Intrinsically Safe Signal Conditioner Market Report Scope & Overview:

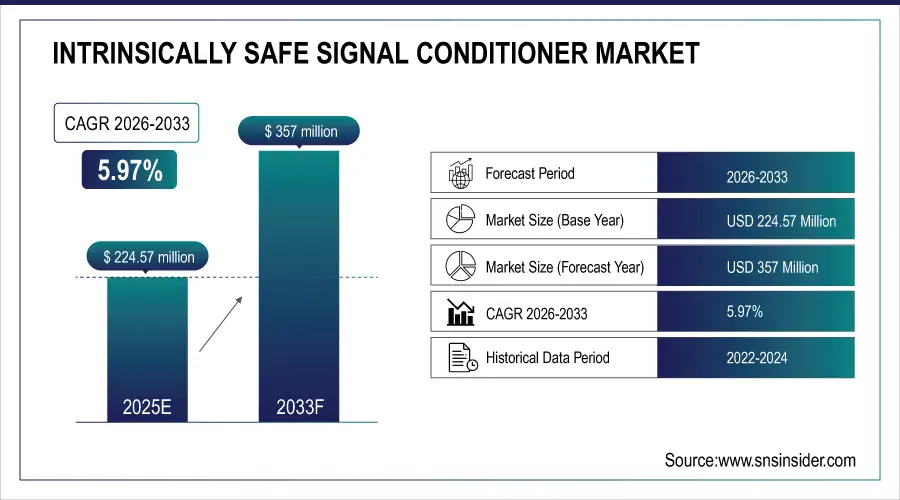

The Intrinsically Safe Signal Conditioner Market Size was valued at USD 224.57 Million in 2025E and is expected to reach USD 357 Million by 2033, growing at a CAGR of 5.97% over the forecast period of 2026-2033.

The Intrinsically Safe Signal Conditioner Market is witnessing steady growth, driven by the rising adoption of automation and safety systems in hazardous industrial environments. These devices ensure accurate signal transmission while preventing ignition risks in explosive zones. Growing demand from oil & gas, chemical, mining, and pharmaceutical sectors supports sustained market expansion.

Market Size and Forecast:

-

Intrinsically Safe Signal Conditioner Market Size in 2025E: USD 224.57 Million

-

Intrinsically Safe Signal Conditioner Market Size by 2033: USD 357 Million

-

CAGR: 5.97% from 2026 to 2033

-

Base Year: 2025

-

Forecast Period: 2026–2033

-

Historical Data: 2022–2024

To Get more information on Intrinsically Safe Signal Conditioner Market - Request Free Sample Report

Key Intrinsically Safe Signal Conditioner Market Trends

-

Growing adoption of industrial automation and digital control systems in hazardous environments is driving demand for intrinsically safe signal conditioners.

-

Increasing implementation of safety regulations and explosion protection standards such as ATEX and IECEx is boosting product certification requirements.

-

Rapid expansion of oil & gas, chemical, and mining sectors in emerging economies is fueling installations of safety-certified instrumentation.

-

Integration of Industrial IoT (IIoT) and smart monitoring solutions is creating opportunities for advanced, network-enabled signal conditioners.

-

Manufacturers are focusing on compact, multi-channel, and energy-efficient designs to enhance reliability and reduce maintenance costs.

-

Rising investments in process modernization and plant upgrades are supporting replacement demand for legacy signal conditioning systems.

