Flexitank Market Report Scope & Overview:

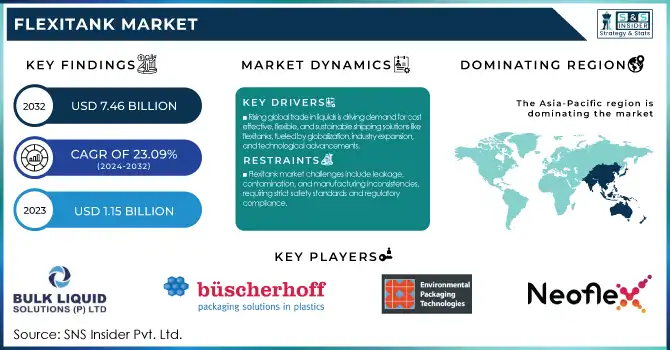

The Flexitank Market Size was estimated at USD 1.15 billion in 2023 and is expected to arrive at USD 7.46 billion by 2032 with a growing CAGR of 23.09% over the forecast period 2024-2032. The Flexitank Market report offers a distinctive analysis by presenting regional production output trends and capacity utilization rates, highlighting efficiency shifts across key manufacturing hubs. It delves into performance & reliability metrics, showcasing advancements in durability and contamination resistance. Additionally, the report explores technological innovations in materials, such as multi-layer polyethylene and biodegradable alternatives, shaping the market’s evolution. The export/import trade flow provides a global supply chain perspective, identifying major shipping routes and demand hotspots. Furthermore, an exclusive section on sustainability initiatives and regulatory shifts enhances the report’s uniqueness, addressing the rising adoption of eco-friendly logistics solutions.

To Get more information on Flexitank Market - Request Free Sample Report

Flexitank Market Dynamics

Drivers

-

Rising global trade in liquids is driving demand for cost-effective, flexible, and sustainable shipping solutions like flexitanks, fueled by globalization, industry expansion, and technological advancements.

Rising global trade in liquids is fueling the demand for efficient and cost-effective shipping solutions. With increasing consumption of edible oils, chemicals, beverages, and industrial liquids, international trade volumes have surged, necessitating advanced logistics solutions like flexitanks. Demand for liquid shipment is expanding due to globalization, rapid expansion of the food and beverage industries, and growing demand for bulk liquid shipment in chemicals and pharmaceuticals, which is supporting the overall expansion of the market. The main trend is the move to replace drum and IBC delivery of raw materials with flexible, lightweight, sustainable packaging. Technological developments in leak-proof, multi-layered flexitanks are also improving safety and minimising contamination risks. More companies that are also adopting recyclable and biodegradable materials are identify sustainable logistics practices that can help reduce these impacts. The recent acceleration of e-commerce and cross-border trade further drives the need for trustful solutions for liquid transport. With industries recalibrating their supply chains for optimum efficiency, the flexitank market is positioned for significant growth trajectory, permitting businesses with flexible and cost-efficient supply chain solutions.

Restraint

-

Quality and risk concerns in the flexitank market stem from leakage, contamination, and inconsistent manufacturing, necessitating strict safety standards, advanced materials, and regulatory compliance for wider adoption.

Quality and risk concerns in the flexitank market primarily revolve around potential leakage, contamination, and quality control challenges. They are intended to be disposable, yet leaks can occur if handled improperly, due to manufacturing defects, or if made from low-grade materials, leading to financial losses and environmental hazards. Forgotten residue from previous loads becomes a contamination risk with respect to the purity of the transported liquids — particularly in the food, pharmaceuticals, and chemicals industries. Furthermore, production quality can vary significantly between manufacturers, which can affect reliability and may deter some customers from using flexitanks. This reinforces the need for strict compliance with safety standards, testing for quality, and safe handling protocols to minimize such risks. Companies investing in improved material technology, strong sealing mechanisms, and real-time monitoring solutions can foster increased confidence in flexitank safety. Certification, compliance with international regulations, and adherence to industry best practices are key to addressing these concerns and ensuring the broader acceptance and sustainability of the flexitank market.

Opportunities

-

Technological advancements in flexitanks enhance safety, durability, and efficiency through improved materials, reinforced designs, and smart monitoring systems.

