Industrial Pumps Market Report Scope & Overview:

To get more information on Industrial Pumps Market - Request Free Sample Report

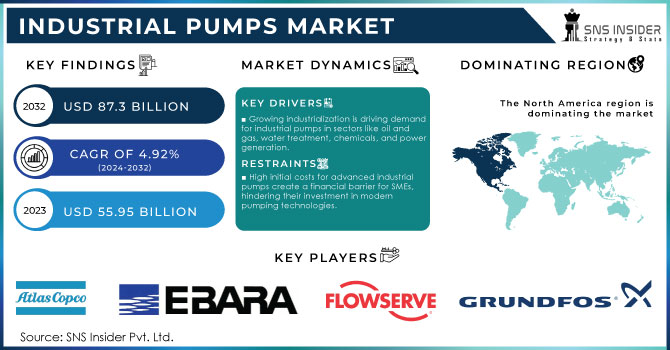

The Industrial Pumps Market Size was valued at USD 55.95 Billion in 2023 and is expected to reach USD 87.3 Billion by 2032 and grow at a CAGR of 4.92% over the forecast period 2024-2032.

The industrial pumps market is a critical component of various sectors, including oil and gas, water and wastewater treatment, chemical processing, and manufacturing. As industries strive for improved efficiency and sustainability, the demand for advanced pump technologies continues to rise. According to a study published in the Journal of Loss Prevention in the Process Industries, optimizing pump efficiency can significantly impact operational costs and energy consumption, which aligns with growing environmental regulations aimed at reducing greenhouse gas emissions. The new eco-regulations are set to reshape future pump designs, emphasizing the importance of compliance among manufacturers and users alike.

Recent advancements in technology have led to significant improvements in pump efficiency, with studies indicating that modern pumps can achieve efficiency ratings exceeding 90%. The U.S. Department of Energy (DOE) has implemented new pump efficiency standards, compelling manufacturers to adapt and innovate in response to these regulatory changes. These regulations are essential in ensuring that the industrial pumps market not only meets performance expectations but also aligns with the global push towards sustainability and energy conservation. As per Pumps & Systems, companies must prepare for compliance with these standards, which may affect product design and manufacturing processes. Furthermore, the integration of automation and IoT technologies in pump systems is on the rise, enhancing operational efficiency and allowing for real-time monitoring and predictive maintenance. The ability to gather data and analyze pump performance metrics has become increasingly valuable for industries, reducing downtime and operational costs. This shift towards smarter pump networks is supported by research from the American Institute of Chemical Engineers (AIChE), highlighting the importance of optimizing pump performance and system design to achieve greater reliability and efficiency.

Another critical aspect of the industrial pump market is the growing emphasis on user satisfaction. Companies are increasingly focused on the factors that influence their purchase decisions, including reliability, efficiency, and total cost of ownership. A shift towards more sustainable practices and eco-friendly technologies is driving companies to adopt pumps that align with their corporate sustainability goals. According to industry reports, the average lifespan of industrial pumps has improved, with users replacing pumps less frequently due to enhanced reliability and performance. Moreover, the market landscape is witnessing a surge in the development of advanced materials and designs that facilitate better energy transfer and reduce maintenance needs. Emerging markets are also playing a vital role in the growth of the industrial pump sector, as industrialization and infrastructure development drive demand for reliable pumping solutions. The integration of cutting-edge technologies and compliance with environmental standards is positioning manufacturers to capture market share in these expanding regions.

MARKET DYNAMICS

DRIVERS

- Growing industrialization is fueling demand for industrial pumps across sectors like oil and gas, water treatment, chemicals, and power generation due to enhanced infrastructure development and the need for efficient fluid management.

Growing industrialization significantly fuels the demand for industrial pumps across multiple sectors. As countries, especially emerging economies, undergo rapid industrial growth, the need for efficient and reliable pumping systems becomes crucial. Industries such as oil and gas require robust pumps to handle the transportation of crude oil, natural gas, and refined products through pipelines and processing plants. Similarly, the water and wastewater treatment sector rely on industrial pumps to manage water supply and sewage treatment processes, ensuring safe and clean water for communities. The chemical industry also demands specialized pumps to transport corrosive and viscous fluids safely, which is essential for maintaining operational efficiency and safety standards.