U.S. Intrinsically Safe Signal Conditioner Market Insights

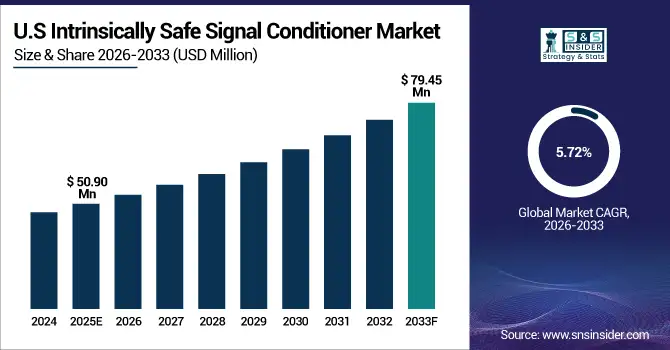

The U.S. Intrinsically Safe Signal Conditioner Market size was USD 50.90 million in 2025 and is expected to reach USD 79.45 million by 2033 growing at a CAGR of 5.72% over the forecast period of 2026-2033. The rise in industrial automation and the enforcement of stringent safety regulations have significantly increased demand for intrinsically safe equipment. As industries such as oil & gas, chemicals, and pharmaceuticals expand, the need for reliable signal transmission in explosive zones is accelerating market adoption nationwide.

Intrinsically Safe Signal Conditioner Market Growth Driver

-

Rising Industrial Automation and Safety Compliance Standards Drive Intrinsically Safe Signal Conditioner Market Growth

The increasing adoption of industrial automation and the enforcement of stringent safety compliance standards are major forces driving the growth of the Intrinsically Safe Signal Conditioner Market. As industries such as oil & gas, mining, and chemicals modernize their production systems, the need for intrinsically safe solutions that can function reliably in explosive or hazardous environments has surged. The integration of Industry 4.0 technologies like IoT-based monitoring and real-time data transmission—has accelerated demand for advanced signal conditioning equipment that ensures precision, reliability, and operator safety. This growing emphasis on regulatory compliance, coupled with technological advancement, is significantly contributing to market expansion.

For instance, in March 2025, Pepperl+Fuchs launched a new range of intrinsically safe isolators designed for use in automated refineries and chemical plants. These devices enhance safety and data integrity in hazardous zones, aligning with ATEX and IECEx standards illustrating how technological progress directly supports the market’s safety-driven growth trajectory.

Intrinsically Safe Signal Conditioner Market Restraint

High Installation and Maintenance Costs Restrain Intrinsically Safe Signal Conditioner Market Expansion

Despite robust demand, the high installation and maintenance costs associated with intrinsically safe signal conditioners remain a key restraint to market growth. These devices require complex design specifications, precision engineering, and compliance with international safety certifications, which collectively increase capital expenditure for end users. Additionally, periodic calibration and testing to maintain explosion-proof performance add to operational expenses, discouraging smaller enterprises from adopting them. This cost-intensive nature limits large-scale deployment, especially in developing economies where budget constraints and low awareness of safety standards persist, thereby slowing overall market penetration.

For example, many mid-sized chemical plants in Latin America have delayed automation upgrades due to the high initial investment required for intrinsically safe systems. The need for trained technicians and certified installation further escalates costs, leading to a slower adoption rate despite evident safety and operational benefits.

Intrinsically Safe Signal Conditioner Market Opportunity

-

Integration of Smart Monitoring Technologies Presents Lucrative Growth Opportunities

The integration of smart monitoring and predictive maintenance technologies into intrinsically safe signal conditioners presents a significant growth opportunity for the market. As industries increasingly adopt digital transformation strategies, the combination of safety compliance with real-time analytics and AI-driven performance tracking is becoming a valuable differentiator. Smart signal conditioners enhance operational efficiency by detecting faults early, reducing downtime, and improving asset reliability in hazardous zones. The trend toward connected safety devices and IIoT-based condition monitoring offers manufacturers a pathway to develop advanced, data-centric conditioning solutions tailored to modern industrial needs.

For instance, in June 2024, MTL Instruments introduced a next-generation intrinsically safe signal conditioner equipped with IoT connectivity and cloud-based monitoring features. This innovation allows operators to manage safety systems remotely and optimize maintenance schedules demonstrating how smart integration creates tangible operational and safety advantages in industrial environments.

