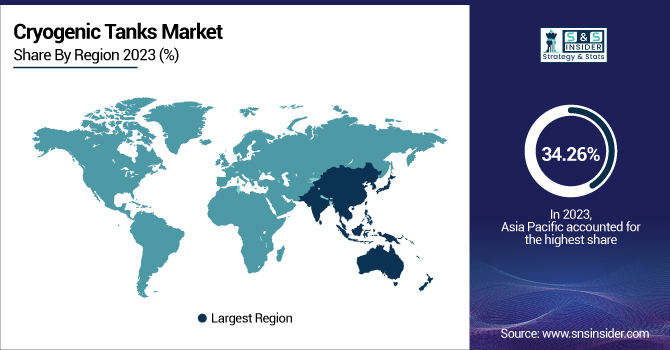

The Asia Pacific market leads the cryogenic tanks industry, with a share of 34.26% of total revenue in 2023 due to the rising use of LNG, medical gases, and industrial gases. Nations such as China, India, and Japan are experiencing fast-paced industrial growth, healthcare development, and clean energy uptake, increasing demand for cryogenic storage products. Market leaders like INOX India and CIMC Enric have introduced high-capacity LNG storage tanks to cater to increasing energy demand. Linde and Air Liquide have also increased their cryogenic gas manufacturing facilities to fulfill increasing demand. Continuous investment in LNG terminals, hydrogen infrastructure, and medical gas storage further reinforces the region's leadership in the cryogenic tanks market.

The North American cryogenic tanks market is anticipated to grow at a CAGR of 6.06% over the forecast period, driven by rising LNG production, hydrogen economy development, and growth in the healthcare sector. The U.S. and Canada are spending significantly on LNG export terminals and cryogenic transport solutions to aid clean energy transition. Players such as Chart Industries and Air Products have developed next-generation vacuum-insulated cryogenic tanks to improve LNG and hydrogen storage efficiency. In 2023, Air Liquide commissioned a big liquid hydrogen storage facility to enable aerospace and industrial applications. The high emphasis on decarbonization, adoption of clean fuels, and cryogenic technology is driving the region's market growth.

Need any customization research on Cryogenic Tank Market - Enquiry Now

Key Players

-

ISISAN A.Ş. – (Cryogenic Storage Tanks, Vacuum Insulated Piping)

-

Cryolor – (Cryogenic Transport Trailers, Vacuum Insulated Cryogenic Storage Tanks)

-

FIBA Technologies, Inc. – (Cryogenic ISO Containers, Tube Trailers)

-

Cryofab, Inc. – (Cryogenic Dewars, Custom Cryogenic Tanks)

-

SURETANK – (Cryogenic Offshore Tanks, ISO Tank Containers)

-

Super Cryogenic Systems Pvt Ltd. – (Liquid Nitrogen Containers, Cryogenic Freezers)

-

Chart Industries – (LNG Storage Tanks, Cryogenic MicroBulk Systems)

-

Wessington Cryogenics – (Cryogenic Pressure Vessels, Liquid Helium Storage Tanks)

-

Eden Cryogenic LLC – (Vacuum Insulated Cryogenic Tanks, Cryogenic Pump Systems)

-

INOX India Limited – (LNG Transport Tanks, Cryogenic Bulk Storage Tanks)

-

AIR WATER INC – (Cryogenic Liquid Cylinders, Industrial Gas Storage Tanks)

-

Linde PLC – (Cryogenic Bulk Tanks, Hydrogen Storage Solutions)

-

Air Products and Chemicals, Inc. – (Cryogenic Tank Trailers, Liquid Nitrogen Generators)

Recent Trends

-

April 2023 – Chart Industries introduced the "Cryo-Vantage" series, an advanced cryogenic storage solution that improves efficiency in liquefied gases like LNG, oxygen, and hydrogen. This new series enhances thermal insulation, reducing boil-off rates significantly.

-

September 2023 – Linde unveiled a cryogenic carbon capture tank system that integrates with industrial processes to capture CO₂ emissions using cryogenic temperatures, improving sustainability.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 6.78 Billion |

| Market Size by 2032 | USD 10.61 Billion |

| CAGR | CAGR of 5.17% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | •By Cryogenic Liquid - (Liquefied Nitrogen, Liquid Natural Gas (LNG), Liquid Hydrogen, Liquid Oxygen, Others) •By Application - (Storage, Transportation) •By End Use - (Manufacturing, Healthcare, Food & Beverages, Others) •By Material – (Steel, Nickel Alloy, Aluminum Alloy) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | ISISAN A.Ş., Cryolor, FIBA Technologies, Inc., Cryofab, Inc., SURETANK, Super Cryogenic Systems Pvt Ltd., Chart Industries, Wessington Cryogenics, Eden Cryogenic LLC, INOX India Limited, AIR WATER INC, Linde PLC, Air Products and Chemicals, Inc. |