Furthermore, the power generation sector utilizes various pumping systems for cooling, water supply, and fuel transport, emphasizing the critical role of pumps in sustaining energy production. Infrastructure development, such as the construction of roads, bridges, and residential complexes, contributes to this demand as new facilities require integrated pumping solutions for various applications. Additionally, advancements in industrial processes, aimed at increasing productivity and reducing costs, are further driving the adoption of sophisticated pumping technologies. As a result, the convergence of industrialization, infrastructure growth, and technological innovation creates a robust market environment for industrial pumps, fostering ongoing investment and expansion in this essential sector. This dynamic reinforces the pivotal role of industrial pumps in facilitating and sustaining economic growth across diverse industries.

- Technological advancements in pump systems, including smart pumps and energy-efficient designs, are improving operational efficiency and performance, driving increased investment in innovative pumping solutions.

Technological advancements in pump technologies are significantly transforming the industrial pumps market, particularly through innovations like smart pumps and energy-efficient designs. Smart pumps integrate advanced monitoring and control systems that allow for real-time data collection and analysis. This technology enables operators to optimize pump performance, detect anomalies, and predict maintenance needs, leading to reduced downtime and enhanced operational efficiency. Energy-efficient pump designs are also gaining traction as industries increasingly prioritize sustainability and cost savings. These pumps consume less energy compared to traditional models, which not only lowers operational costs but also aligns with global efforts to reduce carbon emissions. Innovations such as variable frequency drives (VFDs) allow pumps to adjust their speed based on demand, further enhancing energy efficiency.

Additionally, advancements in materials and coatings have led to more durable and corrosion-resistant pumps, which can operate effectively in harsh environments. This durability reduces maintenance frequency and prolongs the lifespan of the equipment, providing long-term savings for businesses. The combination of these technologies is attracting significant investments in new pump systems. Companies are recognizing the competitive advantage offered by adopting cutting-edge technologies, leading to a surge in demand for high-performance pumps across various sectors, including water treatment, oil and gas, and manufacturing. As industries continue to embrace digital transformation and sustainability initiatives, the role of advanced pumping technologies will become increasingly critical in driving operational efficiency and performance.

RESTRAIN

- High initial costs for advanced industrial pumps create a financial barrier for small and medium-sized enterprises (SMEs), hindering their ability to invest in modern pumping technologies.

High initial costs represent a significant barrier to the adoption of advanced industrial pumps, particularly for small and medium-sized enterprises (SMEs). These businesses often operate under tight budget constraints, making large capital expenditures challenging. Advanced industrial pumps are typically designed with cutting-edge technology and materials, which enhance efficiency, reliability, and performance. However, this sophistication comes at a premium price, deterring SMEs from investing in these solutions. The financial strain associated with acquiring these pumps can lead SMEs to opt for less efficient, lower-cost alternatives that may not meet their operational needs or regulatory requirements. Consequently, these companies may miss out on potential long-term savings associated with energy-efficient pumps, as well as the improved operational efficiencies that come from modern technology. Additionally, the high initial costs can limit SMEs' ability to scale their operations or expand into new markets, as funds may be tied up in outdated equipment or repairs.

Moreover, the reluctance to invest in advanced pumping solutions may hinder SMEs from meeting the growing demands for sustainable practices in industries like water treatment and energy management. In this context, it becomes crucial for manufacturers and policymakers to explore financing options, such as leasing programs or subsidies, to help SMEs overcome these cost barriers. By addressing the financial challenges associated with acquiring advanced industrial pumps, stakeholders can promote wider adoption of innovative technologies and support the growth and competitiveness of SMEs in the market.

KEY SEGMENTATION ANALYSIS

By Product Type

In 2023, the centrifugal pump dominated the market share over 68.02%. These pumps are employed for managing and overseeing the flow of gases, vapors, liquids, and other fluids. Because of their low maintenance needs and capability for increased fluid flow rates, these items are extensively used in various sectors such as water supply, food & beverage, pharmaceutical, and chemical industries. Moreover, these pumps are utilized in power generation plants to move the coolant.

