Acrylate Market Report Scope & Overview:

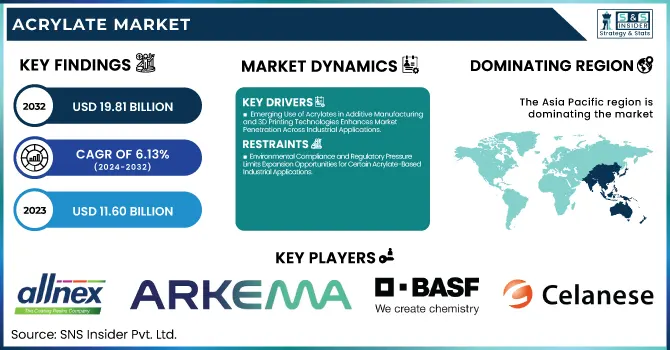

The Acrylate Market Size was valued at USD 11.60 Billion in 2023 and is expected to reach USD 19.81 Billion by 2032, growing at a CAGR of 6.13% over the forecast period of 2024-2032.

To Get more information on Acrylate Market - Request Free Sample Report

The acrylate market is undergoing a transformative shift driven by evolving demand, innovation, and capacity expansion. Our report captures the pulse of this dynamic landscape by examining raw material procurement patterns, highlighting how sourcing trends for propylene and acrylic acid impact pricing and supply security. It also covers strategic investments and expansions, showcasing how key players are scaling operations and entering new markets. Through benchmarking against substitute chemicals, the report compares acrylates with alternatives like vinyl acetate to assess performance and cost-efficiency. Additionally, a detailed cost component analysis of acrylates breaks down production expenses, offering insights into margins and profitability. Together, these segments offer a data-rich foundation for understanding current trends and making strategic decisions.

The US Acrylate Market Size was valued at USD 3.38 Billion in 2023, with a market share of about 68% growing at a significant CAGR over the forecast period of 2024-2032.

The United States acrylate market is witnessing steady growth, driven by robust demand from industries such as paints and coatings, adhesives, and plastics. The resurgence in residential and commercial construction, supported by initiatives like the U.S. Infrastructure Investment and Jobs Act, is fueling the need for acrylate-based coatings and sealants. Additionally, innovation by U.S.-based companies like Dow Inc. and H.B. Fuller is advancing product development for high-performance adhesives in automotive and packaging applications. According to the American Coatings Association, sustainable and low-VOC acrylate formulations are also gaining traction, aligning with tightening environmental regulations and boosting domestic consumption.

Acrylate Market Dynamics

Drivers

-

Emerging Use of Acrylates in Additive Manufacturing and 3D Printing Technologies Enhances Market Penetration Across Industrial Applications

The acrylate market is gaining traction with the rising adoption of additive manufacturing and 3D printing technologies, particularly in industrial and medical sectors. Acrylate-based resins are widely preferred in stereolithography (SLA) due to their excellent curing properties, precision, and mechanical stability. With the U.S. leading in 3D printing innovation supported by institutions like the National Institute of Standards and Technology (NIST) there has been an increase in the demand for specialized acrylate resins used in customized prototypes, dental models, and biomedical components. Companies such as Formlabs and Carbon3D are increasingly integrating acrylate derivatives in their product lines to deliver high-resolution, rapid-cure solutions. This emerging trend is reshaping how manufacturers perceive acrylate functionality, expanding its scope beyond conventional industries. Moreover, as industries increasingly pivot towards lightweight, customized, and rapid-production parts, acrylate-based 3D printing materials are filling a crucial gap. This niche but fast-growing demand creates opportunities for both raw material suppliers and resin formulators. The integration of acrylate resins with digital manufacturing platforms is fostering a new class of industrial-grade materials with improved tensile strength, biocompatibility, and durability. As a result, this technological integration is no longer just a side-stream but is fast becoming a core growth engine for the global acrylate market.