Intrinsically Safe Signal Conditioner Market Segment Highlights:

-

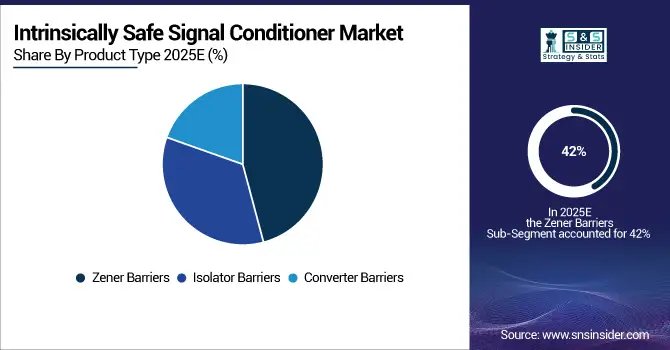

By Product Type: Zener Barriers – 42% (largest), Isolator Barriers – 38%, Converter Barriers – 20%

-

By Application: Oil & Gas – 30% (largest), Chemical & Petrochemical – 25%, Mining – 15%, Energy & Utilities – 12%, Pharmaceuticals – 10%, Food & Beverage – 8%

-

By End User: Process Industries – 35% (largest), Manufacturing Facilities – 28%, Energy & Power Plants – 22%, Transportation & Infrastructure – 15%

Intrinsically Safe Signal Conditioner Market Segment Analysis

By Product Type

The Zener Barriers segment dominates the Intrinsically Safe Signal Conditioner Market with a 42% share in 2025, driven by their cost-effectiveness, simple design, and reliability in limiting voltage and current to prevent ignition in hazardous environments. These barriers are widely used in oil & gas, chemical, and petrochemical applications where intrinsic safety is essential for preventing explosions. Isolator Barriers, accounting for 38%, are gaining traction due to their ability to provide galvanic isolation, reduce signal noise, and improve accuracy in data transmission—making them ideal for modern automation systems and digital control setups. The Converter Barriers segment, with 20%, supports analog-to-digital signal transformation and power conversion functions for specialized monitoring and control systems, primarily used in process automation and industrial safety applications.

By Application

The Oil & Gas segment leads the market with a 30% share, owing to the sector’s extensive use of intrinsically safe systems in refineries, drilling sites, and offshore platforms. Strict regulatory requirements for explosion protection drive the need for reliable signal conditioning in these volatile environments. The Chemical & Petrochemical segment, holding 25%, uses these devices for process monitoring and safe control of hazardous substances. The Mining sector, at 15%, benefits from their ability to ensure operational safety in underground environments. Energy & Utilities hold 12% share due to increased adoption in power generation and grid automation. Pharmaceuticals, accounting for 10%, utilize them in cleanroom automation, while Food & Beverage, with 8%, apply them in process control and quality assurance systems.

By End User

The Process Industries segment dominates with a 35% share, as industries such as oil & gas, chemicals, and energy rely heavily on intrinsically safe signal conditioners for safety-critical operations. The need for continuous monitoring and precise control in hazardous environments has increased product adoption. Manufacturing Facilities, with 28%, use these conditioners to enhance safety and automation in production lines handling flammable or reactive materials. Energy & Power Plants, holding 22%, implement these devices in control systems for turbines and substations to ensure explosion-proof communication. Lastly, Transportation & Infrastructure, with a 15% share, benefits from their use in monitoring systems for tunnels, railways, and airports where hazardous gas detection and secure signal transmission are crucial.

