Encoder Market Report & Overview:

The Encoder Market size was valued at USD 2.81 billion in 2023 and is expected to grow to USD 6.23 billion by 2032 and grow at a CAGR of 9.25 % over the forecast period of 2024-2032 The key drivers are growing demands for advanced automation in different sectors, increasing acceptance of the Industry 4.0 and its increasing penetration into automotive industries around the world. All these factors will contribute to the growth of the immersion cooling market for the years to come. Challenges with mechanical failure in a harsh environment, however, may hold up industry players. The market's growth is also influenced by regional technological advancements, changing consumer behavior, and evolving supply-demand dynamics, particularly in terms of maintenance and lifecycle data.

Get E-PDF Sample Report on Encoder Market - Request Sample Report

Encoder Market Dynamics

Drivers:

-

Industrial automation and Industry 4.0 initiatives are driving significant growth in the encoder market.

The industrial sector is witnessing a significant rise in automation adoption, with over 550,000 industrial robots installed globally, According to the International Federation of Robotics (IFR)'s World Robotics 2023 report, automation adoption is dramatically rising in the industrial sector, with more than 550,000 industrial robots installed across the globe. This growth is creating an increased demand for industrial encoders used in applications, including linear measurement, material handling and robotics. Rising demand for accuracy in the movement and position correction of automated processes, particularly welding, assembly, and grinding are further creating a market push. Additionally, Industry 4.0 initiatives like “Manufactured in China 2025” and “National Strategy for Manufacturing” in China and India respectively will also fuel this demand by supporting technological transformation and industrial modernization in general. As a result, encoders have become essential in providing motion feedback for efficient operations in modern manufacturing, making the encoder market a key growth area.

Restraints:

-

Impact of Environmental Factors on Encoder Accuracy and Ongoing Innovations for Enhanced Performance

Encoders play a crucial role in closed-loop servo systems, delivering feedback to controllers to ensure motors reach the desired position or speed. Consequently, the performance of encoders is expected to degrade over time and lead to a reduction in the precision of the system. To meet these challenges, manufacturers are consistently innovating and creating new technologies and materials for improving encoder precision and accuracy. As bright as these innovations are, they can also be quite expensive in production, making encoders less affordable for some applications. To address these challenges, manufacturers are continuously developing advanced technologies and materials aimed at enhancing encoder accuracy and reliability. While these innovations hold promise, they can lead to higher production costs, potentially impacting the affordability of encoders in certain applications. Ongoing advancements strive to balance improved performance with cost-efficiency in industrial encoder systems.

Opportunities

-

Government Initiatives Accelerating the Growth of Industrial Automation and Robotics

Governments across the globe are increasingly backing the adoption of automation technologies as part of their efforts to advance the structural development of manufacturing sectors. Manufacturing industries play a vital role in national economies; thus, governments focus on initiatives that help these industries grow and become modernized. Such initiatives are likely to further drive the adoption of industrial robots in manufacturing processes, leading to automation. The change this will bring is expected to stimulate substantial growth in industrial automation market as more and more sectors embrace automation tools to increase efficiency and productivity. The rise in government support is creating favorable conditions for the widespread adoption of industrial robotics and related technologies.

Challenges:

-

Impact of Harsh Environments on Encoder Performance and Reliability

One of the major challenges for the encoder market is their performance in harsh environments. Encoders may be adversely affected by extreme temperatures, humidity, dust, and vibration. Liquid contamination, solid particles, signal output failure, and mechanical bearing overload are some of the factors that can cause encoder malfunction or total failure. Robust encoder designs with protection against such harsh conditions, such as erratic electrical noise or loss of power, are thus needed to ensure continued use and precision. These issues disrupt system operations, causing erratic behavior or complete stoppage, which underlines the need for robust encoder designs capable of withstanding such adverse conditions to ensure continued precision and functionality.

Encoder Market Segment Analysis

By Type

In 2023, the Rotary Encoder segment dominated the encoder market, accounting for approximately 70% of the market share. The growth of the rotary encoders market is primarily driven by the increasing demand for precise rotational measurement and position feedback in industrial automation, robotics, and motion control systems. These devices are essential for industries that use automated machinery and equipment, as they supply dependable feedback that is both accurate and reliable, even in complex and high-speed applications. The increasing demand for precise motion control and the growing adoption of automation technologies further solidifies the market leadership of rotary encoders.

The Linear Encoder segment is expected to witness the fastest growth in the encoder market from 2024 to 2032. As demand around the world for precise linear motion control across a range of areas continues to increase robotics and CNC machinery to automation systems. Demand for linear encoders is driven up by other applications, including the automotive and electronics industries, where accuracy and speed are, too, imperative. They are increasingly becoming more critical to modern manufacturing and industrial systems due to their ability to relay accurate position feedback over long distances and in challenging environments, leading to higher adoption rates across industry verticals.

