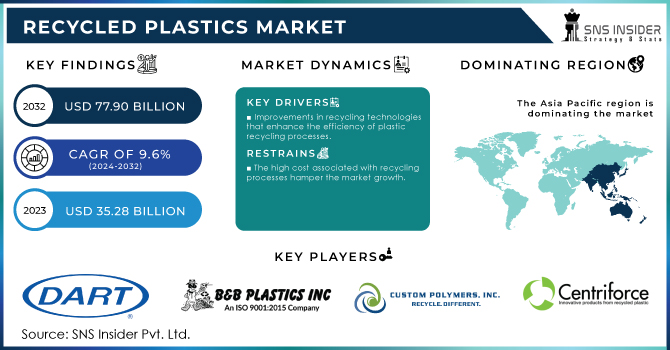

Recycled Plastics Market Size & Overview:

The Recycled Plastics Market Size was valued at USD 35.28 Billion in 2023 and is expected to reach USD 77.90 billion by 2032 and grow at a CAGR of 9.6% over the forecast period 2024-2032. Increasing awareness about environmental issues, particularly plastic pollution and its impact on marine life, is a significant driver of the recycled plastics market. Every year, millions of tons of plastic waste end up in the heaps, ocean causing severe harm to marine life. Marine animals ingest plastics, which can lead to starvation, poisoning, and death. Public awareness campaigns by organizations such as the Ocean Conservancy and WWF highlight the devastating impact of plastic pollution, effectively raising public consciousness and pushing for changes in both consumer behavior and corporate practices. For instance, the European Union implemented a ban on single-use plastics like straws, cutlery, and plates starting in 2021. The EU's Single-Use Plastics Directive aims to reduce plastic waste and promote recycling.

Get More Information on Recycled Plastics Market - Request Sample Report

As consumers become more environmentally conscious, they are increasingly seeking eco-friendly and sustainably sourced products. This shift in consumer behavior compels businesses to adopt recycled plastic in their products and packaging to meet the growing demand for sustainable practices. The combination of heightened awareness and changing consumer preferences is significantly boosting the adoption of recycled plastics across various industries.

Moreover, in California, U.S. California's SB 54, passed in 2022, requires all plastic packaging in the state to be recyclable or compostable by 2032. It also mandates a 25% reduction in plastic packaging waste.

Furthermore, advancements in recycling technologies are improving the quality and efficiency of plastic recycling processes. Innovations such as chemical recycling and improved sorting technologies are making it easier to recycle a wider range of plastic types.

Recycled Plastics Market Dynamics:

Drivers

Improvements in recycling technologies that enhance the efficiency of plastic recycling processes.

Improvements in recycling technologies have significantly enhanced the quality and efficiency of plastic recycling processes, leading to increased recycling rates and better-quality recycled materials. For instance, advanced sorting technologies like Near-Infrared spectroscopy and robotic sorting systems have improved the accuracy and speed of sorting different types of plastics, reduced contamination, and increasing the purity of recycled products.

Moreover, chemical recycling methods, such as depolymerization and pyrolysis, have enabled the breakdown of hard-to-recycle plastics into their basic monomers or fuels, contributing to a circular economy by creating high-quality recycled plastics that can be reused in manufacturing. For example, companies like Carbios have developed enzymatic recycling processes that can depolymerize PET plastics, achieving a recycling efficiency of over 90%. These technological advancements not only enhance the overall efficiency of recycling processes but also help meet regulatory targets and consumer demand for sustainable products, driving the growth of the recycled plastics market.

Restrain

The high cost associated with recycling processes hamper the market growth.

High costs associated with recycling processes, including collection, sorting, and processing, can make recycled plastics more expensive than virgin plastics, discouraging widespread adoption. Additionally, contamination in plastic waste streams often reduces the quality of recycled materials, limiting their applicability in high-grade applications. Inconsistent and inadequate recycling infrastructure, especially in developing regions, further exacerbates these challenges. Regulatory barriers and lack of standardized practices across different regions also create difficulties for global market expansion. These factors collectively restrain the market, necessitating continued innovation and policy support to overcome these obstacles.

Recycled Plastics Market Segmentation Analysis

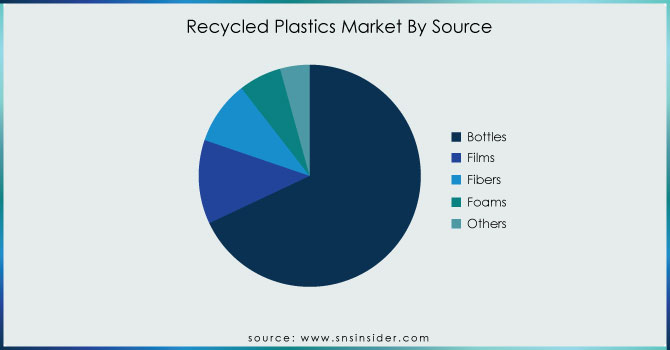

By Source

The bottles segment held the largest market share in the source segment around 68.00% in 2023. Bottles especially PET bottles are very recyclable and are collected in large quantities via curbside recycling programs and well-established deposit-return programs. Compared to other sources, the infrastructure for recycling bottles is more advanced, guaranteeing a consistent supply of premium recycled PET. The production of new bottles, food-grade containers, and other consumer items is in high demand for this rPET due to legal regulations as well as business sustainability objectives. The recycling rate for PET bottles in the US reached 27.9% in 2020, according to the National Association for PET Container Resources, demonstrating effective mechanisms for collecting and processing. Furthermore, recycled PET made from bottles has high clarity and quality, which makes it ideal for a variety of uses and solidifies its market-leading position in recycled plastics.