Restraints

-

Environmental Compliance and Regulatory Pressure Limits Expansion Opportunities for Certain Acrylate-Based Industrial Applications

The acrylate market faces increasing regulatory scrutiny concerning emissions, toxicity, and waste management. Acrylates, particularly in their monomeric form, can pose health and environmental risks due to their volatility and potential bioaccumulation. In the United States, the Environmental Protection Agency (EPA) continues to review and update chemical safety regulations under the Toxic Substances Control Act (TSCA). These measures are further reinforced by state-level initiatives, such as California’s Proposition 65, which mandates warning labels for products containing hazardous substances. While these regulations aim to protect public health and the environment, they also impose stringent compliance costs on manufacturers. Investments in advanced treatment systems, worker safety measures, and emissions control technology become non-negotiable, driving up production costs. Moreover, the restrictions on usage and transportation of certain acrylate derivatives limit the scope of their application in emerging technologies, especially in biomedical and electronic components. Thus, environmental compliance remains a critical restraint that shapes investment decisions and market accessibility for acrylate-based solutions.

Opportunities

-

Integration of Acrylates in High-Performance Composite Materials for Aerospace and Automotive Applications Creates New Revenue Streams

With the rising demand for lightweight, durable, and high-performance materials in aerospace and automotive industries, acrylates are being increasingly integrated into composite structures. These materials offer superior bonding strength, UV resistance, and environmental stability key attributes for next-generation vehicles and aircraft. In the United States, automotive leaders like Ford and General Motors are adopting acrylate-based adhesives and sealants in electric vehicle battery packs and body frames. Similarly, the U.S. Department of Defense and NASA have shown interest in advanced acrylate composites for use in structural and insulation applications. The compatibility of acrylates with carbon and glass fiber matrices further enhances their utility in structural reinforcement. As fuel efficiency standards tighten and the push toward electrification continues, acrylates offer manufacturers a compelling balance between performance and weight. This integration not only enhances market visibility for acrylates but also drives innovation pipelines in structural adhesive technologies.

Challenge

-

Limited Public Awareness and Misconceptions Regarding Safety of Acrylate Products in Consumer Applications Impact Adoption Rates

A key challenge facing the acrylate market is the limited public understanding and persistent misconceptions regarding the safety of acrylate-containing products. Despite advancements in product formulations and compliance with stringent safety standards, acrylates are often perceived as hazardous chemicals due to their synthetic origin and volatile organic compound (VOC) content. In consumer-facing sectors such as cosmetics, personal care, and household products, this perception can significantly influence purchasing decisions. Advocacy groups and health blogs frequently raise concerns over potential allergic reactions or environmental harm, sometimes without scientific backing. This information gap slows down the acceptance of new acrylate-based solutions, even when they are proven to be safe and effective. U.S. regulatory bodies like the Food and Drug Administration (FDA) and the Environmental Protection Agency (EPA) have set safety thresholds, but communication of these standards to the general public remains weak. Consequently, consumer hesitation limits full market penetration in several high-value segments.

Acrylate Market Segmental Analysis

By Type

Butyl Acrylate dominated the acrylate market in 2023 with a market share of 42.3%. This dominance is primarily driven by its extensive utilization in producing water-based coatings, adhesives, textiles, and sealants. Butyl acrylate exhibits excellent weathering resistance, flexibility, and adhesive properties, making it the most suitable choice across industries such as automotive, construction, and packaging. The robust growth of the construction and infrastructure sectors in economies like China and India has substantially driven the demand for butyl acrylate in architectural coatings. According to the National Bureau of Statistics of China, investment in real estate development rose significantly in 2023, further propelling the use of butyl acrylate-based coatings. Moreover, in automotive coatings, butyl acrylate remains a preferred ingredient due to its ability to improve gloss and durability. Reports from the U.S. Department of Energy highlighting the need for sustainable and efficient vehicle coatings also underscore its relevance. Additionally, industry players such as BASF and Arkema have expanded their butyl acrylate capacities in Asia Pacific to meet rising demand, reinforcing the segment's stronghold in the acrylate market.

By Grade

Standard Grade dominated the acrylate market in 2023 with a market share of 45.2%. This segment's dominance is attributed to its broad applicability across industrial coatings, textiles, plastics, and adhesives, where high purity is not always required. Standard grade acrylates offer a balanced profile of performance and cost-effectiveness, which is essential for mass-market applications. Its wide adoption is driven by the construction and packaging sectors, where it serves as a base for water-based paints and flexible packaging adhesives. Organizations such as the World Green Building Council emphasize the shift toward eco-friendly coatings and adhesives, favoring the use of standard grade acrylates due to their low volatile organic compound (VOC) emissions. Moreover, government initiatives in countries like India under schemes like the “Smart Cities Mission” have increased infrastructure development, thereby fueling demand for standard grade acrylate coatings. Industry leaders such as LG Chem and Nippon Shokubai continue to invest in expanding standard grade production to cater to high-volume markets, reaffirming the grade’s leading position in the global acrylate market.