Technological advancements in the flexitank market are driving improvements in safety, durability, and efficiency. Advancements in material science, including multi-layer polyethylene and advanced barrier films, increase resistance against contamination, leaks, and deviations in temperature to enable the safe transport of different liquid products. Reliability is enhanced with reinforced designs and anti-static properties that prevent rupture or spills. Furthermore, advanced tracking systems and onboard IoT-enabled sensors provide live monitoring of liquid levels, temperature, and pressure, which enable operators to streamline logistics and avoid losses. These innovations enhance operational efficiency and bolster supply chain transparency, rendering flexitanks increasingly appealing to sectors such as food & beverage, chemicals, and pharmaceuticals. In addition, advancements in sustainable materials and recyclable flexitank properties are in line with sustainability objectives globally, creating opportunities for widespread adoption. As technology changes, further advantages will keep developing flexitank opportunity performance, cost-benefits and sustainability.

Challenges

-

Raw material price volatility in the flexitank market affects production costs, pricing stability, and overall profitability due to fluctuating petroleum-based material costs.

Raw material price volatility poses a significant challenge for the flexitank market, as the cost of essential components like polyethylene, polypropylene, and specialized coatings fluctuates due to supply chain disruptions, geopolitical tensions, and changing crude oil prices. Plastics are derived from petroleum so if the price of oil increases, production costs go up as well, making it hard for manufacturers to keep prices steady. In addition to that, changes in the availability of raw materials can cause delays in production, and/or increase operational costs. Increased costs may be passed along to consumers, which could dampen demand and affect competition in the marketplace. Strategies employed by manufacturers to mitigate these risks include long-term supplier contracts, alternative source for raw materials, cost-effective production methods, etc. At the same time, breakthroughs in biodegradable and recyclable materials may alleviate costs concerns while meeting sustainability goals. Overall, the volatility of raw material prices is one of the main challenges to profitability and long-term development of the flexitank industry.

Flexitank Market Segmentation Analysis

By Layer Type

The multi-layer segment dominated with a market share of over 56% in 2023, due to its enhanced durability, contamination resistance, and superior temperature control. More specifically, these flexitanks are made up of layers of polyethylene or polypropylene, which provide better protection from leaks and external environmental influences. This level of product protection makes them the ideal solution for the transport of food grade liquids, pharmaceuticals and chemicals, where safety and hygiene are paramount. Moreover, multi-layer flexitanks provide stronger, puncture- and rupture-resistant during transportation. The multi-layer flexitank shipments market is also boosted by the increasing commerce of bulk liquids across borders coupled with safety and regulated standards to operate in the market for transport of liquids. The liquid segment reiterates its reign in the market with sustained demand as industries focus on safe and efficient liquid logistics.

By Application

The Foodstuffs segment dominated with a market share of over 32% in 2023, due to the growing demand for bulk liquid transportation of edible oils, fruit juices, and other perishable food products. Flexitanks are the best solution in terms of cost, weight, and to avoid contamination, compared to traditional means (drums and iso tanks). With their high capacity (up to 24,000 liters), single-use nature, and easy installation, these containers are designed to transport food-grade liquids safely and hygienically. Apart from this, flexitanks help save costs on freight, waste of product, and avail the maximum utilization of container space, which is anticipated to increase the demand in the food industry. Owing to surging global trade and stringent food safety regulations, food manufacturers and exporters increasingly opt for flexitanks, bolstaining the segment’s basic dominance in the market.

Flexitank Market Regional Outlook

Asia-Pacific region dominated with a market share of over 47% in 2023, due to its strong industrial base and increasing trade activities. The region's thriving food & beverage, chemical, and pharmaceutical industries drive significant demand for cost-effective bulk liquid transportation solutions. Flexitank adoption has also been bolstered in countries such as China, India and Southeast Asian countries that are prominent exporters of edible oils, juices, wines, and industrial chemicals. Moreover, growing manufacturing sector in the region and rising demand for effective logistics solutions further boost the market growth. The presence of leading flexitank manufacturers and government trade policies also facilitates market growth. In addition, increasing awareness regarding the cost-effectiveness and zero waste generation of flexitanks is bolstering the growth of the market for flexitanks as compared to conventional bulk liquid packaging methods. Witnessing a steady growth in trade across the globe, Asia-Pacific is the dominant market for flexitanks backed by a solid supply chain network and growing production that exports across different industries.