By Signal Type

In 2023, Incremental encoders held the largest share of the encoder market, accounting for around 58%. They are low cost, simple design, providing accurate movement feedback that are widely preferred by users in the motion control applications. Incremental encoders produce pulses that are counted to determine displacement or rotation, making them suitable for use in applications such as motor control, robotics, and conveyor systems. The prospect of high resolution and real-time precision measurement are factors contributing to their widespread usage across industrial verticals. In addition, incremental encoders are simpler than absolute types; both features are responsible for their cost-effectiveness and widespread use in atomized systems. The growing demand for automation in manufacturing processes is expected to sustain the dominance of incremental encoders in the market.

The absolute encoders segment is expected to experience the fastest growth in the encoder market from 2024 to 2032, due to the growing need for higher-accuracy position feedback in automation systems. Regionally, North America and Europe are expected to record considerable growth owing to the high adoption of industrial automation and major investments in advanced manufacturing technologies. Factors such as the increasing use of absolute encoders, especially in Asia Pacific region, mainly China and Japan, can be attributed to the growth of industrial automation and robotics, and government initiatives for smart manufacturing. Higher accuracy and reliability of such encoders are driving its use in applications such as aerospace, robotics, and medical devices, contributing to growth of the market.

By Technology

The optical encoder segment led the encoder market with a share of around 53% in 2023, Optical encoders are widely utilized across various industrial sectors, including robotics, automotive, aerospace, and manufacturing, thanks to their high-resolution feedback and low mechanical wear. These sensors are also allowing for high-speed operations as they provide accurate positioning and velocity feedback, which makes them particularly suited for applications where high precision is of paramount importance. Optical encoders are gaining traction with industry 4.0 technology and increasing demand for automation, particularly in Robotic systems, CNC machines and material handling systems. As technological advancements continue, optical encoders are expected to maintain a dominant position in the market, contributing to future growth.

The inductive encoder segment is the fastest growing in the encoder market during the forecast period of 2024-2032. Inductive encoders are gaining traction due to their robust performance in harsh environments, where other types of encoders may struggle. With their suitability for challenging industrial environments, such as mining, automotive manufacturing, and heavy machinery, these encoders can be employed under conditions of high temperature, humidity, dust or vibration. They do so without having direct physical contact between the sensor and the encoder track, giving them durability and a long lifespan, making them suitable for use in demanding applications.As industries increasingly prioritize automation and precision, the demand for inductive encoders is expected to rise, propelling the segment’s growth.

By Application

The industrial segment dominated the encoder market, accounting for approximately 29% of the market share in 2023. This dominance is primarily driven by the growing adoption of automation technologies across manufacturing sectors, where encoders play a crucial role in motion control and position feedback systems. Industrial applications, including robotics, CNC machines, conveyor systems, and material handling, heavily rely on encoders for precision, reliability, and performance. With increasing demand for high-efficiency production processes, manufacturers are investing in encoder solutions that offer accuracy, durability, and the ability to withstand harsh environments. The industrial sector’s ongoing expansion in automation and the rise of Industry 4.0 are expected to further fuel the growth of encoders in this application segment.

The automotive segment is the fastest-growing in the encoder market, projected to see significant growth over the forecast period from 2024 to 2032 This growth can largely be accounted for by the continual rising interest in next-generation motor vehicle technology like electric vehicle (EV), autonomous driving systems and automotive safety features. Encoders are being deployed in these applications for high-accuracy motion control, position feedback, and sensor systems that enable critical features such as adaptive cruise control, lane-keeping assistance, and electric steering. As automakers continue to innovate with more automated and electrified vehicle systems, the need for reliable and high-precision encoders in automotive manufacturing and components will drive substantial growth in this segment.

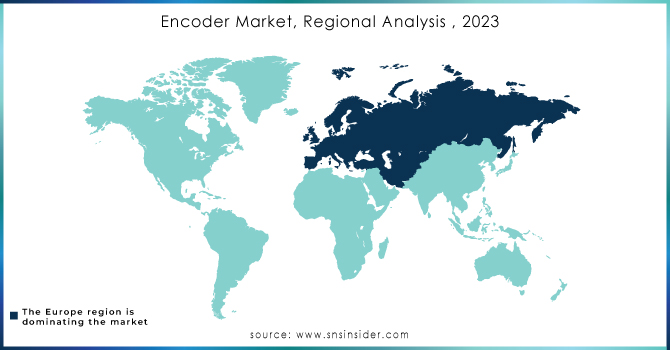

Encoder Market Regional Analysis

North America dominated the encoder market with a share of approximately 35% in 2023, owing to the industrial base, inclination towards technology in the region, and automation adoption due to industrialization. The dominance of this region is due primarily to the presence of key players, along with the growing demand for industrial robots, advanced manufacturing technologies, and automotive systems. Moreover, the introduction of Industry 4.0 initiatives and government-backed automation schemes also magnified the market growth. Due to the high necessity for accuracy and reliability in industries like automotive, aerospace and manufacturing, With a robust demand for precision and reliability in sectors such as automotive, aerospace, and manufacturing, North America is poised to maintain its leadership position in the encoder market over the forecast period.