By Application

Adhesives & Sealants dominated the acrylate market in 2023 with a market share of 35.3%. The growing need for high-performance, flexible, and weather-resistant adhesives across automotive, electronics, packaging, and construction sectors has been the primary factor behind this segment’s leadership. Acrylate-based adhesives provide superior bonding strength, transparency, and aging resistance, making them ideal for applications that require durable adhesion. The shift towards lightweight and electric vehicles has further amplified the demand for advanced adhesives, as indicated in reports by the U.S. Environmental Protection Agency promoting fuel efficiency. Additionally, global packaging companies are increasing their adoption of acrylate-based pressure-sensitive adhesives for labels and tapes. The Food and Drug Administration (FDA) also supports the use of certain acrylate adhesives in food packaging due to their low toxicity, further boosting their market share. Leading manufacturers such as Henkel and 3M are expanding their product lines with acrylate-based adhesives, reinforcing the application’s dominance. With innovations targeting eco-friendly and high-bonding solutions, the adhesives and sealants application is expected to maintain its stronghold in the coming years.

By End-use Industry

Building & Construction dominated the acrylate market in 2023 with a market share of 32.4%. This leadership is attributed to the heavy usage of acrylates in paints, coatings, adhesives, and sealants for architectural applications. Acrylates provide superior weather resistance, color retention, and adhesion properties essential for both residential and commercial construction. The booming construction activities in emerging nations, supported by government infrastructure programs, have fueled demand for acrylate-based materials. For instance, India’s National Infrastructure Pipeline (NIP), with an investment plan of over $1.5 trillion, has significantly accelerated demand for construction chemicals, including acrylates. Similarly, in the U.S., the Infrastructure Investment and Jobs Act passed in 2021 has supported a resurgence in public works, increasing the need for coatings and adhesives. Organizations such as the International Construction Market Survey report steady global growth in construction output, further boosting acrylate use. Industry players like Dow and Sika AG have strengthened their construction portfolios with acrylate products, underlining this segment’s dominant role in the global market.

Acrylate Market Regional Outlook

Asia Pacific dominated the acrylate market in 2023 with a market share of 42.6%. The dominance of the Asia Pacific region stems from rapid industrialization, urbanization, and the expansion of key end-use sectors such as construction, automotive, textiles, and packaging. Countries like China, India, and Japan have been at the forefront due to large-scale infrastructure investments, increasing automotive production, and a growing consumer base. China alone accounted for a major portion of the demand due to its expansive manufacturing sector and initiatives under the 14th Five-Year Plan emphasizing green development, which includes eco-friendly coatings and adhesives using acrylates. India’s push for industrial corridors and urban housing projects under schemes like “Housing for All” has also boosted acrylate demand. Japan's well-established automotive and electronics industries have increased their consumption of high-performance acrylate-based materials. According to the Asian Development Bank, infrastructure investment in Asia is expected to reach over $1.7 trillion annually, ensuring continued dominance in the acrylate market. Major producers such as Mitsubishi Chemical and LG Chem have regional production bases, further strengthening Asia Pacific’s leading position.

On the other hand, North America is the fastest-growing region in the acrylate market during the forecast period, with a significant CAGR. This growth is attributed to rising demand for sustainable and high-performance materials across sectors like construction, automotive, and packaging. The United States, in particular, has seen a surge in demand for eco-friendly paints, sealants, and adhesives due to stricter environmental regulations by the Environmental Protection Agency (EPA). The adoption of advanced automotive adhesives in electric vehicles, supported by the U.S. Department of Energy’s Vehicle Technologies Office, is also driving growth. Additionally, the Canadian government’s support for green building certifications has increased demand for low-VOC acrylate-based construction chemicals. The region is witnessing considerable innovation in bio-based acrylates as well, with research institutions and companies like Arkema and Dow investing in sustainable product development. Furthermore, the North American Free Trade Agreement (now USMCA) facilitates smoother trade of acrylate materials across the U.S., Canada, and Mexico, contributing to supply chain efficiency. With these factors combined, North America is set to maintain its position as the fastest-growing region in the global acrylate market.