Get Customized Report as per your Business Requirement - Request For Customized Report

By Type

The polyethylene segment held a significant market share around 27.22% of the total volume in 2023. The increased need for packaging materials in consumer goods, food and beverage, industrial, and other industries is the reason for this high share. Among many other places, it is also frequently utilized in the packaging of laundry detergents, milk cartons, chopping boards, and trash cans.

Moreover, because of its exceptional chemical and mechanical qualities, polypropylene is widely utilized in the production of medical devices, laboratory equipment, automobile components, packaging, and labels, among many other products. It has outstanding mechanical strength and is resistant to a variety of chemical solvents, acids, and bases. Additionally, it is one of the world's best-formulated polymers.

By Application

In the application segment, packaging held the largest market share around 38.42% of the total volume in 2023. The demand is growing because they account for a large amount of plastic usage, and packaging materials such as bottles, films, and containers are a primary focus of recycling initiatives. Recycle facilities are receiving a growing amount of the large amount of plastic trash produced by packaging instead of landfills, where it is converted into high-grade recycled products. The usage of recycled content in packaging is being driven by pressure on businesses to meet legal requirements and lessen their environmental impact.

Recycled Plastics Market Regional Outlook

Asia Pacific dominated the recycled plastics market with the highest revenue share of about 48.57% in 2023. This is because the number of small enterprises is increasing, as is their relevance in the market. Furthermore, the region imports and recycles waste plastic, as well as converting it for important applications. The availability of low-cost labor and significant industrial locations in nations such as China are seen as major drivers of the region's plastic recycling industry growth. The Asia-Pacific region's overall growth of the plastic recycling sector is being influenced by the region's heavy use of automobile industries and industrialization

European countries, on the other hand, are experiencing a faster development rate in the plastic recycling business as a result of the constraints and rigorous regulations governing plastic waste. According to figures from European countries, about 4.4 million tonnes of plastic garbage is generated each year in Europe, with landfills becoming landfills over time. As a result of these charges, the European government has increased its recycling efforts and increased awareness among industrial sectors.

Key Players

Dart Container Corporation, B & B Plastics Inc., Plasgran Ltd., Custom Polymer, Inc., Viridor Waste Management Ltd., KW Plastics, Dart Container Corporation, Kuusakoski Recycling Ltd., Centrifore Products Ltd., CarbonLite Industries LLC, Dart Container Corporation, and other players.

Recent Development:

-

In 2023, Carbios continued to advance its enzymatic recycling technology for PET plastics, aiming to achieve industrial-scale production. The company partnered with major brands like L'Oreal and Nestle to further develop and commercialize this technology, demonstrating its commitment to sustainability and innovation.

-

In 2023, Plastic Energy expanded its global footprint by opening new pyrolysis facilities in Europe and Asia. These facilities convert plastic waste into synthetic oils, which can be used to produce new plastics, thereby contributing to a circular economy.

-

In 2022, Eastman Chemical Company introduced its molecular recycling technology, which breaks down polyester waste into its basic building blocks for reuse in producing new plastics. The company announced significant investments in new facilities to scale up this technology.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | US$ 35.28 Billion |

| Market Size by 2032 | US$ 77.90 Billion |

| CAGR | CAGR of 9.60% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Source (Bottles, Films, Fibers, Foams, Others) • By Type (PET, PE, PVC, PP, PS, Others) • By End-use Industry (Packaging, Building & Construction, Textile, Automotive, Electrical & Electronics, Others) |

| Regional Analysis/Coverage | North America (USA, Canada, Mexico), Europe (Germany, UK, France, Italy, Spain, Netherlands, Rest of Europe), Asia-Pacific (Japan, South Korea, China, India, Australia, Rest of Asia-Pacific), The Middle East & Africa (Israel, UAE, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Rest of Latin America) |

| Company Profiles | Dart Container Corporation, B & B Plastics Inc., Plasgran Ltd., Custom Polymer, Inc., Viridor Waste Management Ltd., KW Plastics, Dart Container Corporation, Kuusakoski Recycling Ltd., Centrifore Products Ltd., CarbonLite Industries LLC, Dart Container Corporation, and other players. |

| DRIVERS | • Improvements in recycling technologies that enhance the efficiency of plastic recycling processes. |

| Restraints | • The high cost associated with recycling processes hamper the market growth. |