REGIONAL ANALYSIS

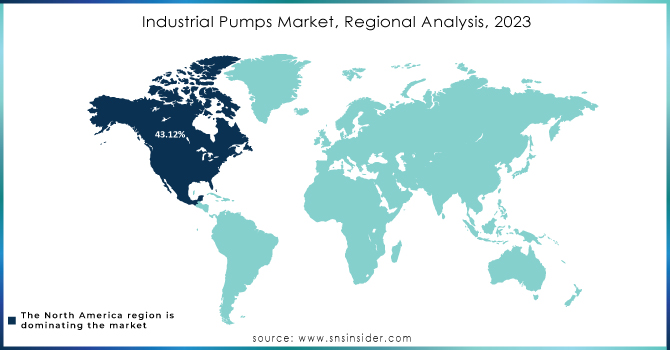

In 2023, North America region dominated the market share over 43.12% of the market share. Industrial pumps are utilized for precise dosing of catalysts in chemical production facilities. Additionally, they are utilized in oil production and refining plants to transfer both crude and processed oil between different locations.

Europe is projected to expand in the upcoming years as a result of its well-established industrial sector. These pumps are utilized across different sectors like chemical, power generation, and construction. Moreover, there has been a growing need for effective rotary pumps in order to lessen the environmental impact in industrial operations and enhance carbon credit, thus propelling the market in the area.

Do You Need any Customization Research on Industrial Pumps Market - Inquire Now

KEY PLAYERS

Some of the major key players of Industrial Pumps Market

-

Atlas Copco AB: (Industrial Equipment and Compressors)

-

Ebara Corporation: (Pumps and Fluid Systems)

-

Flowserve Corporation: (Pumps, Valves, and Seals)

-

Grundfos Holding A/S: (Pumps and Pump Systems)

-

ITT Inc.: (Pump Systems and Fluid Management)

-

KSB SE & Co. KGaA: (Pumps and Valves)

-

Sulzer Ltd.: (Pumps and Mixing Solutions)

-

The Gorman-Rupp Company: (Pumps and Pumping Systems)

-

The Weir Group Plc: (Mining and Oil & Gas Pumps)

-

Xylem Inc.: (Water and Wastewater Solutions)

-

Pentair plc: (Water Treatment and Filtration Systems)

-

Schneider Electric: (Pump Control Solutions)

-

SPX Flow: (Pumps and Fluid Handling)

-

National Oilwell Varco: (Oilfield Equipment and Pumps)

-

Honeywell International Inc.: (Fluid Control Solutions)

-

Kohler Co.: (Water and Wastewater Pumps)

-

Eaton Corporation: (Fluid Power and Pump Solutions)

-

Cameron International: (Schlumberger) (Pump Systems for Oil & Gas)

-

Tsurumi Manufacturing Co., Ltd.: (Submersible Pumps)

-

Baker Hughes: (Oilfield Equipment and Pump Systems)

RECENT DEVELOPMENTS

-

In 11th April 2024: Sulzer has announced significant investments in its U.S. manufacturing and supply chain to enhance pump production capabilities. This initiative will include expanding its facilities and optimizing supply chain processes, aiming to improve efficiency and better serve the North American market.

-

In 25th April 2024: Netzsch will unveil an advanced Nemo progressing cavity pump at ACHEMA 2024 in Frankfurt. This new model targets the chemical sector, especially in battery production, designed to handle aggressive and abrasive media without costly mechanical seals. Attendees can explore the innovation at Netzsch's booth.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 55.95 Billion |

| Market Size by 2032 | USD 87.3 Billion |

| CAGR | CAGR of 4.92% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Product Type (Centrifugal Pumps, Positive Displacement Pumps, Reciprocating Pumps, Rotary Pumps, Others) • By Application (Oil & Gas, Chemicals, Construction, Power Generation, Water & Wastewater Treatment, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | Atlas Copco AB, Ebara Corporation, Flowserve Corporation, Grundfos Holding A/S, ITT Inc., KSB SE & Co. KGaA, Sulzer Ltd., The Gorman-Rupp Company, The Weir Group Plc, Xylem Inc., Pentair plc, Schneider Electric, SPX Flow, National Oilwell Varco, Honeywell International Inc., Kohler Co., Eaton Corporation, Cameron International (Schlumberger), Tsurumi Manufacturing Co., Ltd., Baker Hughes. |

| Key Drivers | •Growing industrialization is fueling demand for industrial pumps across sectors like oil and gas, water treatment, chemicals, and power generation due to enhanced infrastructure development and the need for efficient fluid management. •Technological advancements in pump systems, including smart pumps and energy-efficient designs, are improving operational efficiency and performance, driving increased investment in innovative pumping solutions. |

| RESTRAINTS | • High initial costs for advanced industrial pumps create a financial barrier for small and medium-sized enterprises (SMEs), hindering their ability to invest in modern pumping technologies. |