Get Customized Report as per Your Business Requirement - Enquiry Now

Key Players

-

Allnex (Alkyl acrylates, Polyfunctional acrylates)

-

Arkema S.A. (including Sartomer) (2-Ethylhexyl acrylate, Lauryl acrylate, Hydroxyethyl acrylate)

-

BASF SE (Butyl acrylate, Methyl acrylate, Ethyl acrylate)

-

Celanese Corporation (Vinyl acetate-acrylate copolymers, Ethylene-acrylic acid copolymers)

-

DIC Corporation (Acrylic emulsion polymers, UV-curable acrylates)

-

Dow Inc. / The Dow Chemical Company (Butyl acrylate, 2-Ethylhexyl acrylate, Methyl acrylate)

-

Eastman Chemical Company (Isobornyl acrylate, Ethyl acrylate derivatives)

-

Evonik Industries AG (Methacrylate monomers, Dimethylaminoethyl acrylate, Specialty acrylates)

-

Formosa Plastics Corporation (Butyl acrylate, Methyl acrylate)

-

H.B. Fuller Company (Acrylic pressure-sensitive adhesives, Acrylate copolymers)

-

Hitachi Chemical Co., Ltd. (Acrylic resins, UV-curable acrylate coatings)

-

INEOS (Butyl acrylate, Ethyl acrylate, Methyl acrylate)

-

Kuraray Co., Ltd. (Acrylic emulsions, Acrylic pressure-sensitive adhesives)

-

LG Chem Ltd. (2-Ethylhexyl acrylate, Butyl acrylate, Methyl acrylate)

-

LyondellBasell Industries (Acrylic acid esters, Butyl acrylate)

-

Mitsubishi Chemical Corporation / Group (Acrylic acid, Butyl acrylate, Hydroxyethyl acrylate)

-

Nippon Shokubai Co., Ltd. (Acrylic acid, Butyl acrylate, 2-Ethylhexyl acrylate)

-

SIBUR Holding PJSC (Butyl acrylate, 2-Ethylhexyl acrylate)

-

Sumitomo Chemical Co., Ltd. (Acrylic acid esters, Methyl acrylate, Ethyl acrylate)

-

Toagosei Co., Ltd. (Acrylic acid, Butyl acrylate, Functional acrylates)

Recent Developments

-

August 2024: BASF transitioned its Ethyl Acrylate production to a bio-based version with 40% certified bio-content, reducing its carbon footprint by 30%. Produced in Ludwigshafen using sustainable bioethanol, the move aligns with BASF’s sustainability goals.

-

October 2024: Arkema launched bio-based Ethyl Acrylate at its Carling, France facility. With 40% bio-carbon content and 30% lower carbon footprint, the product supports Arkema’s decarbonization strategy and targets growth in green industries.

| Report Attributes | Details |

|---|---|

| Market Size in 2023 | USD 11.60 Billion |

| Market Size by 2032 | USD 19.81 Billion |

| CAGR | CAGR of 6.13% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | •By Type (Butyl Acrylate, Ethyl Acrylate, 2-Ethyl Hexyl Acrylate, Methyl Acrylate, Others) •By Grade (Standard grade, Technical grade, Chemical grade, Pharmaceutical grade) •By Application (Paints, Coatings, & Printing Inks, Plastics, Adhesives & Sealants, Fabrics, Others) •By End-use Industry (Building & Construction, Packaging, Consumer Goods, Automotive, Textiles, Bio-medical, Cosmetic & Personal Care, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Company Profiles | BASF SE, Dow Inc. / The Dow Chemical Company, Arkema S.A. (including Sartomer), Evonik Industries AG, LG Chem Ltd., Mitsubishi Chemical Corporation / Group, Nippon Shokubai Co., Ltd., SIBUR Holding PJSC, Formosa Plastics Corporation, Sumitomo Chemical Co., Ltd. and other key players |