Intrinsically Safe Signal Conditioner Market Regional Analysis

Asia-Pacific Intrinsically Safe Signal Conditioner Market Insights

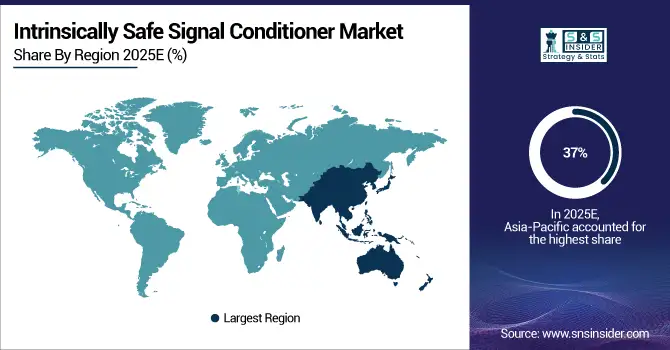

Asia-Pacific dominates the Intrinsically Safe Signal Conditioner Market with a 37% share in 2025, making it the largest and fastest-growing regional market. The growth is primarily fueled by rapid industrialization, expansion of manufacturing facilities, and stringent safety regulations across oil & gas, mining, and chemical sectors in countries such as China, India, Japan, and South Korea. Increasing investments in process automation and industrial IoT applications are further driving demand for intrinsically safe signal conditioners. Moreover, the growing presence of global automation leaders, combined with regional government support for industrial safety compliance and smart manufacturing initiatives, is strengthening Asia-Pacific’s market position.

Get Customized Report as per Your Business Requirement - Enquiry Now

North America Intrinsically Safe Signal Conditioner Market Insights

North America holds a 30% share of the Intrinsically Safe Signal Conditioner Market in 2025, driven by strong regulatory frameworks such as ATEX and NEC standards promoting safety in hazardous industries. The U.S. leads the region’s market due to the widespread adoption of advanced industrial automation, oil & gas exploration, and energy infrastructure modernization projects. Rising demand for reliable and explosion-proof instrumentation in process industries, along with increased investment in smart factory technologies, continues to propel market growth. The presence of key manufacturers and technological innovators further reinforces North America’s dominance.

Europe Intrinsically Safe Signal Conditioner Market Insights

Europe accounts for a 25% share of the Intrinsically Safe Signal Conditioner Market in 2025, supported by robust industrial automation and safety regulations across key economies such as Germany, the U.K., and France. The region’s emphasis on process safety, sustainable industrial development, and adherence to stringent ATEX and IECEx standards drives adoption across chemical, pharmaceutical, and energy sectors. Ongoing advancements in industrial communication systems and automation technologies, coupled with the region’s focus on minimizing explosion risks in hazardous work environments, continue to boost market demand.

Middle East & Africa Intrinsically Safe Signal Conditioner Market Insights

The Middle East & Africa holds a 5% share of the Intrinsically Safe Signal Conditioner Market in 2025, driven by increased investments in oil & gas infrastructure, petrochemical plants, and mining operations. Countries such as Saudi Arabia, the UAE, and South Africa are expanding industrial facilities that require intrinsically safe signal conditioners for reliable process monitoring in volatile conditions. Government initiatives promoting industrial diversification, digital transformation, and infrastructure modernization are further contributing to market expansion, particularly in energy and utility applications.

Latin America Intrinsically Safe Signal Conditioner Market Insights

Latin America accounts for a 3% share of the Intrinsically Safe Signal Conditioner Market in 2025, with gradual growth led by Brazil and Mexico. Expansion in the region’s oil & gas, mining, and manufacturing industries is driving adoption of intrinsically safe systems to meet safety and compliance standards. The increasing integration of automation technologies and process monitoring systems within energy and industrial facilities is supporting market development. Additionally, regional investments in safety equipment upgrades and cross-border industrial collaborations are creating new opportunities for market players.

Competitive Landscape for Intrinsically Safe Signal Conditioner Market:

Pepperl+Fuchs SE

Pepperl+Fuchs SE is a global leader in industrial sensor technology and explosion protection, offering a wide range of intrinsically safe devices for hazardous area applications.