Asia Pacific is the fastest-growing region in the encoder market over the forecast period 2024-2032, owing to rapid industrialization, automation, and wide adoption of Industry 4.0 technologies. Additionally, demand from the manufacturing, automotive, and robotics industries all contribute to this growing demand centered in countries such as China, Japan, and South Korea. This has created demand for better encoder solutions as the area goes through significant investment, development of smart manufacturing, and deployment of robots. Besides, the government's initiatives to promote technological advancements and self-sufficiency, for instance, "Made in China 2025," will further boost the adoption of encoders across industrial applications.

Get Customized Report as Per Your Business Requirement - Request For Customized Report

Encoder Market Key Players

Some of the major Players in Encoder Market along with their Product:

-

Fortive (US) (Encoders, sensors, test equipment)

-

HEIDENHAIN (Germany) (Linear and rotary encoders, measurement systems)

-

ifm electronic GmbH (Germany) (Sensors, encoders, automation systems)

-

Maxon (Switzerland) (DC motors, drives, encoders)

-

Mitutoyo Corporation (Japan) (Measuring instruments, linear encoders)

-

Pepperl+Fuchs SE (Germany) (Sensors, encoders, industrial automation)

-

Pilz GmbH & Co. KG (Germany) (Safety sensors, encoders)

-

Renishaw plc. (UK) (Encoders, measurement systems, automation)

-

Sensata Technologies, Inc. (US) (Pressure sensors, encoders, automation solutions)

-

OMRON Corporation (Japan) (Encoders, sensors, automation systems)

-

Baumer Electric AG (Switzerland) (Encoders, sensors, measurement solutions)

-

Schneider Electric (France) (Industrial automation, encoders, sensors)

-

Panasonic Corporation (Japan) (Encoders, sensors, automation solutions)

-

Honeywell International, Inc. (US) (Sensors, encoders, automation systems)

-

Rockwell Automation, Inc. (US) (Industrial automation, encoders, sensors)

-

Dynapar (US) (Encoders, motion control systems)

-

Fraba B.V. (Netherlands) (Encoders, position sensors)

-

Wachendorff Automation GmbH & Co KG (Germany) (Rotary encoders, position sensors)

-

Fenac Engineering (Italy) (Encoders, motion control systems)

-

Heidenhain Corporation (US) (Encoders, measurement systems, CNC controls)

-

TE Connectivity (US) (Sensors, encoders, connectivity solutions)

-

BEI Sensors (US) (Encoders, motion sensors, automation solutions)

List of Suppliers who provide raw material and component in Encoder Market

-

Honeywell International, Inc.

-

Texas Instruments

-

NXP Semiconductors

-

STMicroelectronics

-

Analog Devices

-

Broadcom Inc.

-

Maxim Integrated

-

Renesas Electronics Corporation

-

Murata Manufacturing

-

Omron Corporation

Recent Development

-

Jan. 2, 2025, Honeywell Int’l Inc. v. 3G Licensing, S.A. In Honeywell Int’l Inc. v. 3G Licensing, S.A., the Federal Circuit reversed a ruling of non-obviousness by the Patent Trial and Appeal Board (PTAB), holding that the PTAB’s decision was not supported by substantial evidence and that it operated under the incorrect legal standard.S

-

September 5, 2024 – Panasonic Technics and the SL-1300G TurntablePanasonic's Technics division expands its line of turntables with the innovative SL-1300G, featuring new ΔΣ-Drive tech and an iron-coreless motor. This new model comes with precise vibration reduction and updated precision engineering, taking Technics' Grand Class lineup to the next level.

| Report Attributes | Details |

| Market Size in 2023 | USD 2.81 Billion |

| Market Size by 2032 | USD 6.23 Billion |

| CAGR | CAGR of 9.25% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Type(Rotary Encoder, Linear Encoder) • By Signal Type(Absolute Encoders, Incremental Encoders) • By Technology(Magnetic, Optical, Inductive, Others) • By Application(Industrial, Healthcare & Life Sciences, Automotive, Consumer Electronics, Power, Food & Beverage, Aerospace, Printing ,Textile, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | HEIDENHAIN (Germany), ifm electronic GmbH (Germany), Maxon (Switzerland), Mitutoyo Corporation (Japan), Pepperl+Fuchs SE (Germany), Pilz GmbH & Co. KG (Germany), Renishaw plc. (UK), Sensata Technologies, Inc. (US), OMRON Corporation (Japan), Baumer Electric AG (Switzerland), Schneider Electric (France), Panasonic Corporation (Japan), Honeywell International, Inc. (US), Rockwell Automation, Inc. (US), Dynapar (US), Fraba B.V. (Netherlands), Wachendorff Automation GmbH & Co. KG (Germany), Fenac Engineering (Italy), Heidenhain Corporation (US), TE Connectivity (US), and BEI Sensors (US). |