North America is the fastest-growing region in the Flexitank Market, primarily due to the increasing adoption of cost-effective bulk liquid transportation solutions. Flexitanks provide a distinct advantage over drums and intermediate bulk containers as a transportation method by cutting costs, improving container space efficiency, and reducing handling requirements. Market growth is also being driven by a growing interest in sustainable and efficient packaging solutions, as businesses look to minimize their waste and streamline supply chains. Moreover, the food and beverage, chemical, and pharmaceutical industries in the region are on the rise, fueling the demand for safe heavy liquid transport. With rising environmental concerns and increased legislation on packaging waste disposal, businesses have been driven to adopt flexible, reusable, and lightweight solutions, which include Flexitanks. Technological advancements are also making Flexitanks more durable and leak-resistant, while trade activities are also on the rise, further contributing to rapid Flexitank adoption trends across various industries located in North America.

Get Customized Report as per Your Business Requirement - Enquiry Now

Some of the major key players in the Flexitank Market

-

Qingdao BLT Packing Industrial Co., Ltd. (BLT) (Multilayer Flexitanks, Single-layer Flexitanks)

-

Nelson Global (Food-Grade Flexitanks, Industrial Flexitanks)

-

Braid Logistics (Standard Flexitanks, Heating Pad Flexitanks)

-

Bulk Liquid Solutions (Wine Flexitanks, Chemical Flexitanks)

-

Büscherhoff Packaging Solutions GmbH (Multilayer PE Flexitanks, Barrier Flexitanks)

-

Environmental Packaging Technologies Inc. (EVOH Barrier Flexitanks, Recyclable Flexitanks)

-

Full-Pak Bulk Containers (ISO Tank Flexitanks, Agricultural Flexitanks)

-

K Tank Supply Ltd (Customizable Flexitanks, High-Volume Flexitanks)

-

Mak & Williams Flexitank Supply (Disposable Flexitanks, Reinforced Flexitanks)

-

MYFLEXITANK (Aseptic Flexitanks, Bulk Liquid Transport Flexitanks)

-

KriCon Group (Standard Flexitanks, Anti-Static Flexitanks)

-

Qingdao LAF Technology Co., Ltd. (Flexitanks for Edible Oils, Beverage Flexitanks)

-

SIA FLEXITANKS (Chemical-Resistant Flexitanks, Pharma-Grade Flexitanks)

-

Shanghai Yunjet Plastic Packaging Co., Ltd. (Multilayer Flexitanks, Single-Use Flexitanks)

-

TRUST Flexitanks (High-Durability Flexitanks, Specialized Liquid Transport Flexitanks)

-

Techno Group USA (Liquor Flexitanks, Industrial Oil Flexitanks)

-

Hillebrand Gori Group GmbH (Wine Flexitanks, Beverage Transport Flexitanks)

-

Neoflex (Customized Flexitanks, Eco-Friendly Flexitanks)

-

FLUIDTAINER FLEXITANK SDN BHD (High-Barrier Flexitanks, Temperature-Controlled Flexitanks)

-

Qingdao Hengxin Plastic Co. Ltd. (PE Flexitanks, Reusable Flexitanks)

Suppliers for (High-quality flexitanks with strong durability and leak-proof designs) on the Flexitank Market

- Qingdao BLT Packing Industrial Co., Ltd.

- Braid Logistics

- Bulk Liquid Solutions

- Environmental Packaging Technologies Inc.

- SIA Flexitanks

- Qingdao LAF Packaging Co., Ltd.

- TRUST Flexitanks

- Rishi FIBC Solutions Pvt. Ltd.

- Hengxin Plastic Co., Ltd.

- MYFLEXITANK

Recent development

In November 2023: ASF, Inc., a logistics service provider, expanded its flexitank portfolio to offer more efficient and eco-friendly shipping solutions for non-hazardous bulk liquid cargo.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 1.15 Billion |

| Market Size by 2032 | USD 7.46 Billion |

| CAGR | CAGR of 23.09% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Layer Type (Single Layer, Multi-layer) • By Application (Foodstuffs, Wine & Spirits, Chemicals, Oils, Industrial Products, Pharmaceutical Goods, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Qingdao BLT Packing Industrial Co., Ltd. (BLT), Nelson Global, Braid Logistics, Bulk Liquid Solutions, Büscherhoff Packaging Solutions GmbH, Environmental Packaging Technologies Inc., Full-Pak Bulk Containers, K Tank Supply Ltd, Mak & Williams Flexitank Supply, MYFLEXITANK, KriCon Group, Qingdao LAF Technology Co., Ltd., SIA FLEXITANKS, Shanghai Yunjet Plastic Packaging Co., Ltd., TRUST Flexitanks, Techno Group USA, Hillebrand Gori Group GmbH, Neoflex, FLUIDTAINER FLEXITANK SDN BHD, Qingdao Hengxin Plastic Co. Ltd. |