-

In June 2025, Pepperl+Fuchs launched its K-System Pro Series Intrinsically Safe Signal Conditioner, designed to deliver enhanced diagnostic capabilities and higher signal accuracy. The new system features real-time condition monitoring and modular configuration options, supporting automation and process safety across oil & gas and chemical industries.

R. STAHL AG

R. STAHL AG is a prominent manufacturer of explosion-protected equipment and systems, catering to industrial safety and automation requirements in hazardous environments.

-

In April 2025, R. STAHL introduced its IS1+ Advanced Barrier Line, integrating digital communication interfaces and improved isolation performance. The innovation allows seamless integration with DCS systems, reducing installation complexity and enhancing operational safety in petrochemical and offshore facilities.

Eaton Corporation plc

Eaton Corporation plc is a diversified power management company providing energy-efficient solutions, including intrinsically safe electrical components and signal conditioning devices.

-

In May 2025, Eaton unveiled its MTL4500 Next-Gen Signal Conditioner Series, offering advanced galvanic isolation and cybersecurity-ready communication modules. The development supports Industry 4.0 applications and improves reliability in mission-critical automation systems across the energy and utilities sector.

Honeywell International Inc.

Honeywell International Inc. is a global technology and manufacturing company offering automation, sensing, and control solutions for safety-critical industrial environments.

-

In March 2025, Honeywell launched its SafeLink IS-X Series Signal Conditioners, featuring AI-enabled fault prediction and enhanced explosion protection. This innovation strengthens Honeywell’s industrial automation portfolio, particularly in refining, mining, and pharmaceutical process control systems.

Intrinsically Safe Signal Conditioner Market Key Players

Some of the Intrinsically Safe Signal Conditioner Companies

-

Pepperl + Fuchs SE

-

R. STAHL AG

-

Honeywell International Inc.

-

Fluke Corporation

-

Eaton Corporation plc

-

Siemens AG

-

Rockwell Automation, Inc.

-

ABB Ltd.

-

Extronics Ltd.

-

Littelfuse, Inc.

-

MTL Instruments (Eaton)

-

Phoenix Contact GmbH & Co. KG

-

Yokogawa Electric Corporation

-

Schneider Electric SE

-

Turck Inc.

-

Weidmüller Interface GmbH & Co. KG

-

Bartec GmbH

-

PR Electronics

-

Sensata Technologies Holding PLC

-

Moore Industries-International, Inc.

| Report Attributes | Details |

|---|---|

| Market Size in 2025E | USD 224.57 Million |

| Market Size by 2033 | USD 357 Million |

| CAGR | CAGR of5.97% from 2026 to 2033 |

| Base Year | 2025E |

| Forecast Period | 2026-2033 |

| Historical Data | 2022-2024 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Product Type (Zener Barriers, Isolator Barriers, Converter Barriers) • By Application (Oil & Gas, Chemical & Petrochemical, Mining, Energy & Utilities, Pharmaceuticals, Food & Beverage) • By End-User (Process Industries, Manufacturing Facilities, Energy & Power Plants, Transportation & Infrastructure) |

| Regional Analysis/Coverage | North America (US, Canada), Europe (Germany, France, UK, Italy, Spain, Poland, Russsia, Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Australia,ASEAN Countries, Rest of Asia Pacific), Middle East & Africa (UAE, Saudi Arabia, Qatar, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Mexico, Colombia Rest of Latin America) |

| Company Profiles | Pepperl + Fuchs SE, R. STAHL AG, Honeywell International Inc., Fluke Corporation, Eaton Corporation plc, Siemens AG, Rockwell Automation, Inc., ABB Ltd., Extronics Ltd., Littelfuse, Inc., MTL Instruments (Eaton), Phoenix Contact GmbH & Co. KG, Yokogawa Electric Corporation, Schneider Electric SE, Turck Inc., Weidmüller Interface GmbH & Co. KG, Bartec GmbH, PR Electronics, Sensata Technologies Holding PLC, Moore Industries-International, Inc. |